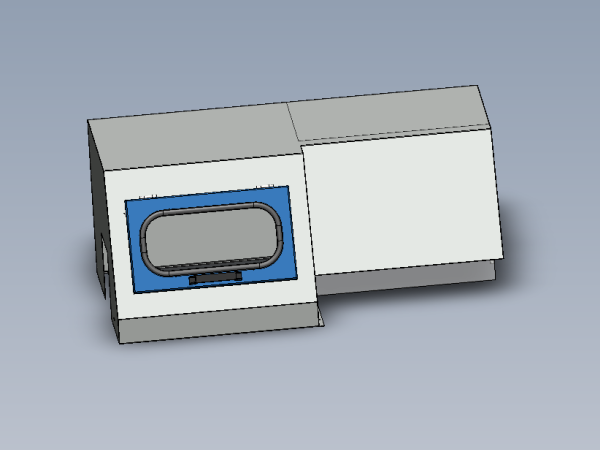

Bench assembly details for Saw top Hood

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach hinges to top hood

- 4 Étape 3 - Fit top door to hood

- 5 Étape 4 - In the following step

- 6 Étape 5 - Fit door switch

- 7 Étape 6 - Fit acoustic sound proofing

- 8 Étape 7 - Fit Rear emergency stop

- 9 Étape 8 - Fit light

- 10 Étape 9 - Fit Cable retentions

- 11 Étape 10 - Mount camera

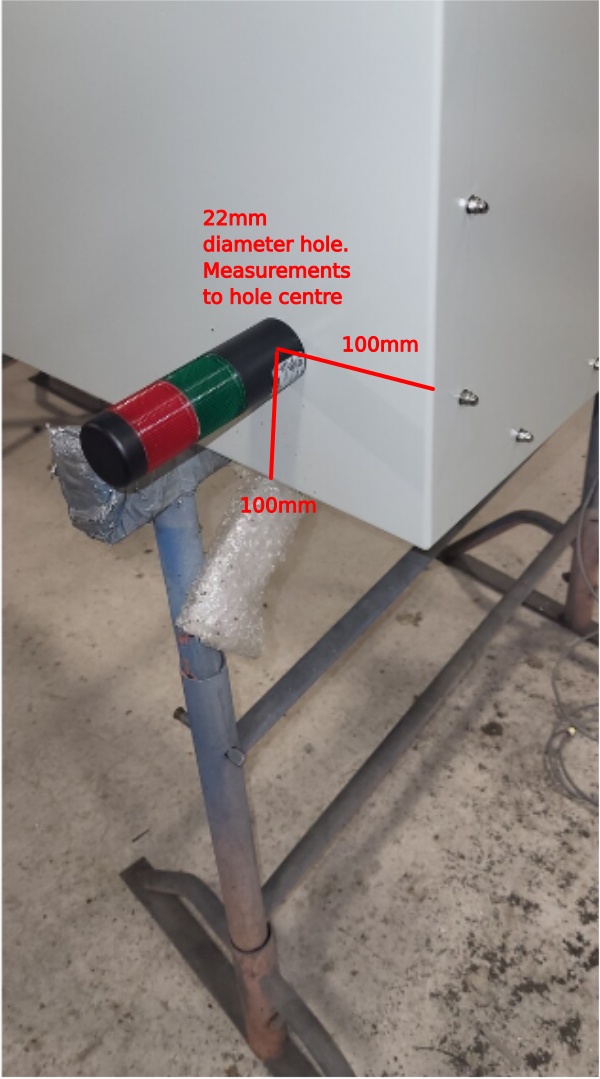

- 12 Étape 11 - Fit beacon to top hood

- 13 Étape 12 - Fit console mount bracket

- 14 Étape 13 - Fit connection box

- 15 Étape 14 - Fit Top door screen

- 16 Étape 15 - Attach gas strut

- 17 Étape 16 - Loom cables

- 18 Étape 17 - Assembly safety flap

- 19 Étape 18 - Fit safety flap to hood

- 20 Étape 19 - Fit trunking to rear

- 21 Étape 20 - Fit stickers to hood

- 22 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Standard Hss drill set

Standard tap set

Acoustic foam cutting board and straight edge

Utility Blade

Parts Required

Pre wired light, beacon and network cable from electrical department

C0001152 Camera: HikVision DS-2CD2343G0-I-2.8mm x 1

C0001239 Micro SD Card 32Gb Class 10 x 1

D0000770 Door Hinge (M0016) x 2

D0001877 Saw Top Door Mk4 x 1

D0004641 Hinge Pin Block (D7445) x 1

D0004642 Flap Counterbalance Bar x 1

D0004645 Safety Flap Hinge Pin x 1

D0004679 Flap Stiffening Bar x 1

D0004705 Flap Hinge Bar x 1

D0004747B top door screen x 1

D0004807 Flap x 1

D0007445 Hinge Pin Block OH (D4641) x 1

D0016251 Saw Hood Switch Mount Plate (Bernstein) x 1

E0000275 Button: Base Fixing 1 N/C x 1

E0001072 Emergency Stop Module Bevelled 1NO 1NC x 1

E0001569 Guard Lock Switch: Bernstein Radius Actuator (Key) x 1

H0004643 4mm Axxis Clear 145mm x 690mm x 1

M0000002 12mm Grey Acoustic Foam with Black PVC Facing x 1 (consumable stock )

M0000036 Sign - Ear Protection x 1

M0000048 Gas Spring 15mm x 100mm x 1

M0000539 Handle Black Nylon 200mm M8 Fixings x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

