Fitting and setting details for Sy assembly and centralise top table

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Mount R0000562 Bench assemble centralise top table

- 4 Étape 3 - Adjust position

- 5 Étape 4 - Fit finger Guard

- 6 Étape 5 - Mount R0015037 Bench assemble SY Assembly

- 7 Étape 6 - Adjust square

- 8 Étape 7 - Adjust Height of Sy assembly

- 9 Étape 8 - Quality check

- 10 Étape 9 - Set Parallel to backfences

- 11 Étape 10 - Recheck Settings

- 12 Étape 11 - Finalise Fasteners

- 13 Étape 12 - Recheck settings

- 14 Étape 13 - Check adjustment grubscrews

- 15 Commentaires

Introduction

Tools Required

Standard hex keyset

1 meter straight edge

Large parallels

150mm engineers square

Engineers level 300mm

Parts Required

H0004543 Gap cover saw finger guard

R0000562 Bench assemble centralise top table

R0015037 Bench assemble SY AssemblyÉtape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

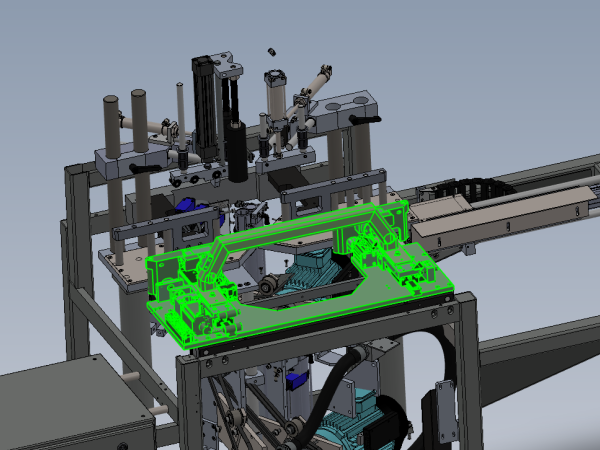

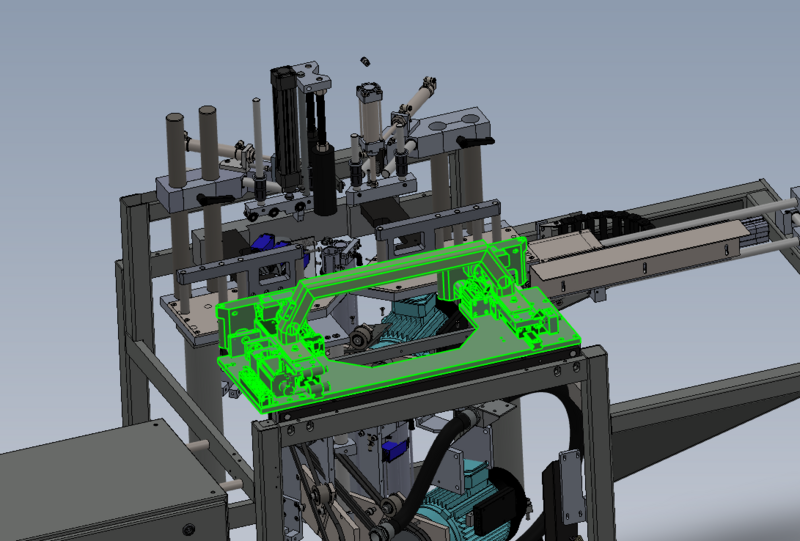

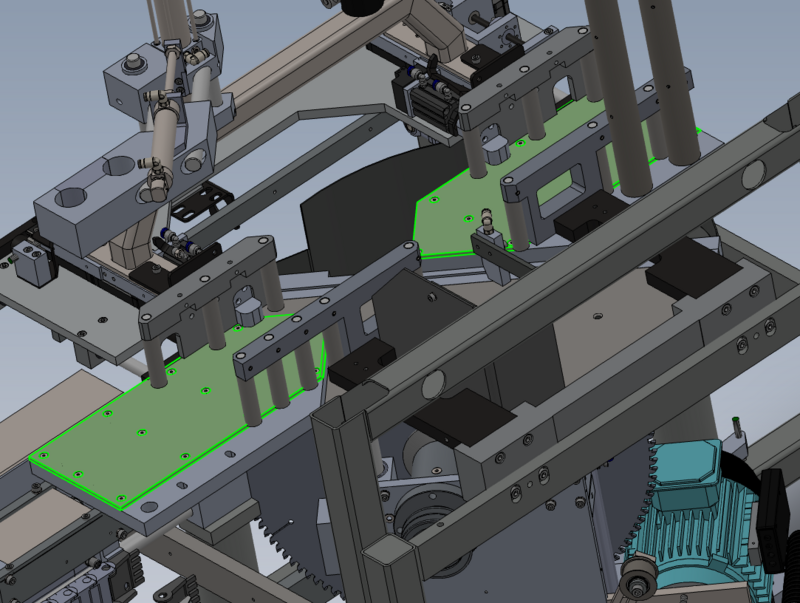

Étape 2 - Mount R0000562 Bench assemble centralise top table

Attach R0000562 Bench assemble centralise top table as shown

