Pneumatic installation details for ZX5 module B

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Machine Handing

- 4 Étape 3 - Y269 Ring blow output

- 5 Étape 4 - Y270 Clamp hold

- 6 Étape 5 - Y350 Clamp infeed top

- 7 Étape 6 - Y351 infeed side clamp

- 8 Étape 7 - Y360 work blowers

- 9 Étape 8 - Y386 Outfeed clamps

- 10 Étape 9 - Y389 V cut

- 11 Étape 10 - Y395 Clamps V

- 12 Étape 11 - 12mm blue connections Ring feed

- 13 Étape 12 - 12mm blue connections Valve bank supply

- 14 Étape 13 - 12mm blue connection V cut valve

- 15 Étape 14 - Rear pipe exit handing

- 16 Étape 15 - Finalise Blue 12mm ring main

- 17 Étape 16 - Ring Spindle anti drop valve installation

- 18 Étape 17 - 12mm red Connection Bulkhead /Air gun

- 19 Étape 18 - 12mm Red connection Z support cylinder

- 20 Étape 19 - 12mm red connection VZ support cylinder

- 21 Étape 20 - 12mm red connection Z support pilot 1

- 22 Étape 21 - 12mm red connection rear lower panel

- 23 Étape 22 - 12mm red connection 12mm from bulkhead

- 24 Étape 23 - 12mm red connection rear bulkhead

- 25 Étape 24 - Z support cylinder Feeds

- 26 Étape 25 - VZ support cylinder feed

- 27 Étape 26 - Z support exhaust

- 28 Commentaires

Introduction

Tools Required

Pipe cutters

Pipe identification numbers

Parts Required

D0015703 Air Gun Bracket x 1

