Pneumatic installation details for ZX5 module B

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Connect Air service unit

- 4 Étape 3 - Connect Air gun

- 5 Étape 4 - Finalise Y395 Connections

- 6 Étape 5 - Y386 connections

- 7 Étape 6 - Y351 and Y270 connections

- 8 Étape 7 - Y360 connection

- 9 Étape 8 - Fit Quick exhaust valves to Z supports

- 10 Étape 9 - Assemble V cut valve

- 11 Étape 10 - Mount to cross beam

- 12 Étape 11 - Connect Y389

- 13 Étape 12 - Y389 cylinder connections

- 14 Étape 13 - Fit rear lower panel

- 15 Commentaires

Introduction

Tools Required

Pipe cutters

Pipe identification numbers

Parts Required

D0015703 Air Gun Bracket x 1

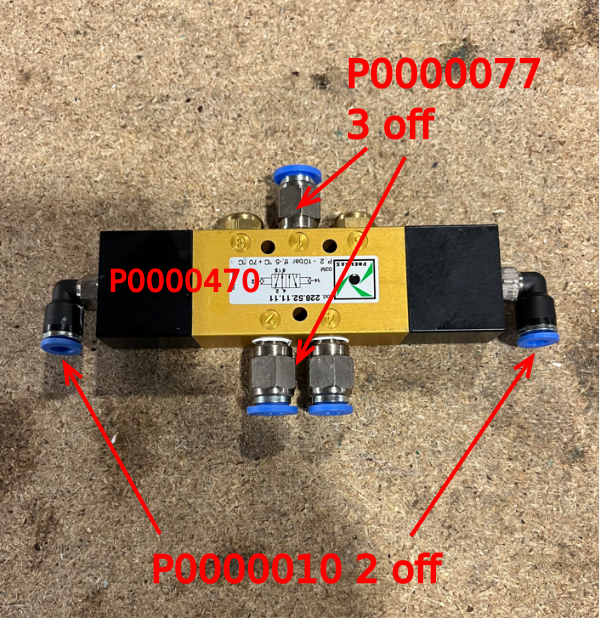

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 2

P0000046 Fitting: 'Y' Adaptor 6mm x 4

P0000053 6mm T (P16) x 2

P0000075 Parallel Y Connector 8mm x 1

