Correct settings and installation procedure for transfer beam assemblies

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Install Frame pitching jigs

- 4 Étape 3 - Attach Jigs

- 5 Étape 4 - Move Module E

- 6 Étape 5 - Level module E

- 7 Étape 6 - Adjust height of module E

- 8 Étape 7 - Remove setting jigs

- 9 Étape 8 - Fit Transfer beam 1 and 9

- 10 Étape 9 - Information

- 11 Étape 10 - Check Parallel

- 12 Étape 11 - Check Squareness

- 13 Étape 12 - Adjust squareness

- 14 Étape 13 - Check adjustment

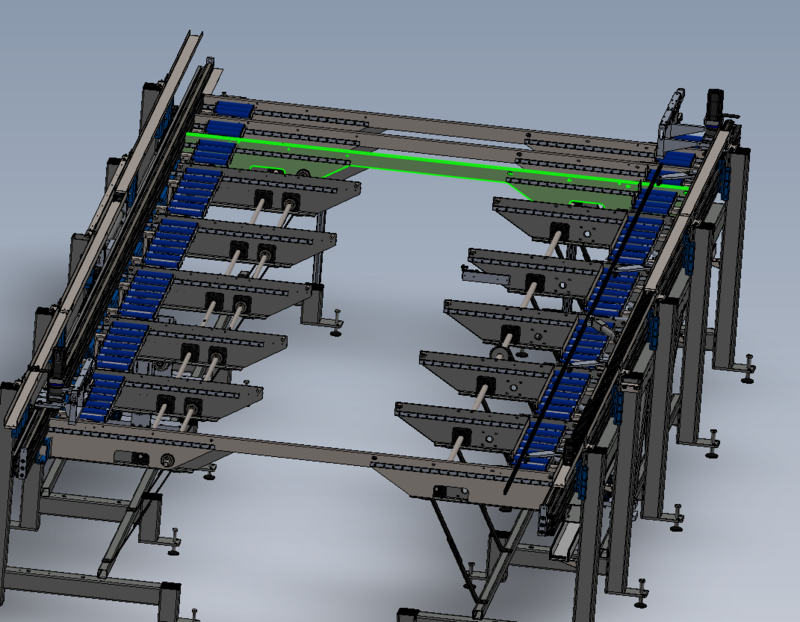

- 15 Étape 14 - Install Transfer beam 2

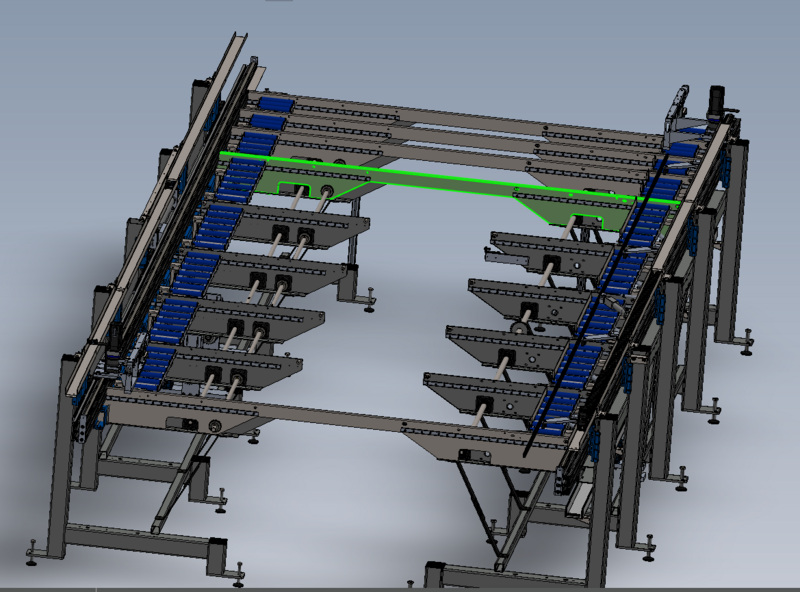

