Heater plates that are out of alignment can cause poor welds that can crack and fail. When addressing issues of poor welds, heater plate alignment should be one of the first checks carried out after checking temperatures.

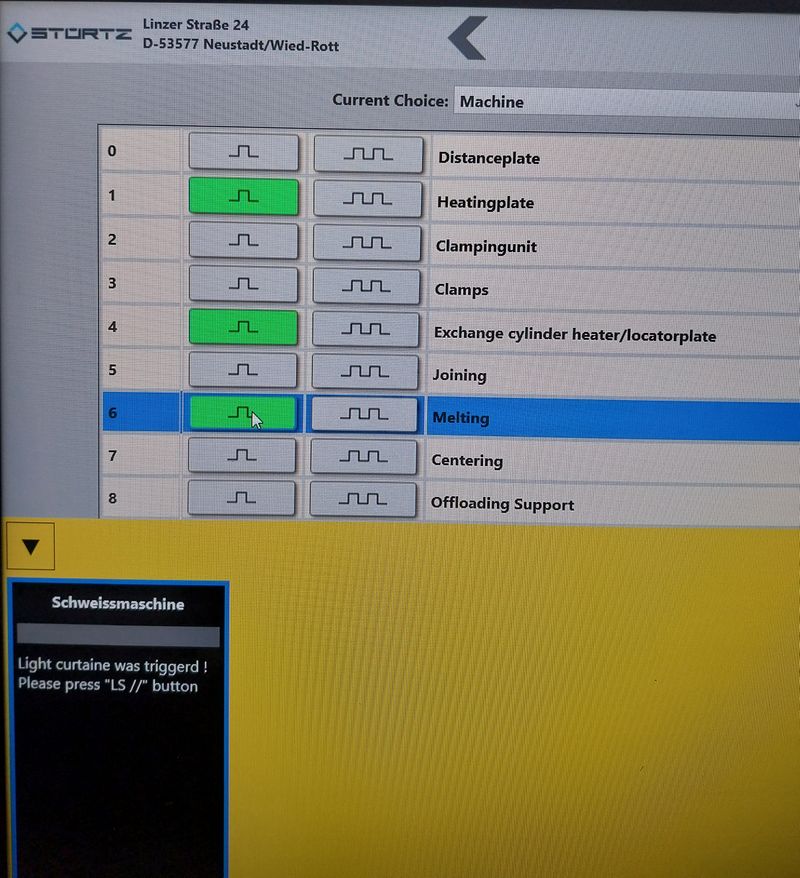

Étape 1 - Put Machine Into Input/Output Mode

First put the machine into input/output mode. This will then allow us to move the heater plates into a position to be worked on. Ensure the items highlighted in GREEN are on.

