Heater plates that are out of alignment can cause poor welds that can crack and fail. When addressing issues of poor welds, heater plate alignment should be one of the first checks carried out after checking temperatures.

Difficulté

Facile

Durée

30 minute(s)

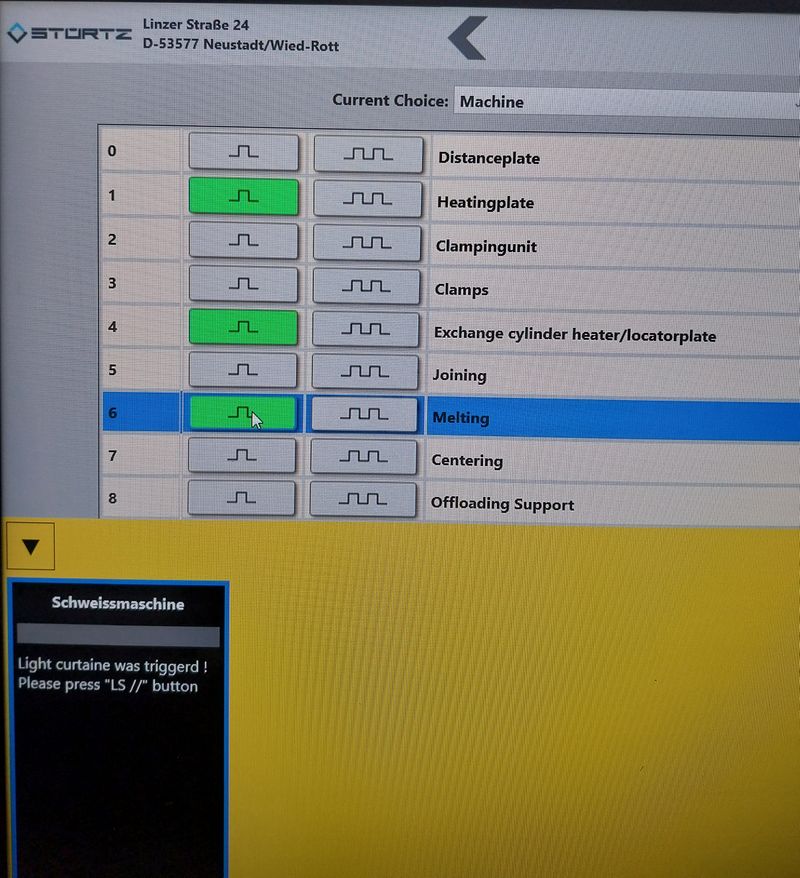

Étape 1 - Put Machine Into Input/Output Mode

First, make sure the heater plates are cool enough to work on. If not then gloves will be required to protect your hands from the heat