Dry fit fasteners

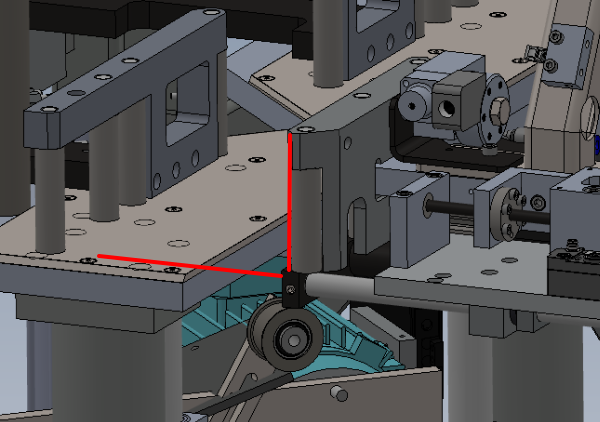

Étape 3 - Adjust position

Set initial position of assembly using engineers level on the indicated axis

Adjust using M8 jacking grubscrews to set position

Set positions level

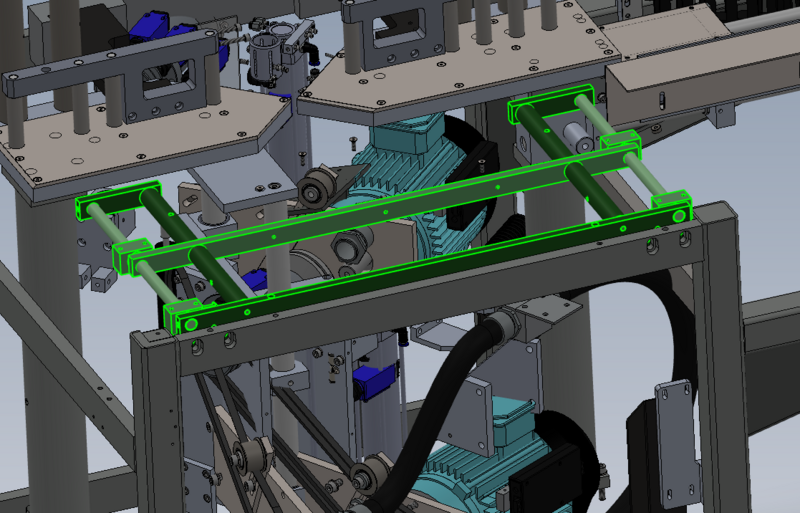

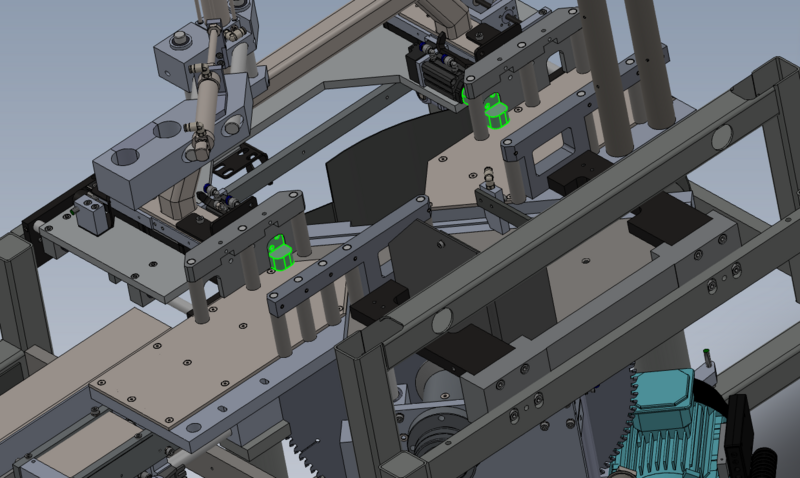

Étape 5 - Mount R0015037 Bench assemble SY Assembly

Mount R0015037 Bench assemble SY Assembly

Dry fit fasteners

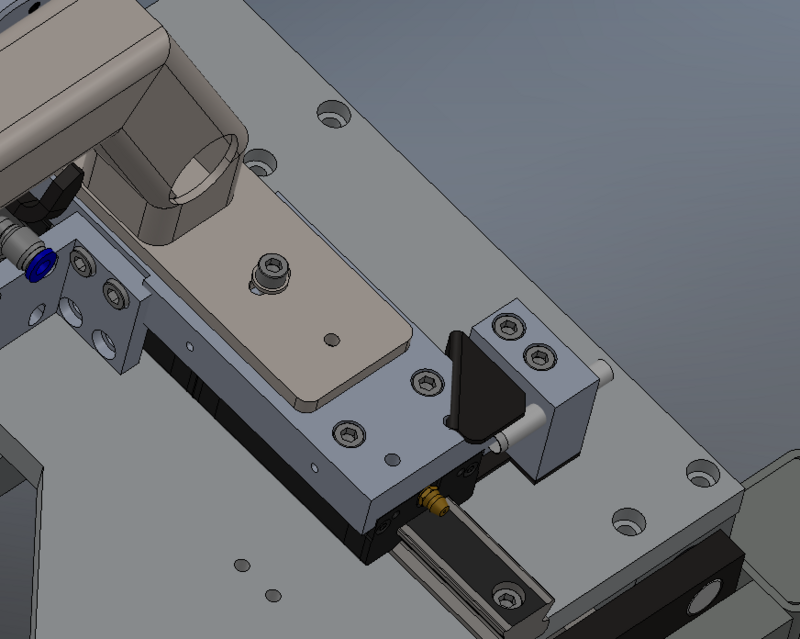

Étape 6 - Adjust square

Use engineers square to check squareness of front rollers to infeed and outfeed cut tables

