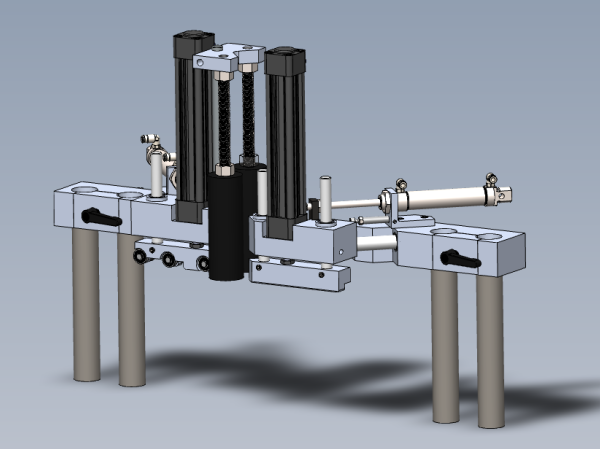

Details of bench assembly for saw clamps

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Fit bearings to 4 off blocks

- 4 Étape 3 - Assemble roller clamp

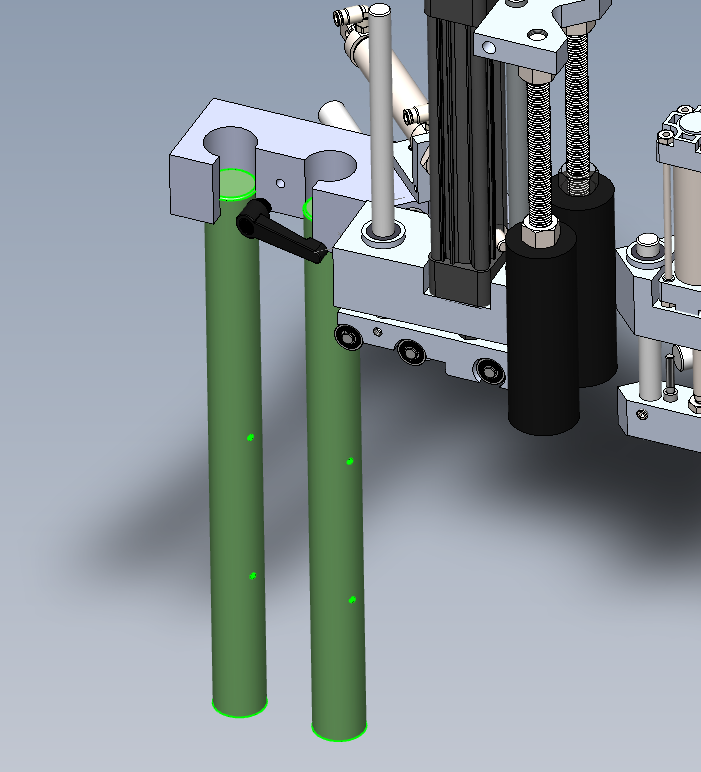

- 5 Étape 4 - Fit Shafts to clamp blocks

- 6 Étape 5 - Fit shafts to clamp heads

- 7 Étape 6 - Fit clamp heads to clamp mount blocks

- 8 Étape 7 - Assemble hard stop

- 9 Étape 8 - Assemble cylinders

- 10 Étape 9 - Fit cylinder and align

- 11 Étape 10 - Fit clamp blocks

- 12 Étape 11 - ~Check hard stops are fitted to clamp mounts

- 13 Étape 12 - Fit top clamp shafts

- 14 Étape 13 - Assemble deflector probe assembly

- 15 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

External circlip pliers

20mm bearing dolly

Reduced shank 5mm hex key

Parts Required

B0000033 Linear Bearing: Ø20 x 30 Compact (Metal Case Only) x 8

B0000034 Linear Bearing: Ø16 x 30 Compact (Metal Case Only) x 8

B0000200 Circlip 8mm External x 12

B0000346 Ball Bearing 8 D 22 D 7 Long + seals x 6

D0004331 Clamp Head (D7450) x 1

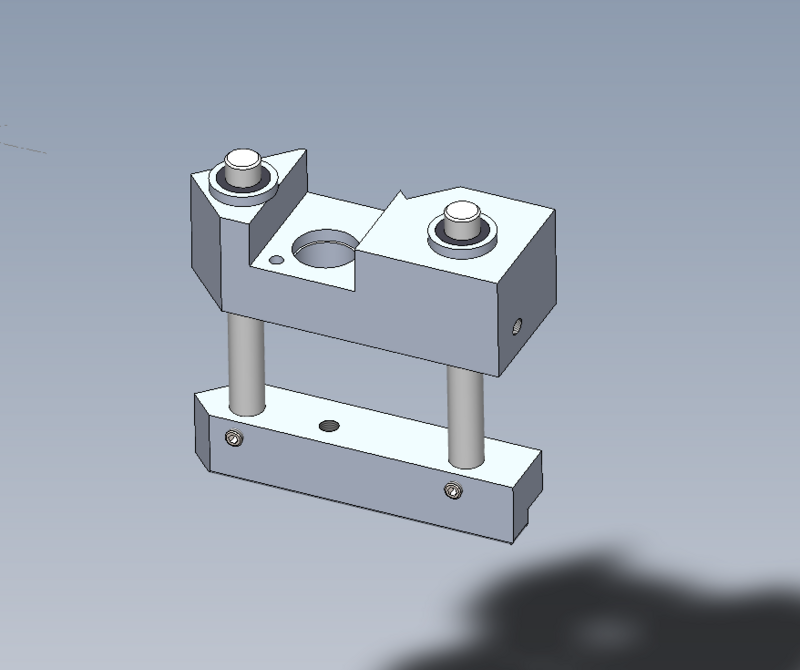

D0004332 Clamp Mount Block (D7449) x 1

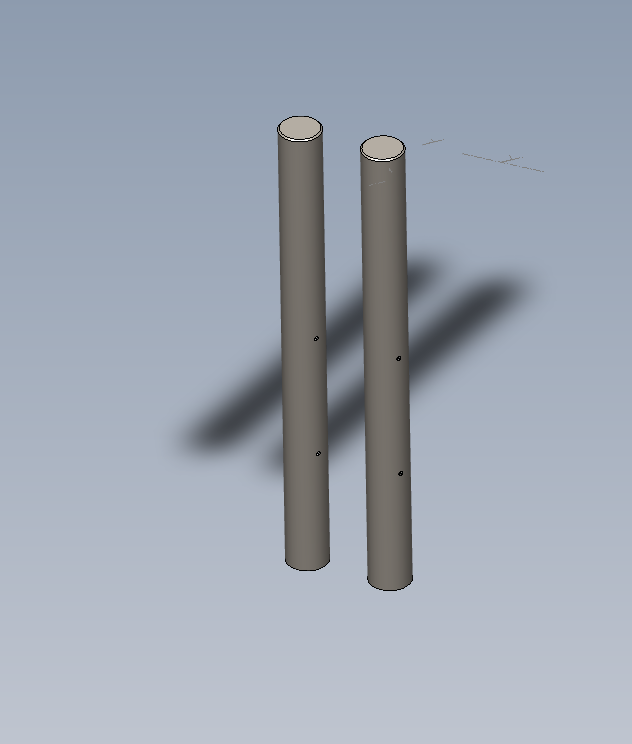

D0004333 Pillar x 2