- 16 Étape 15 - Install Transfer beam 3

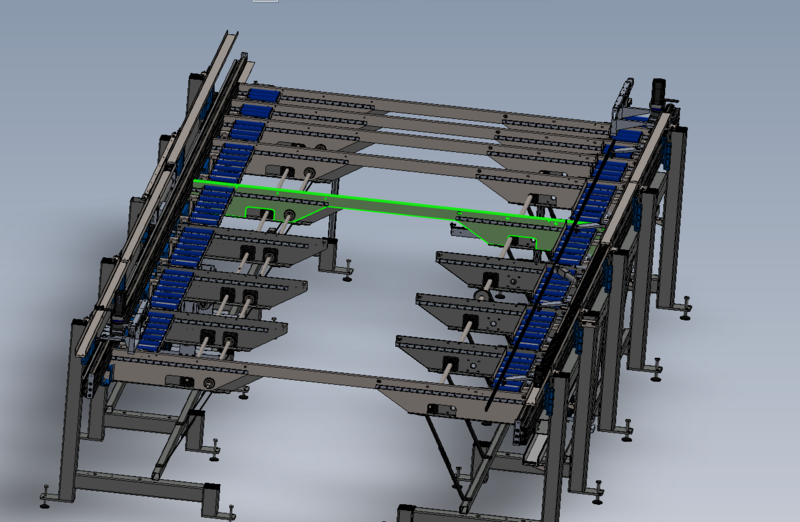

- 17 Étape 16 - Install Transfer beam 4

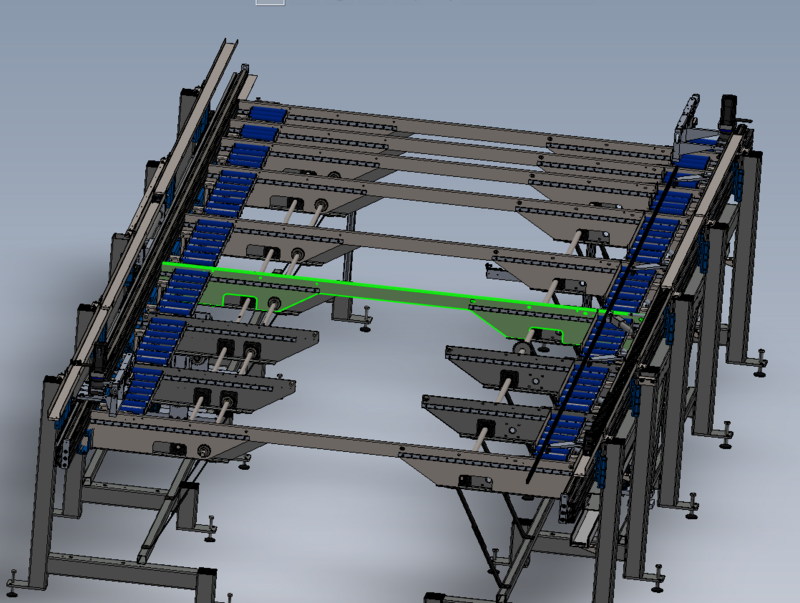

- 18 Étape 17 - Install Transfer beam 5

- 19 Étape 18 - Install Transfer beam 6

- 20 Étape 19 - Install Transfer beam 7

- 21 Étape 20 - Install Transfer beam 8

- 22 Étape 21 - Check Flatness

- 23 Commentaires

Introduction

Tools Required

Standard hex key set

Module pitching jigs

Tape measure 7.5 meter

Engineers level

1 meter spirit level

Parts required

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Install Frame pitching jigs

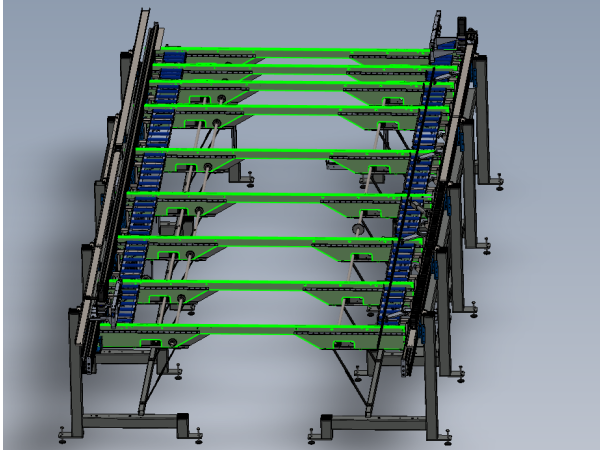

