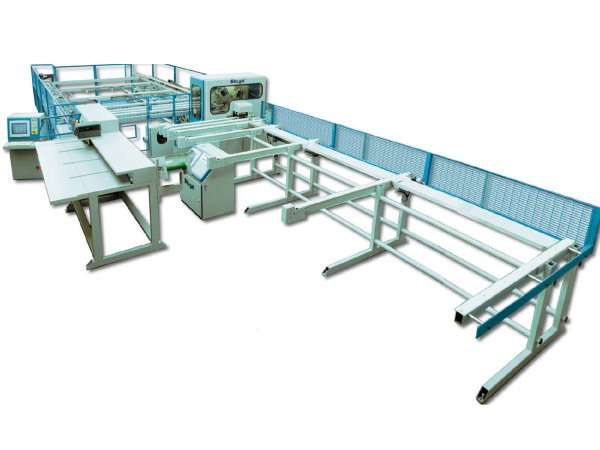

PC network configuration of the original Flowline

Summary

Setup follows the format of two independent machines with independent control systems - MH (Multi-Head) side and saw side. The MH side is a more powerful Industrial PC with Hard drive running an early Windows OS. The Saw side PC is a much smaller DOS based system, containing DOS boot and network software to map a drive and run its control software from a shared directory on the MH side computer.

Both PCs have a network port and are connected through a 5 port switch located in the MH cabinet

| MH Setup Files | Saw Setup Files | MH Front End Software | Saw Front End Software |

|---|---|---|---|

| MH Side |

MH Sidec:\saw\ |

||

| c:\ | |||

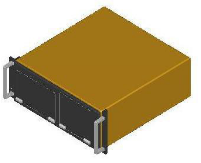

Saw Side PC

- Arcom ACEpc running DOS

- 8Mb Flash Drive containing ROM-DOS to boot up

- Uses NetBEUI or TCP-IP to share all setup data from MH side PC

- Maps d:\ to MH SAW shared directory for all control software

- Old units available for loan

- Instructions in dokit for reflashing drive and programming TCP-IP

- Serial port COM1 used to send instructions to Smartmove/1 or Nextmove ESB Motion control card

- Serial Port COM2 used for printer

- Located in Saw console

MH Side PC

- Arcom APC running Windows 95 or 98

- IDE HDD

- Uses NetBEUI or TCP-IP to share all setup data from MH side PC and share a folder for batch writing

- Old units available for loan

- Contains Nextmove PC motion control card on ISA bus to control Machining centre axes and IO

- Located in a box next to machining centre door

Nextmove PC Card and Breakout Panel

The control signals for the machine are presented via a 100 way D connector at the back of the Nextmove card. A multicore cable connects this to the Breakout Board to allow individual wires and cables to be connected to axis drives, inputs and outputs.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português