Instructions for refurbishment of R0000728 and R0000729 stroke assemblies using Kit R0000299

Sommaire

- 1 Introduction

- 2 Étape 1 - Handing clarification

- 3 Étape 2 - Unless otherwise stated

- 4 Étape 3 - Disassembly

- 5 Étape 4 - Remove blade Guard

- 6 Étape 5 - Remove Blade

- 7 Étape 6 - Remove damper bridge

- 8 Étape 7 - Disconnect front blade assembly

- 9 Étape 8 - Extract front blade assembly

- 10 Étape 9 - Extract 2 off shafts

- 11 Étape 10 - Remove hard stop

- 12 Étape 11 - Remove motor assembly

- 13 Étape 12 - Remove Pinion bolt and shaft bolt

- 14 Étape 13 - Remove drive pinion

- 15 Étape 14 - Remove drive shaft

- 16 Étape 15 - Extract shaft from bearing housing

- 17 Étape 16 - Remove keys from shaft

- 18 Commentaires

Introduction

Assemblies fitted to MK1 ZX4 will require refurbishment at some point of life cycle.

The following instructions should be followed to ensure that correct assembly and setting are performed

Tools / consumables Required

Standard hex key set

Standard spanner set

Double pin saw flange spanner

Drifts and punches

Ballpein hammer

Soft hammer

Degreasing bath

Solvent Fe10

Loctite 243adhesive

Loctite 641 bearing fit

Thixotropic grease