P0000077 Straight Adaptor 8mm - 1/8BSP x 3

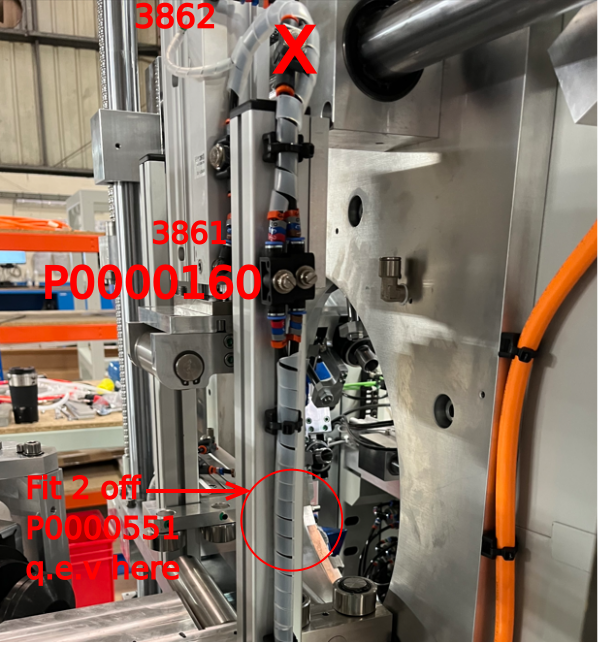

P0000160 Fitting: Flow Controller In Line 6mm x 4

P0000161 Plug-in Reducer 6mm Tube 8mm Fitting x 6

P0000401 6mm inline non return valve x 2

P0000470 Valve: 5/2 PnPnu 1/8BSP x 1

P0000513 Ball valve with QS connector x 1

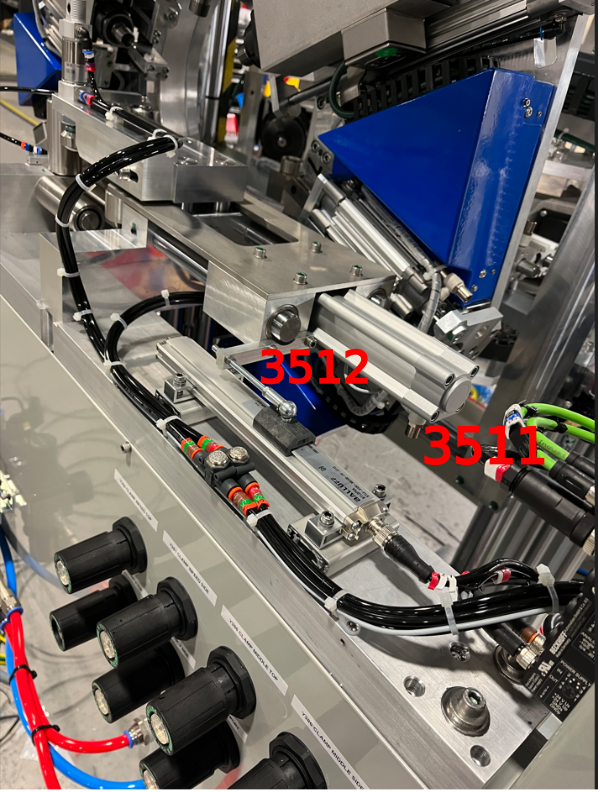

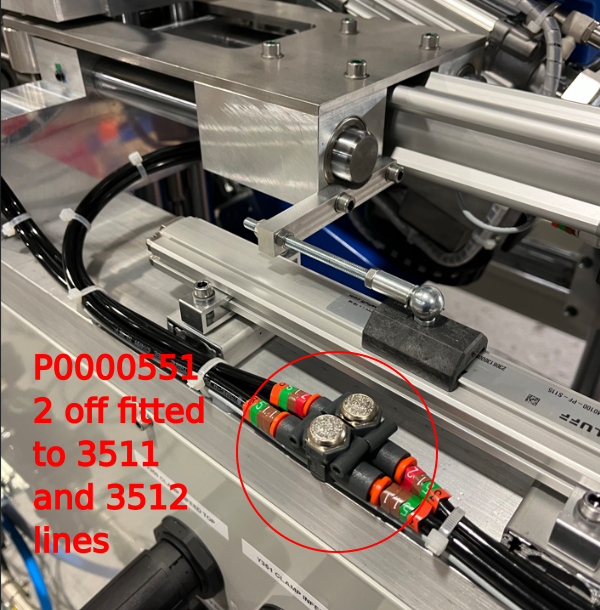

P0000551 6mm inline Quick Exhaust Fitting x 6

P0001106 Plug in reducer 12mm to 8mm x 7

P0001107 12mm Y connector x 8

R0015114 Bench Assemble Valve banks and RegulatorsÉtape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

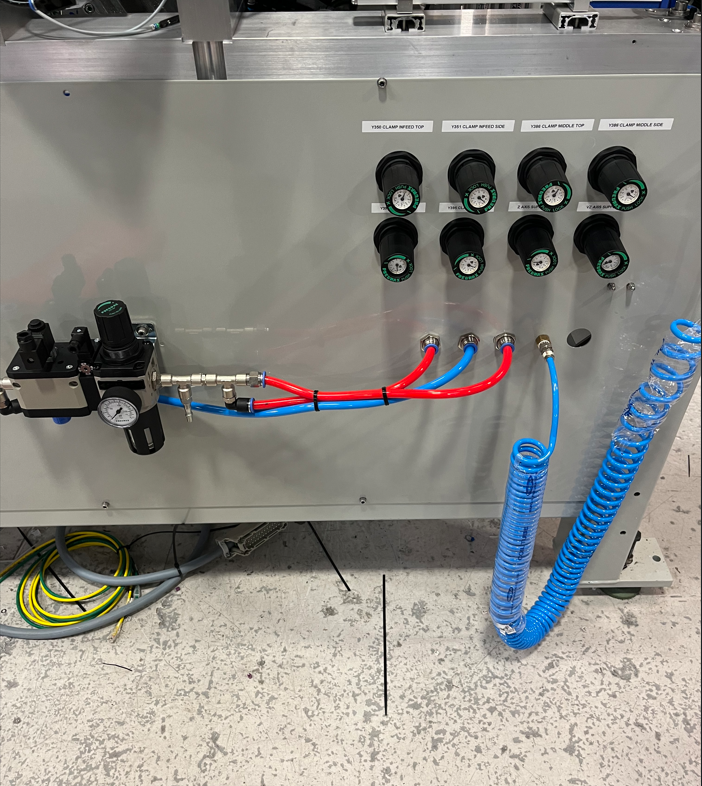

Étape 2 - Connect Air service unit

Connect 2 off 12mm red and 1 off 12mm blue pipes as shown to air service unit

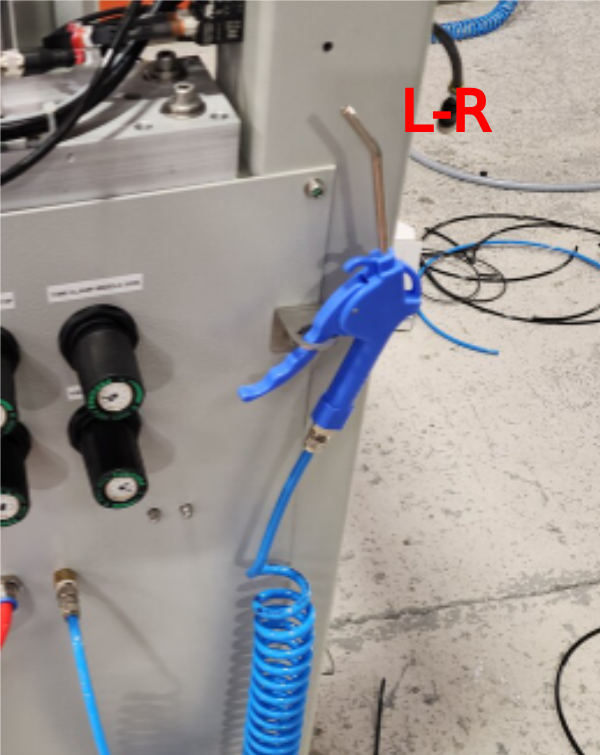

Étape 3 - Connect Air gun

Drill hook hole centre 120mm down at edge of panel. M6 tapped.