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 2

P0000046 Fitting: 'Y' Adaptor 6mm x 4

P0000053 6mm T (P16) x 2

P0000075 Parallel Y Connector 8mm x 1

P0000077 Straight Adaptor 8mm - 1/8BSP x 3

P0000160 Fitting: Flow Controller In Line 6mm x 4

P0000161 Plug-in Reducer 6mm Tube 8mm Fitting x 6

P0000401 6mm inline non return valve x 2

P0000470 Valve: 5/2 PnPnu 1/8BSP x 1

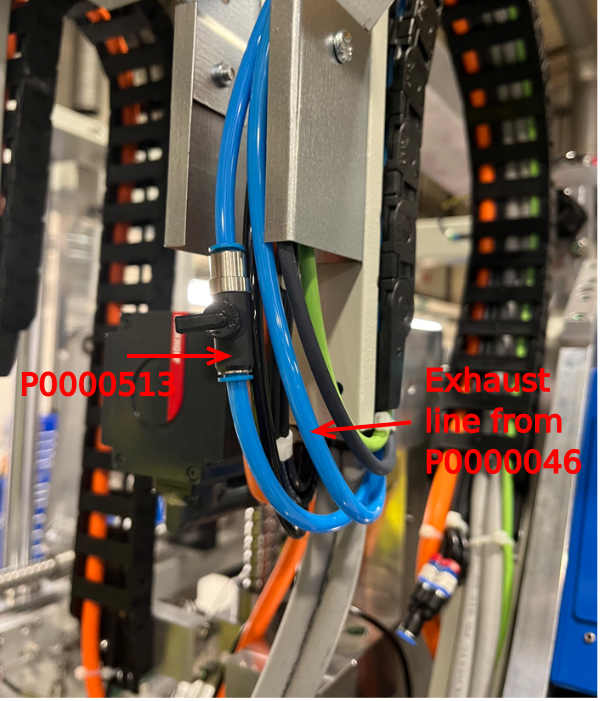

P0000513 Ball valve with QS connector x 1

P0000551 6mm inline Quick Exhaust Fitting x 6

P0001106 Plug in reducer 12mm to 8mm x 7

P0001107 12mm Y connector x 8

R0015114 Bench Assemble Valve banks and Regulators

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

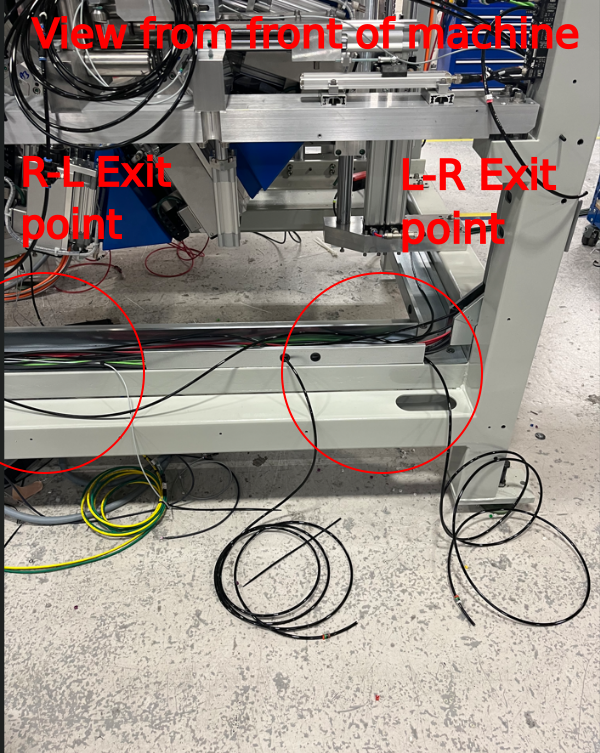

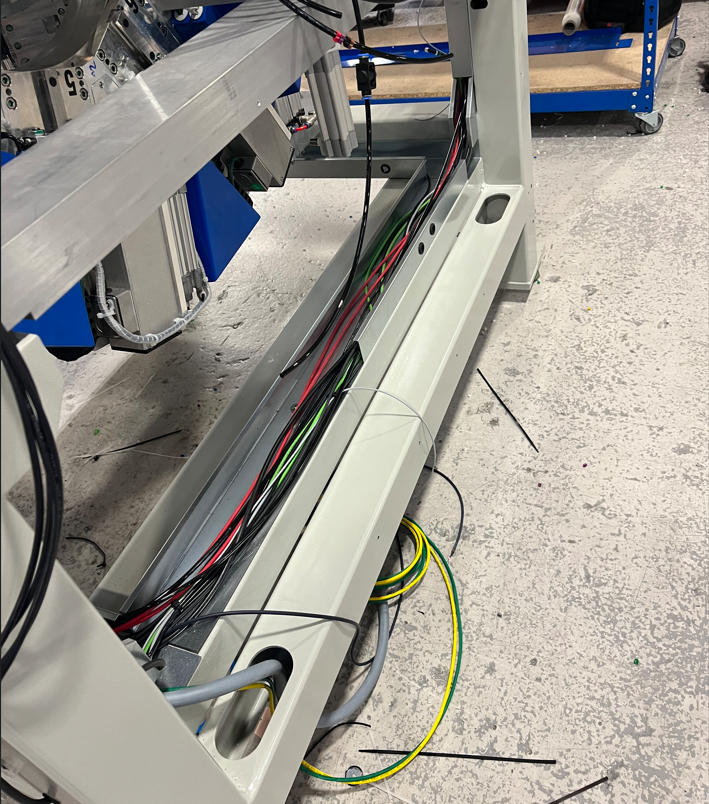

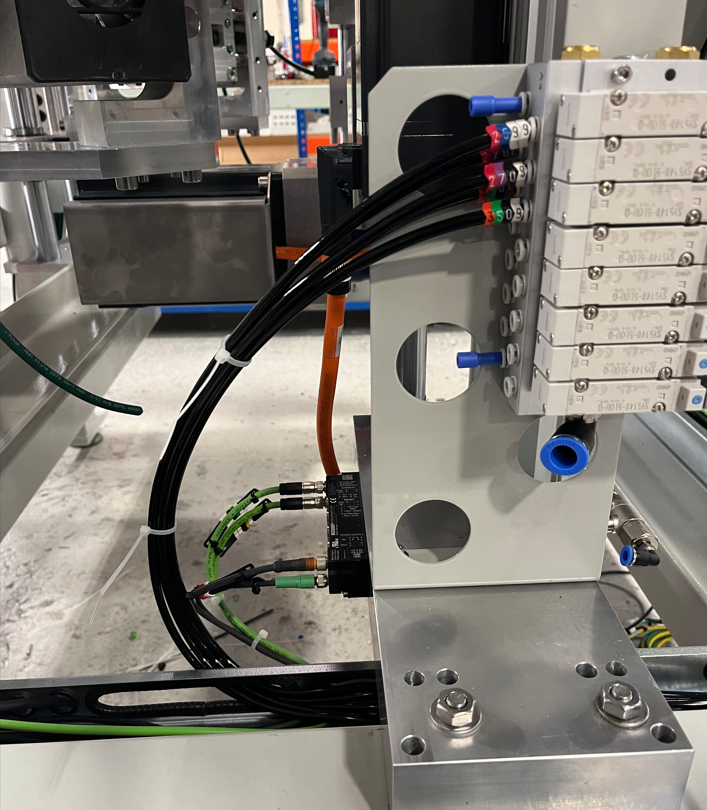

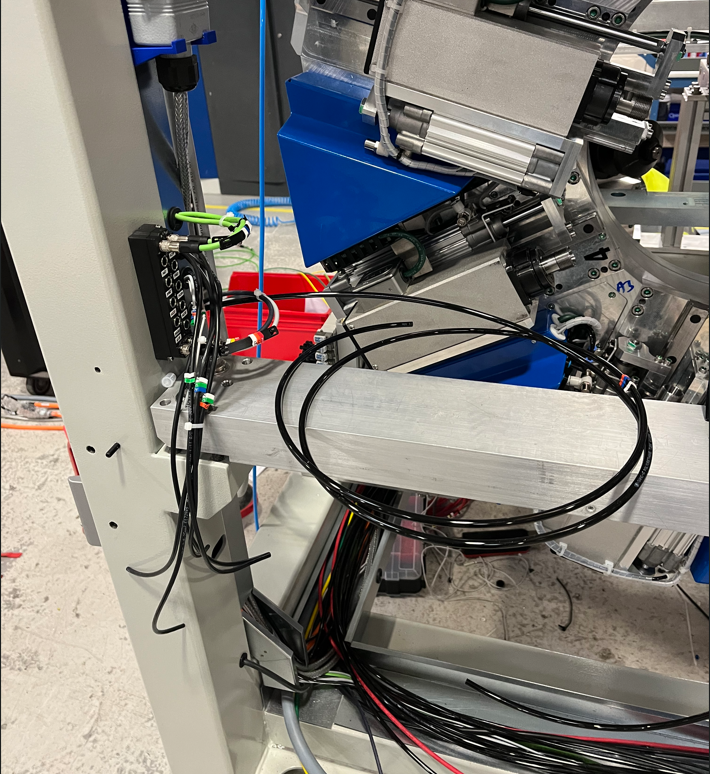

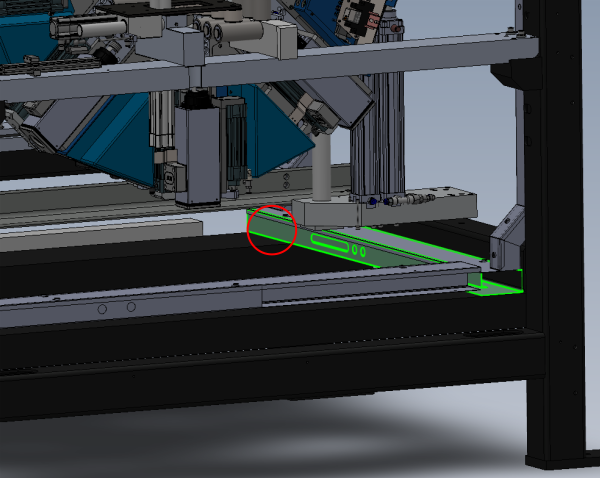

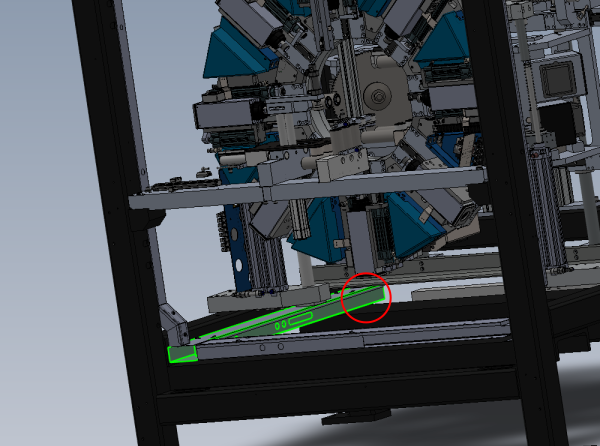

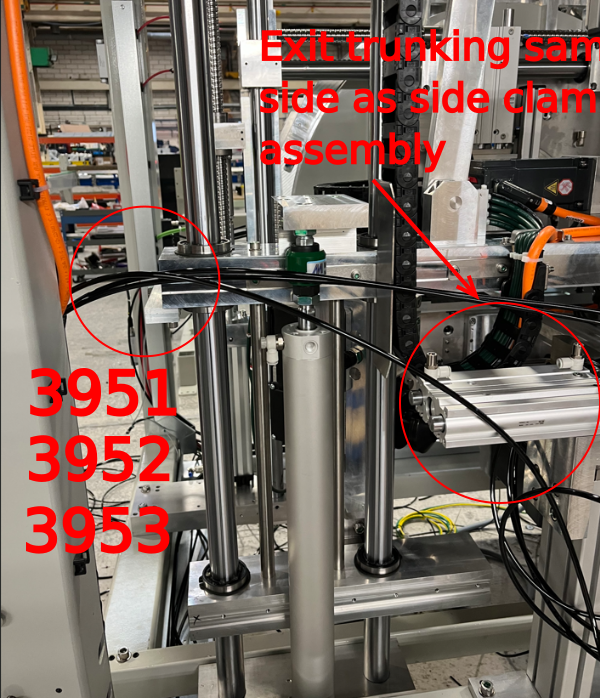

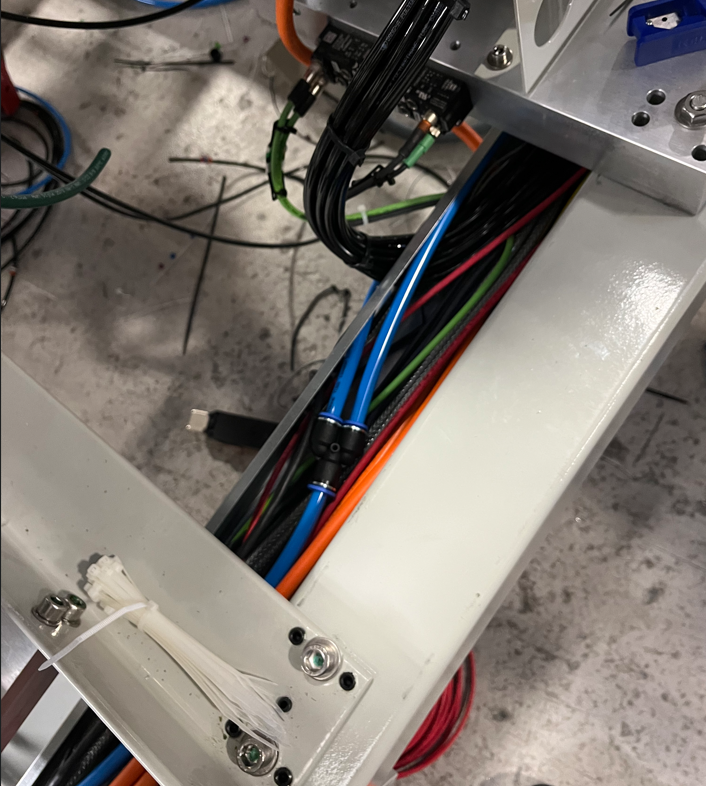

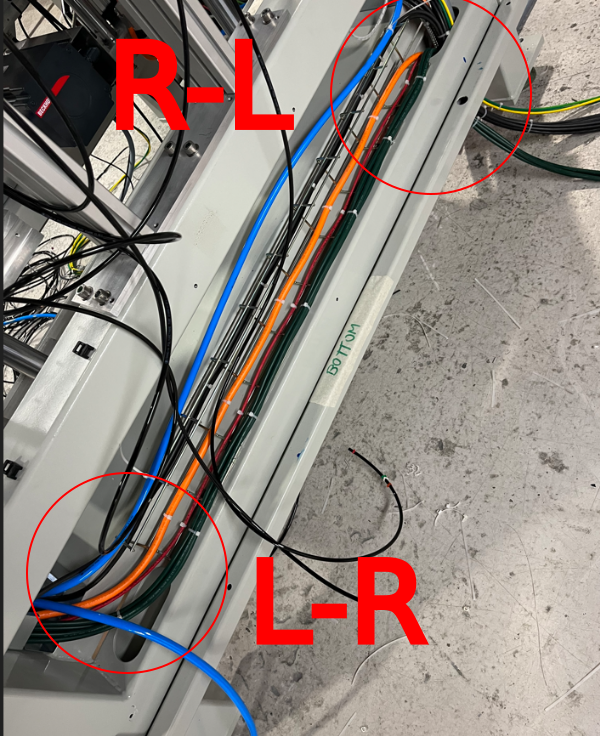

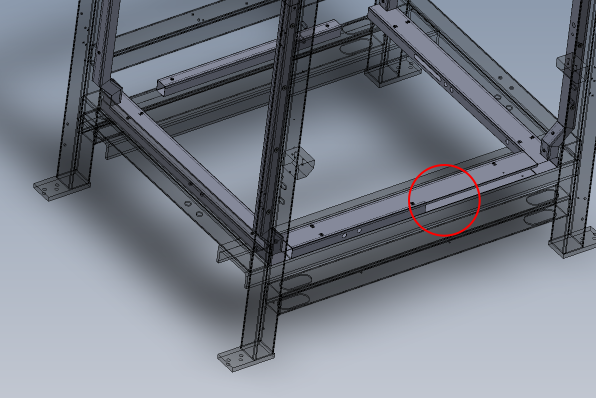

Étape 2 - Machine Handing

Exit point of shown pipes changes in respect to hand of machine

Photo shows L-R configuration

For R-L configuration, the pipes must exit the trunking on the left side ( opposite to shown picture)

