Installation procedure for rotary ring into mainframe

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Safe operation

- 4 Étape 3 - Pre installation checks

- 5 Étape 4 - Fit Lifting strop to rotary ring

- 6 Étape 5 - Lift and position ring

- 7 Étape 6 - Lower to correct position

- 8 Étape 7 - Final Fix top bearing blocks

- 9 Étape 8 - Release weight

- 10 Étape 9 - Fix R axis gearbox and cable

- 11 Étape 10 - Finalise bottom bearing blocks

- 12 Étape 11 - Set R axis gearbox backlash

- 13 Étape 12 - Check R axis Backlash

- 14 Étape 13 - Finalise R axis gearbox

- 15 Étape 14 - Fit R axis servo motor

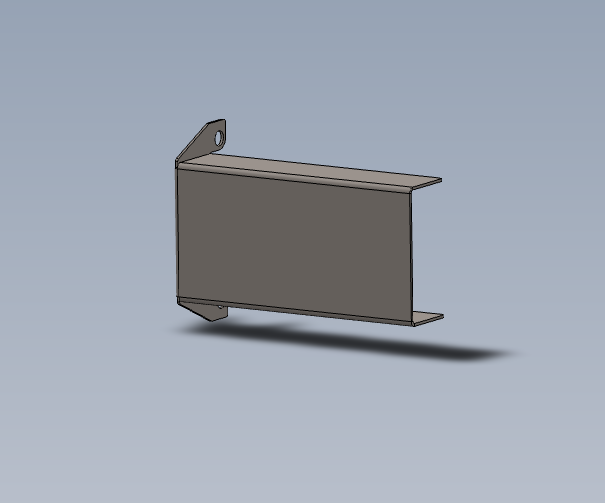

- 16 Étape 15 - Fit R axis gear box timing cover

- 17 Étape 16 - Set friction coupling

- 18 Étape 17 - Fit access plates

- 19 Étape 18 - Fit oil pots

- 20 Étape 19 - Fit ring bungs

- 21 Étape 20 - Fit Y axis hard stops

- 22 Étape 21 - Finalise Y axis leadscrew

- 23 Étape 22 - Fit Y axis Datum switch assembly

- 24 Étape 23 - Fit Z axis datum block assembly

- 25 Étape 24 - Fit ethercat cover

- 26 Étape 25 - Fit tool break assembly

- 27 Étape 26 - Connect Energy chain

- 28 Étape 27 - Quality check

- 29 Commentaires

Introduction

Tools Required

Standard Hex Key set

Standard spanner set

Lifting Strop

Overhead crane operation

Torque wrench

Soft hammer

Ring lubrication oil

Parts Required

A0000309 Domed Blanking Plug 19mm x 3

C0001123 Servo Motor: Beckhoff AM8062 18Nm 3000rpm x 1

D0000263 Stop Y Central x 1

D0002990E Strike Post ZX4 Mk5 x 1

D0002991 Switch carrier x 1

D0006061 Timing Belt cap x 1

D0007861 Y axis hard stop x 2

D0010756 Proximity Switch Mounting Block Reduced Size x 2

D0010894 Ethercat Cover ZX3/ZX4 x 1

D0015542 R Axis Motor Connector Cover x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 2