Attach bracket D0015703 for airgun and insert airgun

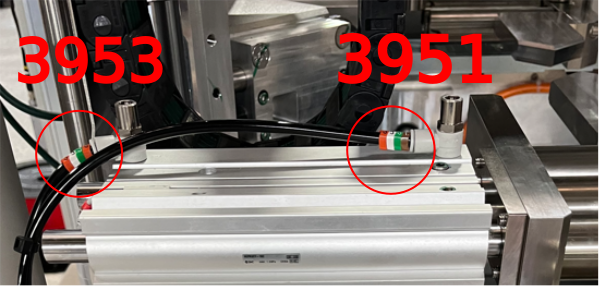

Étape 4 - Finalise Y395 Connections

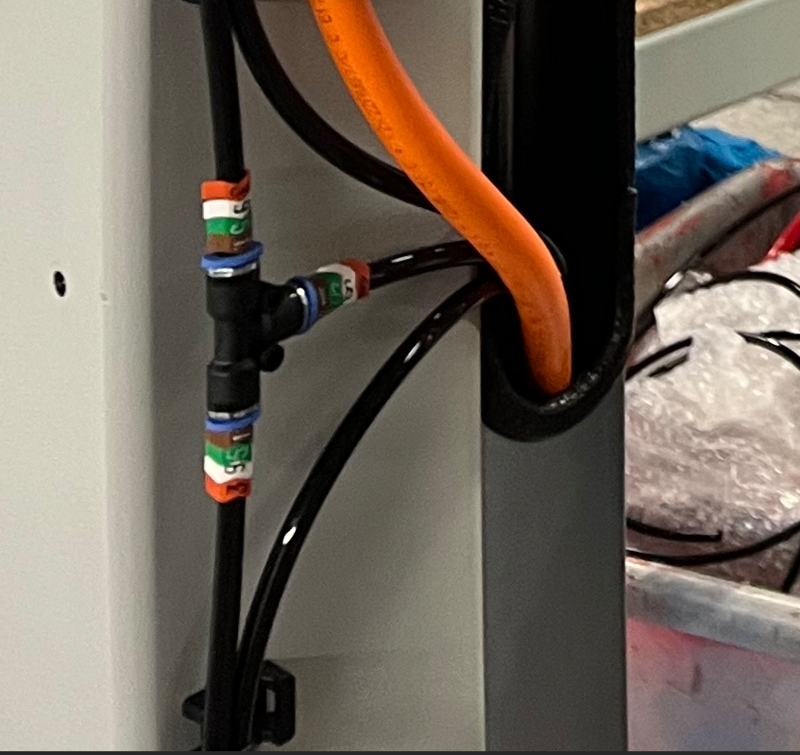

Use P0000053 6mm tee to split 3951 pipe as shown

Run 3952 to top clamp

Run 3953 to side clamp

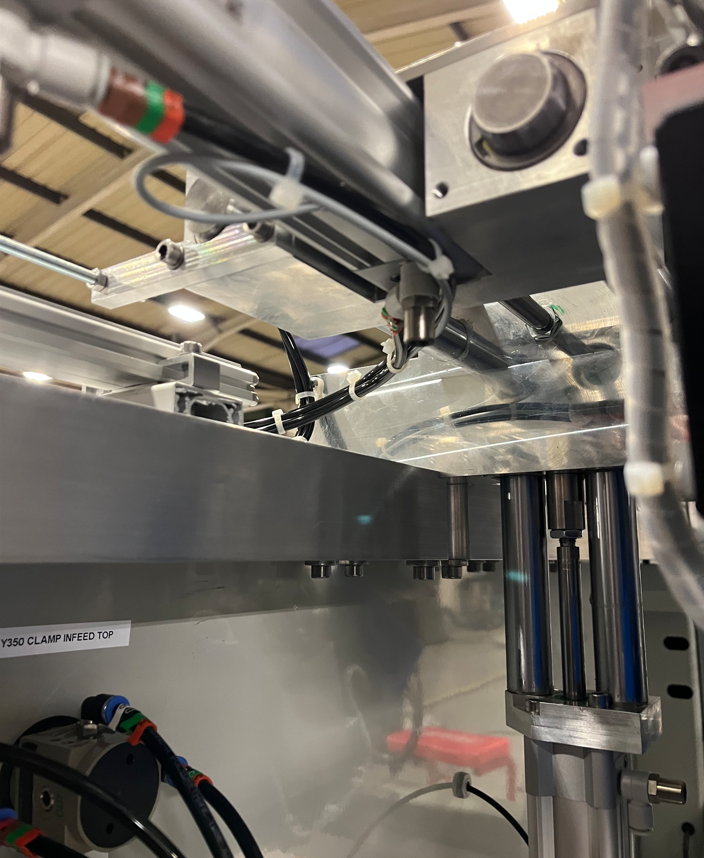

Use 2 off P0000160 flow regs to control flow as shown for top clamp

Use 4 off P0000551 quick exhaust valves, ensuring fitted before flow regulation

Incorporate 2 off reed switches into loom to connect to cylinders X111 Top clamp home and X112 side Clamp home

