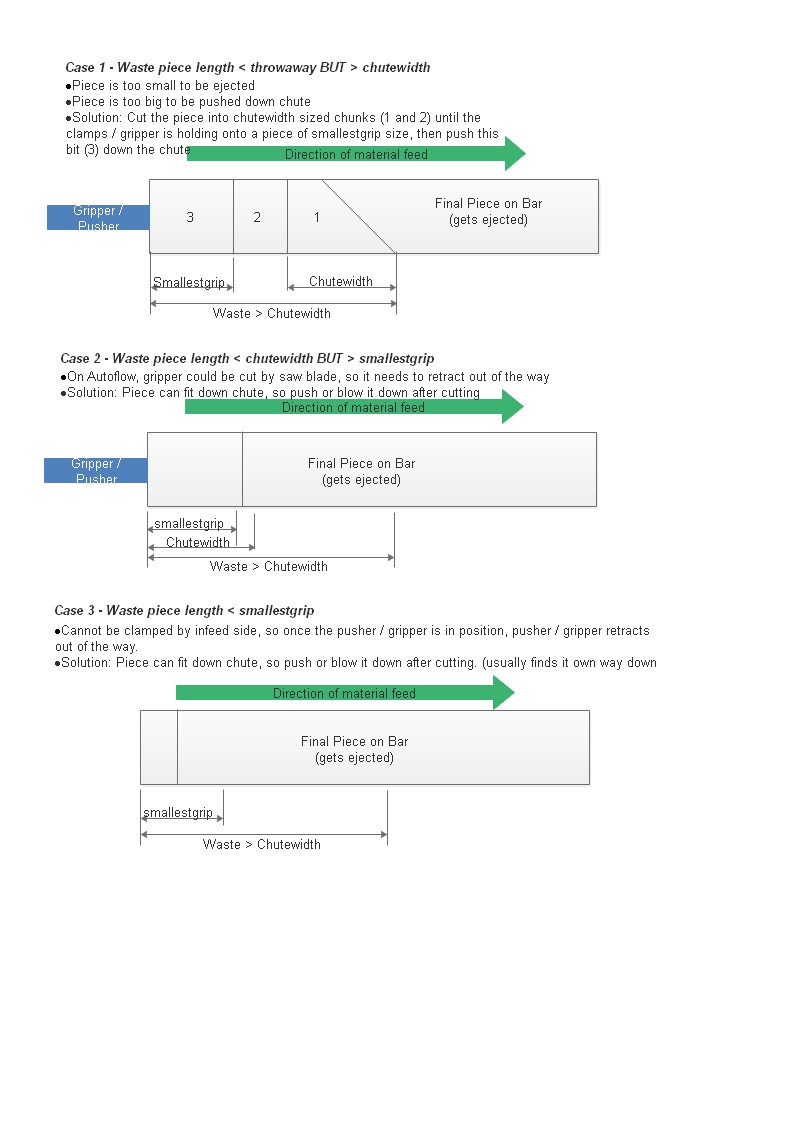

The parameters work together to define the process that happens with the final offcut at the end of a bar when it is too small to be ejected onto the outfeed table. It is surprisingly complicated, particularly on an Autoflow machine where the final piece is gripped.

Technical Bulletin

| TB Number: | 372 |

| Originator: | Gareth Green |

| Machine: | TwinCAT ZX5, ZX4, ZX3, Saw, Autoflow |

| Date: | 11/01/18 |

| Circulate to: | Service |

| Title: | Software Settings for dealing with small offcuts |

Problem

Dealing with a short offcut at the end or start of a bar is surprisingly complicated. Dealing with one case can easily create a problem in another area. This TB seeks to explain the parameters used and give guidance on how to get the best setup. PLEASE NOTE: There will NEVER be a one-size fits all to this complex situation. All customers and all profiles are different

Definitions and Parameters

Note – these parameters have been built up over the years and may only exist in the latest software versions 5.14.2.0 and later.