Parts Required

Kit R0000299 containing

B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2

B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1

B0000335 3ph Brake motor 2 pole 3000rpm x 1

B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2

D0000059 Damper Bridge x 1

D0000062 Damper Bridge Boss x 2

D0007730 ZX4 V Notch Mk1 Spindle Shaft x1

D0007867 Bevel Gear (Left) x 1

D0007868 Bevel Gear (Right ) x 1

D0007873 Motor Gear x 1

D0007874 Pinion Gear x 1

D0007875 Pinion Shaft x 1

Étape 1 - Handing clarification

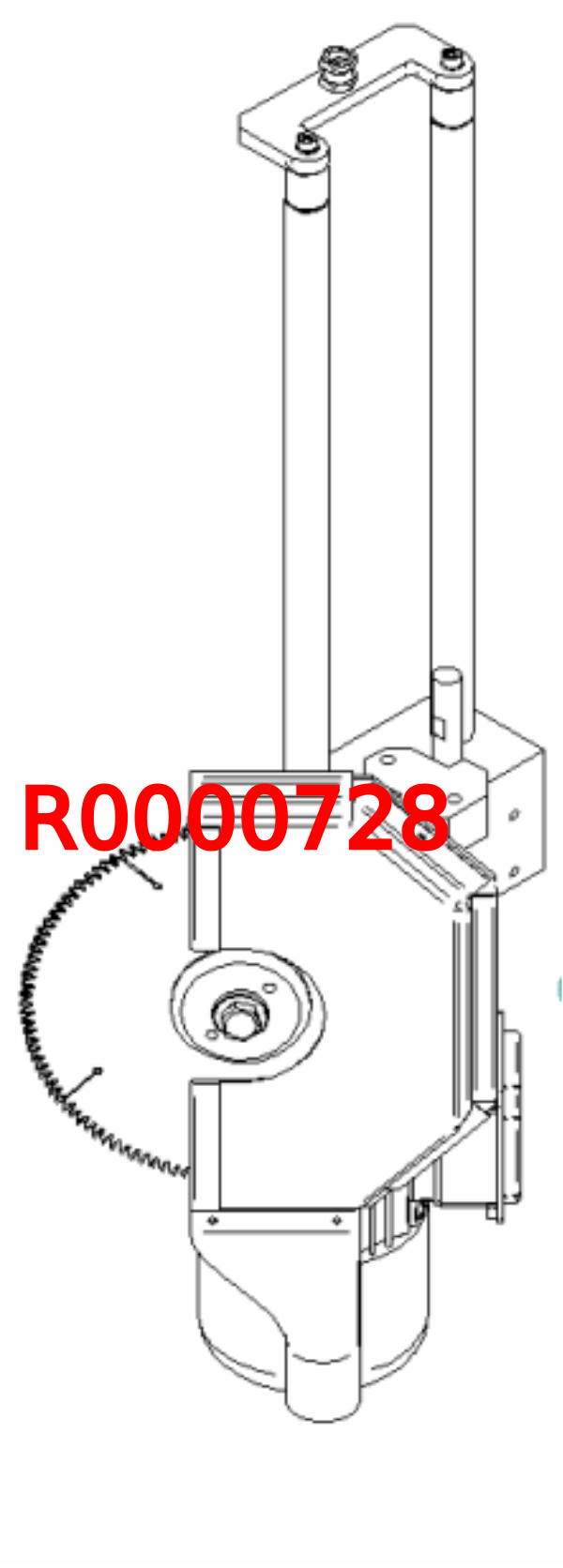

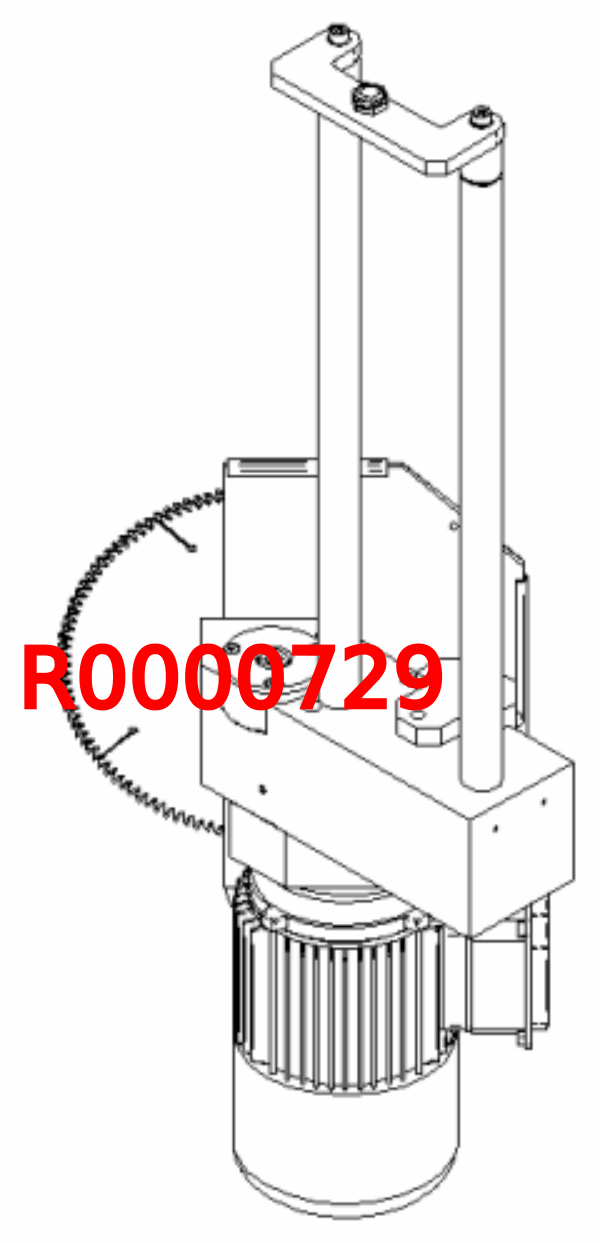

R0000728 and R0000729 are mirror images to each other

Please inspect pictures to clarify and confirm correct hand to be built

(Supplied unit to be refurbished will always be rebuilt as the same hand )

Étape 2 - Unless otherwise stated

Always use Loctite 243 on all fasteners fitted unless stated different

All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required

All fasteners should be marked once finalised

Étape 3 - Disassembly

The stroke assembly must be dismantled in the exact manner stated as many sections can only be removed once mating parts have been extracted