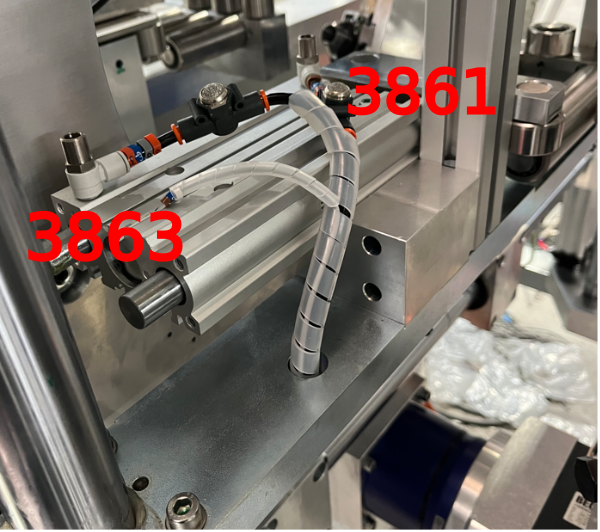

Étape 5 - Y386 connections

Spiral Wrap loom of 3861,3862 and 3863 pipes. Incorporate X59 and X61 reed switches into loom

Use P0000046 6mm Y connector to split3861 into 2 feed pipes

Loom 3861 and 3862 to top clamp with X59 reed switch

Loom 3861 and 3863 to side clamp with X61 reed switch

Utilize cable tie points as shown

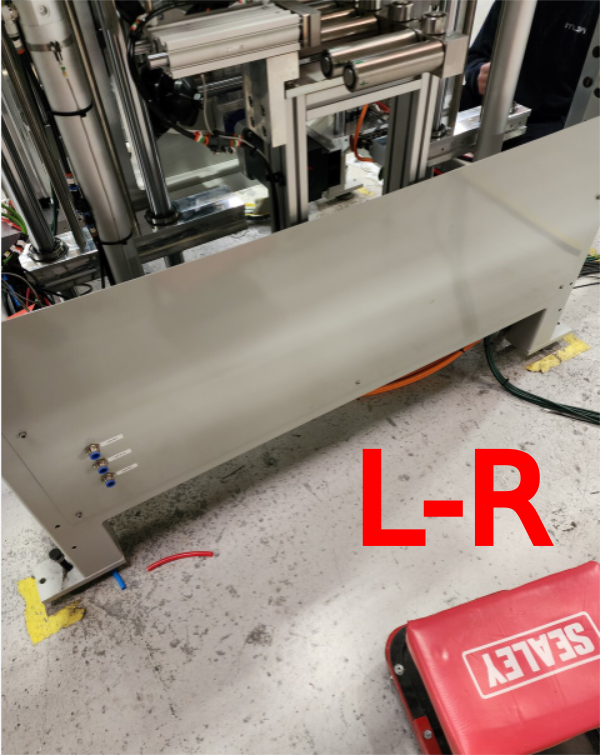

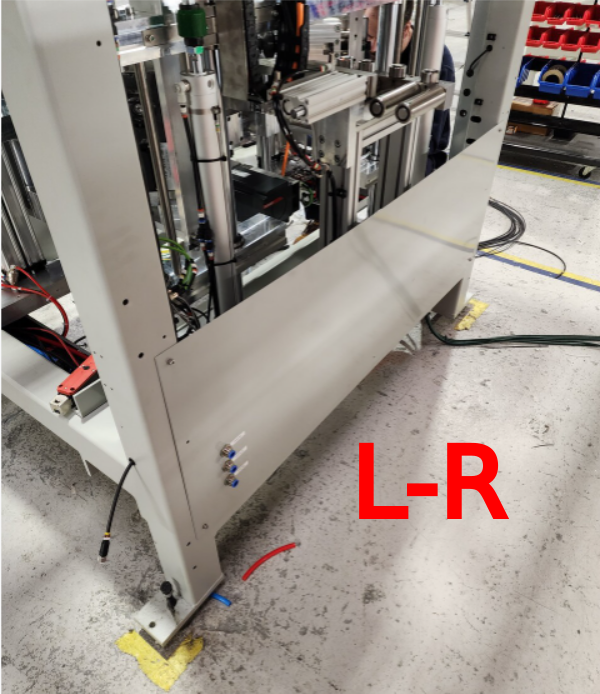

(pictures show L-R configuration )