H0007995 Rotary base cover plate x 2

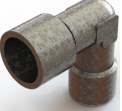

M0000451 Plug and Elbow x 2

R0000971E Bench Assemble R Axis Gearbox

R0010260 Bench Assemble Tool Break Sensor

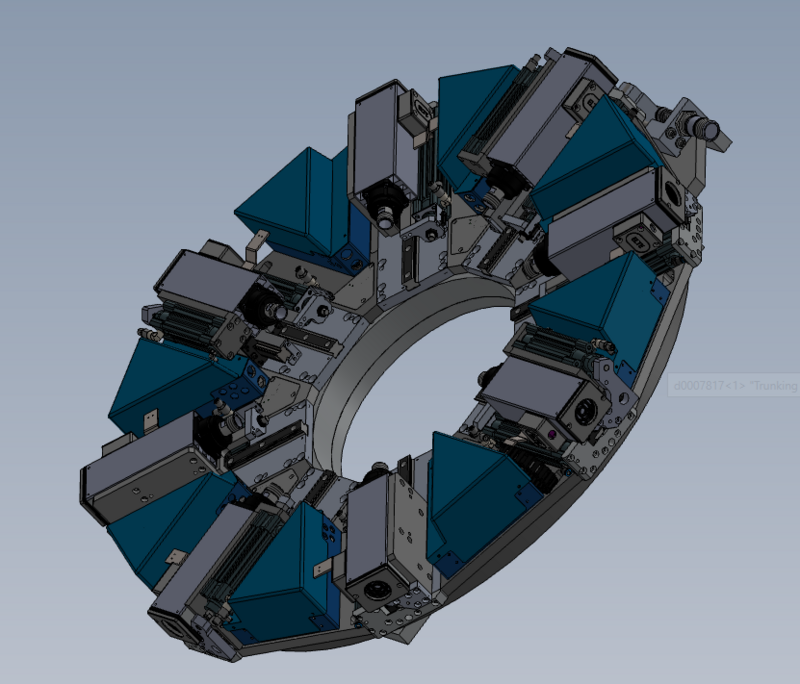

R0015138 Machining Head ZX4 Mk5 (Quad Plunge)

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Safe operation

Installation of rotary ring requires the use of the overhead crane

Please ensure all safety requirements are met, and all employees are confident with the operation and installation progress before commencing work details