D0004358 Clamp Head Bracket (D7447) x 1

D0004359 Clamp Head Cylinder Bar (D7446) x 2

D0004550 Clamp Insert x 2

D0004808 Slide Stop x 2

D0005191 Bearing Protective Washer x 4

D0005425 Clamp block Right (5625) x 1

D0005566 Clamp block left - Roller style (5567) x 1

D0005568 Clamp block left roller shaft x 3

D0007447 Clamp Head Bracket OH (D4358) x 1

D0007449 Clamp Mount Block OH (D4332) x 1

D0007450 Clamp Head OH (D4331) x 1

D0015266 Shaft 38.7mm: 440mm ZX Saw Top Clamp BZP x 2

D0015299 Shaft 16mm: 320mm Chip Deflector ZX5 x 1

D0015446B Chip Deflector Mounting Plate (Tapped) x 1

D0015447B Chip Deflector Probe Ø50 (Tapped) x 2

D0015454 Chip Deflector Rod (M16) x 2

H0004625 Shaft 16mm: 150 Saw Clamp x 2

H0004626 Shaft 16mm: 275 Eject Push x 1

H0004627 Shaft 20mm: 210 Saw Inner Clamp x 2

H0004628 Shaft 20mm: 245 Saw Outer clampx 2

M0001194 Kipp clamp handle x 2

P0000007 Straight Adaptor 6mm - 1/8 BSP tapered thread x 1

P0000054 Cylinder Ø32 x 50 (PIS32A50) x 1

P0000064 Pneumax microcylinder 25bore x 80stroke x 2

P0000295 Elbow Adaptor 6mm - 1/8 BSPT (Metal type) x 3

P0001143 cylinder 32 x 175mm stroke ISO x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