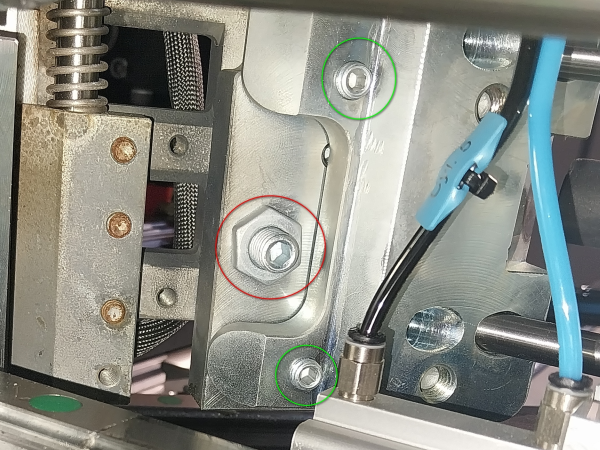

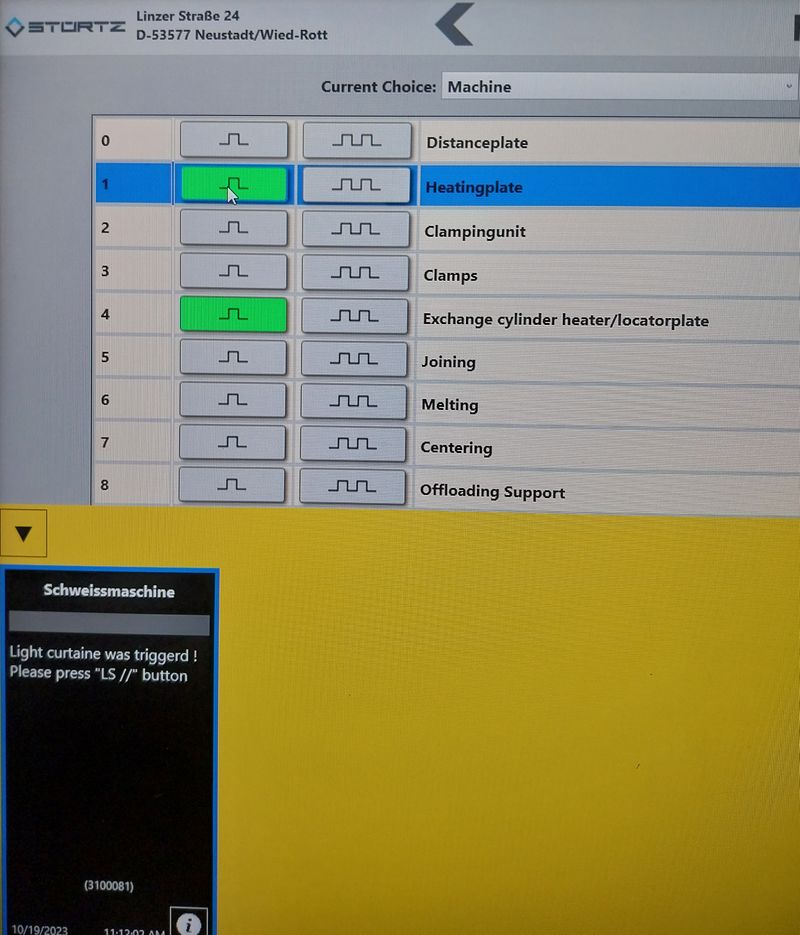

Put the machine into input/output mode. This will then allow us to move the heater plates into a position to be worked on. Ensure the items highlighted in GREEN are on.