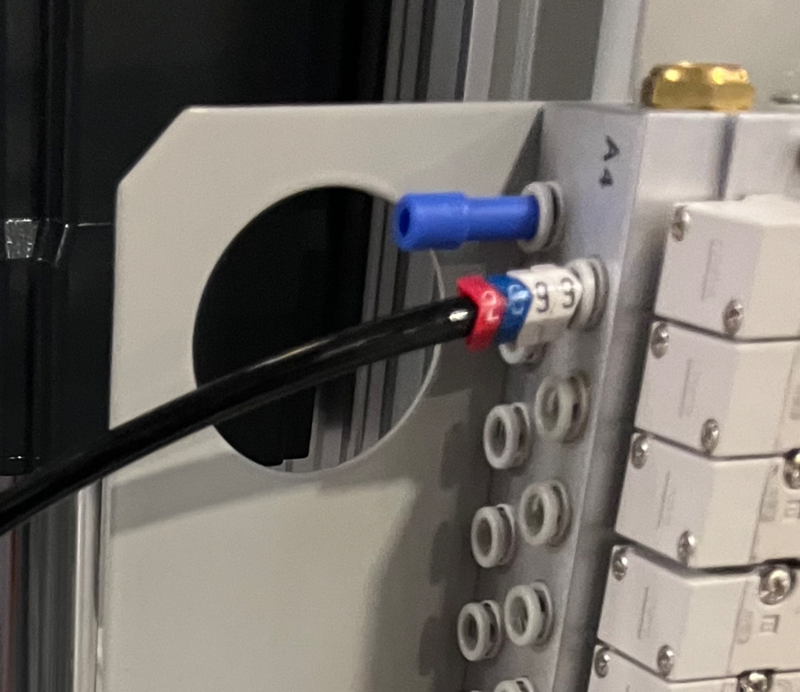

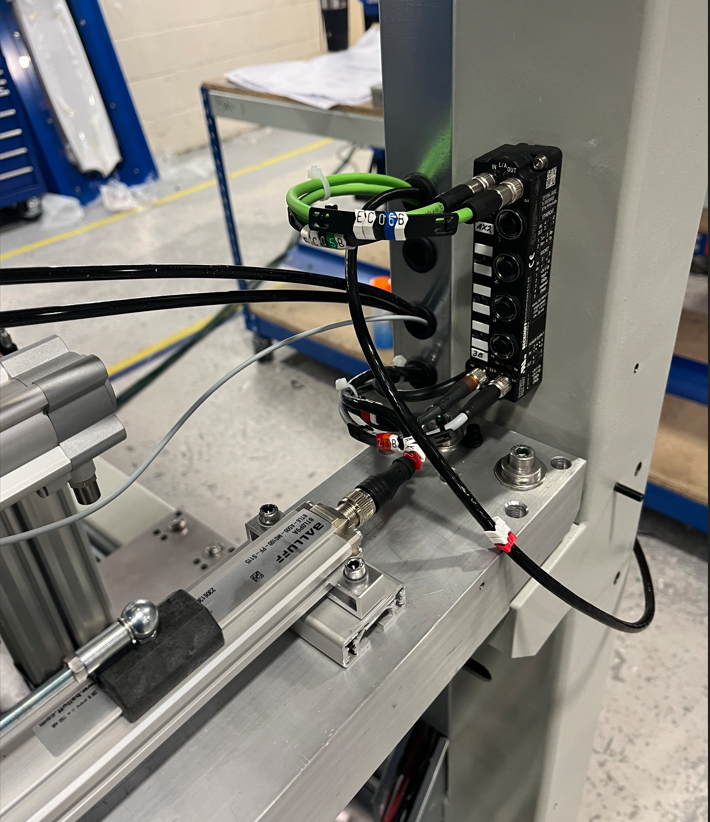

Étape 3 - Y269 Ring blow output

Pipe id 2699

Pipe trailing from rotary head energy chain

Route into trunking and exit as shown to valve bank

Blank port 2

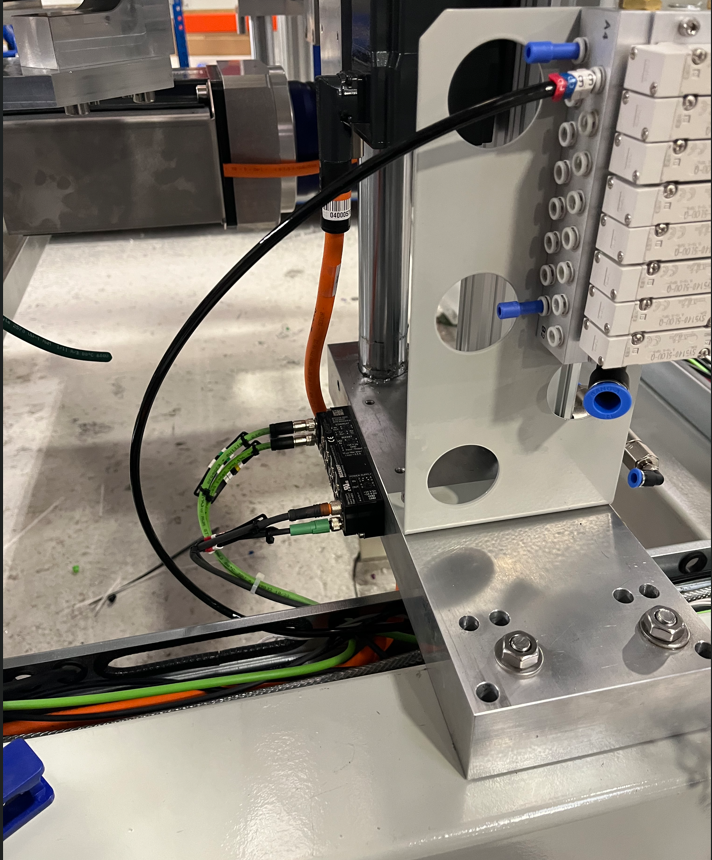

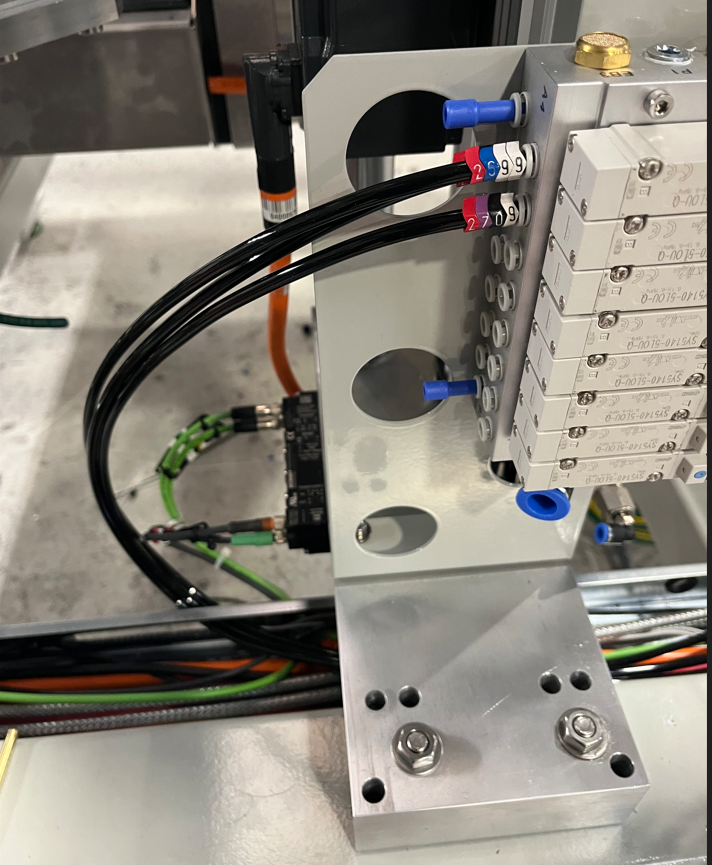

Étape 4 - Y270 Clamp hold

Pipe id 2701

Connect to port 2 on valve bank

Through trunking as shown

Connect to Nose of clamp hold cylinder

Pipe id 2709

Connect to port 4 on valve bank

Through trunking as shown

Leave 2 meter tails on both pipes exiting the trunking

Handing. Pipes always exit trunking as shown next to side clamp assembly

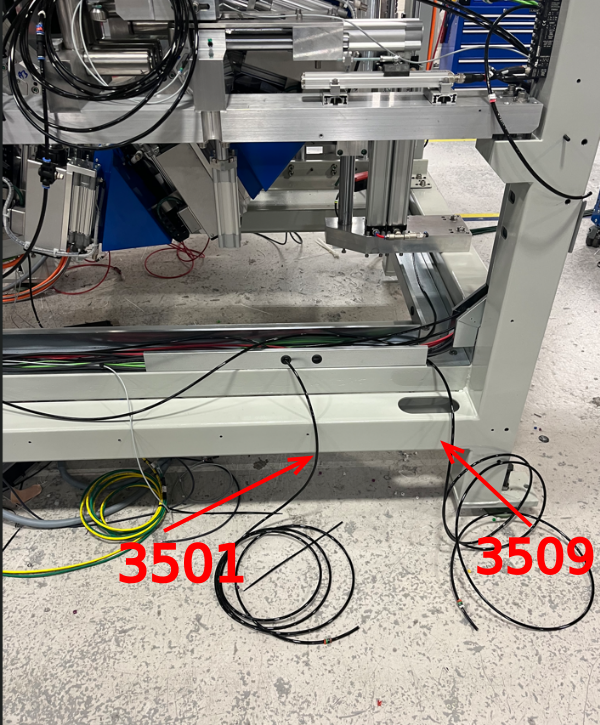

Étape 5 - Y350 Clamp infeed top

Pipe id 3501

Connect to port 2 on valvebank

Through trunking and exit at point shown

