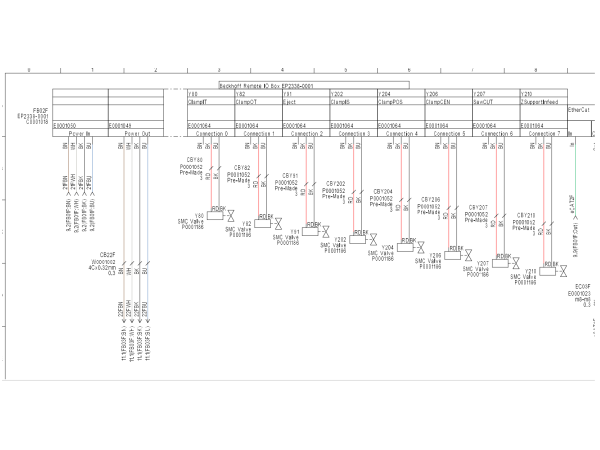

Details for manual pneumatic output testing on module

Sommaire

- 1 Introduction

- 2 Étape 1 - Safety

- 3 Étape 2 - Set Air service unit soft start

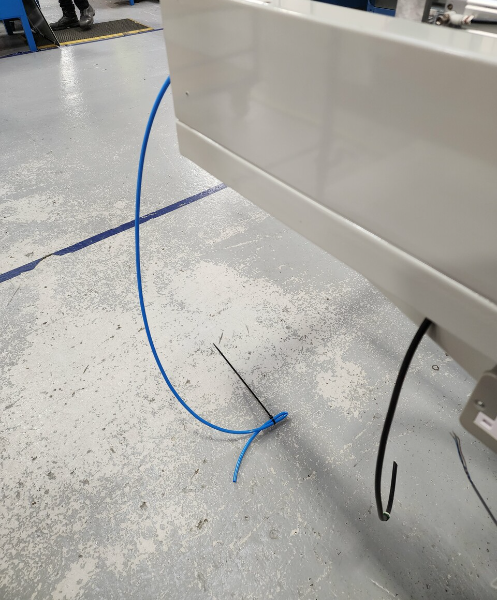

- 4 Étape 3 - Check all open ports

- 5 Étape 4 - Connect main PCL

- 6 Étape 5 - Check for leaks

- 7 Étape 6 - Manual overide

- 8 Étape 7 - Check for leaks

- 9 Étape 8 - Check home positions

- 10 Étape 9 - home positions for outputs

- 11 Étape 10 - home positions for outputs

- 12 Étape 11 - If any deviation from the above

- 13 Étape 12 - Manual valve over ride

- 14 Étape 13 - Y80 Clamp infeed top

- 15 Étape 14 - Y82 Clamp outfeed top