Please use the following steps accurately

Étape 4 - Remove blade Guard

Remove M5 socket cap and washer and slide off blade guard

Blade guard to be reused

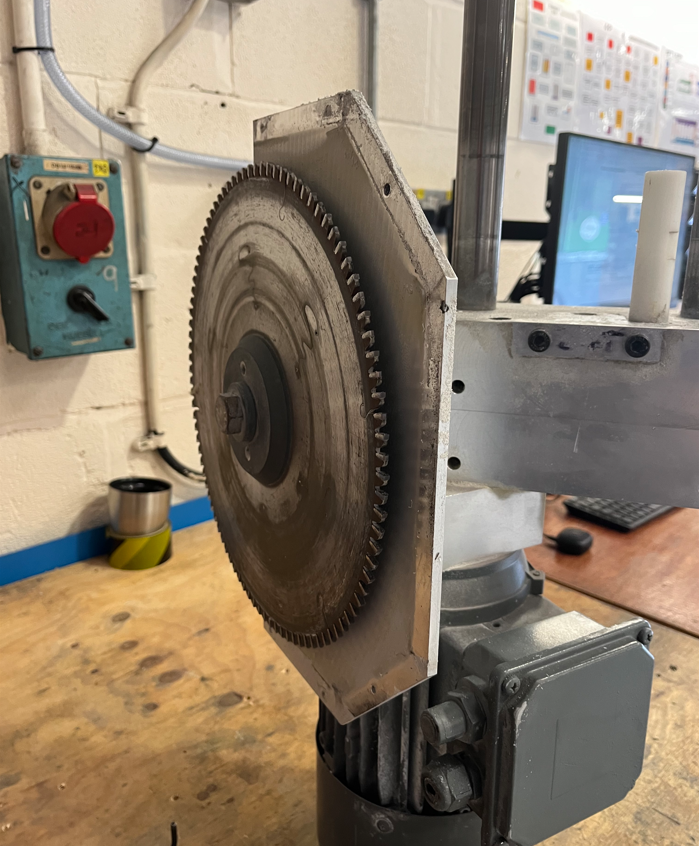

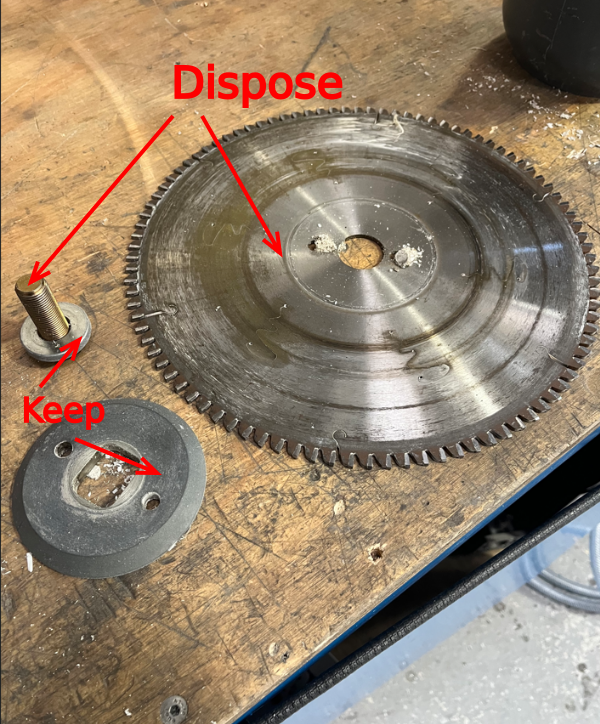

Étape 5 - Remove Blade

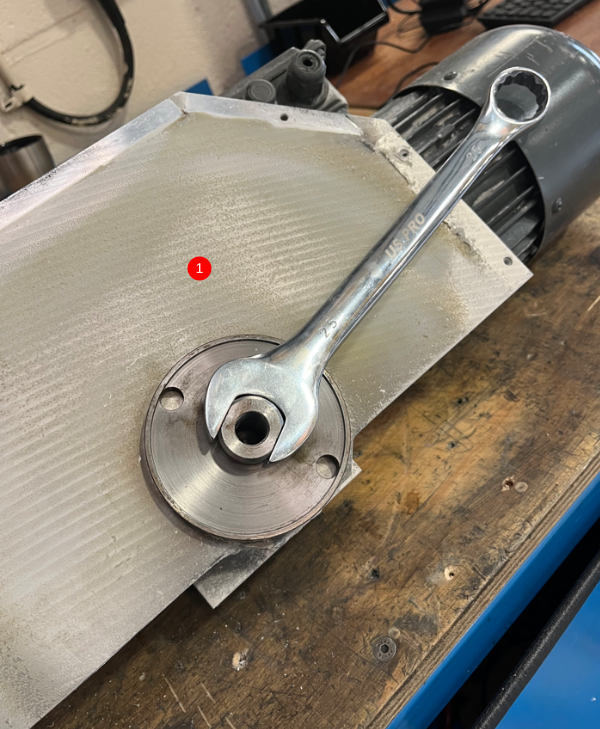

use 24mm ring spanner and saw blade pin spanner to remove blade from assembly

Dispose of saw blade and M16 bolt

Keep M16 Washer and blade flange for rebuid

Étape 6 - Remove damper bridge

Remove 2 off m8 fasteners to remove damper bridge and pillars