Pipe id 3509

Connect to port 4 of valvebank

Through trunking and exit at point shown

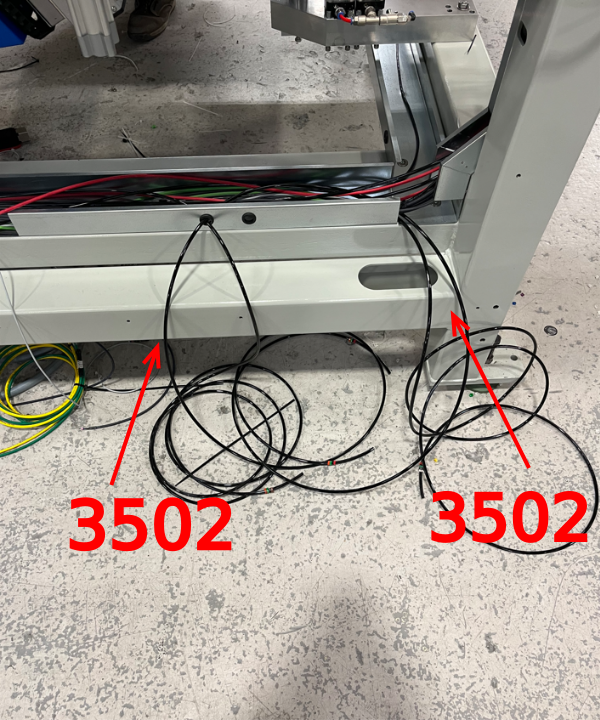

Pipe ID 3502

Run pipe between points shown

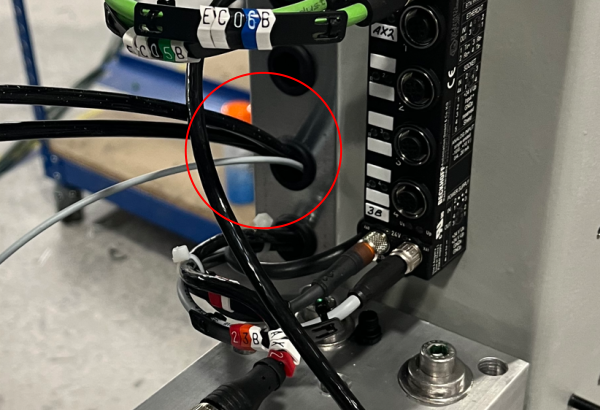

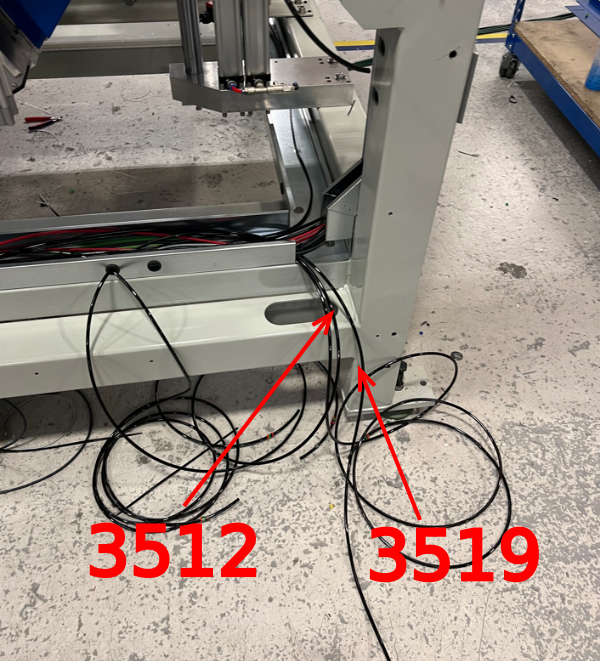

Étape 6 - Y351 infeed side clamp

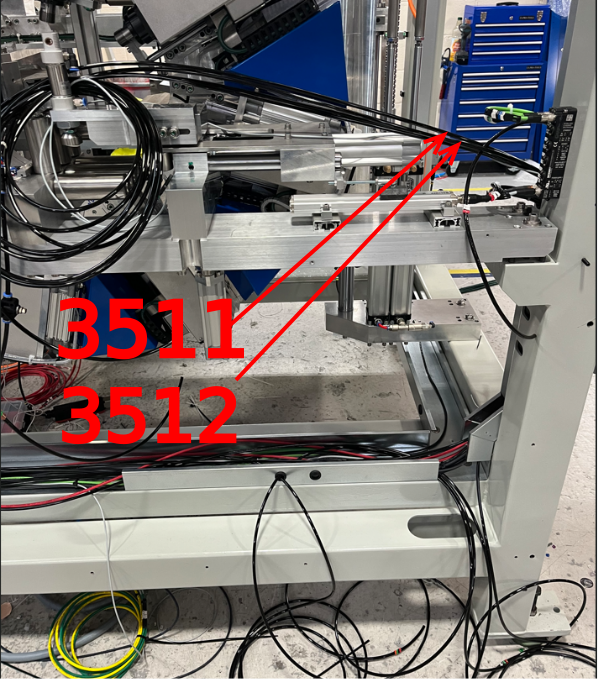

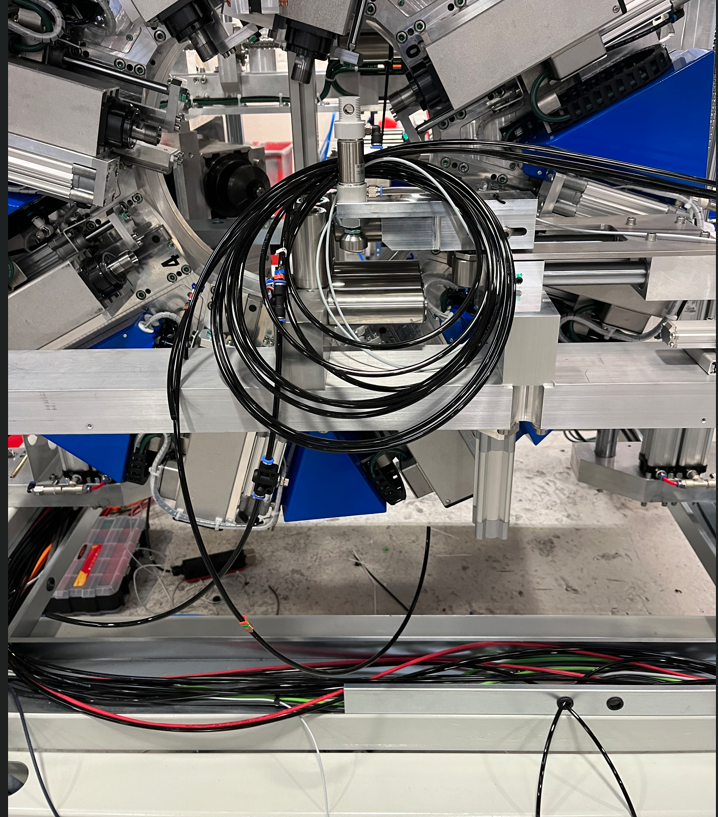

Pipe ID 3511

Connect to port 2 on valve bank

Through trunking and exit at point shown

Pipe ID 3519

Connect to port 4 on valvebank

Through trunking and exit as shown

Pipe ID 3512

Through trunking and exit as shown

leave pipes coiled up ready for later connection

Étape 7 - Y360 work blowers

Pipe Id 3609

Connect to port 4 on valvebank

Blank port 2

Route through trunking and exit as shown.

Leave 1.5meters of pipe from trunking exit