Étape 3 - Pre installation checks

Check z support bars are installed

Y axis leadscrew nut is not positioned in y axis bearing housing

Location dowels are fitted to Y axis bearing blocks

Étape 4 - Fit Lifting strop to rotary ring

Fit and position lifting strop onto rotary ring

Ensure strop is positioned correctly between spindles

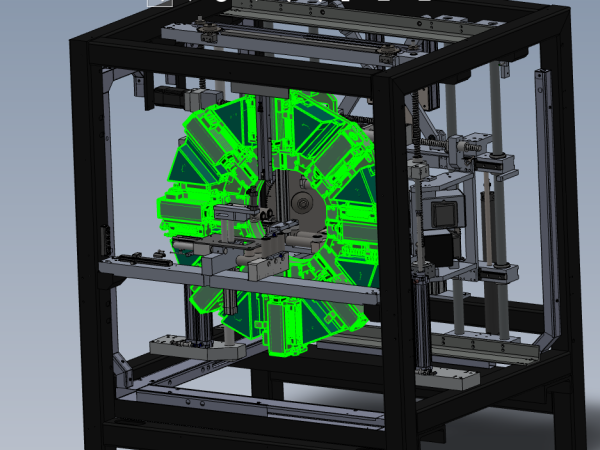

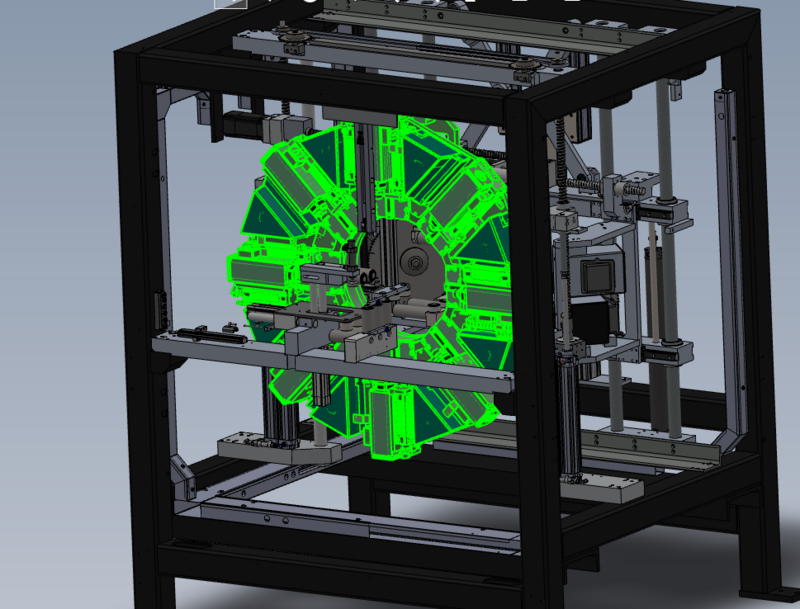

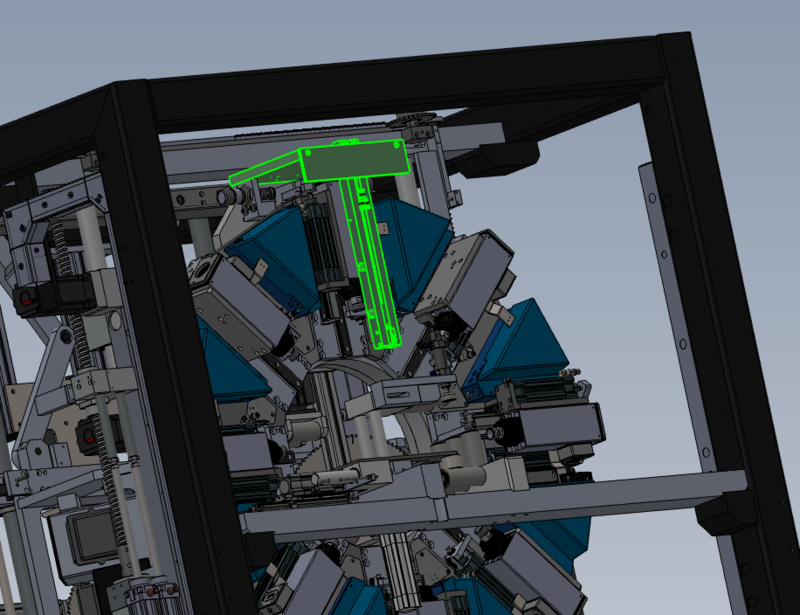

Étape 5 - Lift and position ring

Use overhead crane to lift rotary ring assembly to align over the top of the machine centre main frame

Étape 6 - Lower to correct position

Slowly lower to correct position within machine centre assembly

Height setting is governed by bearing block alignment to back plate of rotary ring

Étape 7 - Final Fix top bearing blocks

Use M8 sockets to Finalise fixing between bearing blocks and rotary ring back plate