Module E will require accurately positioning to align with Module C

Only frame E must be moved

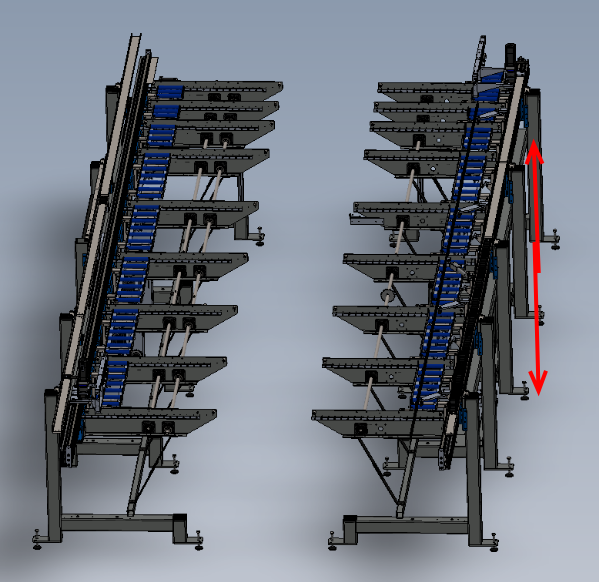

Étape 4 - Move Module E

Move module E in the directions shown to align to jigs

Fasten jigs to module E once aligned

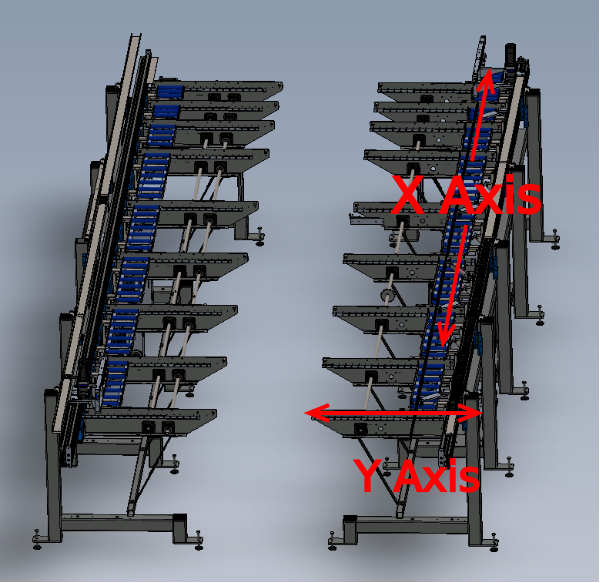

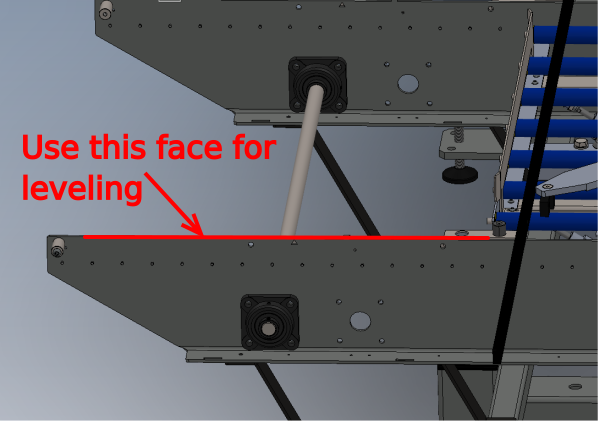

Étape 5 - Level module E

Module E will require re levelling now it has been moved

Level from carriage plate for X axis and support arms for Y axis

Étape 6 - Adjust height of module E

Using loading arms as datum , lift or lower Module E on adjusting bolts to bring module level with module C