Handing, pipe will always exit trunking at side shown opposite to side clamp connections

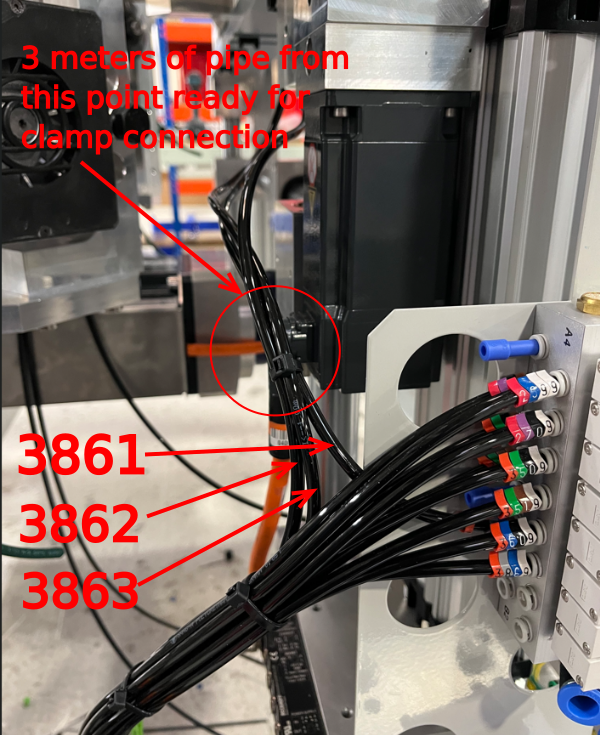

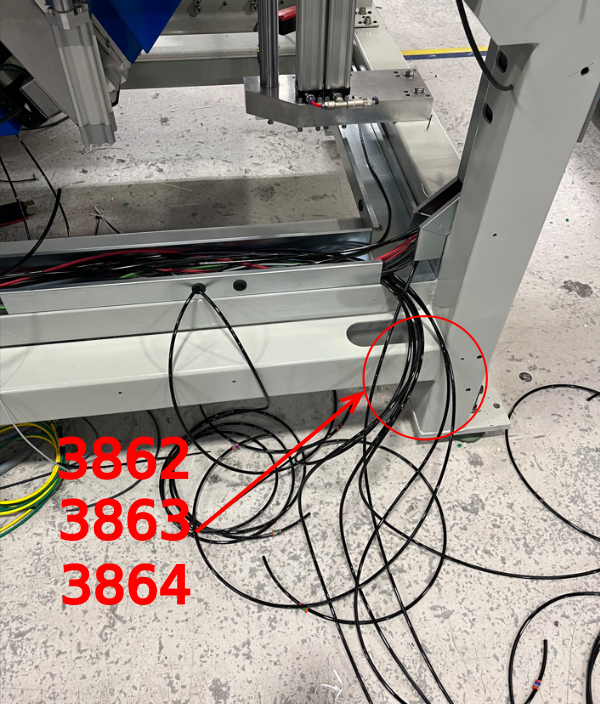

Étape 8 - Y386 Outfeed clamps

Pipe 3861

From port 2 of valvebank directly up to clamp area shown

3862 routes from clamp area to point shown out of trunking

3863 routes from clamp area to point shown out of trunking

3869 connects from port 4 on valve bank and routes to trunking exit point as shown

Étape 9 - Y389 V cut

Connect pipe 3891 to port 2 of valve bank and route as shown . Leave 1 meter tail exiting trunking

Connect pipe 3899 to port 4 of valve bank and route as shown . Leave 1 meter tail exiting trunking

Handing. Pipe exit will always be the trunking closet to the support cylinder with air adjustment fittings