- 16 Étape 15 - Y91 Eject

- 17 Étape 16 - Y202 Side clamp

- 18 Étape 17 - Y204 Clamp position

- 19 Commentaires

Introduction

Tools Required

PCL airline connection

12mm blanking ports

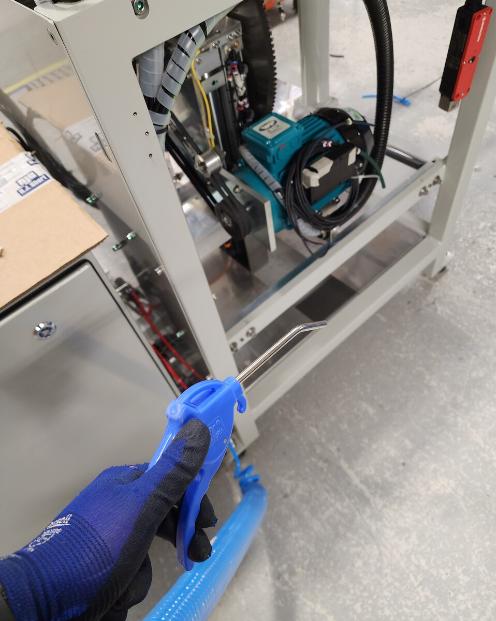

Valve Manual over ride tool

Standard screwdriver set

Additional colleague when setting regulator pressures for outputs

Parts required

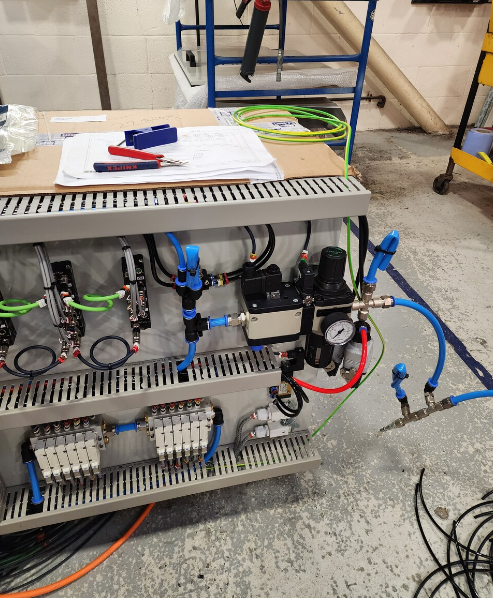

Étape 1 - Safety

Output testing will require valve operation with no e/s circuit

Ensure the following

Work area is clear from all components not required for testing

All colleagues are aware of the procedure being undertaken

No additional colleagues are working on the module