Finalise Fasteners

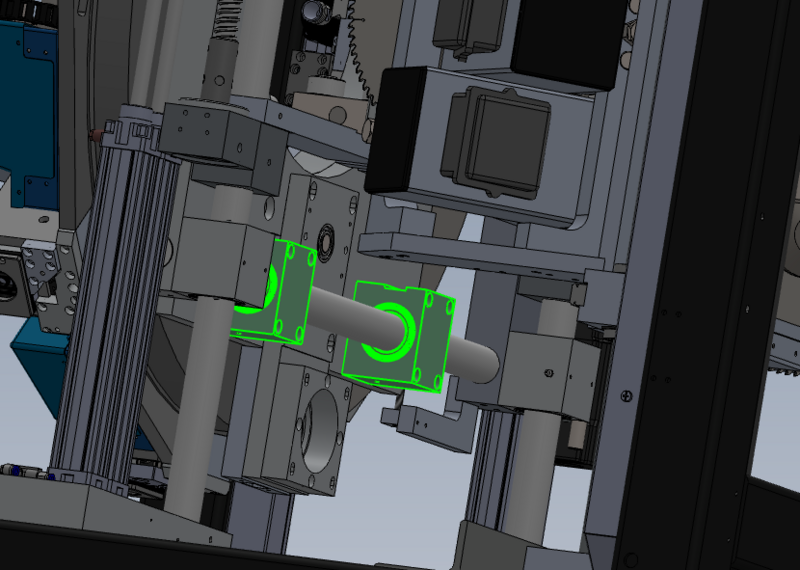

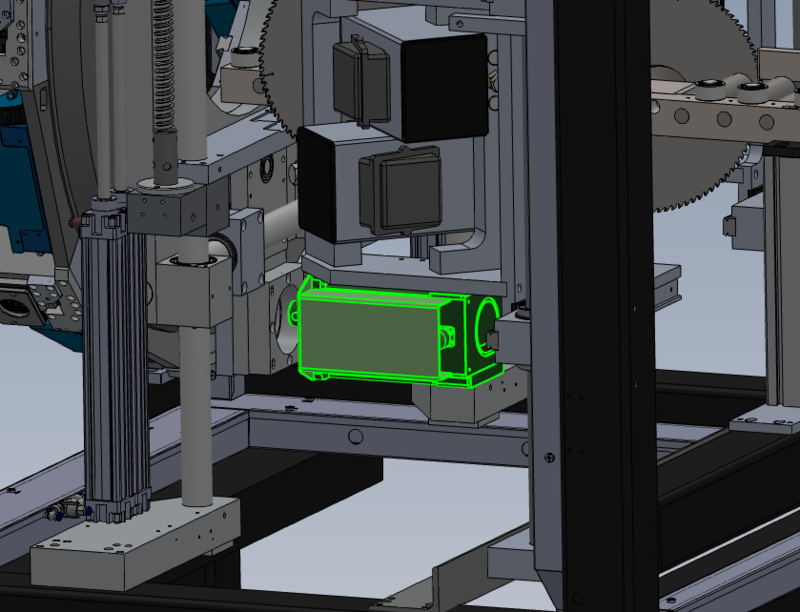

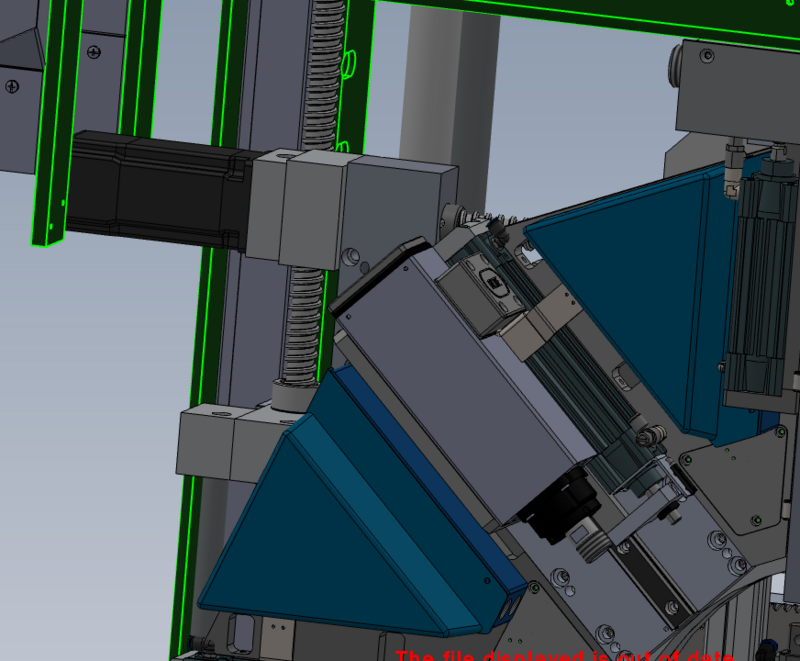

Étape 9 - Fix R axis gearbox and cable

The lower section of the rotary rotary ring will require moving forward to enable r axis gearbox assembly to be fitted