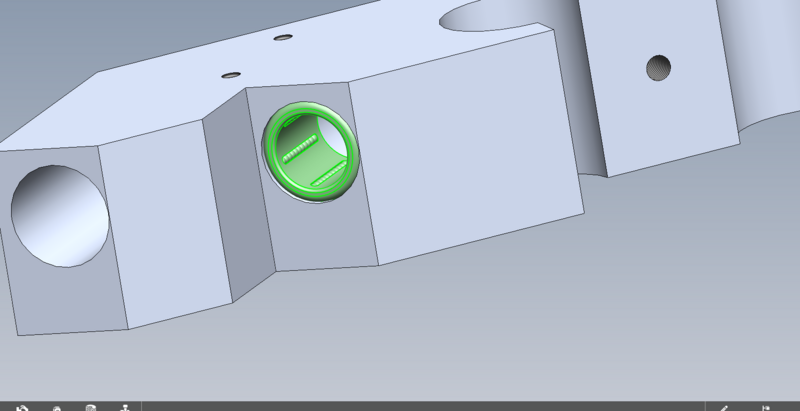

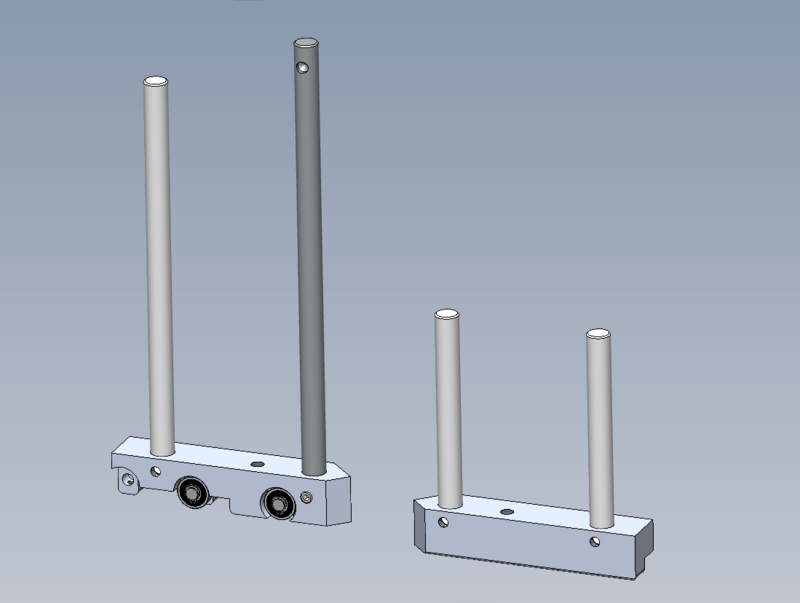

Étape 2 - Fit bearings to 4 off blocks

fit bearings to 4 off blocks

Use bearing dolly where required

Top clamp cylinder blocks and position blocks

Fit retainer rings