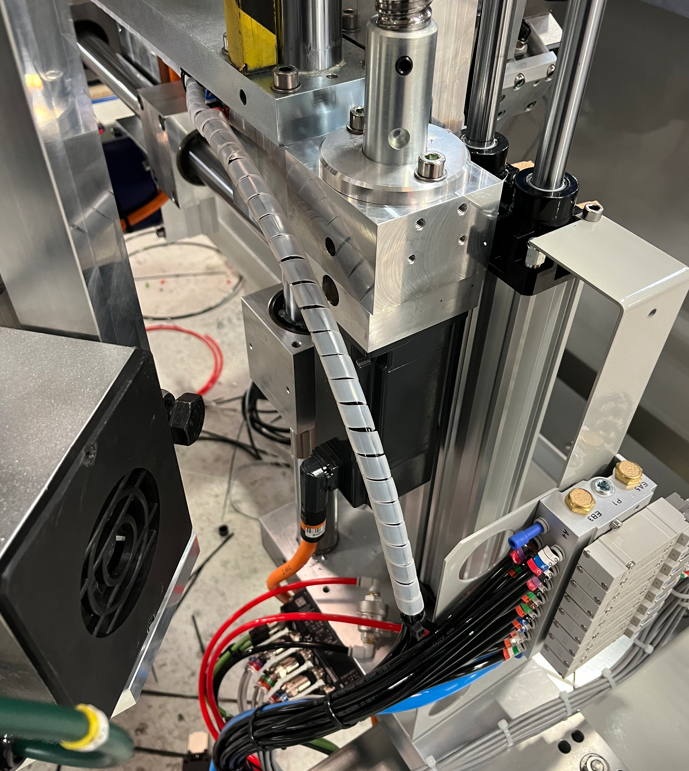

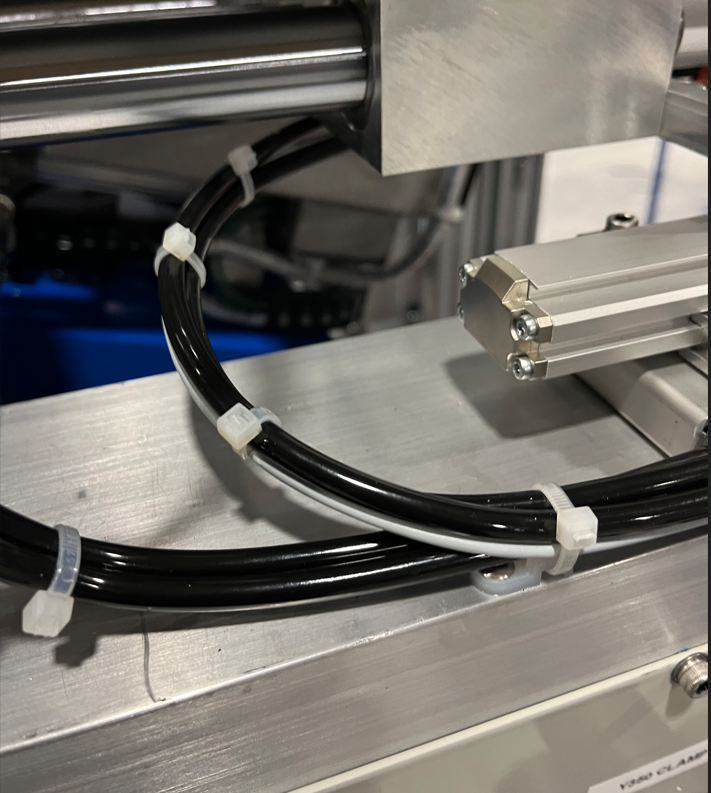

Étape 6 - Y351 and Y270 connections

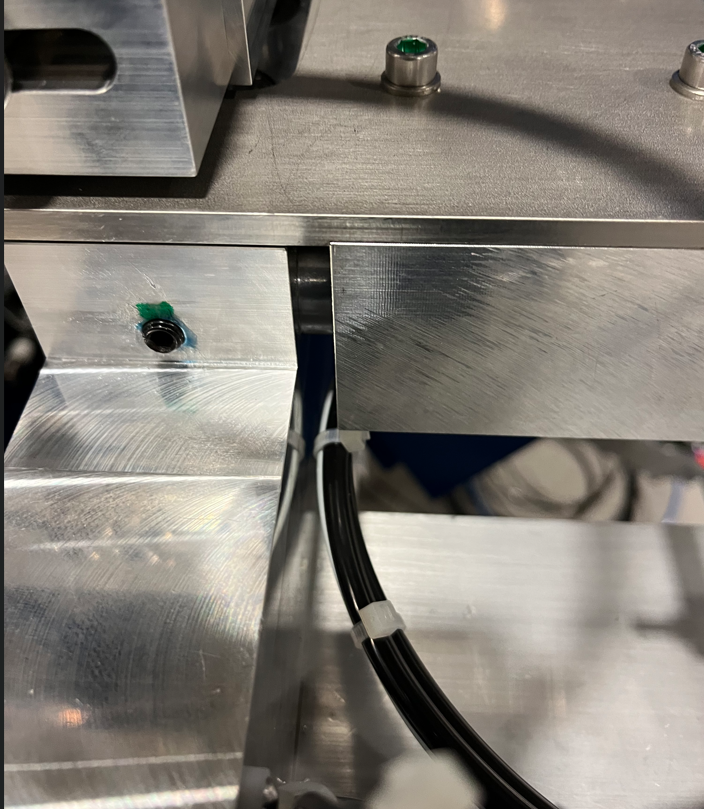

Loom as shown

Incorporate X65 side clamp home reed switch into loom

ensure sufficient slack is left in looms to allow full range of movement