| Parameter | Definition | Range | Notes |

| minable | Measurement of area at the gripper end of the bar. If an operation appears in this area, this amount is added as a waste to the bar length. This stops the cutters machining the gripper. The amount is normally determined by the length of the gripper, and / or the distance of the outfeed clamps to the cutter centreline | 0-200 | This is often how and why a problem offcut is created at the gripper end of the bar– if the minable is bigger than the chutewidth, there will be a regular need to cut into throwawayChunks |

| maxable | Measurement of area at the non-gripper end of the bar. If an operation appears in this area, this amount is added as a waste to the bar length. This stops the cutters machining when only one end of the bar is held. The amount is normally determined by the distance of the cutters to the infeed clamps. | 0-200 | This is often how and why a problem offcut is created at the START of the bar – if the maxable is bigger than the chutewidth, there will be a regular need to cut into throwawayChunks |

| chutewidth | The longest offcut length that can fit down the machine chute | ||

| throwaway | The shortest piece that the machine can reliably eject to the outfeed table. Lengths longer than this need to be pushed down the chute. Therefore the problem offcuts are defined by length >chutewidth and length<throwaway. | 130-800 | The measurement is taken from the end extremes of the profile

The throwaway is determined by the distance between the front rollers on the sawing clamps |

| throwawayChunkSize | Maximum size of chunks that a problem offcut piece will be cut into. | 25-150 | The actual size will depend on how long the offcut actually is – it will be cut into a number equal sized chunks |

| smallestGrip | The smallest offcut piece size that can be gripped and cut at the gripper end of the bar. This is determined by the gripper length and the side / top clamp positions. If the piece is too short, it will flip out of the clamps when you are trying to hold it | 20-200 | This must not be biger that the chutewidth, as this would lead to an impossible situation where the final gripped offcut could not be disposed of. |

| useOffcutAtStart | Determines whether any offcut should be moved to the start of the bar, rather than deal with it at the gripper end | 0 or 1 |

ThrowawayChunk cuts

· The original software cut the chunks using a square 90 degree cut. However this could lead to a chunk shaped perfectly to fall back into a position in front of the rear rollers, jamming when the pusher moves. This square cut has been changed on later software versions (5.14.2.0) to a mitre cut to persuade the piece to fall forwards down the chute.

· A common problem is a maxable size that needs to be cut into two. This would be defined by maxable>throwawayChunkSize> maxable/2. In this case the chink will be cut in half. If half the chunk size is a problem size, this will happen a lot. In this case reduce the throwawaychunkSize so that maxable gets cut into 3 pieces.

Profile Extra Parameters

On software v 5.14 onwards, profile specific parameters were added to allow you to control the offcut per profile. The params.saw contains the default value, but this will be overwritten with a “PEP”, accessible in the profile settings.

Added peps for profile specific

| PEP Parameter | Meaning |

|---|---|

| throwawayChunkSize | size of chunks to cut beginning and end waste into |

| throwaway | size that can be safely ejected as a piece |

| wantHalfTriangle | halves the waste triangle on mitre-mitre cuts |

| trim | amount to trim off the start of a bar |

| smallestGrip | smallest size that the saw can safely hold at end of bar |

Sample Setups

| Machine | minable | maxable | chutewidth | throwaway | throwawayChunkSize | smallestGrip |

| A2014 | 90 | 130 | 160 | 240 | 120 | 140 |

| A2016 | 90 | 140 | 160 | 240 | 120 | 140 |

| A2017 | 90 | 120 | 160 | 240 | 120 | 140 |

| Z055 | 140 | 130 | 125 | 250 | 125 | 120 |

| Z057 | 100 | 110 | 130 | 320 | 125 | 120 |

Tips

· Compare the parameters to similar machine types. If similar but does not seem to be working, ascertain if it is a profile related issue, then reduce the throwawayChunkSize for that profile to ensure it is cut into 3, not 2 – Avoid doing this globally because it will slow the machine down.

· The relationship between the maxable / minable cut in half and where the rear outfeed roller is can be very important.

· If there is an issue at the start of the bar on a normal trim cut, it could be because the batch of profile is longer than expected. This can be overcome by modifying the profile standard length or the profile specific trim parameter, both accessible from the profile parameter screen.

Autoflow Offcut Blower

Some Autoflows are fitted with an offcut blower. This was an addition made to help clear the offcut at the gripper end from the table. It is a common problem that the blower has been knocked out of position or is not working, hence offcuts trapped at the end of the bar on the last cut

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português