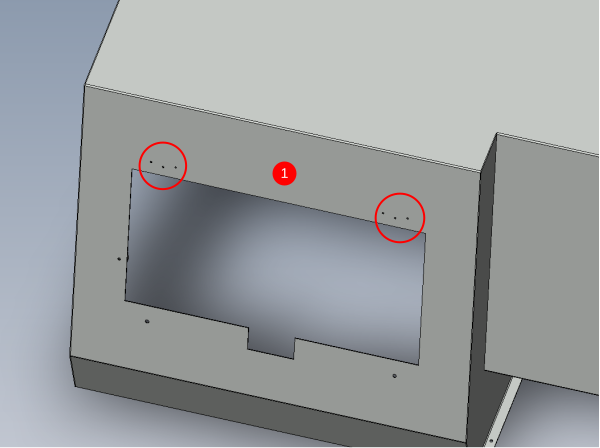

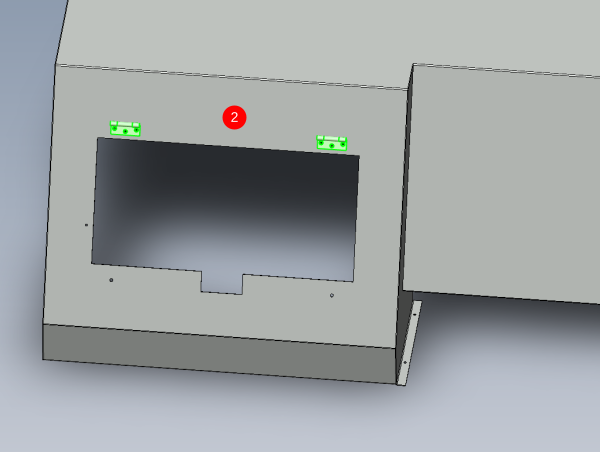

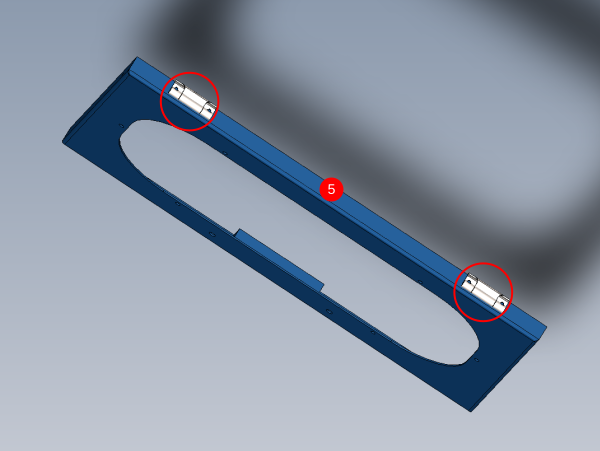

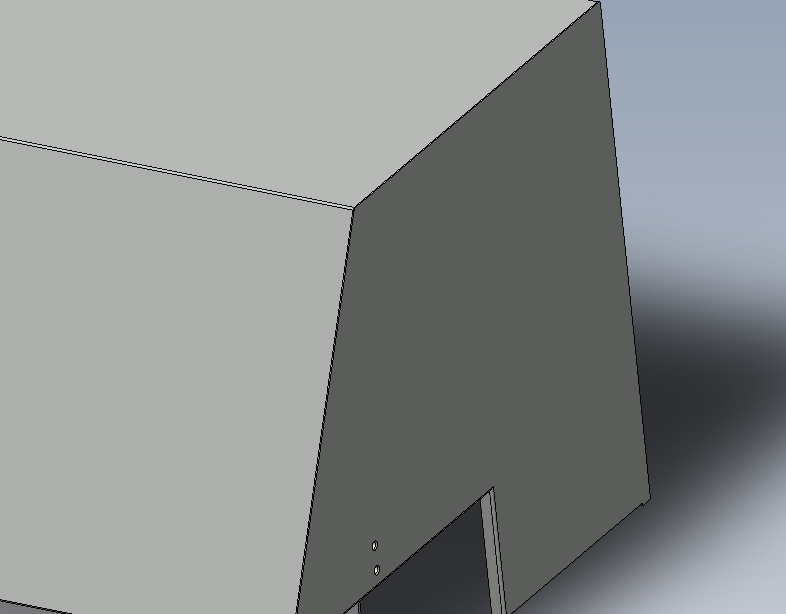

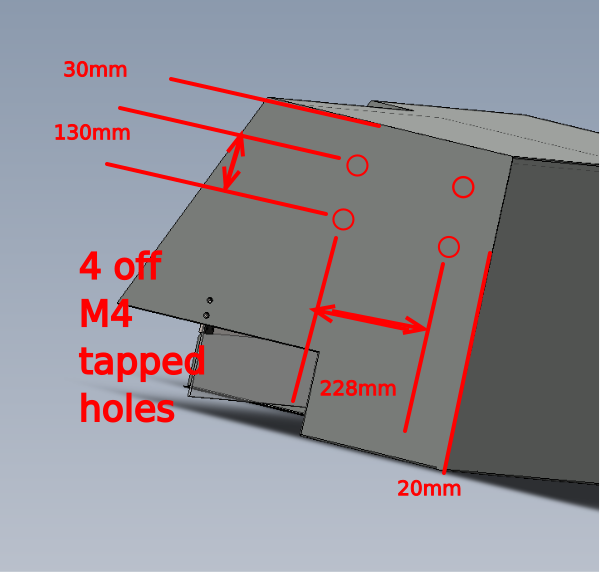

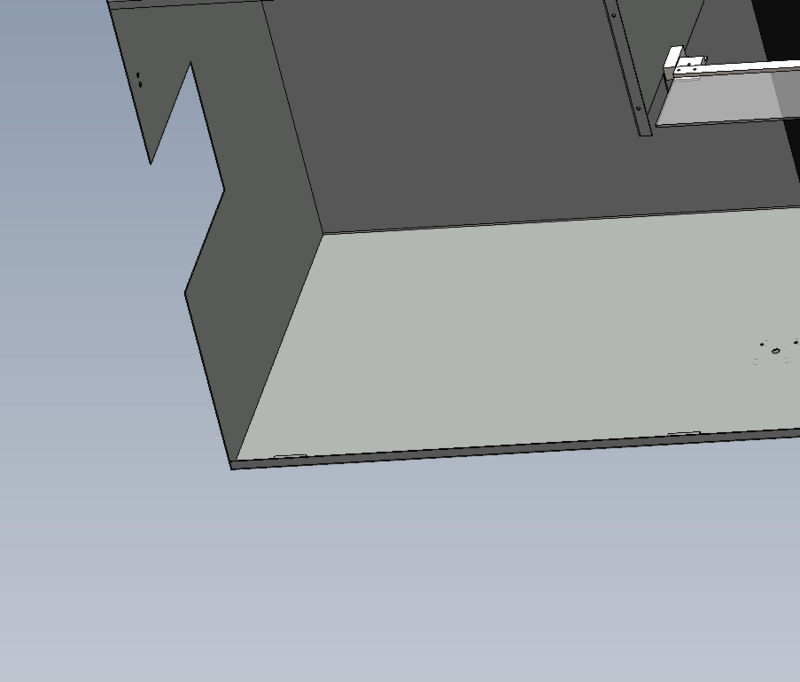

Étape 2 - Attach hinges to top hood

1 Tap 6 off M4 holes on saw hood for hinges

2 Fix 2 off hinges to top hood using 6 off M4 x 12 button

3 Mark hinge positions onto top door , set door even to aperture

4 Drill top door to allow fitment of hinges

5 Remove hinges from top hood and fit to top door using 4 off M4 x 12 button sockets, M4 A form washers, M4 shakeproof washers and standard M4 nuts