Dispose of all parts

Étape 7 - Disconnect front blade assembly

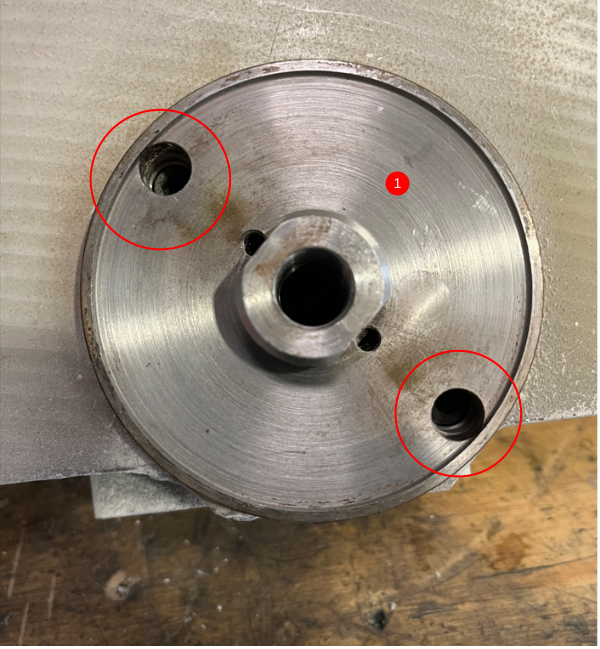

1 Rotate blade flange with a 25mm spanner to align 2 off M6 cap heads through access holes

2 Remove 2 off m6 socket cap bolts

3 Rotate blade flange to align second set of M6 socket caps and remove

4 off in total M6 socket caps to be removed

Étape 9 - Extract 2 off shafts

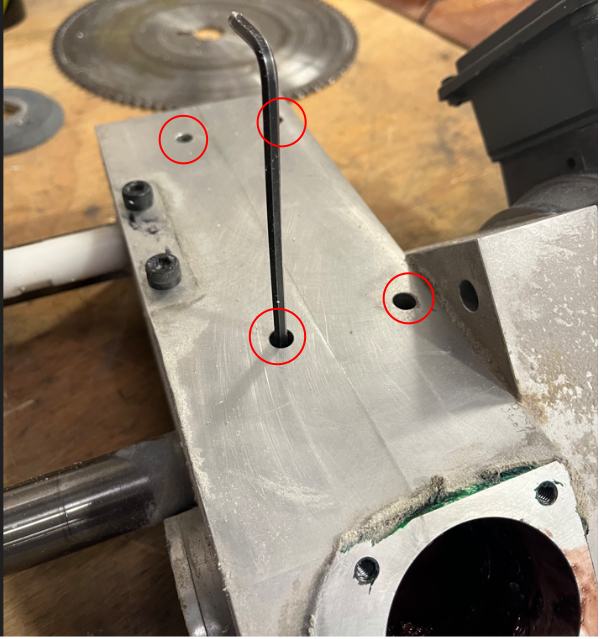

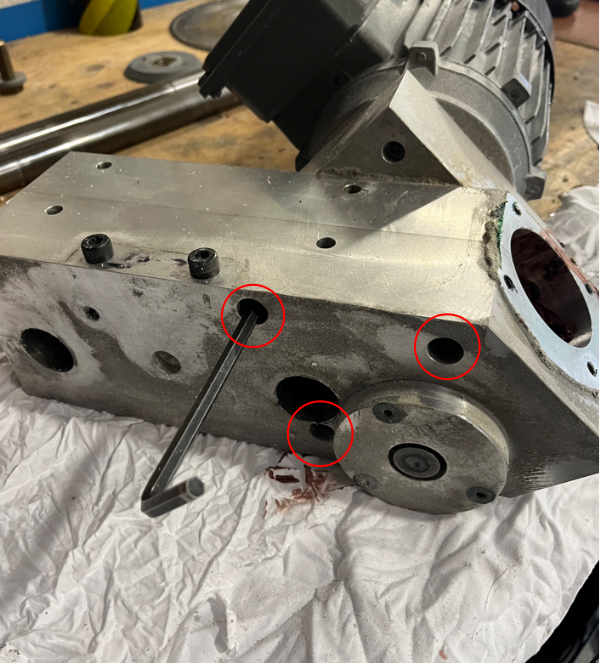

Remove 4 off M8 grubscrews indicated and extract 2 off hardened shafts from main body

