Modification necessary to allow 90mm tall profile Z sections to be handles by Stuga Machines Liniar LCW9022

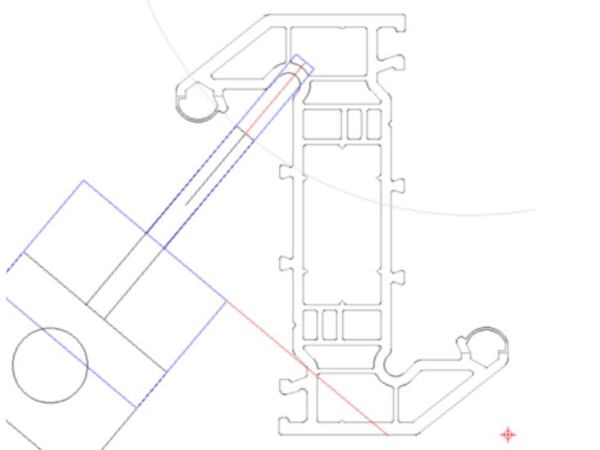

Sawing Clamps - ZX5

The side clamp block D0015174 are modified to allow a roller at a higher position to coincide with the top edge of the 90mm profile

This is a permanent change to this block, and the additional rollers can be fitted as an optional extra - kit is

R0019222 includes the fence

or R0019222B if the fence is already modified

A larger Z block D0015178B is also added to this kit to prevent potential pivot points on the taller Z section.

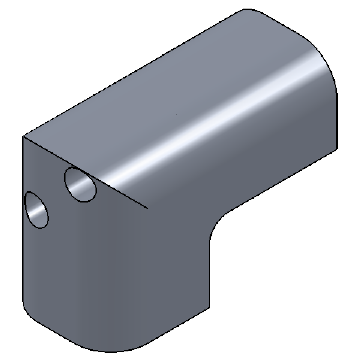

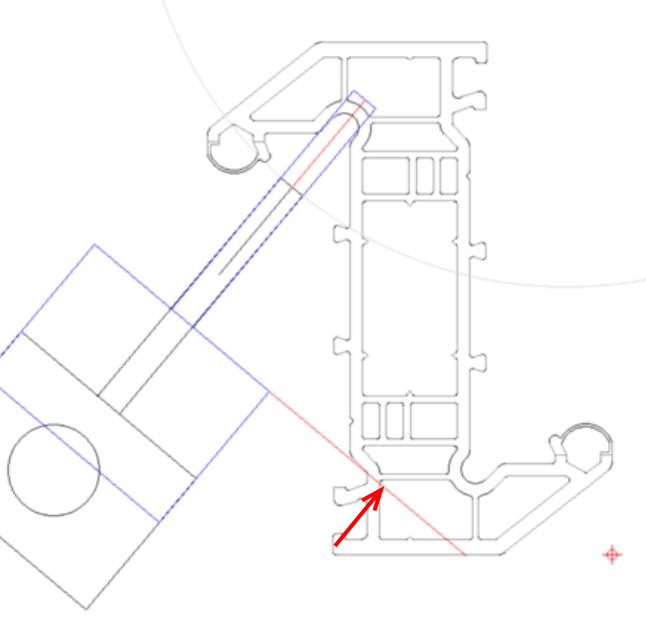

V Notch Clamps - ZX4

- R0019272 subassembly created for a ZX4 Package

- Includes bracket to raise the V notch clamp to clear 90mm as shown

See ECN0213 for design specification

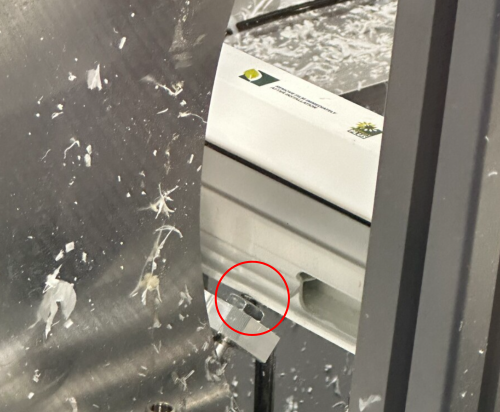

Spindle Plunge Bracket Interference

During testing the DFR operation could not complete the plunge because the spindle plunge bracket interferes with the bottom edge of the profile

There is no way around this issue with the tool depth set at the standard positions (level with inside of the ring)

Solution:

- Increase the plunge length of a specific tool

- Create a special drainage operation for DFR on LCW9022

- Create a variable for the flowops editor to allow a tool depth offset on screen when this tool is selected

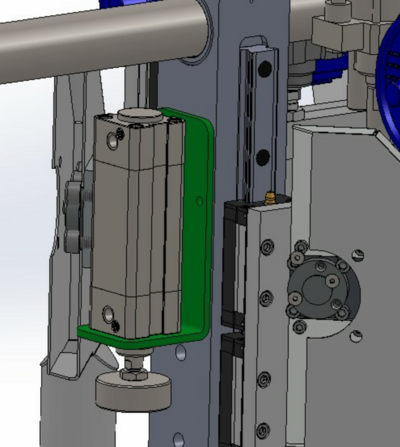

Loading and Gripping Sequence Changes - Machining Side

When gripping on a ZX4, an additional clamping cylinder is needed to hold the profile while the gripper retreats out of the way during the datum hole process. The loading wheel system means this is not so necessary on flowline and ZX5 models. The simple solution here is to add the "Hold clamp" from the ZX5 design.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português