6 Attach handle to top door using M8 (size required) socket caps

7 Add M0000031 panel edging to top door

Étape 4 - In the following step

It is vital that correct interlock blade alignment is achieved when the door closes onto the interlock switch . Do force should be required for the blade to enter the switch

Perfect alignment must be achieved on these parts when closing and opening the top door

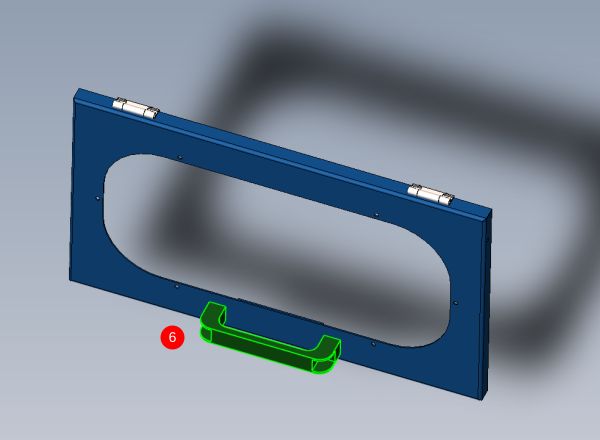

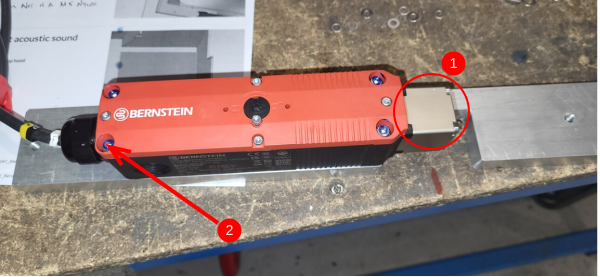

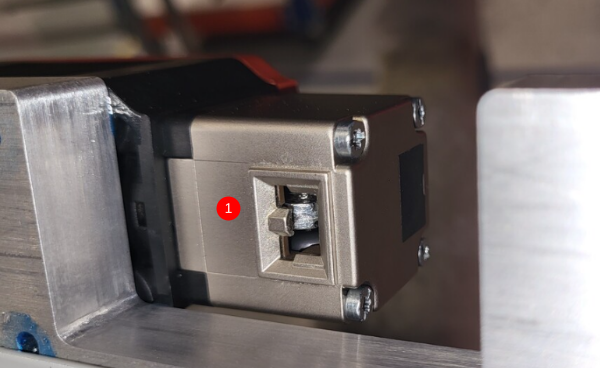

Étape 5 - Fit door switch

1 Rotate end of interlock switch

2 Mount interlock switch to mounting plate as shown using 4 off M4 x 50 socket caps

3 Fit interlock blade to top door using 2 off M6 x 16 socket caps

4 Ensure interlock is set to open position