Use adjusting grubscrews to set square accurately

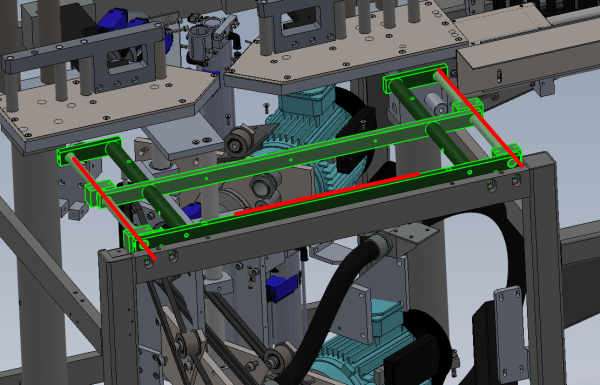

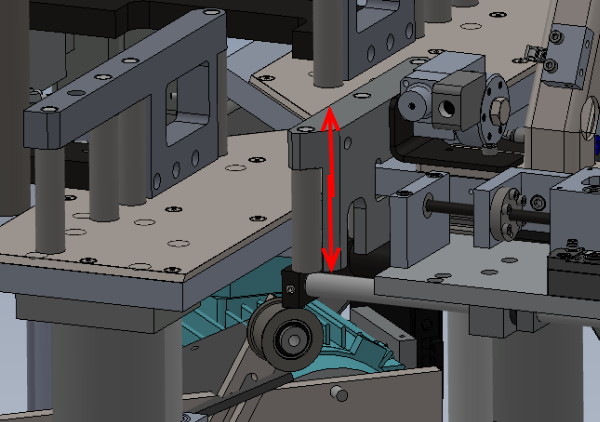

Étape 7 - Adjust Height of Sy assembly

Set height of Sy assembly to cut tables using jacking grubscrews

Set to gap of 1.5mm -+ 0.5mm

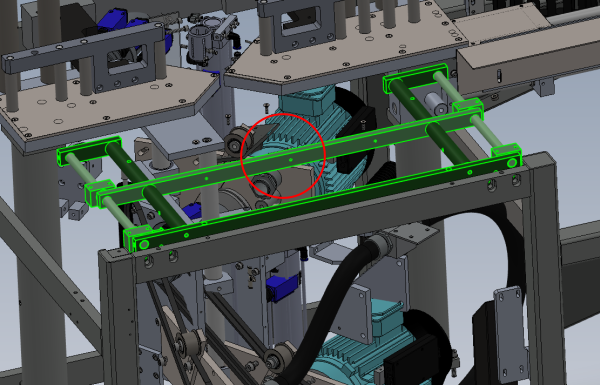

Étape 8 - Quality check

Check once height is adjusted, that Z block operation does not foul cut tables

To do this move both z blocks by hand to active and home position and check contact is not made with the cut tables

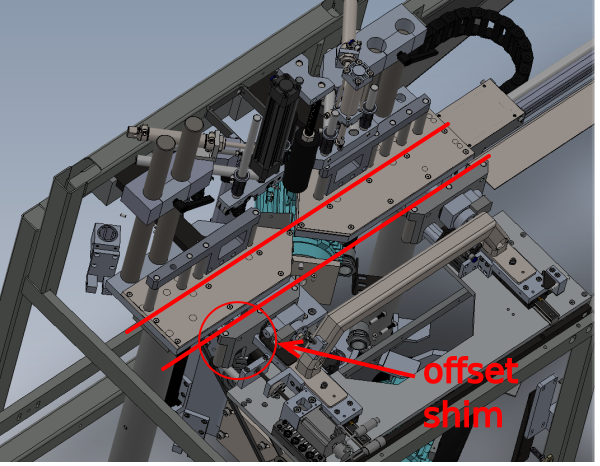

Étape 9 - Set Parallel to backfences

Use 1 meter straight edge and additional 2 off large parallels against back roller fence

Add offset shim of 0.002"/0.05mm to driven side

Set front rollers to touch, using M6 socket caps and counter bore clearance to adjust

Report if unable to achieve parallel from this movement

Étape 10 - Recheck Settings

Recheck all settings once final adjustment has been made

Roller squareness to cut tables

Roller height to cut tables

Parallel to back fences

Étape 11 - Finalise Fasteners

Individually remove and apply adhesive to fasteners and apply final tension

Étape 12 - Recheck settings

Recheck all settings once final adjustment has been made

Roller squareness to cut tables

Roller height to cut tables

Parallel to back fences

Étape 13 - Check adjustment grubscrews

Check that no adjustment grubscrews are loose.

Any grubscrews that are not required should still have adhesive applied and lightly tensioned to set in position

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português