PCL coupling is accessible to release pressure in case of emergency

Testing procedure is fully adhered to

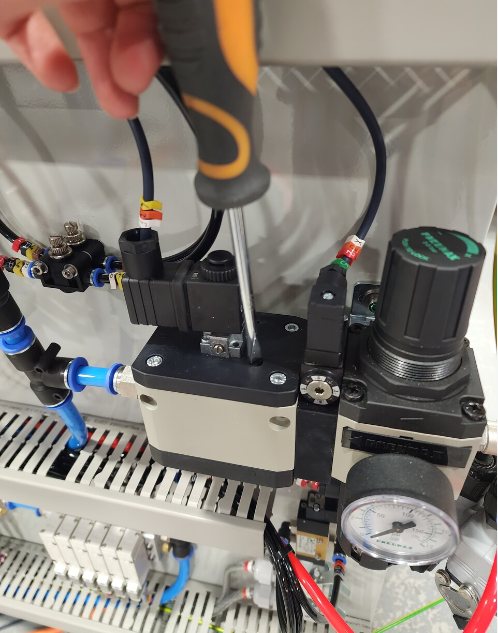

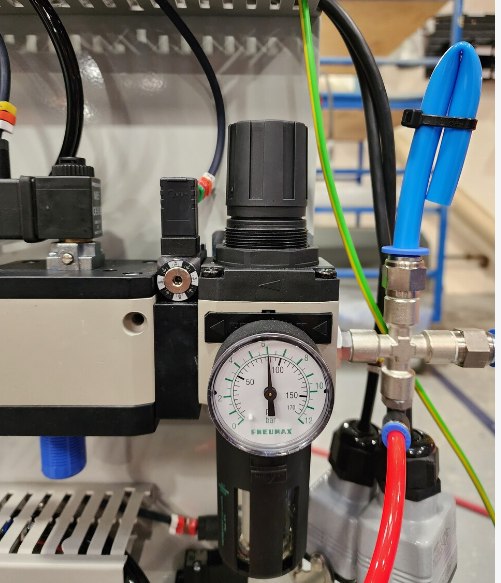

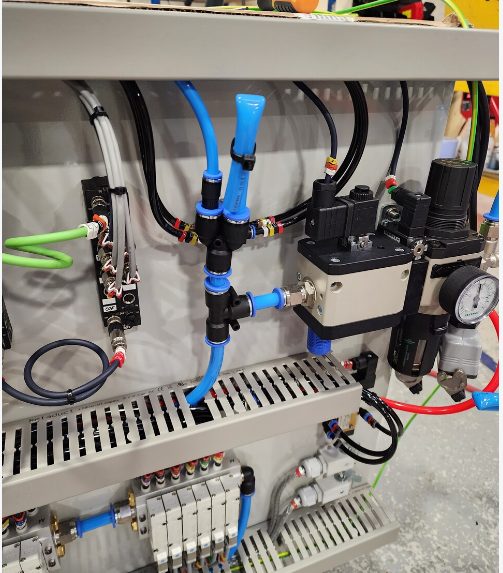

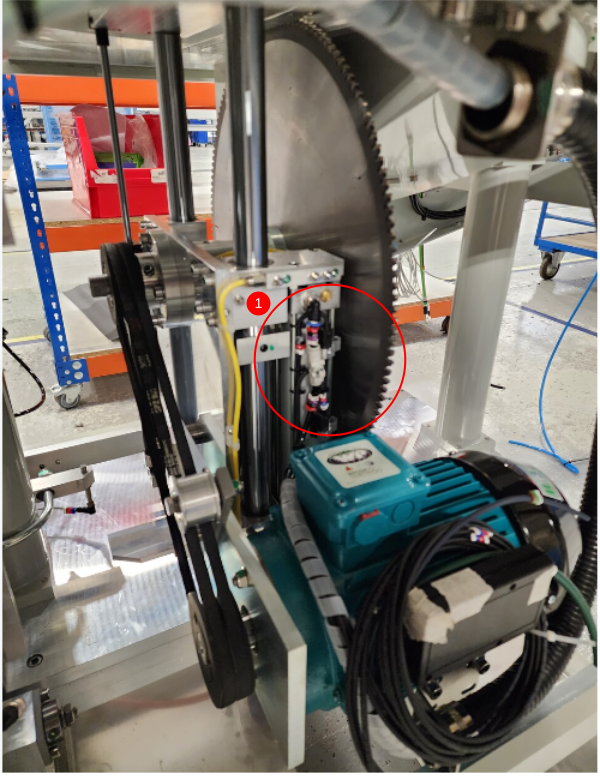

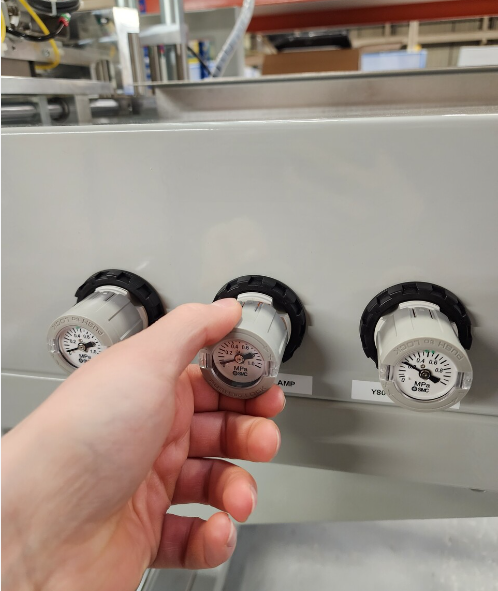

Étape 2 - Set Air service unit soft start

Wind fully out soft start screw situated on top on main air service unit

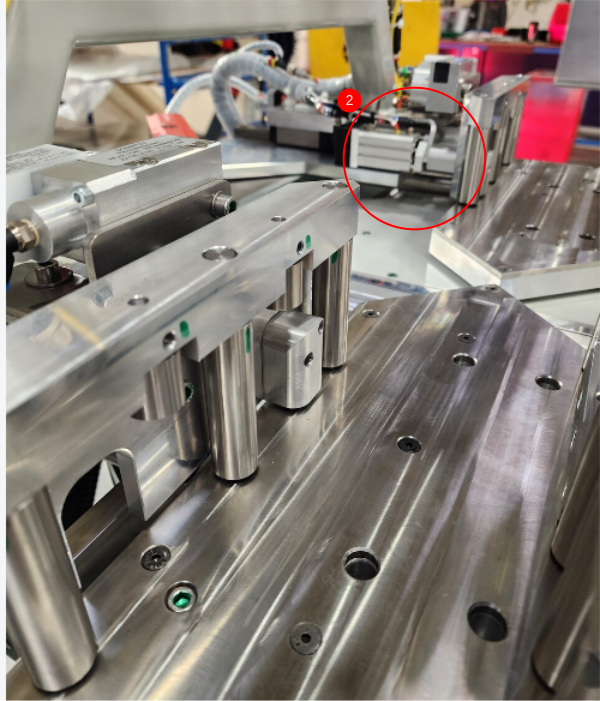

Étape 4 - Connect main PCL

Connect main pcl air feed to air service unit

Increase Air service unit pressure to 6.0bar

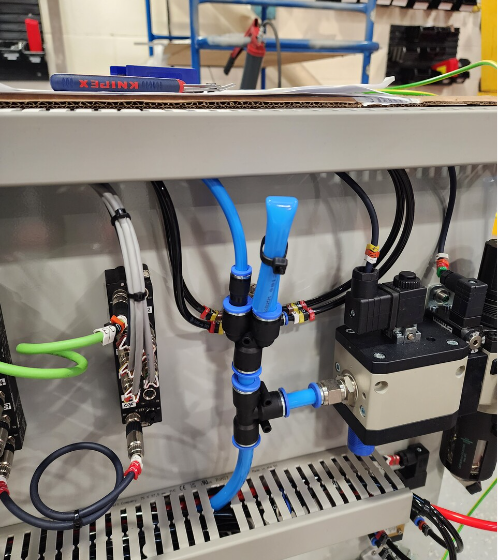