Position Gearbox in place , along with R axis servo control cable

Light fix R axis gearbox in position

Étape 10 - Finalise bottom bearing blocks

Align and finalise bottom bearing blocks to rotary ring back plate

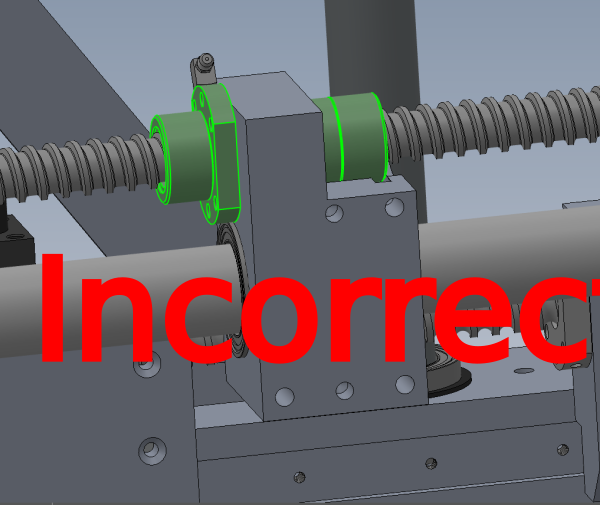

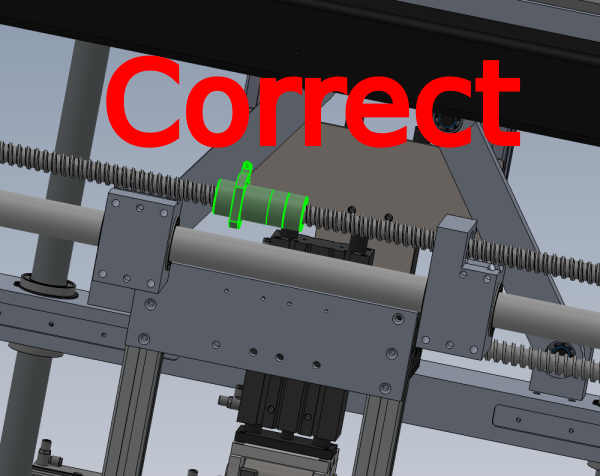

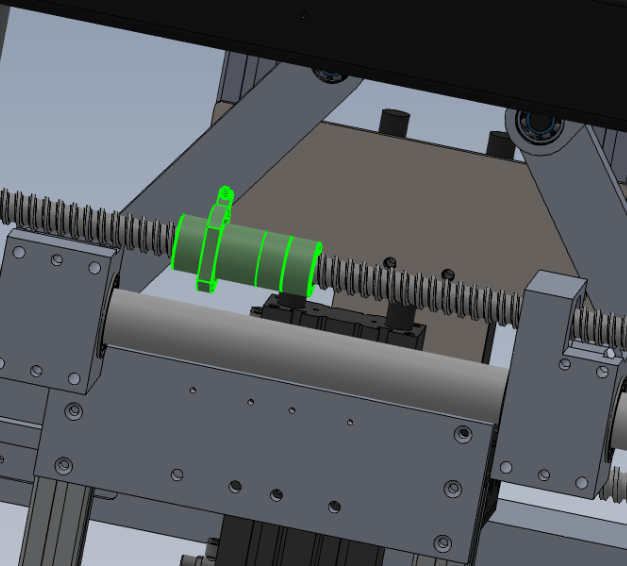

Étape 11 - Set R axis gearbox backlash

Set back lash on gearbox by hand

Push gearbox up towards centre of ring by hand and tighten holding fasteners

Étape 12 - Check R axis Backlash

Quality check for correct backlash between drive gears , requires 2 people

To complete this

Lock gearbox using 8mm hex key positioned in friction coupling of gearbox through access hole

Ensure gearbox is held in a fixed position

Rock rotary ring to check for presence of backlash. No backlash should be present , only minimal belt flex should be observed

Check backlash in 4 points equally spaced around rotary ring rotation

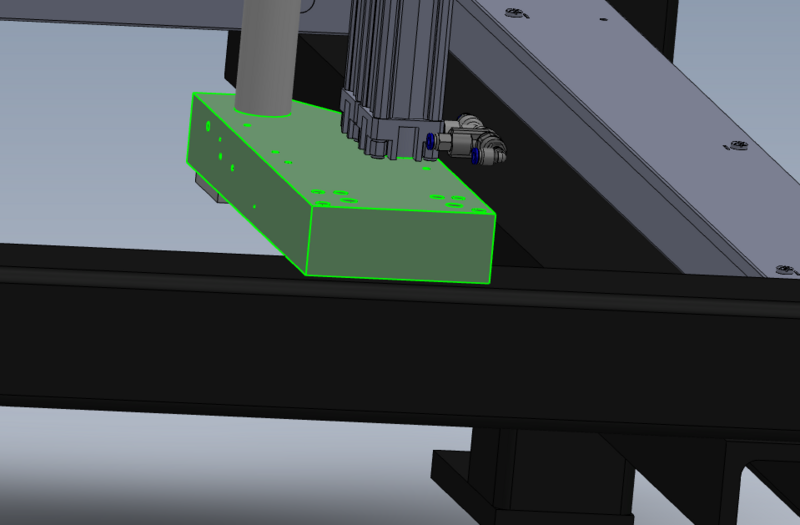

Étape 14 - Fit R axis servo motor

Add M0000031 edging strip to servo motor protection plate

Fit servo motor in conjuction with protection plate and ensuring servo connection cable is connected

