Correct installation , setting and quality checks for installation of material sensor beam

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach mounting brackets to module C and E

- 4 Étape 3 - Position and fix Assembled beam

- 5 Étape 4 - Set height of assembled beam

- 6 Étape 5 - Setting Height

- 7 Étape 6 - Repeat at point B

- 8 Étape 7 - Finalise fasteners

- 9 Étape 8 - Set sensor positions

- 10 Commentaires

Introduction

Tools Required

Standard hex key set

2 Meter straight edge

Parts Required

R0015060 Bench Assemble Flapper Beam

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

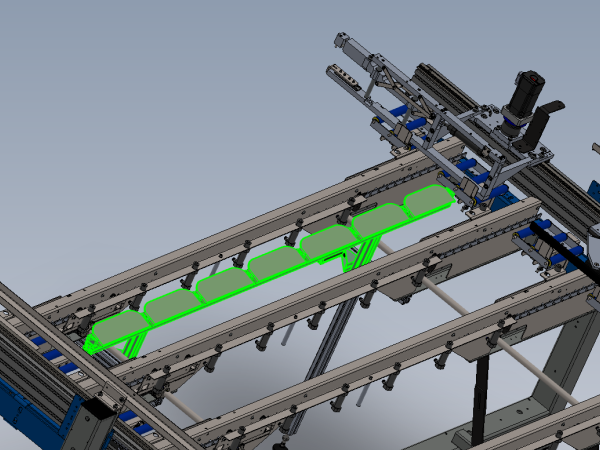

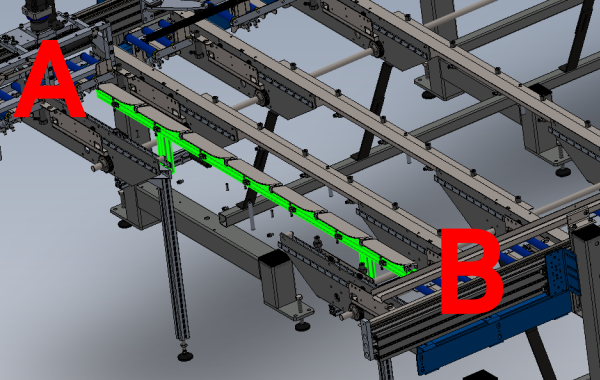

Étape 3 - Position and fix Assembled beam

(front transfer beam removed for clarity )