5 Mark and drill correct position of interlock assembly onto hood, Fit with M6 x 16 socket caps and M6 A form washers

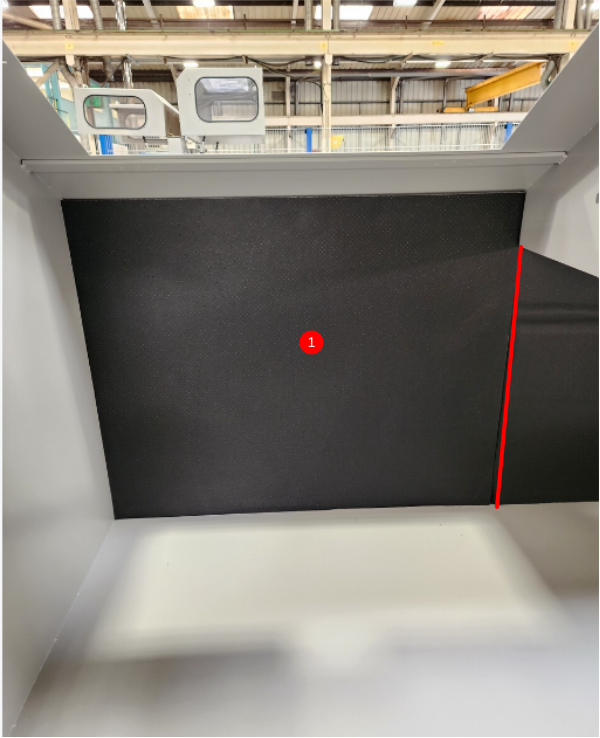

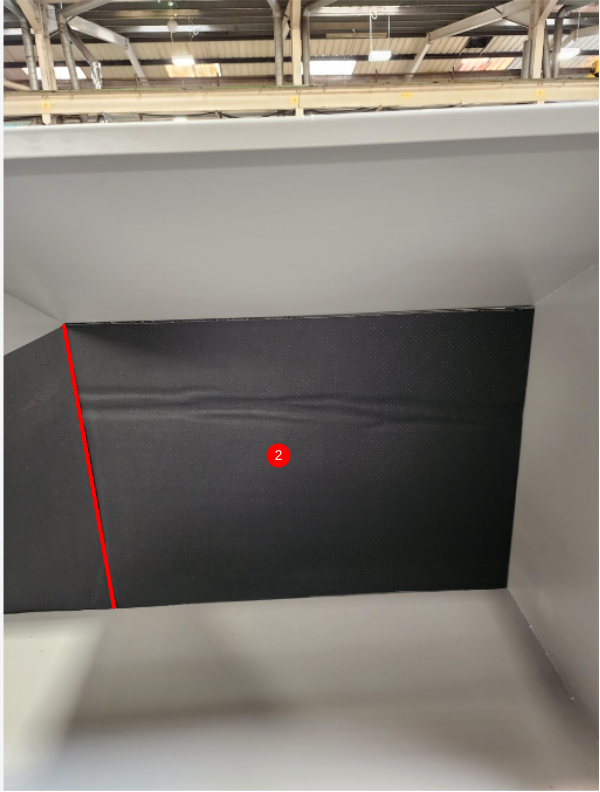

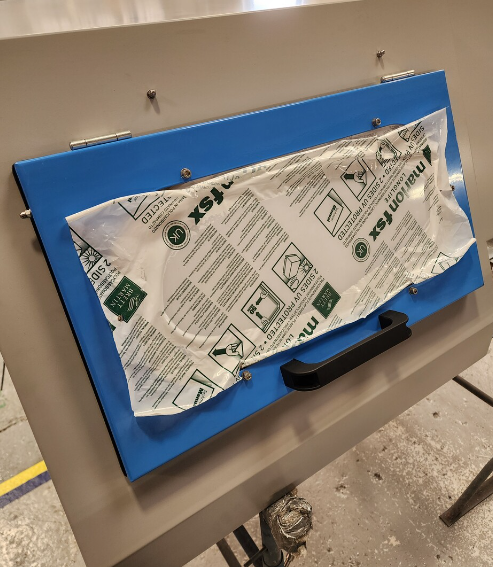

Étape 6 - Fit acoustic sound proofing

Fit acoustic foam to top hood

1 Measure 1st section and cut to size using cutting board and straight edge , and fit to hood

2 Measure 2nd section and cut to size using cutting board and straight edge , and fit to hood

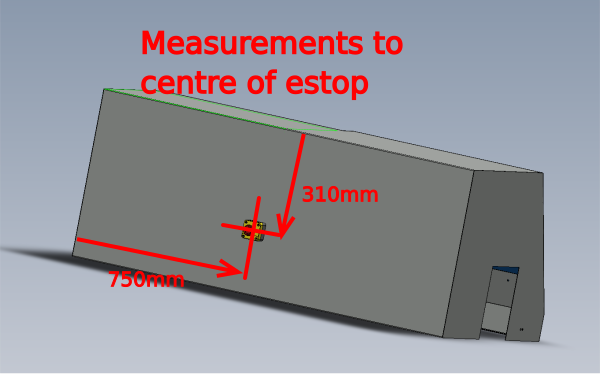

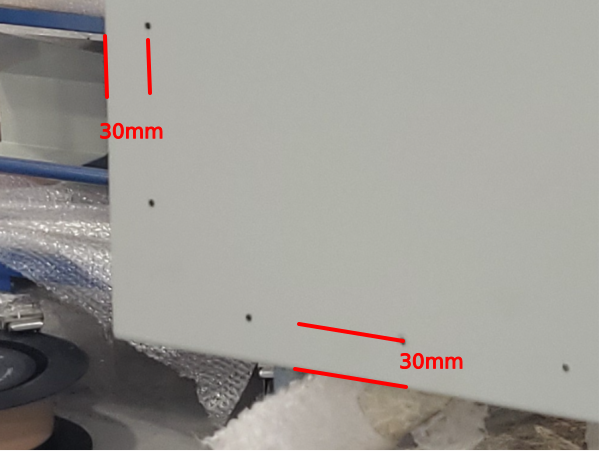

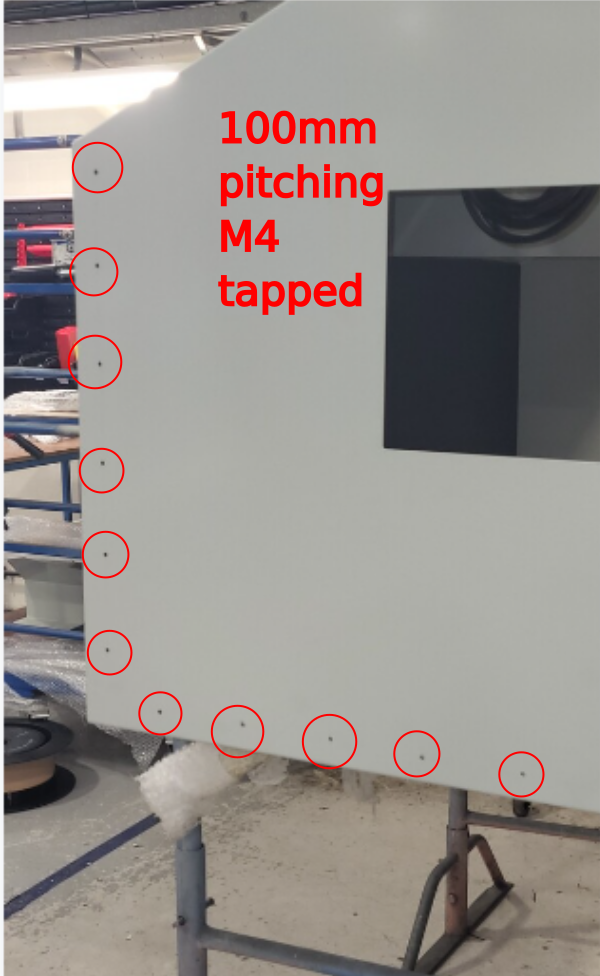

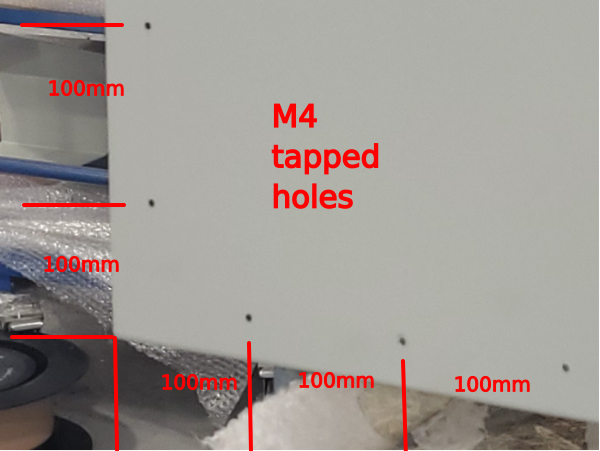

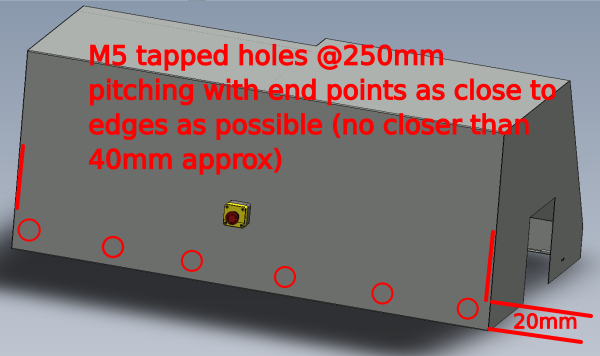

Étape 7 - Fit Rear emergency stop

Fit rear emergency stop module using 4 off M4 x 16 socket caps, 4 off M4 A Form washers and 4 off M4 Nyloc nuts

