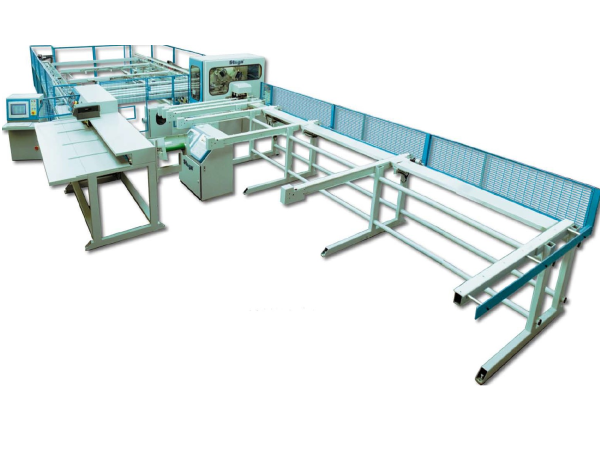

PC network configuration of the Flowline following using a Beckhoff TwinCAT3 system which controls both the saw and windows side.

Sommaire

Following a second wave of obsolescence, this upgrade replaces all the control components with a Beckhoff control system. The major change to this system is that it uses one central system to control both sides of the machine.

A front end Pc is used to provide the user interface, which has a desktop split across two screens, one for each side of the machine. The front end software launches two UI forms, which has a slight downside in that two operators cannot use it at exactly the same time

Uses a Gapton Computers or Netmatters supplied "CNC" machine

A "Back End" Beckhoff PC is used to provide the PLC control systems, running TwinCAT3.

Both PCs need to be on the same network

Front end PC needs TwinCAT3 Engineering Runtime installed, which allows communication to TwinCAT on the back end PC, and installs the System Manager to allow configuration and diagnostics of the front end.

The front end PC needs to have a "Route" set up to the Back end PC for TwinCAT to work

| Front End | Back End | Optional - Diagnostic PC |

|---|---|---|

| F0nn

where nn is the build number |

F0nnBE

where nn is the build number |

F0nnD |

| Setup Files | Front End Software |

|---|---|

*.mul and *.saw initialisation filesc:\ddrive\

|

written in vb.net c:\multi\winmulti.exe |

Location of folder structure of MH side can be changed in the local masterdir.saw. See https://stuga.dokit.app/wiki/Masterdir_File

PCs

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português