Fix assembled beam to supports as shown

Do not finalise fasteners

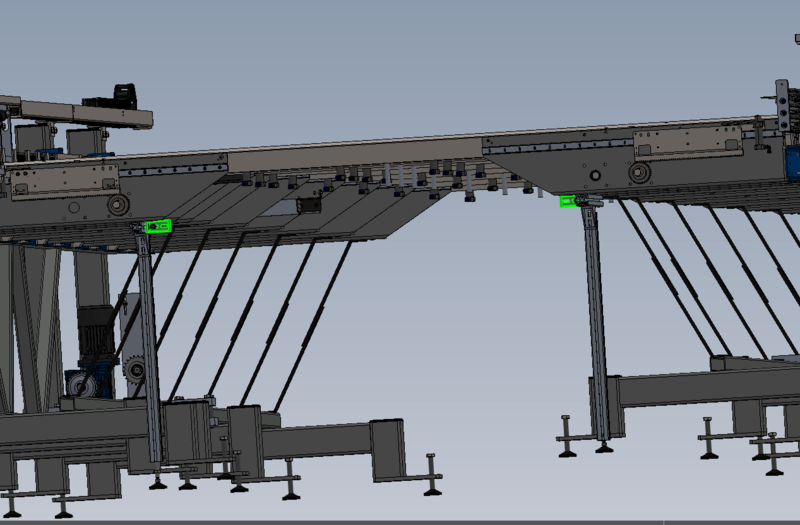

Étape 4 - Set height of assembled beam

Use sliding adjustment on maytec angles /frame to adjust height of assembly

To determine correct height Set end A and B separately

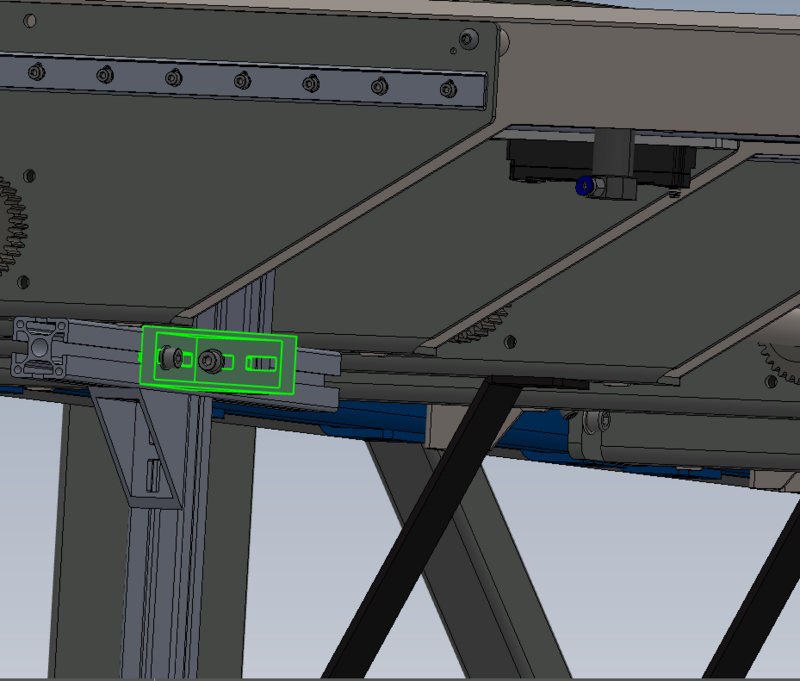

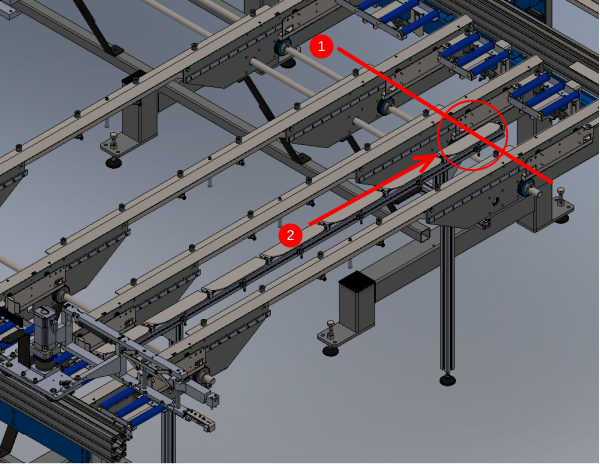

Étape 5 - Setting Height

Span over transfer beams 1 and 2 with straight edge at point A

Lift or lower sensor rail assembly to match the following criteria

When straight edge is pushed to meet radius of sensor plate, it must strike at indicated point of halfway around radius on paddle

Étape 6 - Repeat at point B

Repeat height setting at point B using same criteria

Once point B is set, check that point A has not altered

Étape 7 - Finalise fasteners

Once correct settings have been achieved, double check and finalise all fasteners used for adjusting and mounting .

Ensure all fasteners have 243 applied to threads and are pen marked as complete

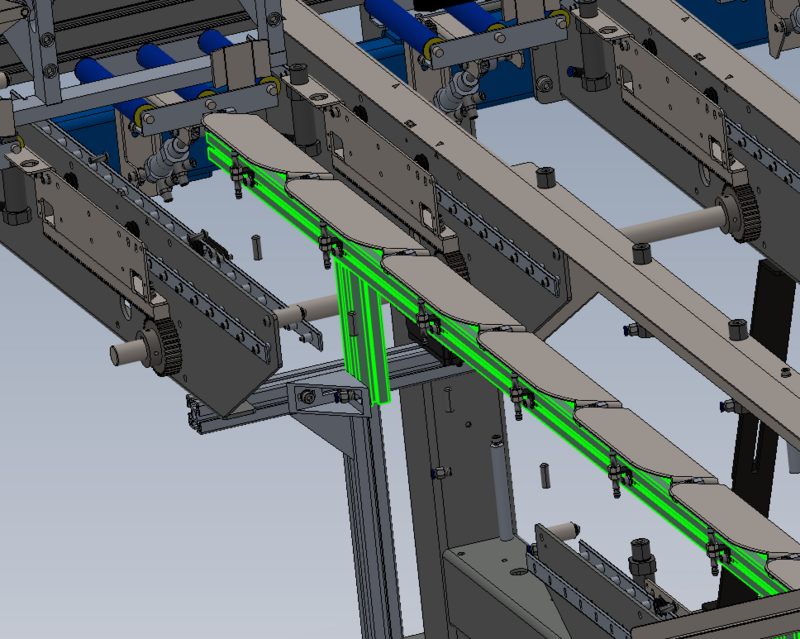

Étape 8 - Set sensor positions

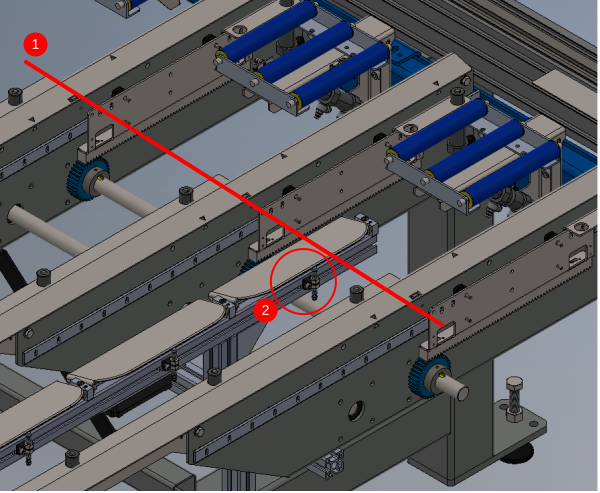

Repeat for each individual Sensor and paddle

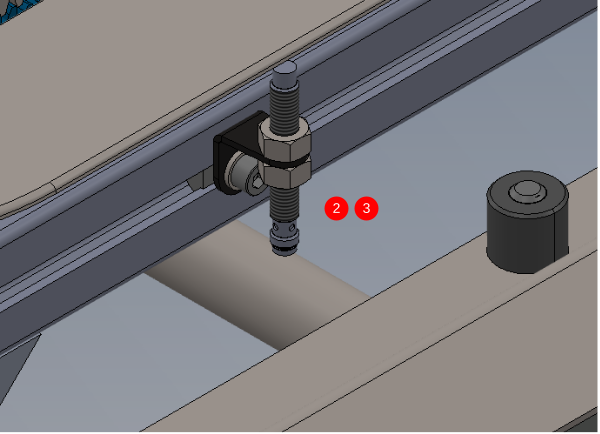

1 Place straight edge over transfer beams and above sensor paddle to be set

2 Adjust sensor to touch paddle in this position

3 Wind sensor back 1/2 turn

4 tighten lock nuts to finalise, checking that shakeproof washers have been fitted to sensor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português