Étape 5 - Check for leaks

Check for audible leaks on the red pipe lines installed and correct if found

Check air gun regulator functions properly . Fully open the regulator (2 bar limited ) and test air gun assembly

Étape 6 - Manual overide

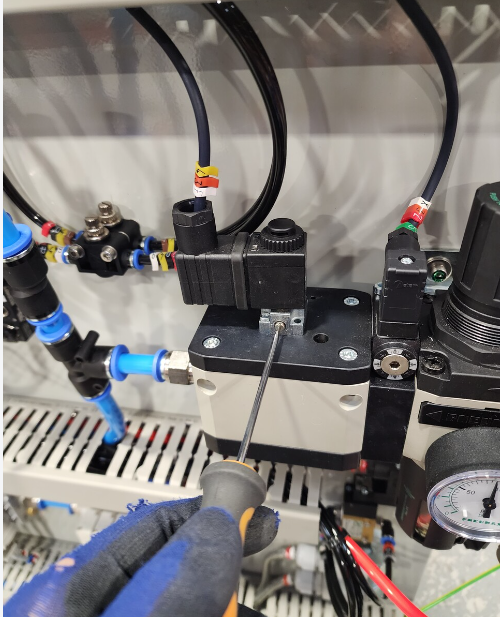

Enable the manual over ride on the main air service unit

This will purge the system with air.

Étape 7 - Check for leaks

Check for audible leaks on blue Pipe line, and active control pipes to cylinders and regulators

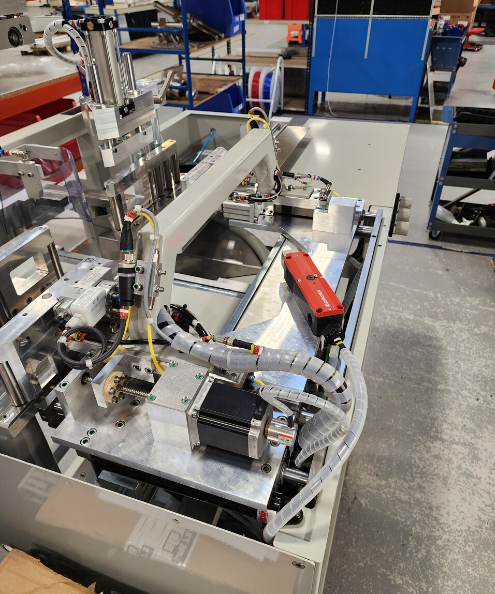

Étape 8 - Check home positions

With the system in the natural state when over ridden, the following cylinder positions should be confirmed