Ensure all bearings are adequately greased once fitted

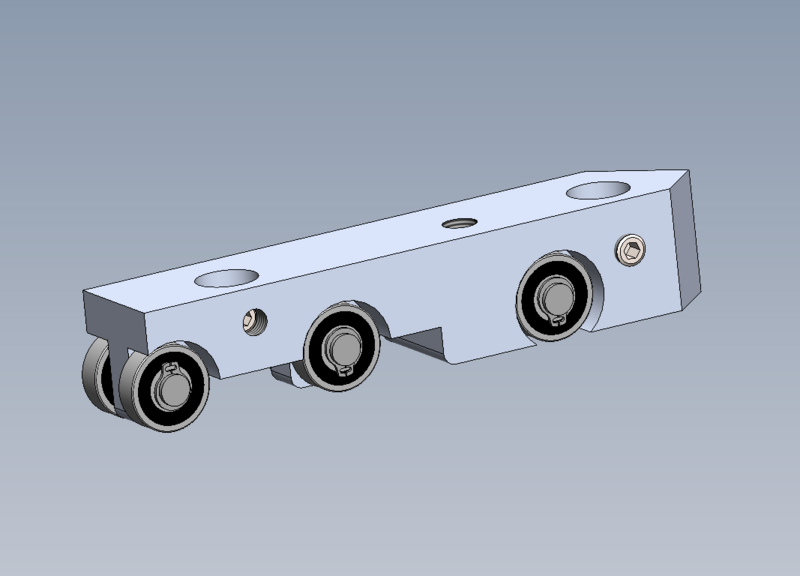

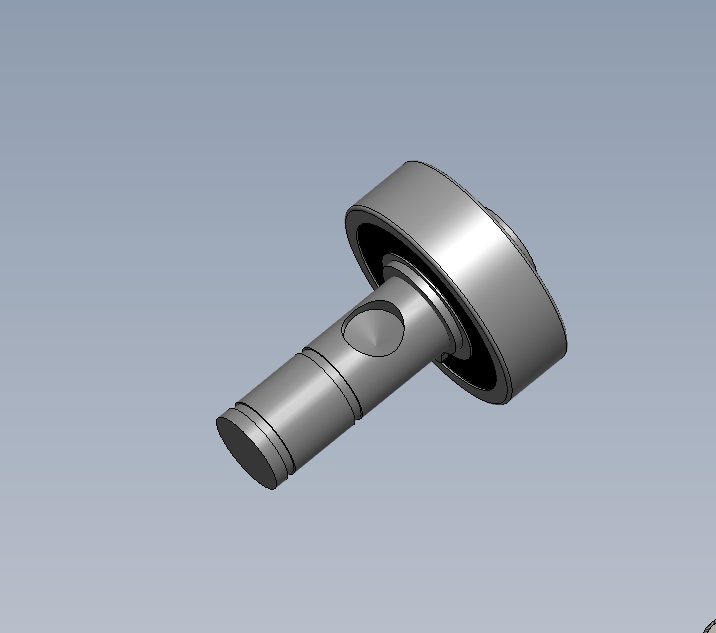

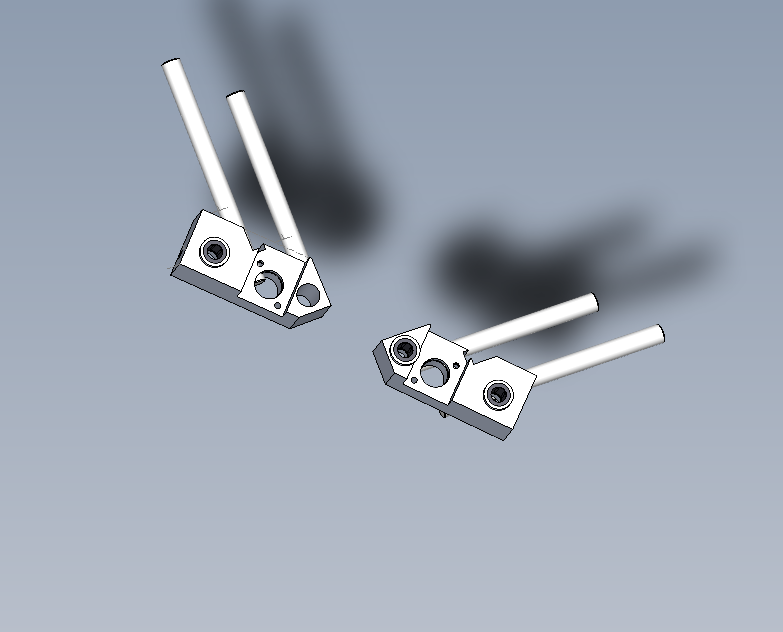

Étape 3 - Assemble roller clamp

Fit circlip to shafts

Fit bearing to shaft