Please provide drilling details to enable update of part drawing

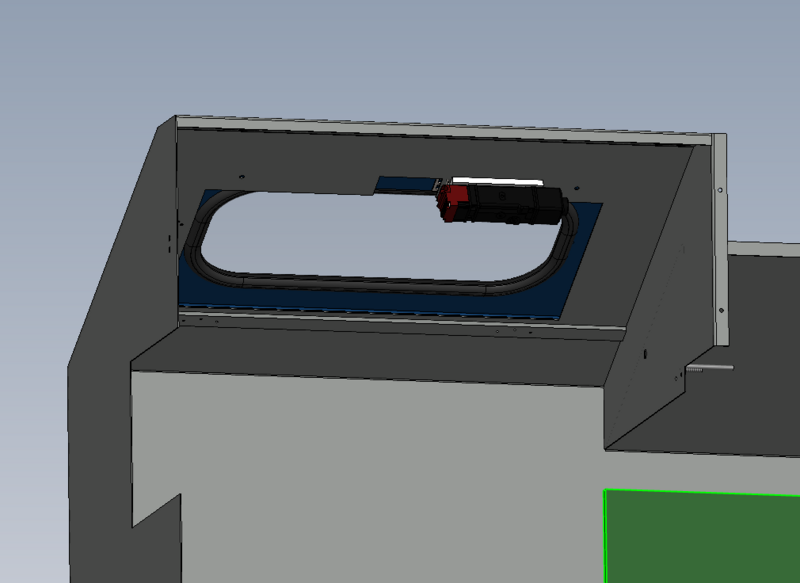

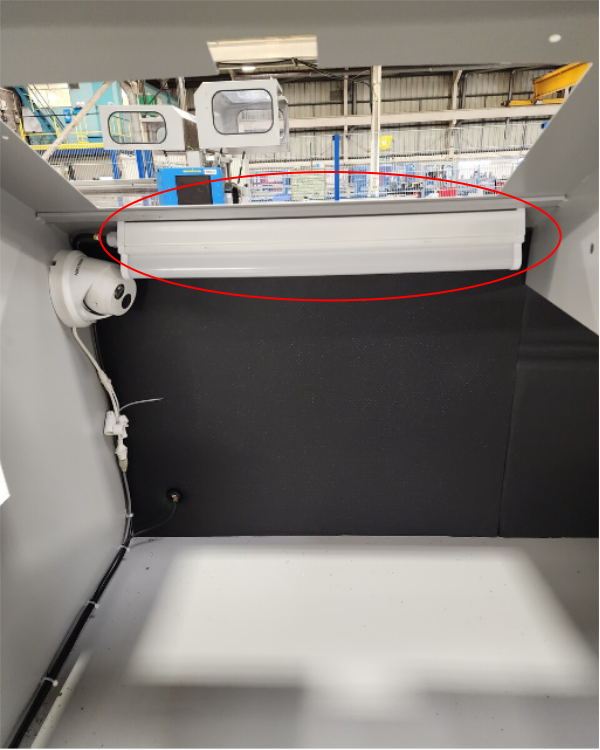

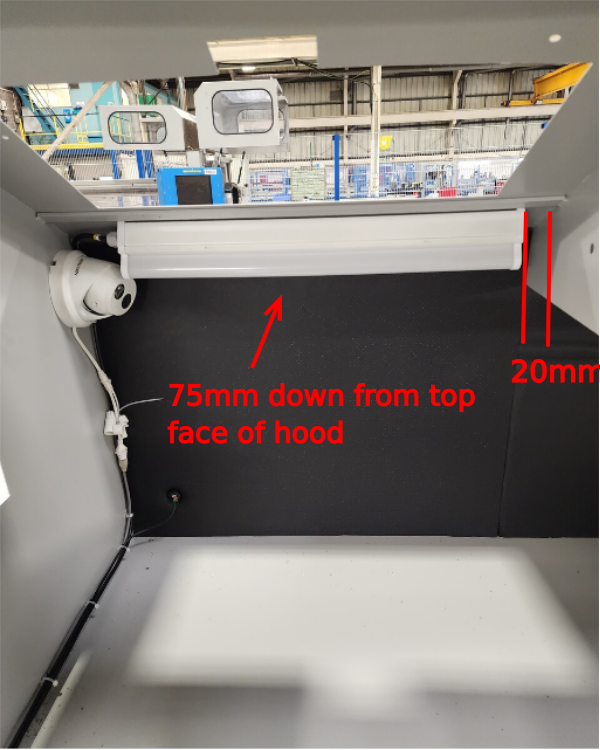

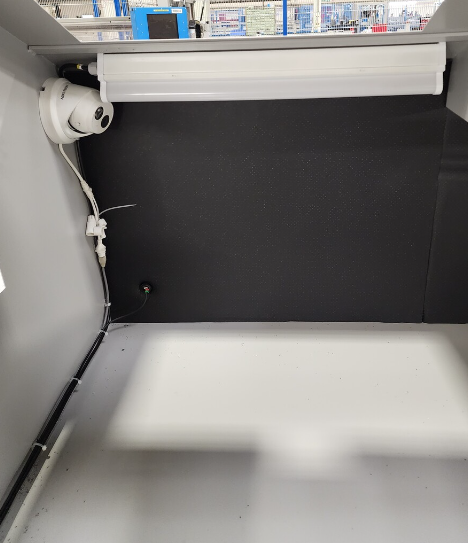

Étape 8 - Fit light

Light will be pre wired by electrical department

Fit light to inside of hood using what fasteners at the position shown

Light should be 75mm down from top face of hood

Ensure clearance is left for mounting of camera

Étape 9 - Fit Cable retentions

Fit cable tie bases on inside of hood using M4 cable tie bases and fix with M4 button sockets and back off with M4 dome nuts ??