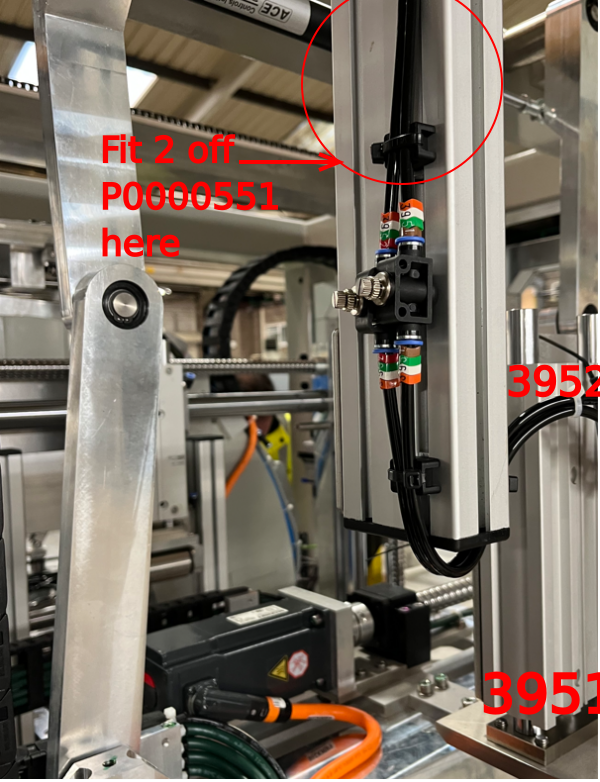

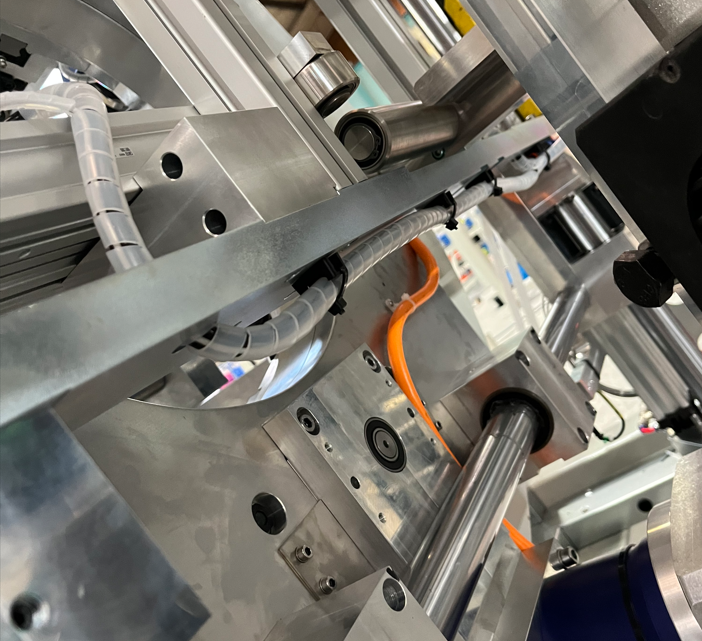

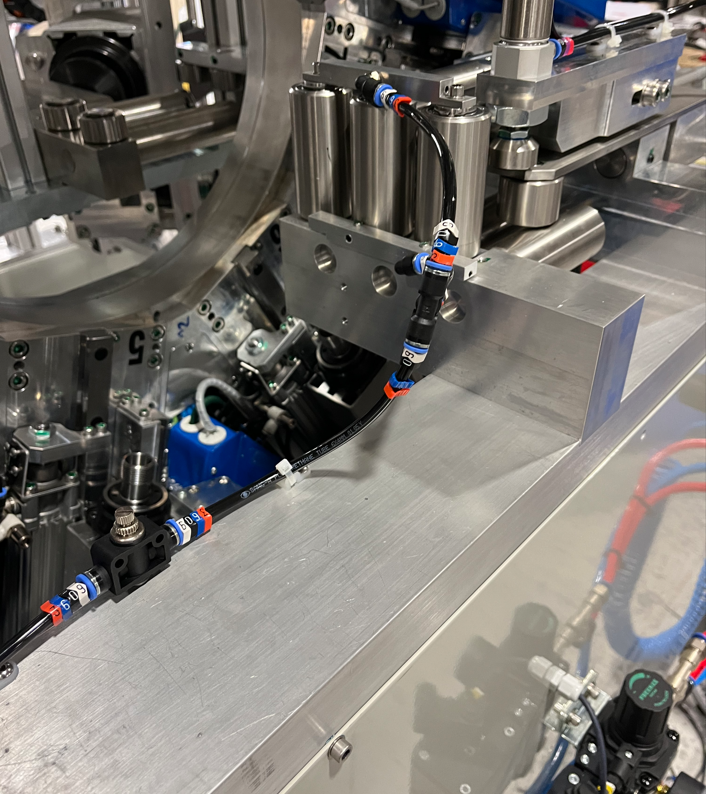

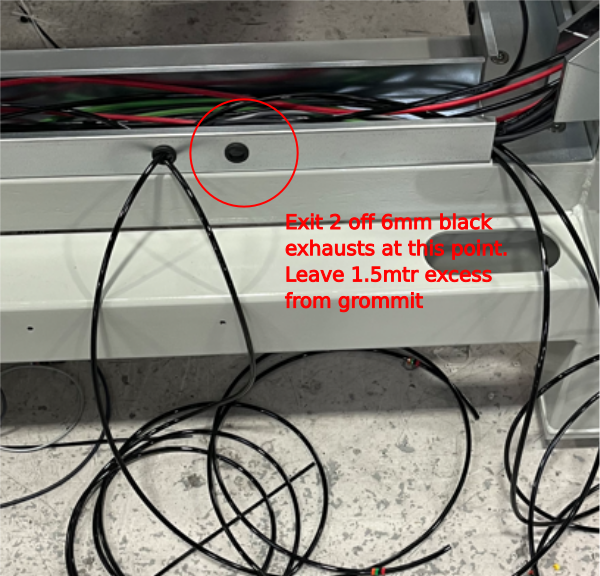

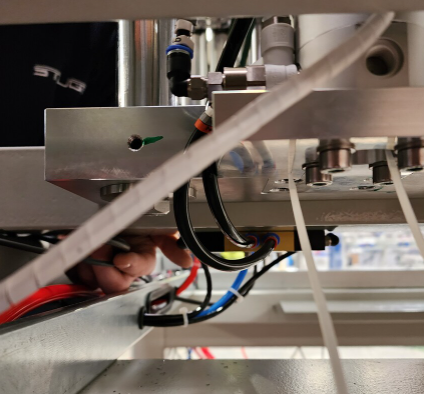

Étape 8 - Fit Quick exhaust valves to Z supports

Fit pre assembled quick exhaust valves to z supports as shown