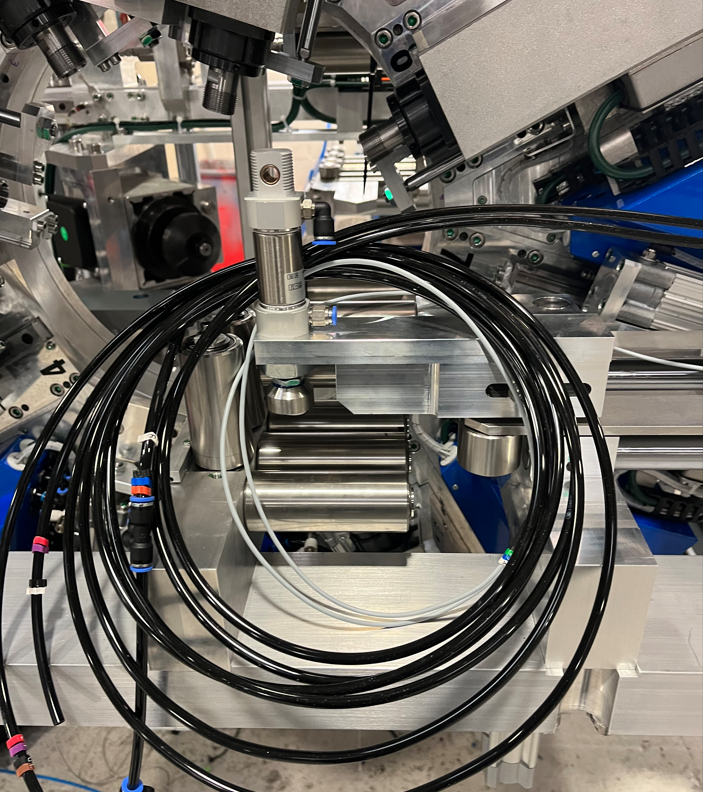

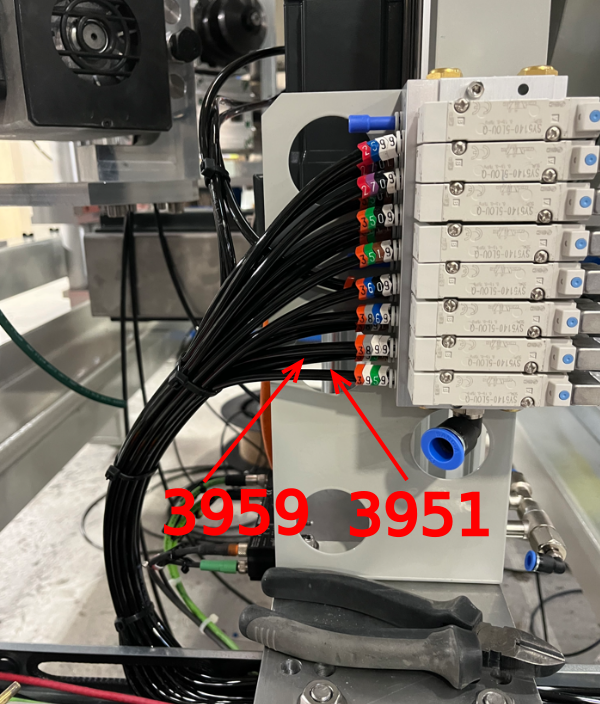

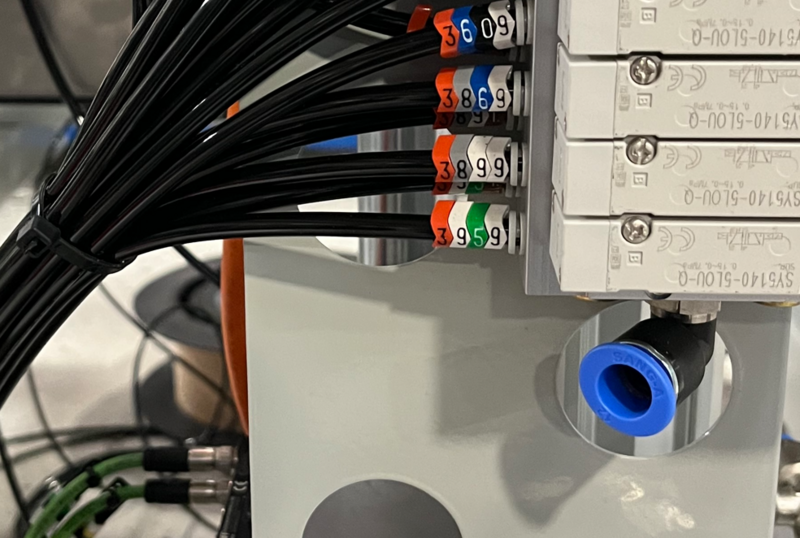

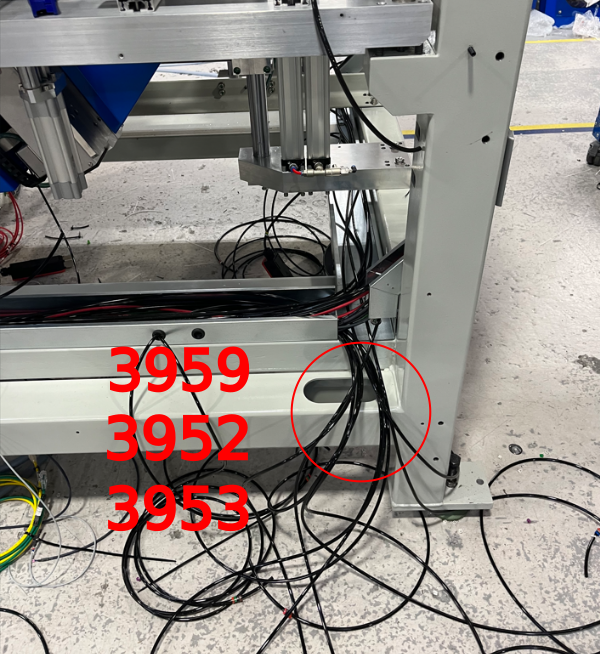

Étape 10 - Y395 Clamps V

3951

Connect to port 2 on valve bank then route through trunking and exit as shown

3959

Connect to port 4 on valve bank then route through trunking and exit as shown

3952

Route between points shown

3953

Route between points shown

Ensure 3 meters of pipe are left for connection once pipes exit trunking

Leave coiled ready for later connection

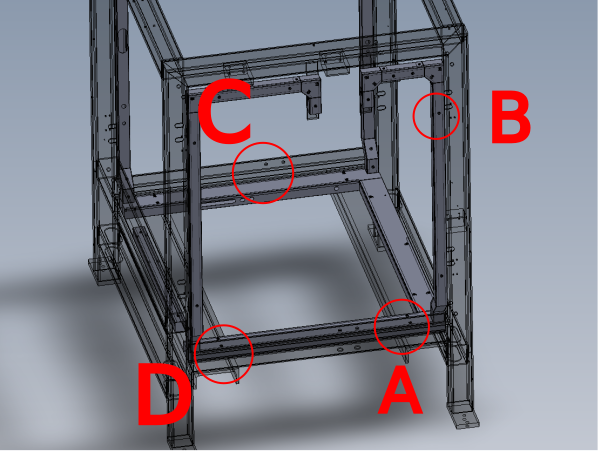

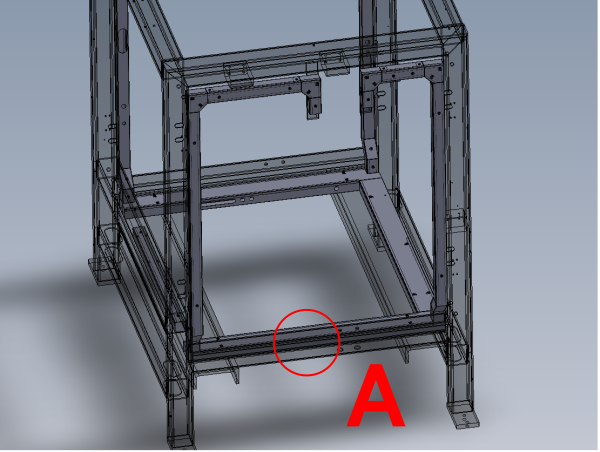

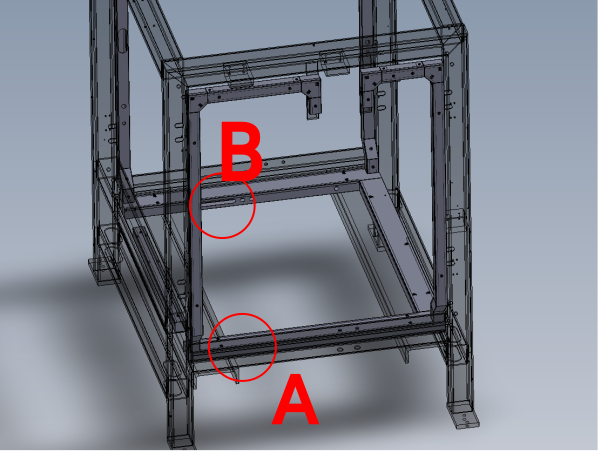

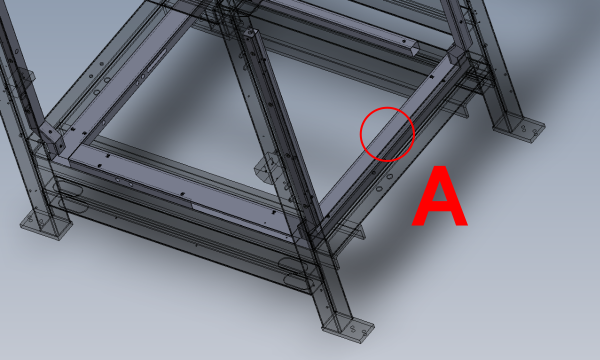

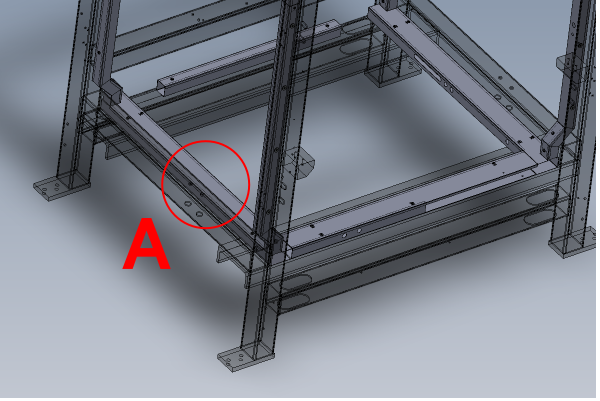

Étape 11 - 12mm blue connections Ring feed

Connection for 12mm ring main as follows