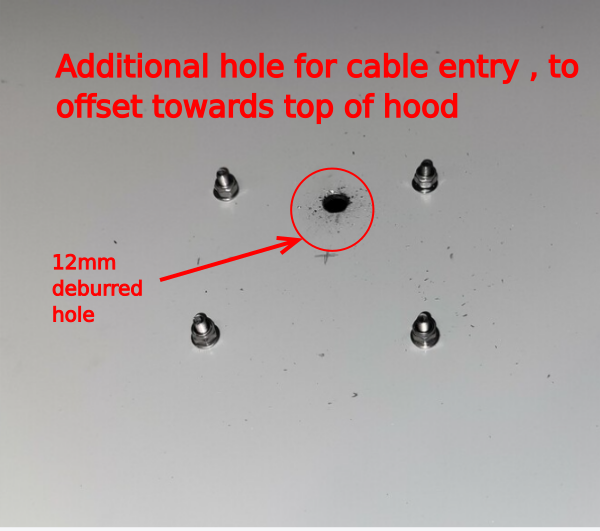

Étape 10 - Mount camera

Fit C0001239 Micro SD Card 32Gb Class 10 x 1 to camera before mounting

Fit camera to top hood using 3 off M4 x 12 socket caps , and back off with M4 dome nuts and M4 A form washers

Ensure camera is fitted the correct orientation. Camera will have a 'UP' marked on body. This must be at the top

Supply drilling details to capture data to update please

Étape 12 - Fit console mount bracket

Fit console mount bracket to top hood(electrical department to provide bracket )

Mount bracket using 2 off M6 x 20 countersunk, 2 off M6 motor plate washer and 2 off M6 Nyloc nuts

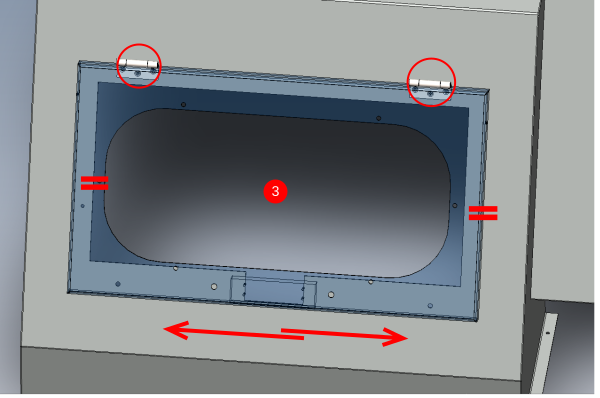

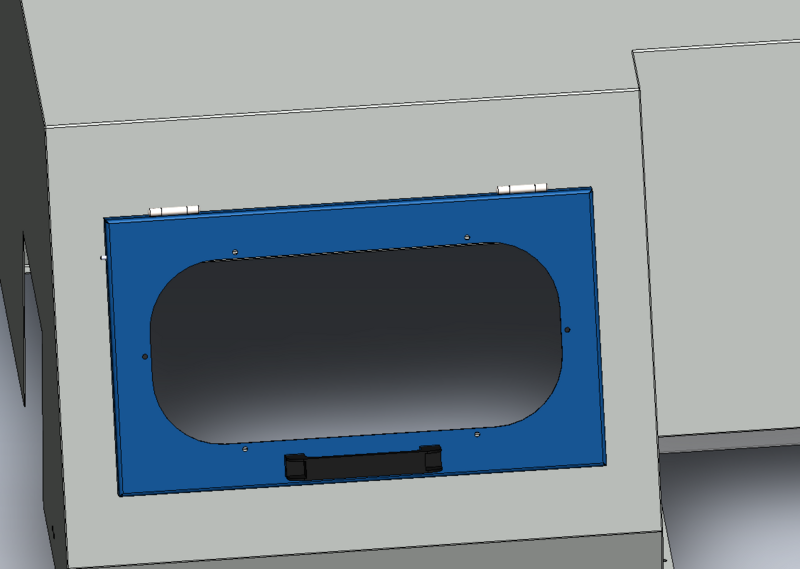

Étape 14 - Fit Top door screen

Fit top door screen to top door

Use M6 x 16 socket caps and M6 A form washers on outward facing face

Use M6 penny washers and M6 Nyloc nuts on inside face

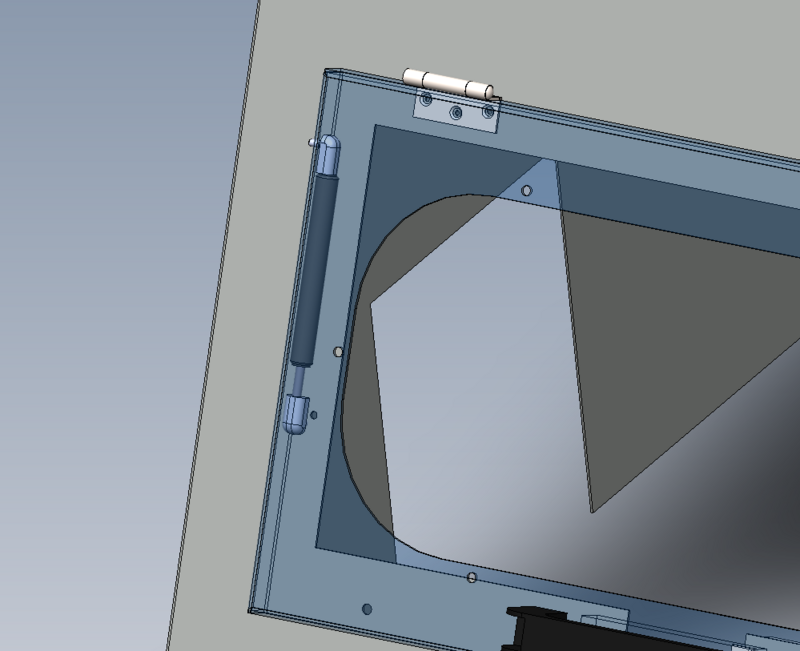

Étape 15 - Attach gas strut

Attach gas strut to top door assembly .