Shafts to be refurbished

Étape 10 - Remove hard stop

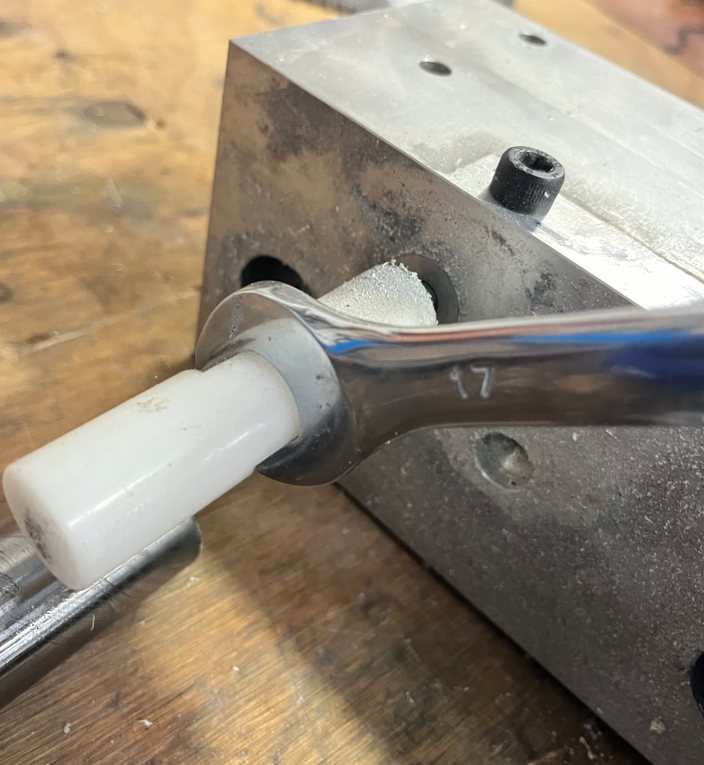

Use 17mm spanner to remove hard stop as shown

Hard stop to be refurbished

Étape 11 - Remove motor assembly

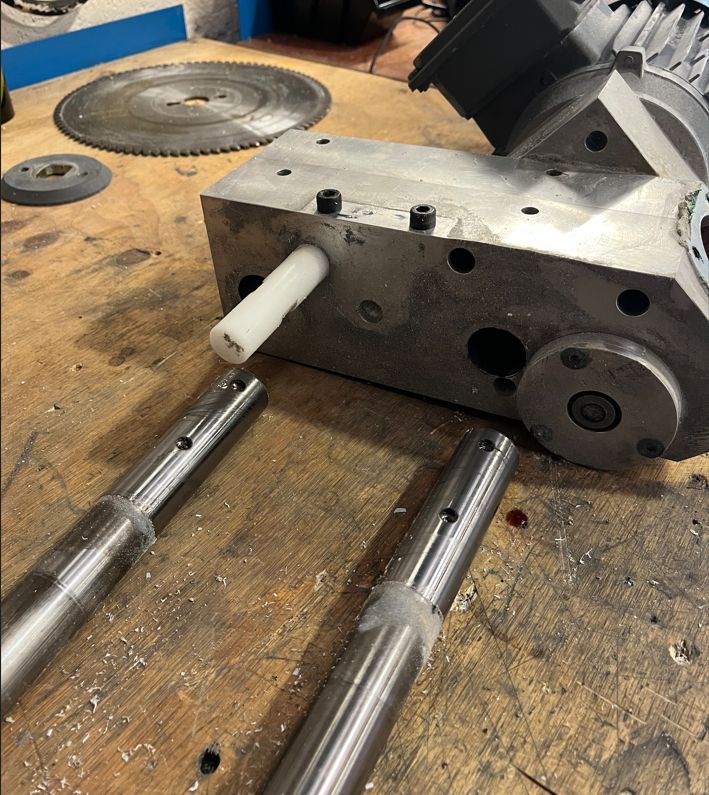

1 Remove 3 off M8 socket caps indicated

2 Separate as shown . Two components are doweled together, use caution to not damage any faces when separating two parts

Étape 13 - Remove drive pinion

Raise pinion shown to allow blocks to be added beneath

Use drift to separate pinion from shaft

Dispose of pinion gear