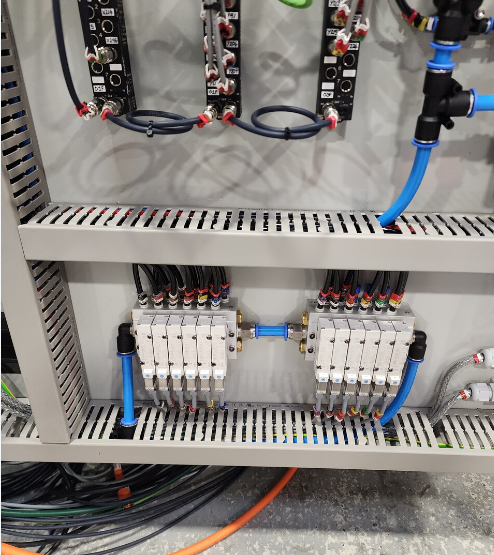

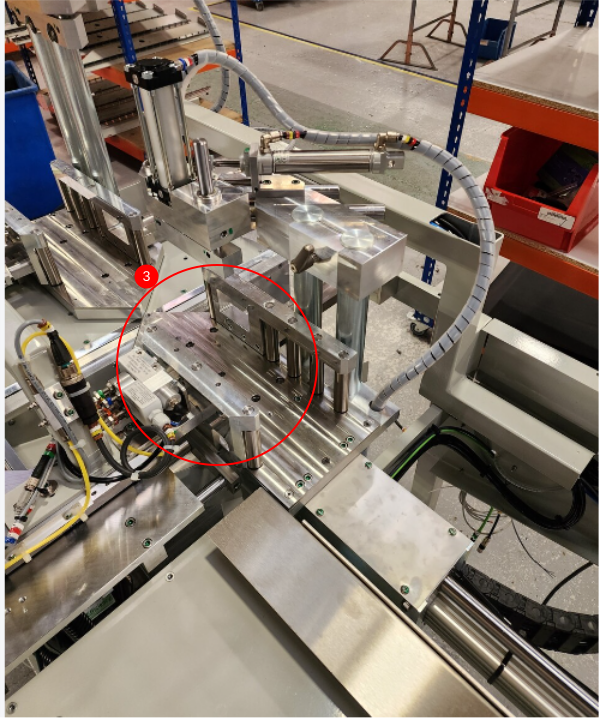

Étape 9 - home positions for outputs

1 Y80 Infeed Top clamp contracted

2 Y82 Outfeed top clamp contracted

3 Y91 eject cylinder contracted

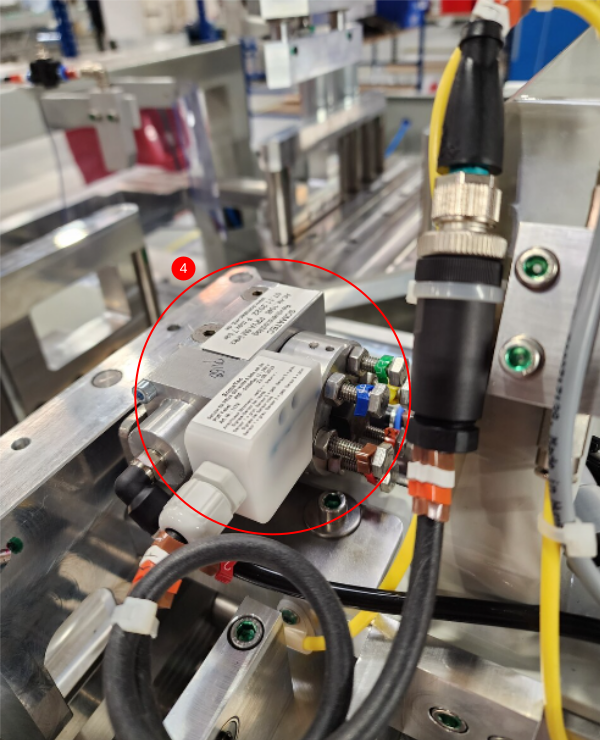

4 Y202 clamp infeed side extended

5 Y204 Clamp pos contracted

6 Y206 Centralise contracted

Étape 10 - home positions for outputs

1 Y207 Saw cut contracted

2 Y210 Z support infeed contracted

3 Y213 Saw blowers switched off

4 Y214 Z turret infeed Not moving

5 Y215 Z turret outfeed . Not moving