Only use the face indicated for levelling between models. This is the face that is used in set up of the arms so continuity occurs for installation

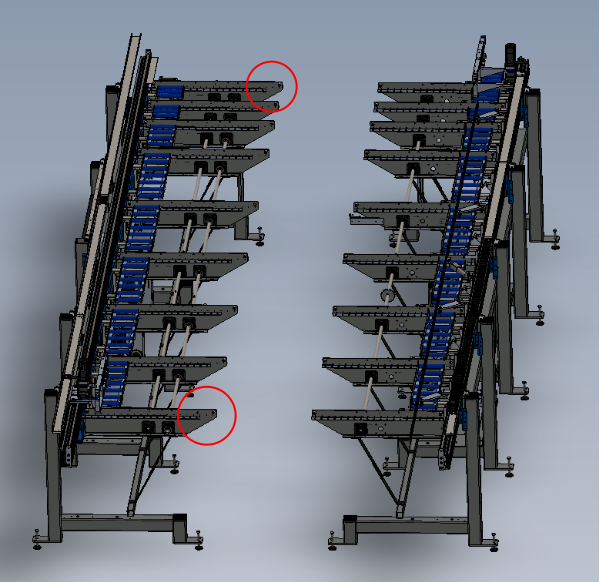

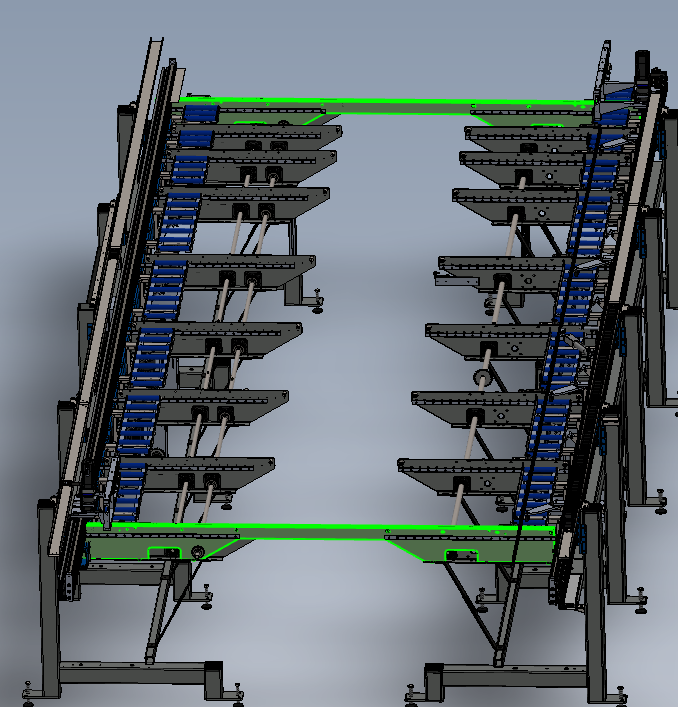

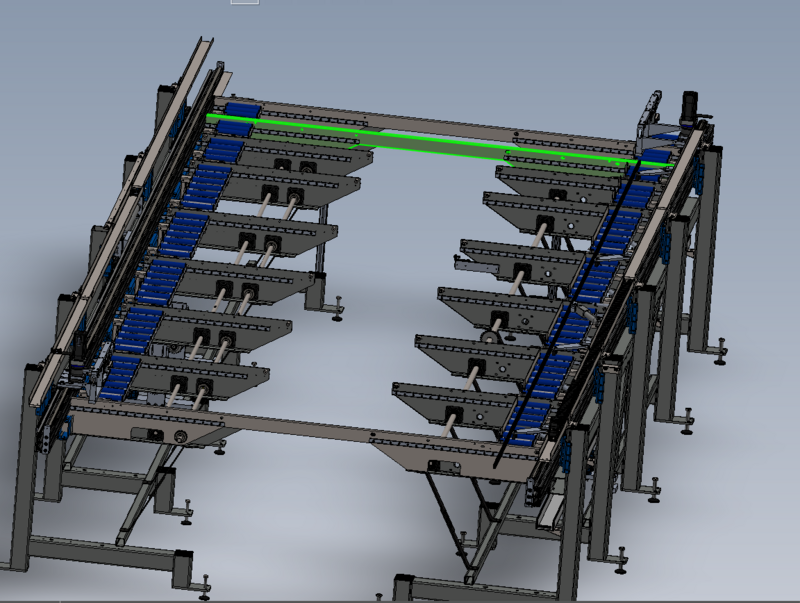

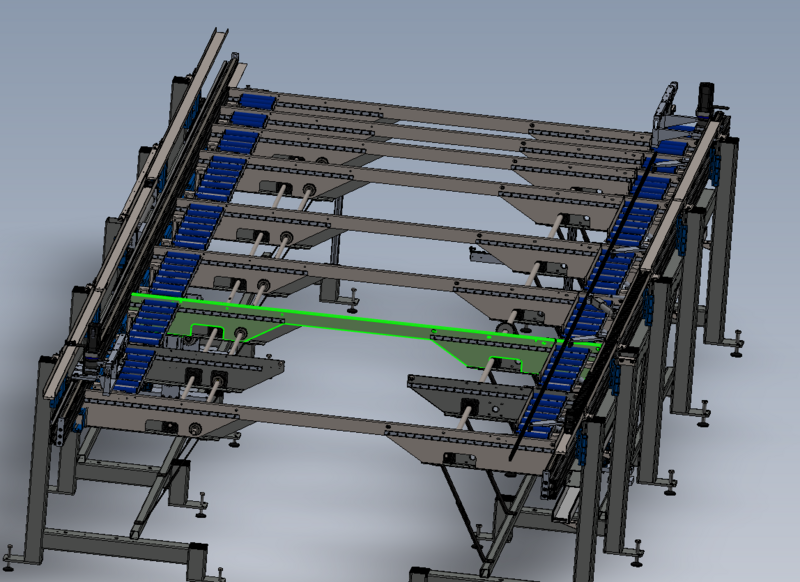

Étape 8 - Fit Transfer beam 1 and 9

Fit transfer beam 1 (with pneumatic rail ) and transfer beam 9 (no pneumatic rail ) to modules

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Check that transfer beams sit flat along indicated faces

Étape 9 - Information

It is important that the squareness and parallel are checked after the levelling of the 2 frames in relation to each other.

If there is a large variance in height between the 2 modules, a discrepancy will be created when measuring for correct positioning

The amount of frame movement required after levelling has been performed will be minimal , and have negligible effect on levels set