Retrieve 6mm blue pipe from point B, and route down trunking to point A

At point A, connect 6mm blue pipe to fittings as shown

Use

P0001107 12mm Y x 1

P0000161 8-6mm reducer x 1

P0001106 12-8mm reducer x 1

Route 2 off 12 mm blue pipes from fittings as shown to points C and D

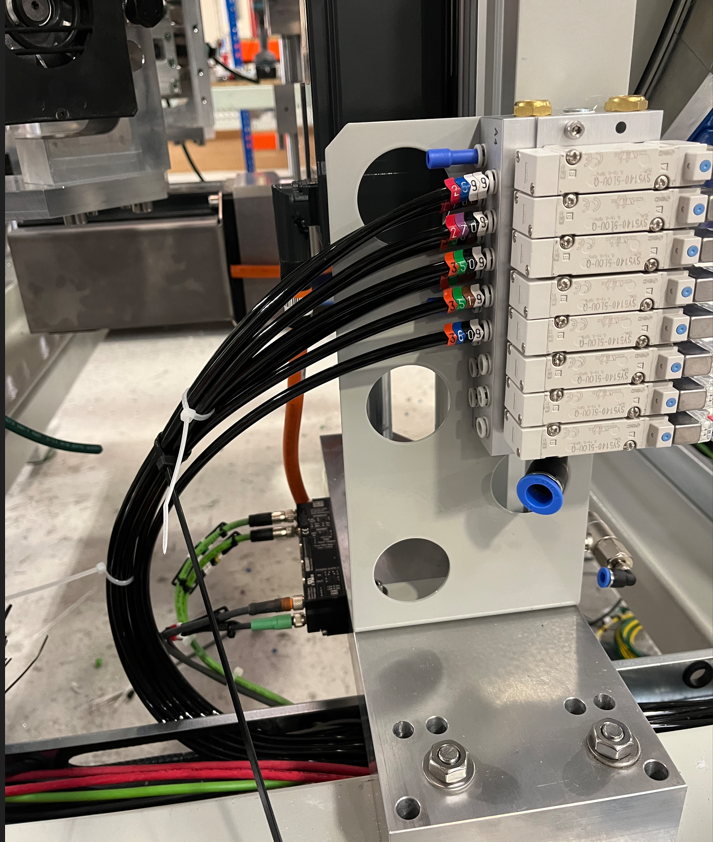

Étape 12 - 12mm blue connections Valve bank supply

Add 12mm Y fitting as shown, and connect additional 12mm pipe and exit as shown to provide valve bank air supply

Use

P0001107 12mm

Étape 13 - 12mm blue connection V cut valve

Connect previous 12mm Y connector to new 12mm Y connector at point A or B

(please note this position will change depending on handing . Position will be determined by the location of the exit point for step 9 , Y389)

Use 12mm to 8mm reducer and connect 8mm blue air pipe , feed out of grommit along with previous fitted 2 off pipes 3891 and 3899