6 Y224 Z support outfeed contracted

Étape 11 - If any deviation from the above

If any deviation from the above check pipe connections to incorrect output

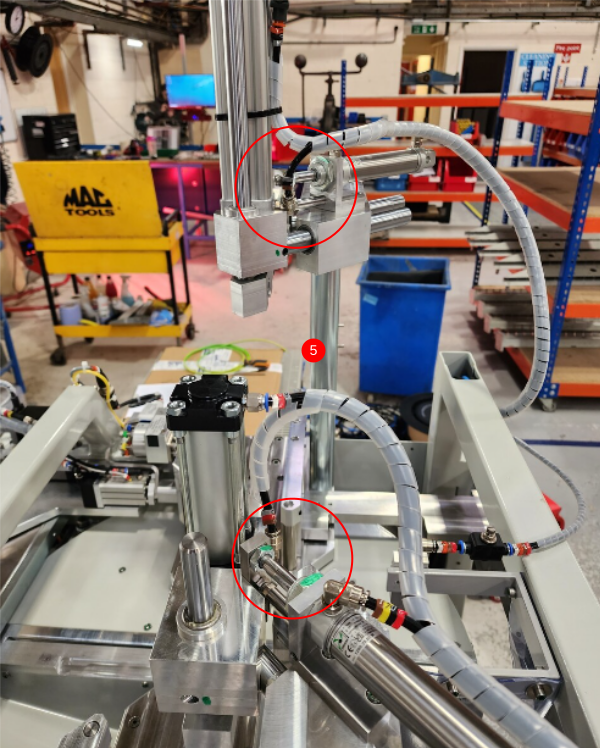

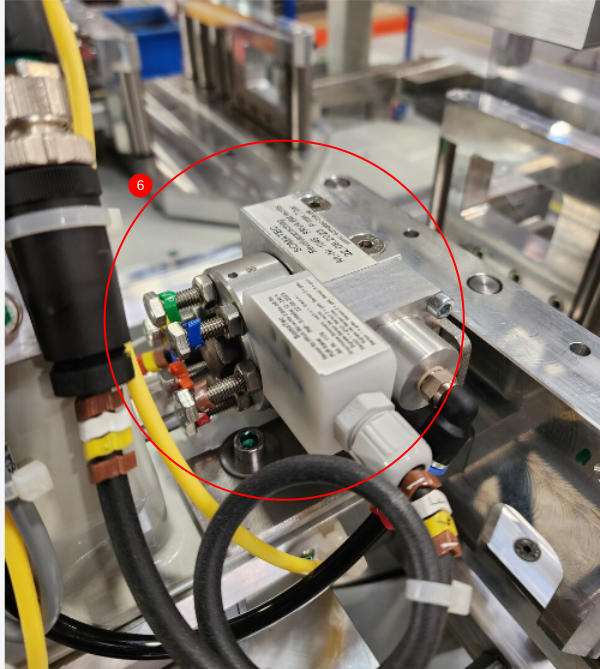

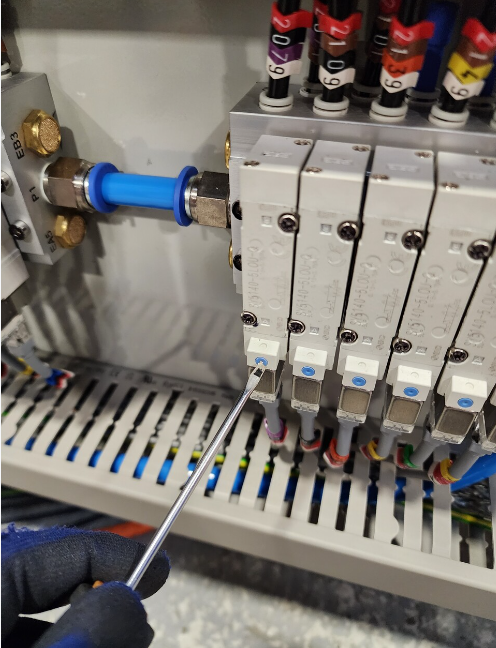

Étape 12 - Manual valve over ride

Each valve can be manually fired from the over ride button. Pressing this will activate the valve and fire the cylinder /output

when a valve is over ridden, ensure attention is paid to any new air leaks that could become present in the active line when fired