Connect additional 6mm black air pipe to each exhaust as shown and route to point shown at front of machine

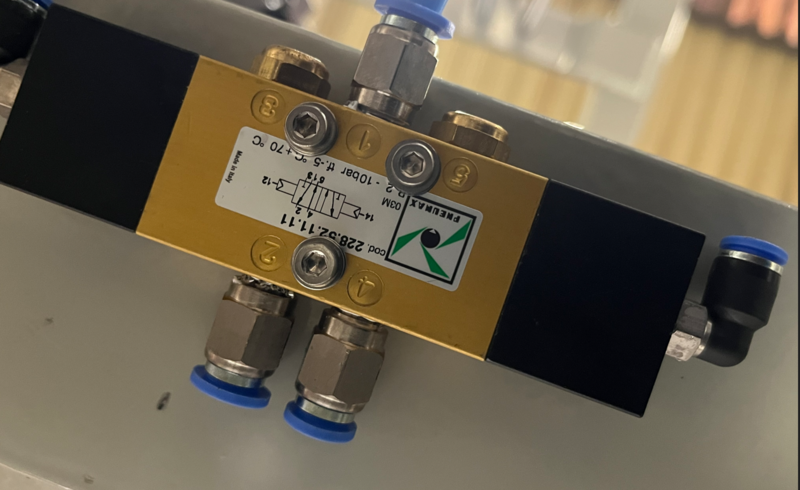

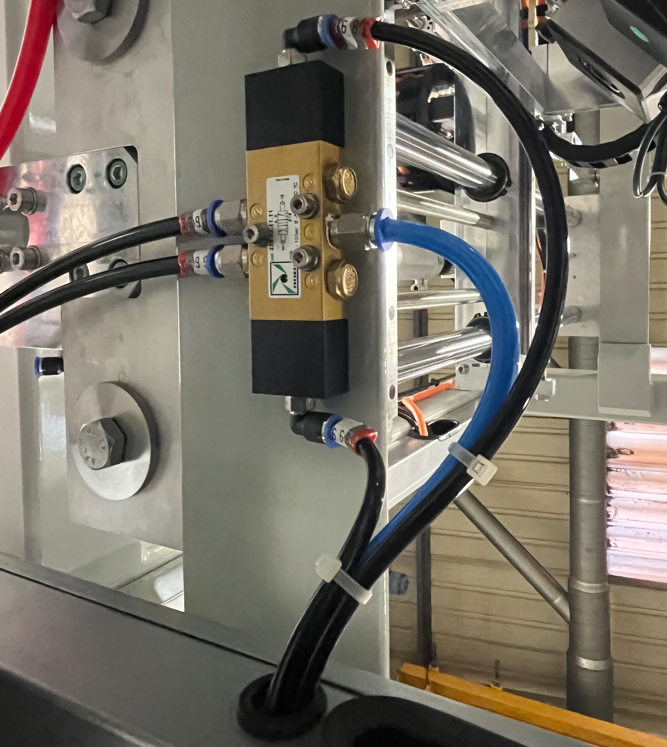

Étape 10 - Mount to cross beam

Drill and mount as shown valve to cross beam.