1 Use M5 dome nut to secure top ball joint.

2 Use M5 nyloc nut and M5 penny washer to fix bottom ball joint

3 Set correct gas pressure

Gradually adjust gas until correct setting is achieved

Door must lift up under own weight but not open violently

Étape 16 - Loom cables

Loom cables to rear lower area of top hood

Network cable to connect camera provided by electrical department

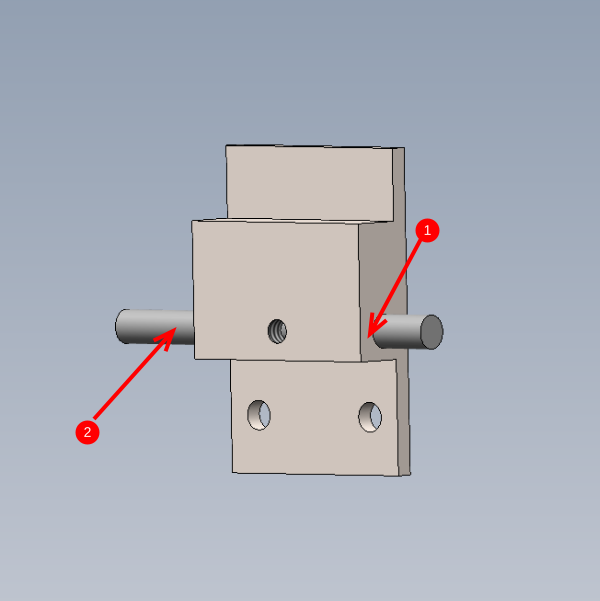

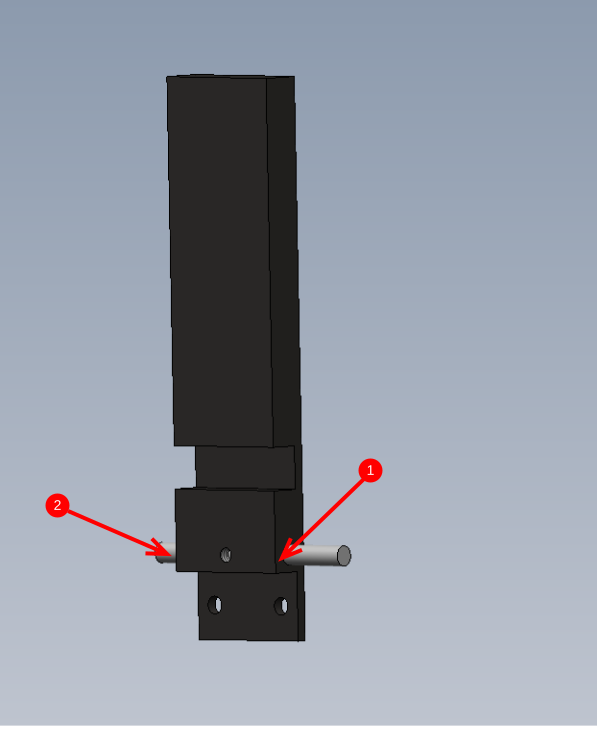

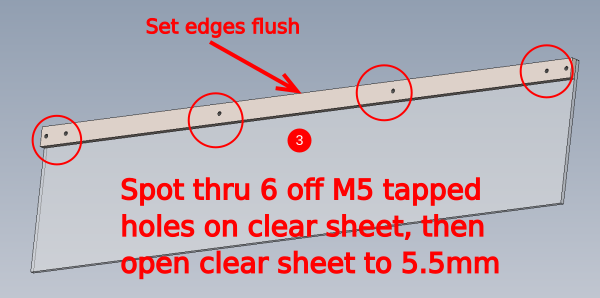

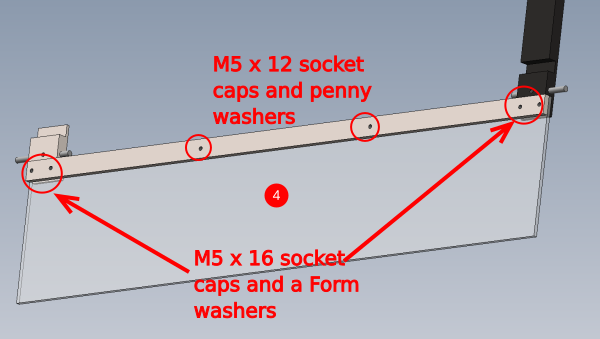

Étape 17 - Assembly safety flap

1 Ream 6mm holes indicated to ensure

2 Pins locate correctly

3 Drill flap to suit stiffening bar

4 Attach end brackets and stiffening bar using 4 off M5 x 16 socket caps and 4 off M5 A form washers and 2 off M5 x 12 socket caps and 2 off M5 penny washers