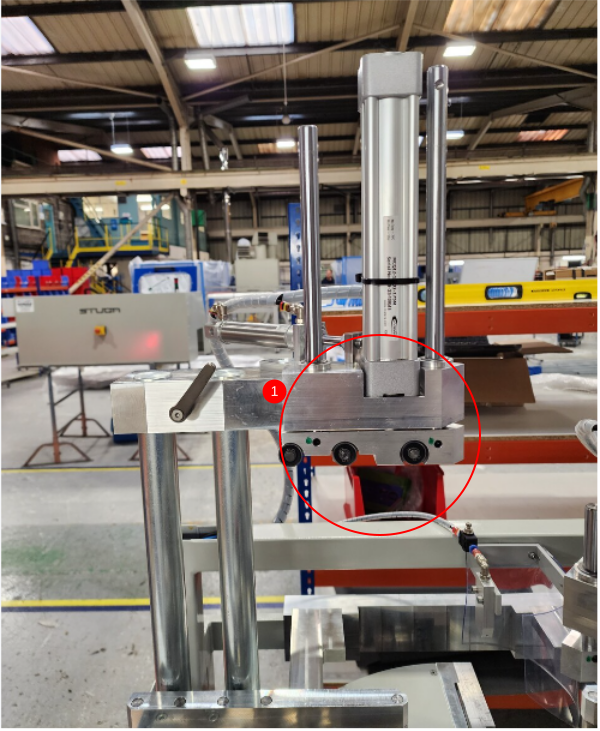

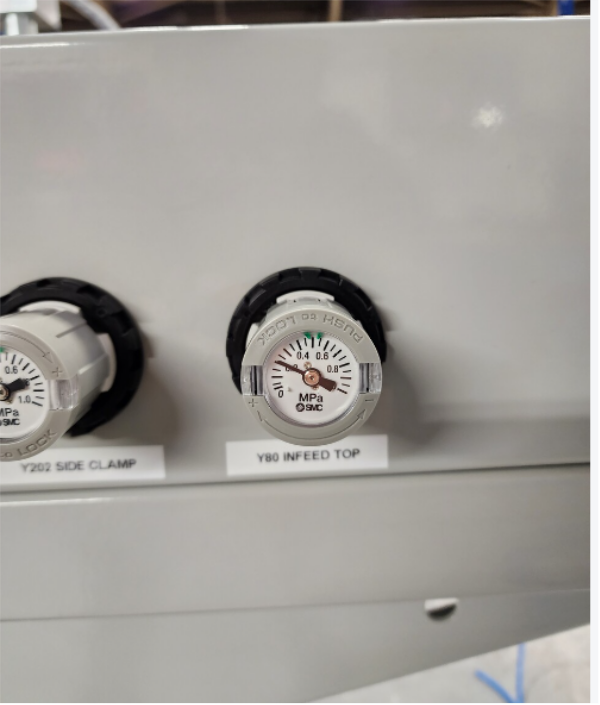

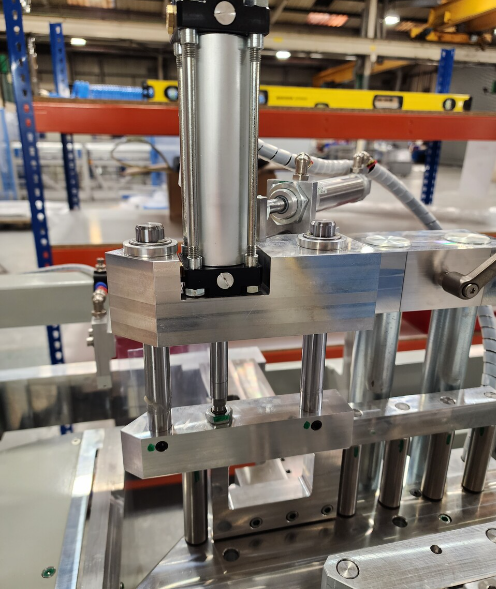

Étape 13 - Y80 Clamp infeed top

Fire and hold valve

Adjust regulator to 0.2 M.P.A

Cylinder should extend

Should retract when valve released

Étape 14 - Y82 Clamp outfeed top

Fire and hold valve

Cylinder should extend

Should retract when valve released

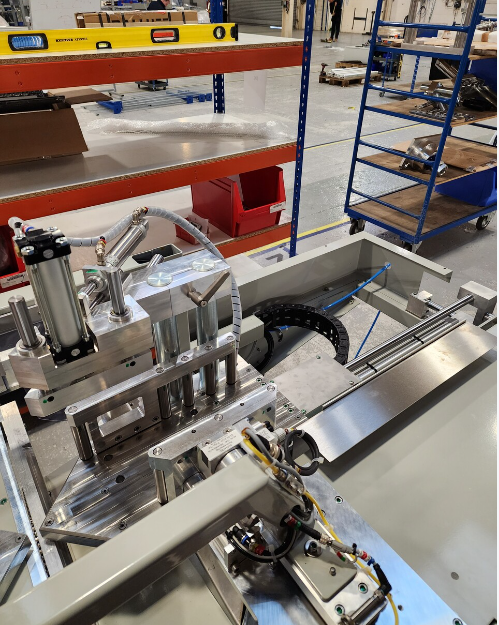

Étape 15 - Y91 Eject

Fire and hold valve

Eject table should move away from saw head