Fix with M4 x 30 socket caps and 2 off A form washers per Socket cap

Fit to cross beam next to 3891 and 3899 pipes exiting trunking

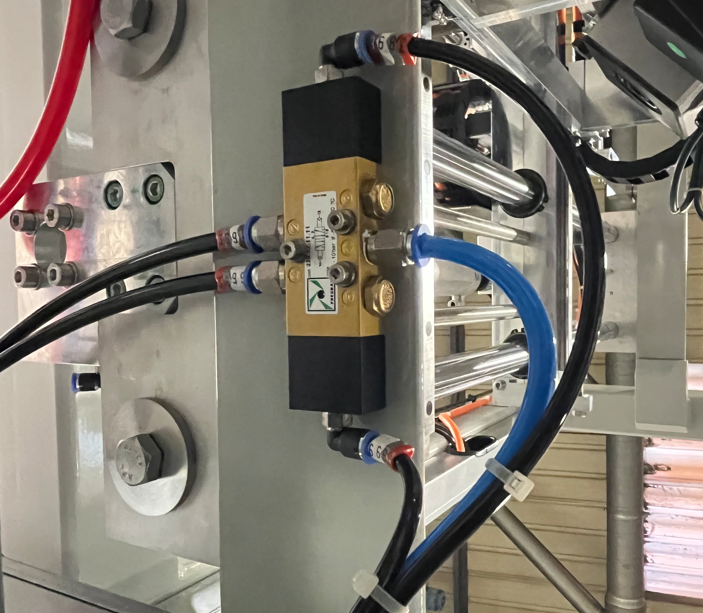

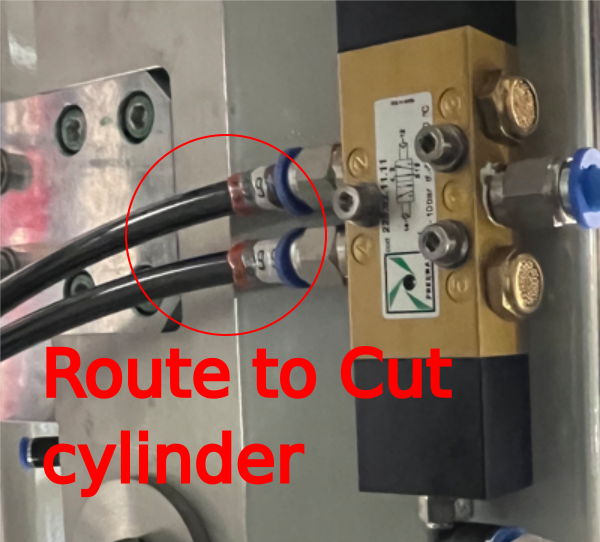

Étape 11 - Connect Y389

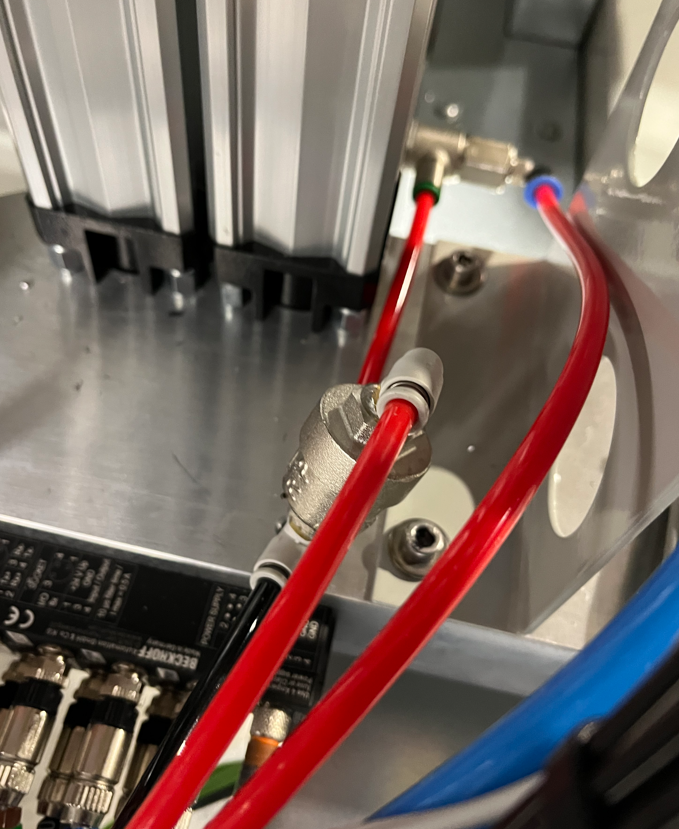

Connect 3891 and 3899 pipes as shown .

Connect 8mm blue connection to valve as shown

Route exit pipes 3891 and 3899 to cut cylinder

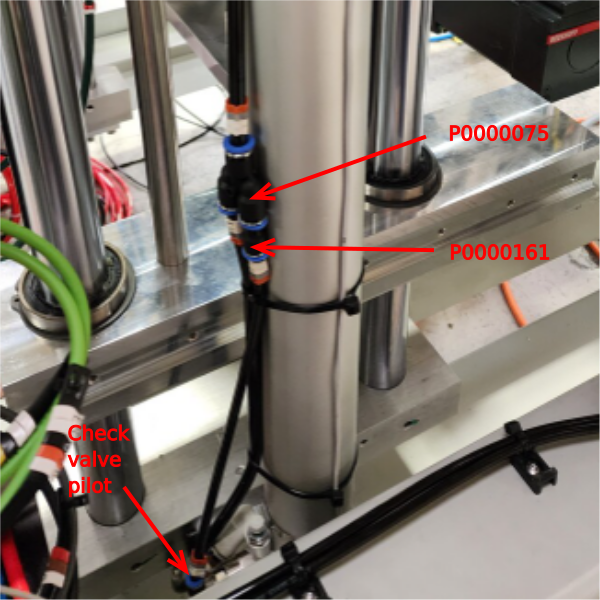

Étape 12 - Y389 cylinder connections

Split feed pipe 3899 as shown with 8mm Y connector

Use 8-6mm reducer and feed check valve at bottom of cylinder with 6mm pipe id 3899

Étape 13 - Fit rear lower panel

Fit rear lower panel as shown, connecting 2 off 12mm red pipes and 1 off 12mm blue pipes to bulkhead connectors

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português