Étape 2 - Remove Setting Plate and Adjust

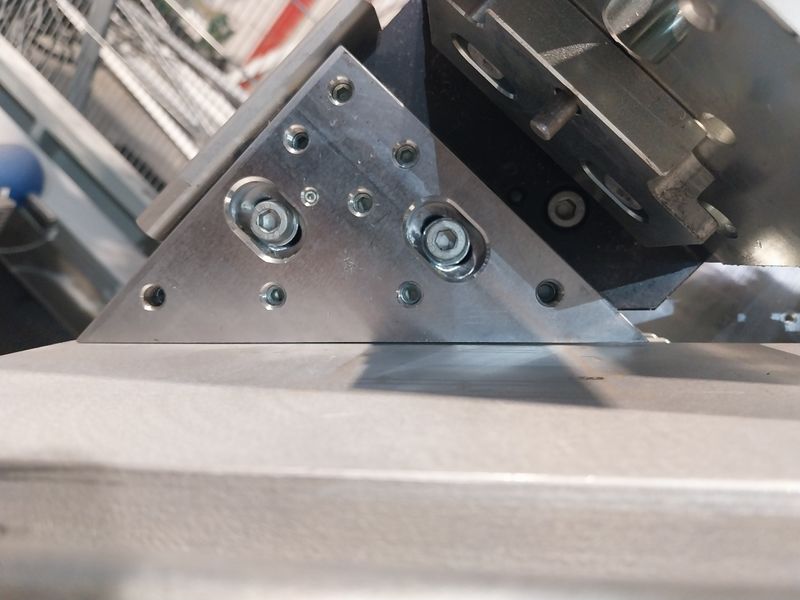

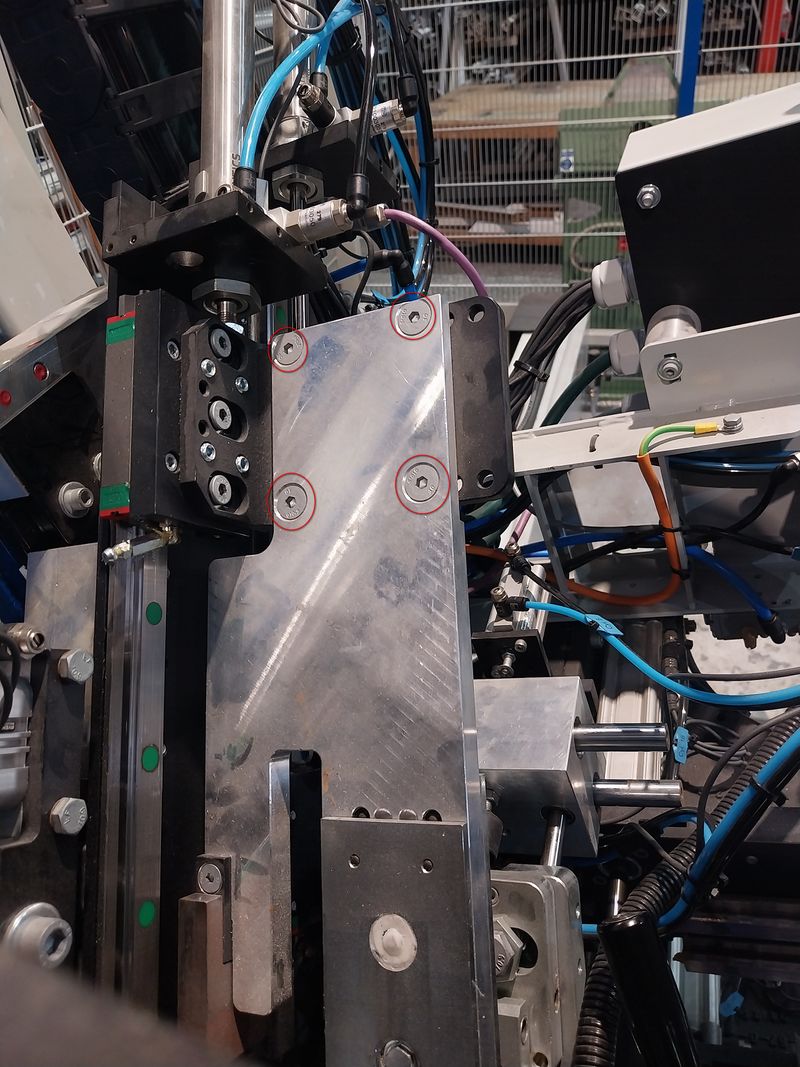

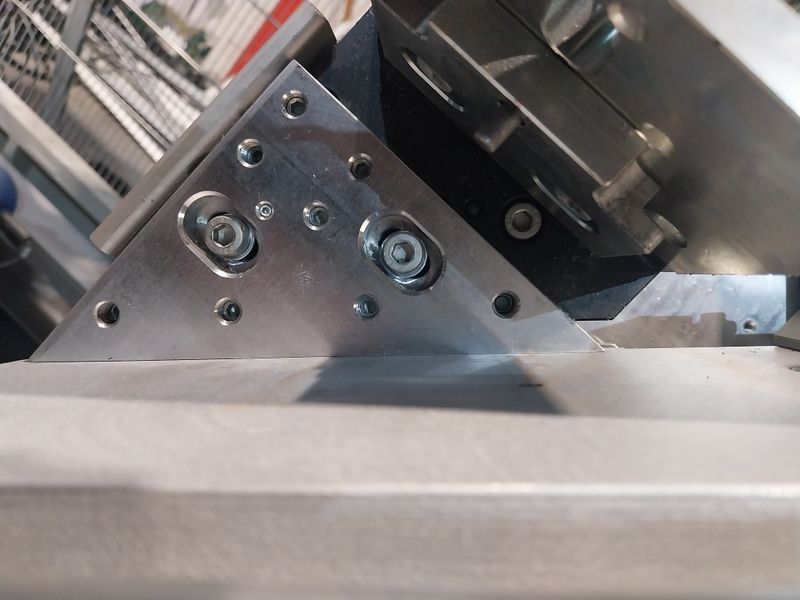

Remove the 4 CS Hex screws and remove the setting plate to get easy access to the adjusters.

- The adjusters highlighted in RED are for adjusting the plate side to side to change the angle.

- There is one on either side of the plate. Both locknuts need slackened off and then the adjustment screws turned in the same direction as each other ie, one in, and the other out. This will ensure they keep a tight grip on the plate.

- Adjust the angle of the heater plate until it aligns with the bed, and then tighten the lock nuts.

- The Grubscrews circled in GREEN are for adjusting the vertical plane of the plate to ensure they are square to the beds. This can be checked with an engineers square.