Should retract when valve released

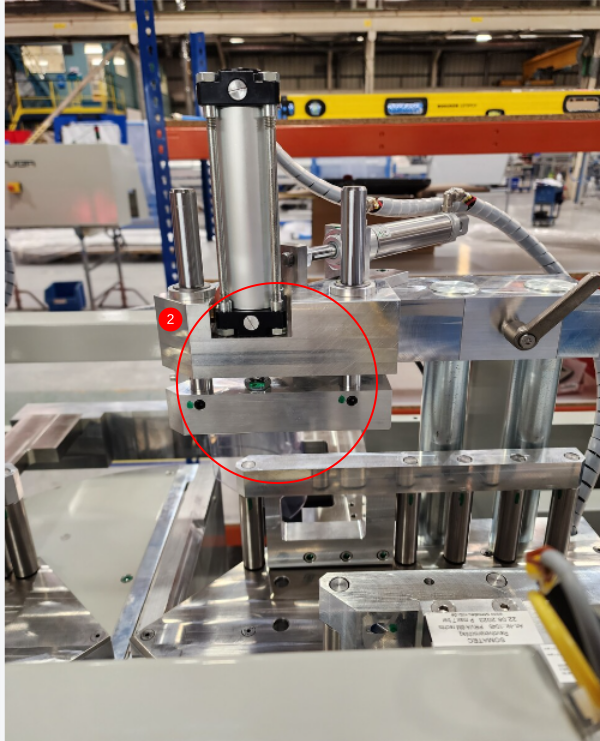

Étape 16 - Y202 Side clamp

Fire and hold valve

Set regulator to 0.2 M.P.A

Side clamp should move towards backfence rollers

Should retract when valve released

Étape 17 - Y204 Clamp position

Fire and hold valve

Clamps should move towards from of machine.

If movement is slow/not present check flow restrictors on back of electrical cabinet identified as 2049

Should retract when valve released

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português