Use

P0001107 12mm y connector

P0001106 12-8mm reducer

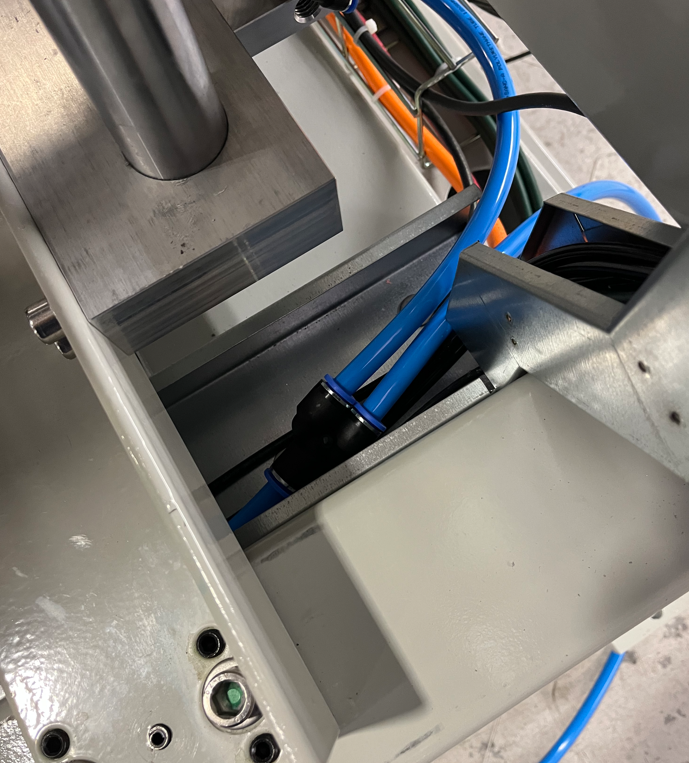

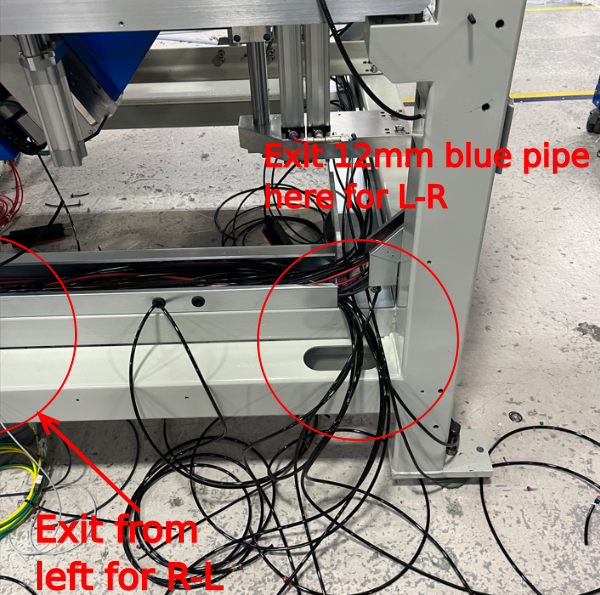

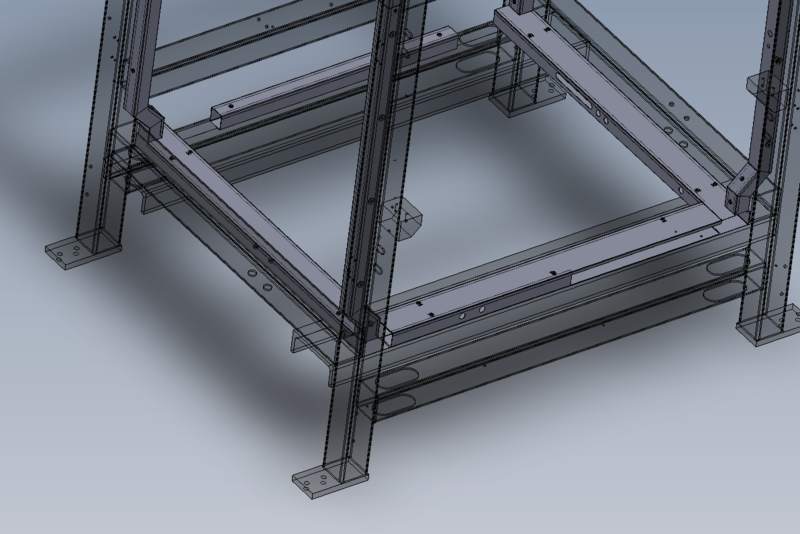

Étape 14 - Rear pipe exit handing

Rear pipe exits change depending on handing of machine

As viewed from rear

R-L pipes exit on the left

L-R pipes exit on the right (shown in picture)

Add 12mm y connector to split current 12mm blue pipe to provide supply pipe to exit rear of machine

Use

P0001107 12mm Y connector

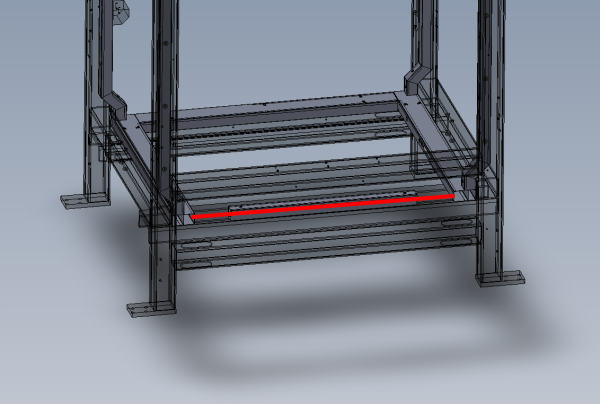

Étape 15 - Finalise Blue 12mm ring main

Bring both 12mm blue pipes to point shown and use 12mm Tee connector to join.

Run 12mm blue feed pipe to front exit of machine ( same exit as 6mm black pipes from valve bank)

Étape 16 - Ring Spindle anti drop valve installation

Identify 6mm blue line from rotary head energy chain .

Add P0000513 Q valve as shown

Add P0000401 non return valve as shown

Add P0000046 as shown

Add additional 6mm blue pipe as shown and end 4 sections into energy chain

Étape 17 - 12mm red Connection Bulkhead /Air gun

Connect 1st 12mm bulkhead on lower front panel with 12mm red pipe

Add 12mm Y connector at point A and fit 12mm to 8mm reducer then add 8mm red pipe to exit trunking and feed Air gun regulator port IN

Étape 18 - 12mm Red connection Z support cylinder

Add new 12mm Y Connector at point A and connect to previous Y connector .

Add 12mm to 8mm reducer and 8mm to 6mm reducer to provide 6mm red pipe to feed to Z support cylinder regulator port IN

Add P0000501 non return to 6mm red pipe just before entry into In port

Étape 19 - 12mm red connection VZ support cylinder

Add 12mm Y connector at point indicated and connect to previous 12mm Y connector

Add 12mm to 8mm reducer and connect 8mm red pipe to feed VZ regulator port IN

Étape 20 - 12mm red connection Z support pilot 1

Add 12mm Y connector at point A

Add 12mm to 8mm reducer, then 8mm to 6mm reducer , then connect 6mm red pipe to exit through grommit and feed pilot valve on z support cylinder 1

Étape 21 - 12mm red connection rear lower panel

Connect previous fitted 12mm Y connector to rear 12mm bulkhead fitting

run pipe along wire basket at rear

Étape 22 - 12mm red connection 12mm from bulkhead

Connect 12mm red pipe front front 12mm bulkhead to Y connector at indicated point

fit 12mm to 8mm reducer then 8mm to 6mm reducer and connect 6mm red pipe to feed pilot valve on z support cylinder 2

Étape 23 - 12mm red connection rear bulkhead

Connect previous fitted Y connector to rear bulkhead with 12mm pipe

Étape 24 - Z support cylinder Feeds

Connect 6mm red pipe to Out port on Z support cylinder

Add 6mm Y connector and connect 2 off 6mm red airpipes to route into trunking and feed both Z support check valves

Étape 25 - VZ support cylinder feed

Connect 8mm red pipe to OUT port on VZ support regulator and feed base QEV valve on VZ support cylinder

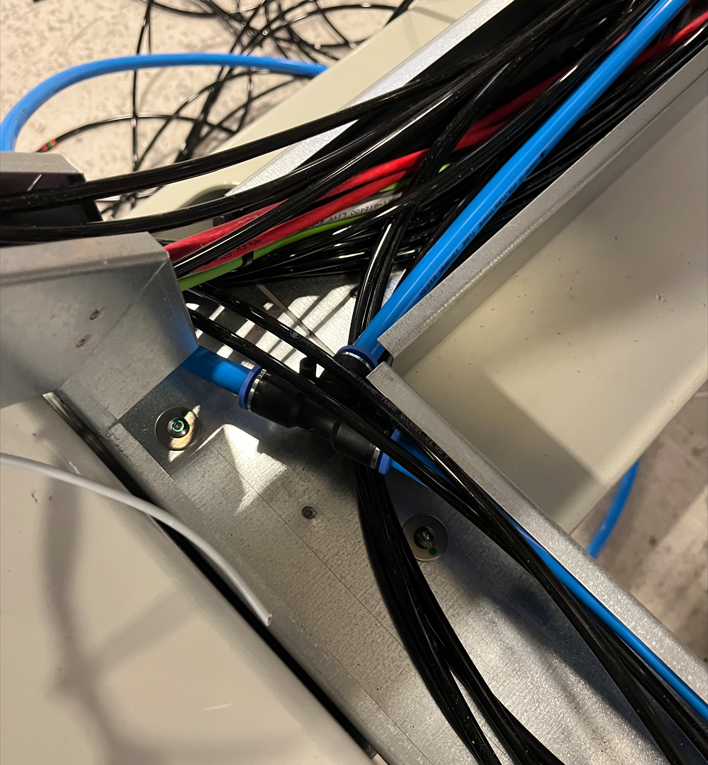

Étape 26 - Z support exhaust

Add 6mm black airpipes to QEV on z support cylinders

Run through trunking to exit point indicated

Connect to blowers on swarf chute

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português