Étape 3 - Check Plate Is Centralised

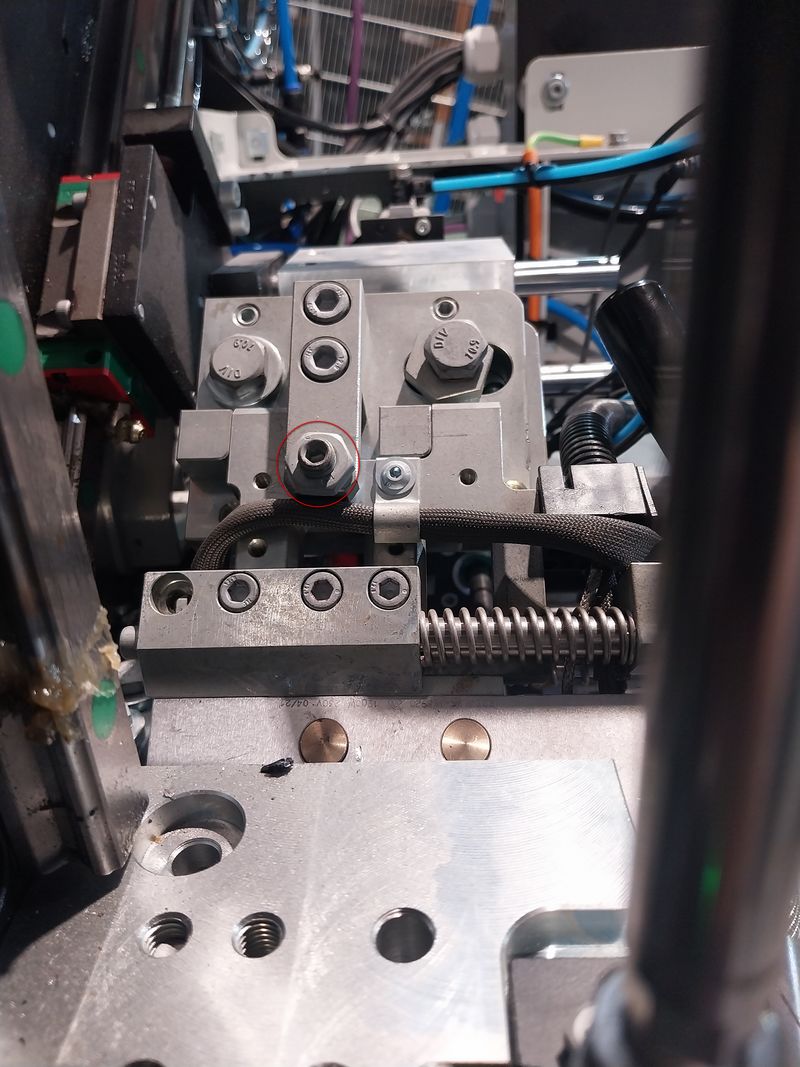

- In the I/O screen switch off "Melting". This will activate the cylinder that moves the heater plate from side to side.

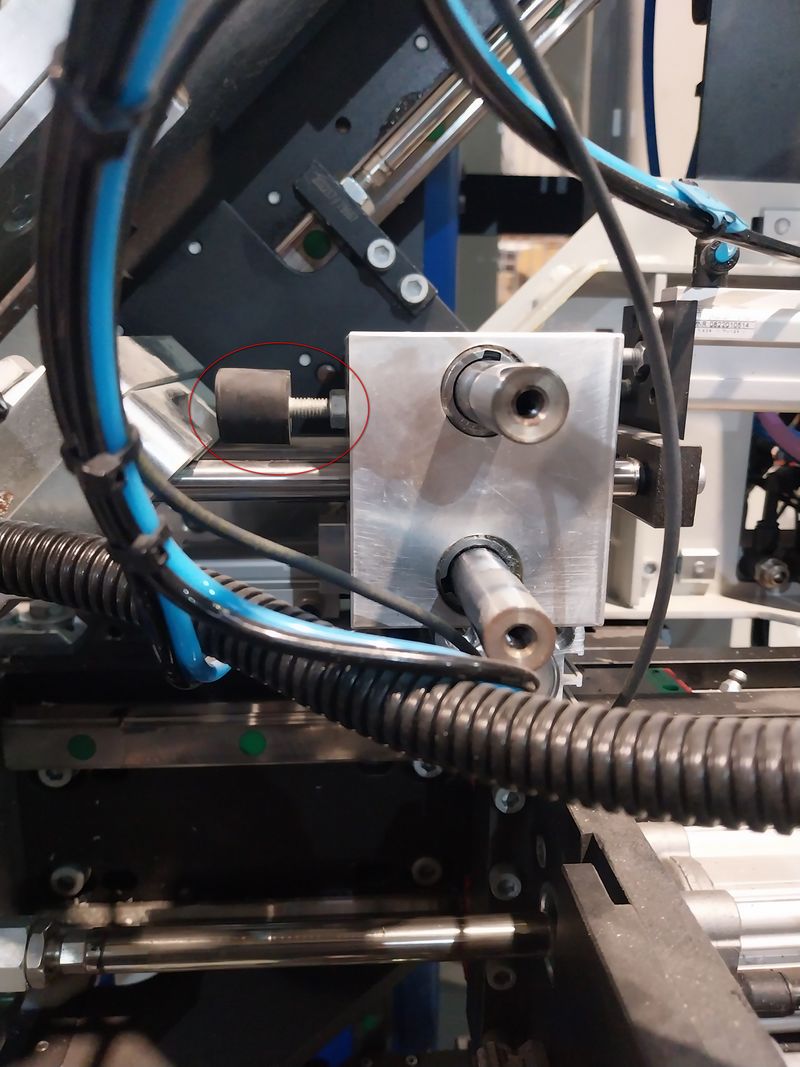

- Check to see if the plate is roughly centred. This is not critical to welding, it merely ensures that the plate doesn't catch on anything and rip the Teflon sheets when moving into position. This can be adjusted by screwing the rubber stop in or out.

- This cylinder is OFF during the welding process to allow the plate to centralise itself between the faces of the profile and give an equal amount of weld on each side

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português