Étape 14 - Remove drive shaft

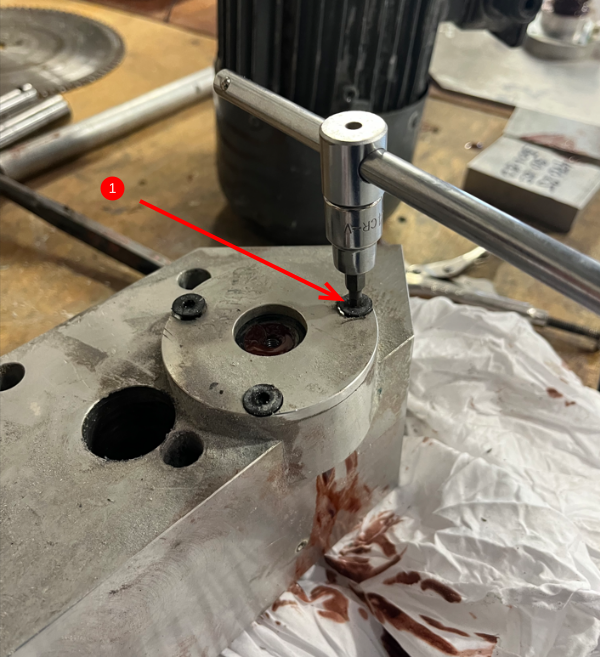

1 Remove 3 off M6 countersunk bolts shown

2 Remove top cap and keep for refurbishment

3 drive shaft from base to extract assembly from housing

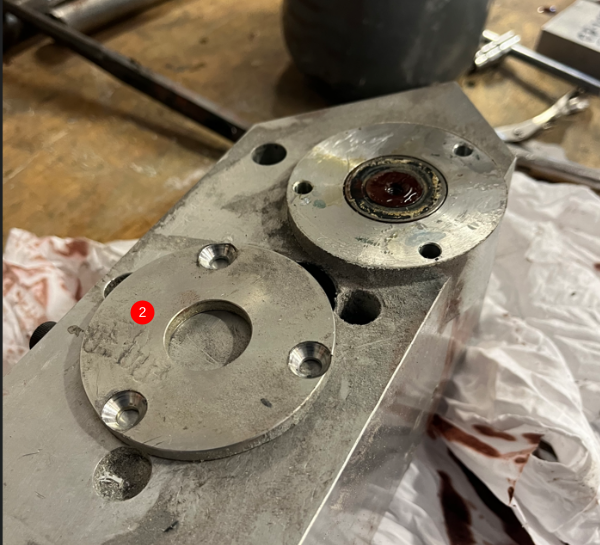

Étape 15 - Extract shaft from bearing housing

Extract shaft as shown, and remove bearings from housing

Dispose of bearings

Étape 16 - Remove keys from shaft

Remove two off keys from shaft to reuse and dispose f rest of components

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português