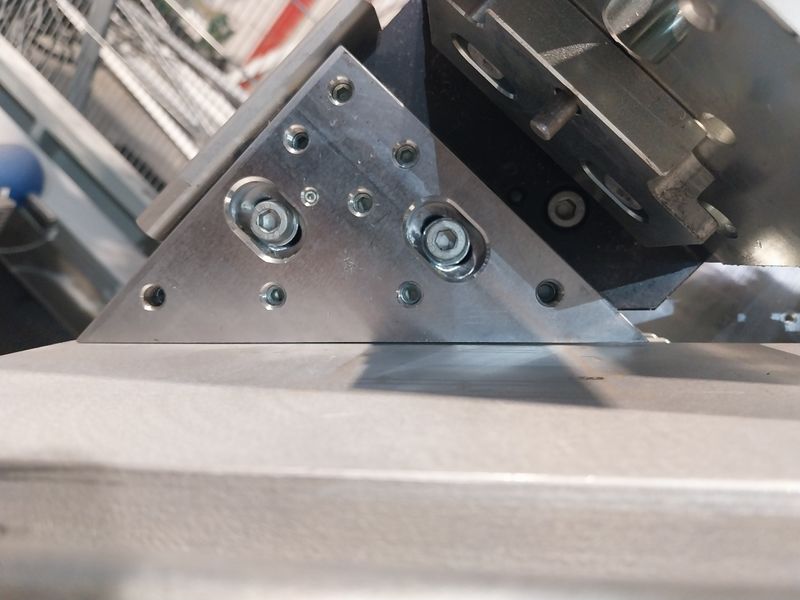

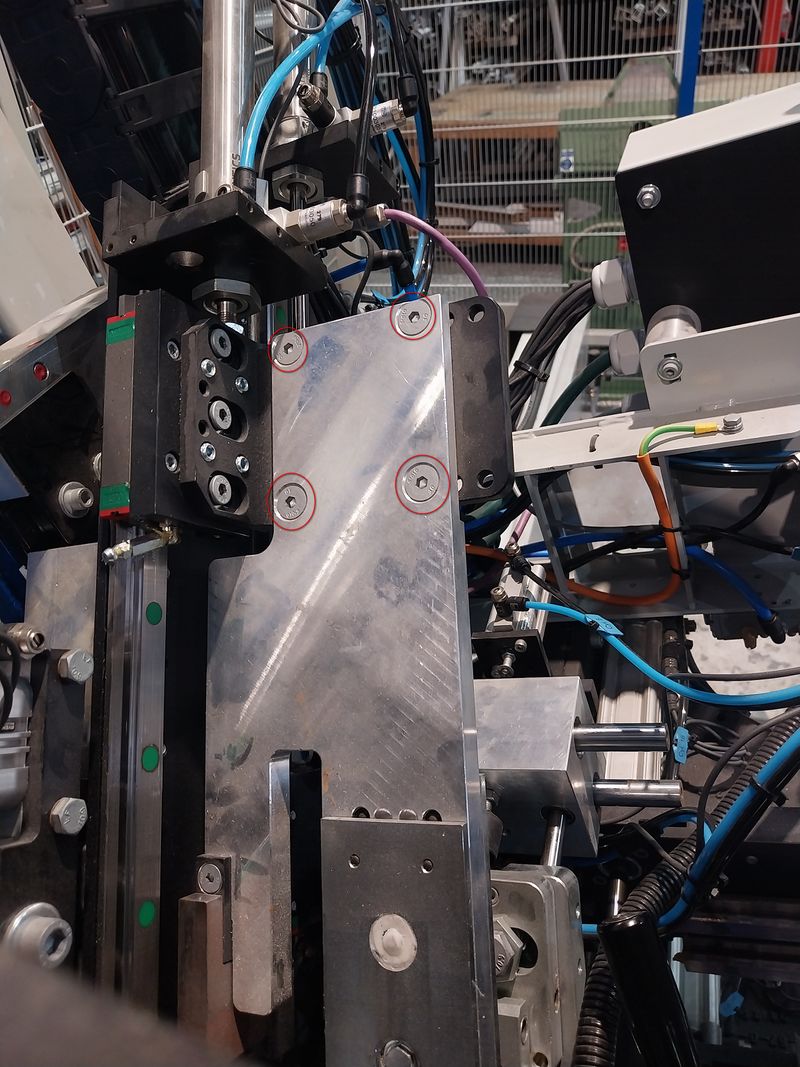

Étape 2 - Remove Setting Plate

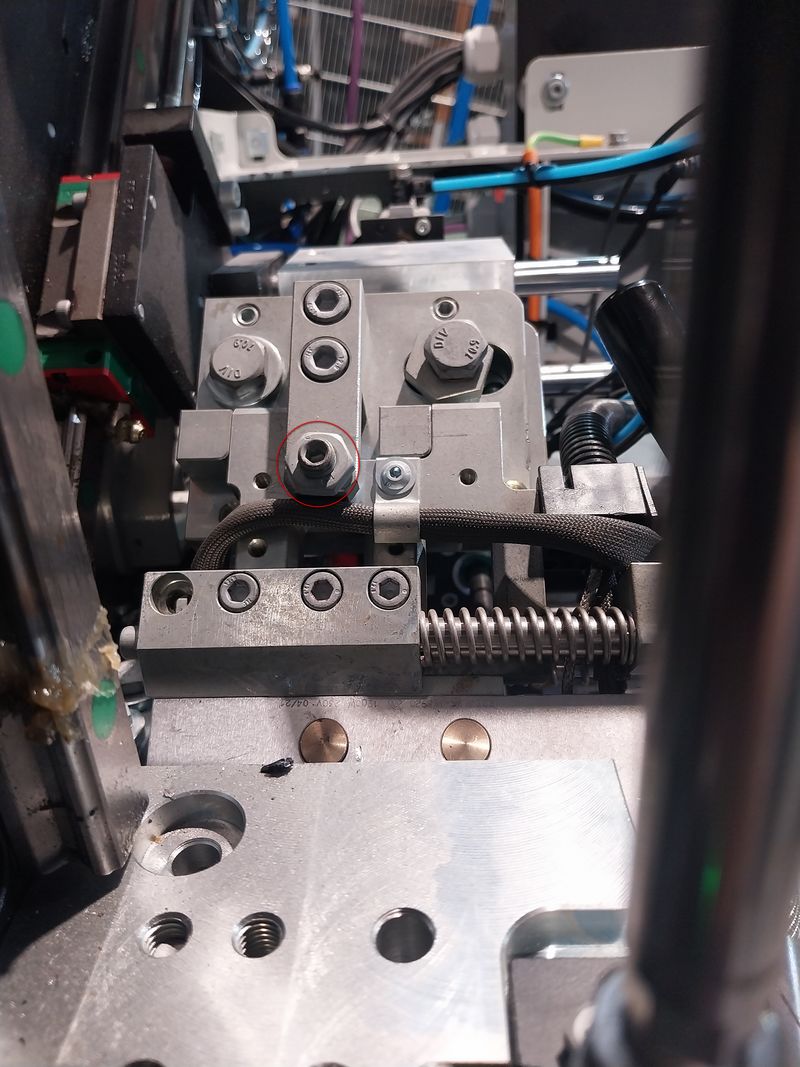

Remove the 4 CS Hex screws and remove the setting plate to get easy access to the adjusters. The adjusters highlighted in RED are for adjusting the plate side to side to change the angle. There is one on either side of the plate. Both locknuts need slackened off and then the adjustment screws turned in the same direction as eachother ie, one in, and the other out. This will ensure they keep a tight grip on the plate.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português