Ensure servo plug is orientated correctly

Étape 16 - Set friction coupling

Use torque wrench to set correct torque on r axis gearbox friction coupling

Fit gearbox blanking plug

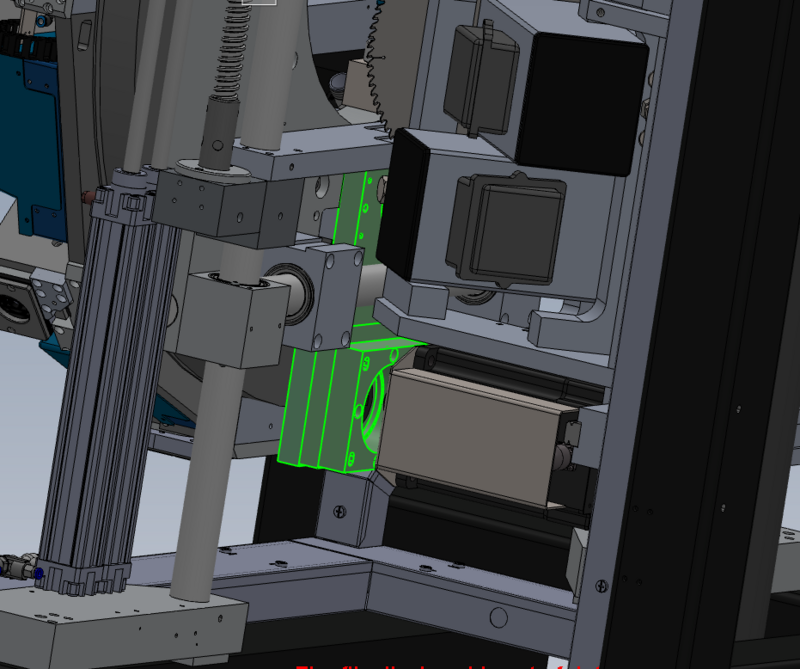

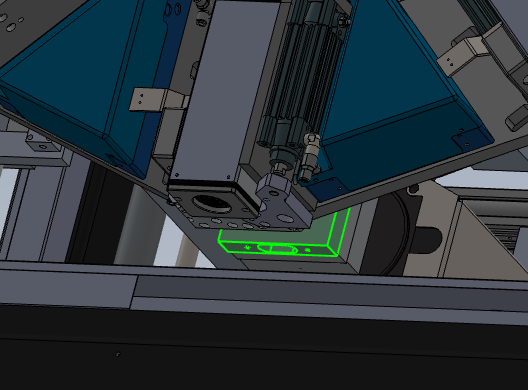

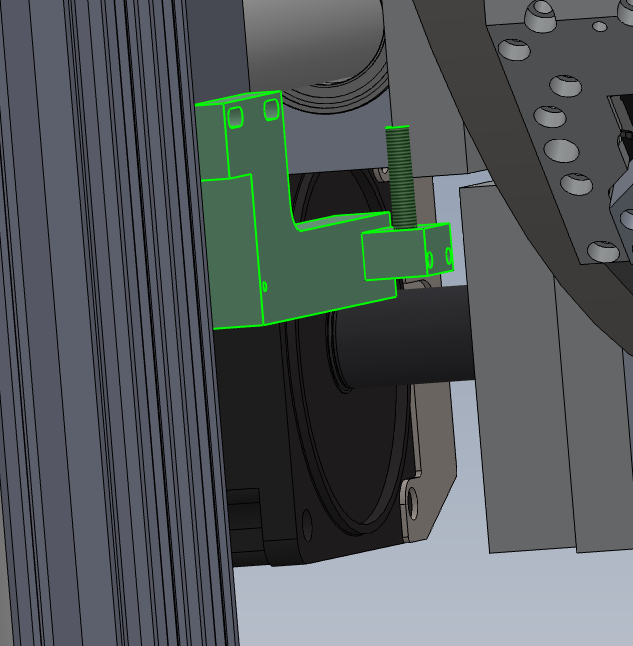

Étape 22 - Fit Y axis Datum switch assembly

Fit Y axis datum bracket, block and sensor

Set sensor position to ensure minimal gap is present (-1mm) along full movement of travel . double check that no contact is made by sensor at any point of travel

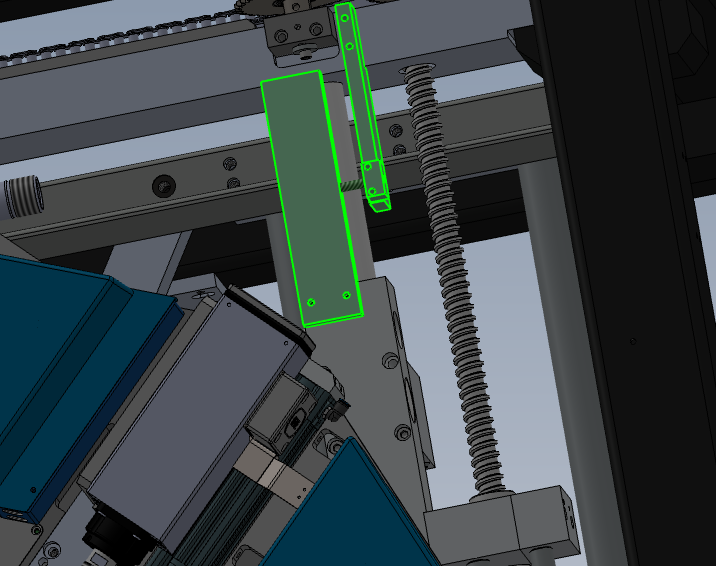

Étape 23 - Fit Z axis datum block assembly

Fit Z axis datum block assembly

Set sensor position to ensure minimal gap is present (-1mm) along full movement of travel . double check that no contact is made by sensor at any point of travel

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português