5 Insert 6mm rods and add 2 off M5 x 6 kcp grubscrew

6 Fit hazard tape to flap

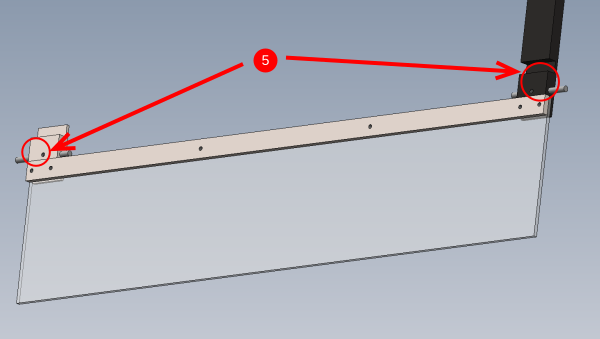

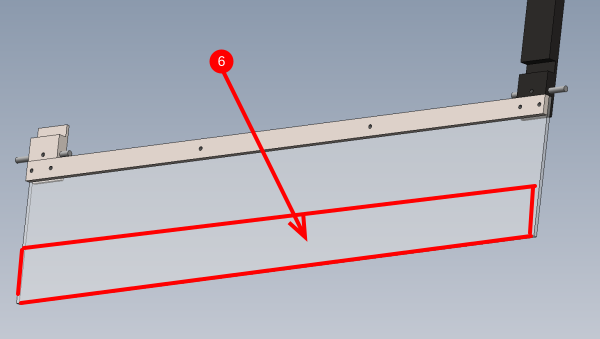

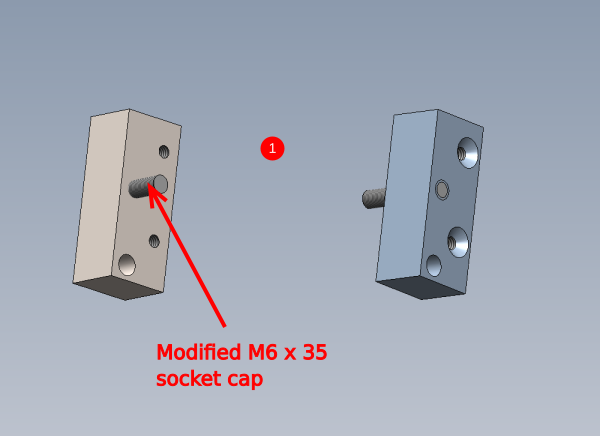

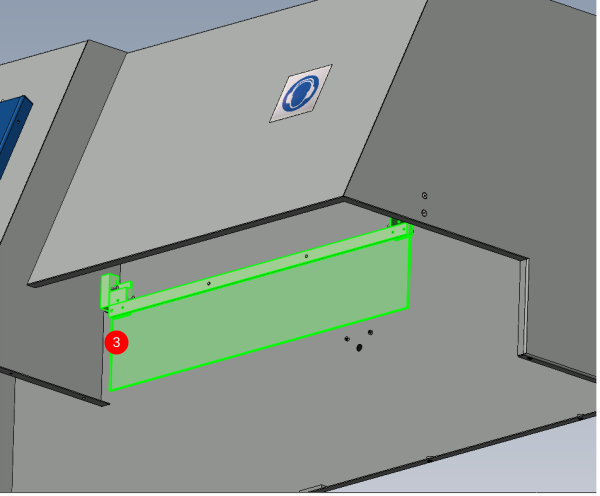

Étape 18 - Fit safety flap to hood

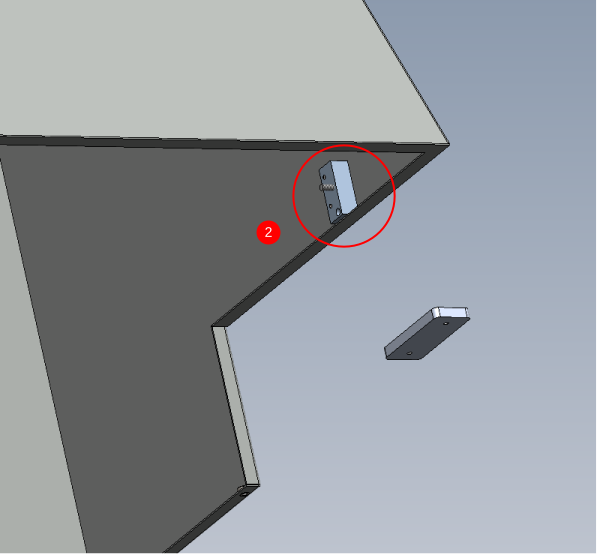

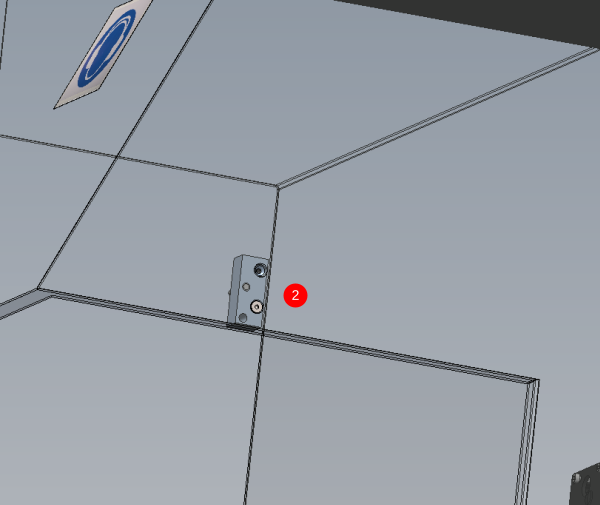

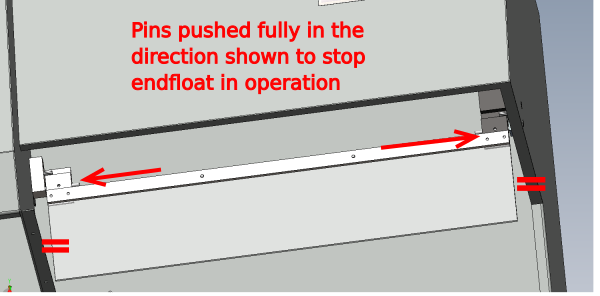

1 Check Mounting blocks have pin fitted as shown. A pair is required (mirrored to each other )

If not modify M6 x 35 socket cap 2 off as follows

- Reduce thread length to 10mm

- Use studlock 270 and fit to block ensuring final tension

- Cut shank of socket cap down to 10mm protrusion and dress clean

2 Fit 1 off mounting block to point shown , using 2 off M5 x 16 socket countersunk s to fix. Ensure correct orientation of block and correct face has countersunk holes for fixing 3 Fit 2nd block to safety flap and fit to hood as shown . Use 2 off M5 x 16 socket caps and M5 penny washers to fix

4 Adjust 6mm pins to centralise flap and stop end float of assembly. Finalise 2 off M5 grubscrews

Étape 19 - Fit trunking to rear

Fit A0001098 37mm x 75mm trunking to rear of hood, secure with M5 x 10 button sockets and M5 penny washers

Provide drilling details for fixing

Étape 20 - Fit stickers to hood

All stickers must be applied wet to ensure no air bubbles are present

Use spray foam and squeegee to fit

1 Large clear STUGA sticker to top of hood. Stuga to read from front

2 Large clear STUGA sticker on rear of hood

3 Service sticker on rear of hood

4 Ambient temperature sticker to front of hood

5 Consumables sticker to front of hood

6 Ear defence sticker to front of hood

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português