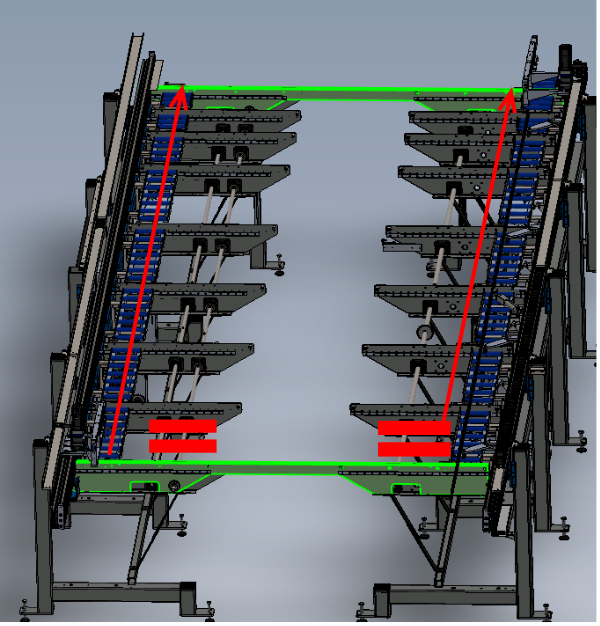

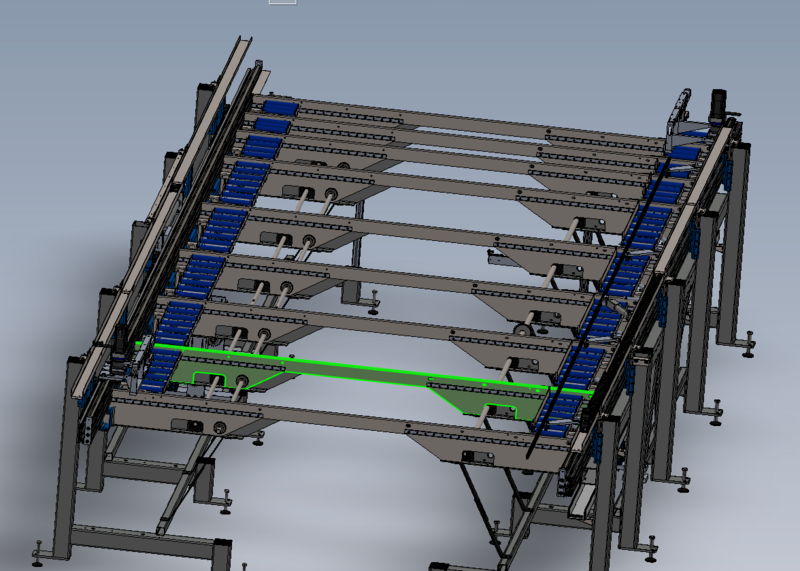

Étape 10 - Check Parallel

Check that beams are Parallel by measuring with a tape measure

Report any discrepancy to supervisor

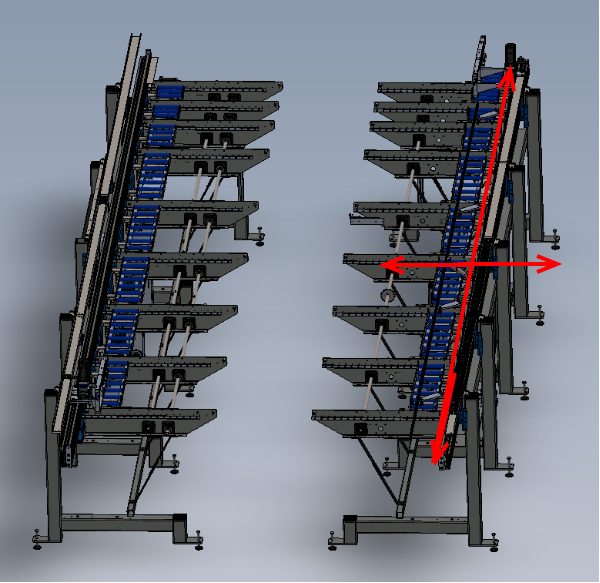

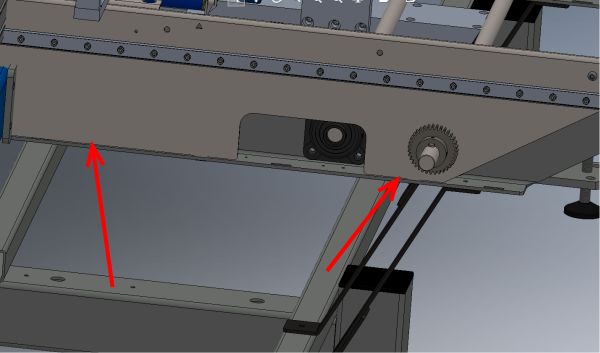

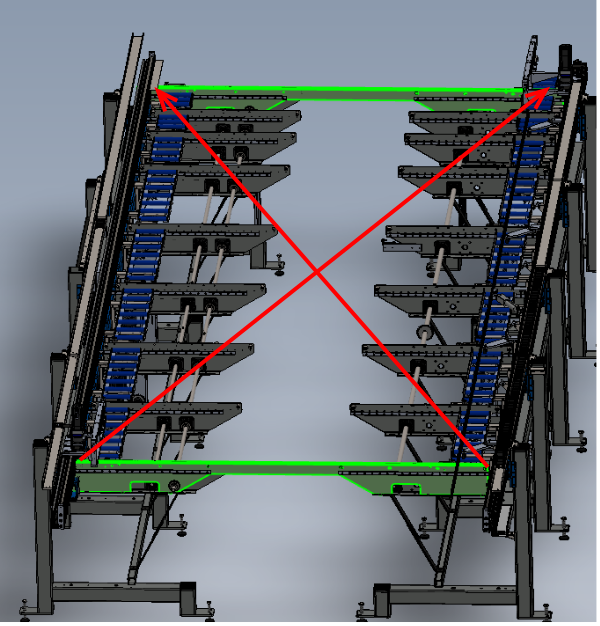

Étape 12 - Adjust squareness

Adjust Squareness by moving Module E in the direction shown

Frame will need to move half the distance of the discrepancy measured on corner measurements

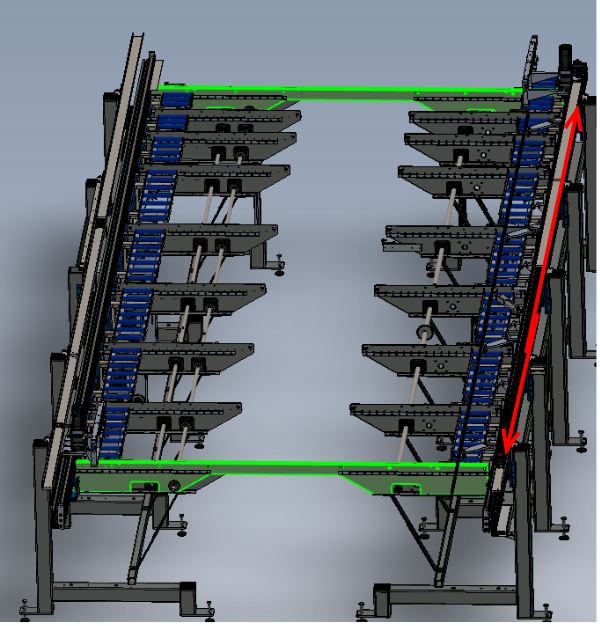

Étape 13 - Check adjustment

Once adjustment is complete, check measurements and levels of all areas adjusted

Étape 14 - Install Transfer beam 2

Install transfer beam 2 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 15 - Install Transfer beam 3

Install transfer beam 3 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 16 - Install Transfer beam 4

Install transfer beam 4 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 17 - Install Transfer beam 5

Install transfer beam 5 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 18 - Install Transfer beam 6

Install transfer beam 6 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 19 - Install Transfer beam 7

Install transfer beam 7 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 20 - Install Transfer beam 8

Install transfer beam 8 and secure

Fasten with button heads

Fasten with M8 set bolts ( stock ordered D.G) please provide size

Do not use adhesive on these bolts as need to be removed for decommission

Étape 21 - Check Flatness

Once all transfer beams are installed, check flatness with a 2 meter straight edge

Span across arms with 2 meter straight edge and check that no arms are sitting higher or lower than other transfer arms

Sign off required by supervisor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português