Fit circlip

Fit to roller clamp block

Fit 2nd bearing

Fit circlip

Fit grubscrew

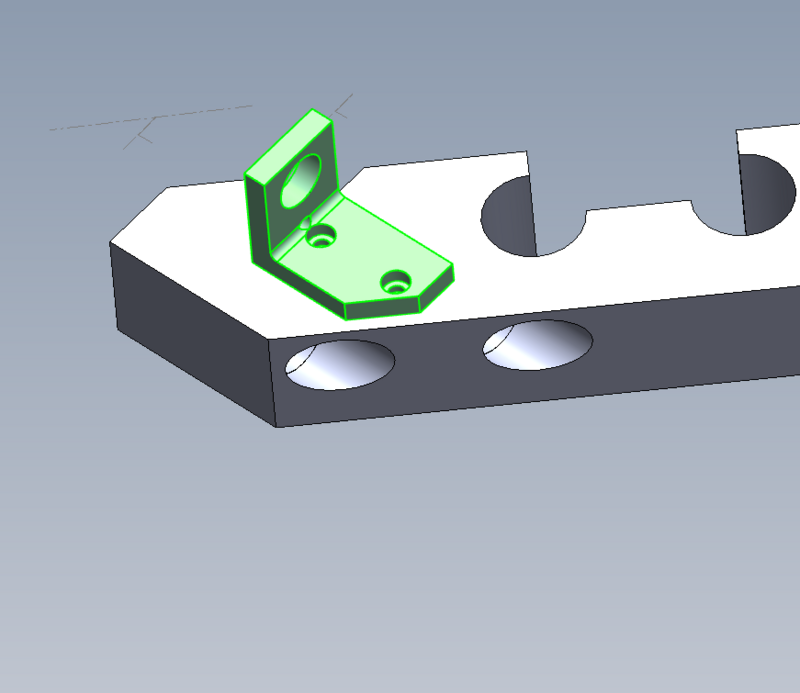

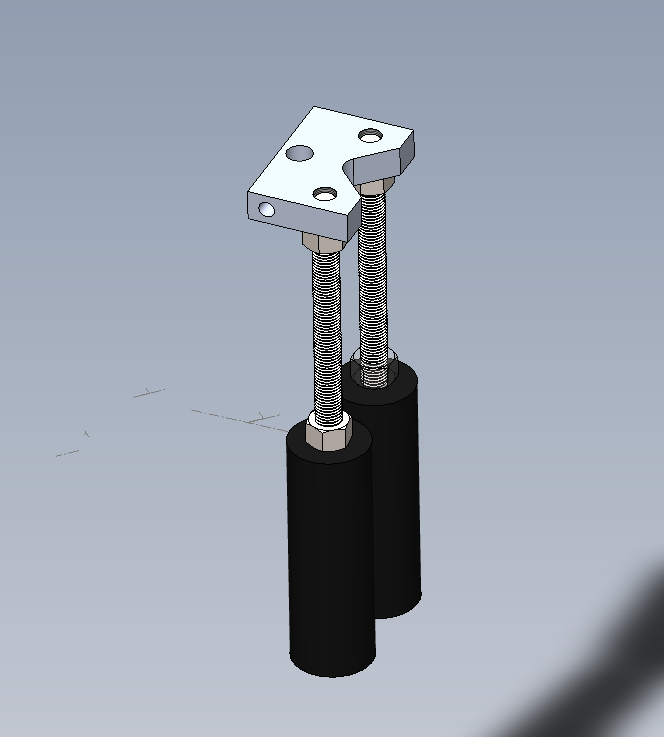

Étape 7 - Assemble hard stop

Assemble hard stops 2 off

Set to 50mm O/A

attach to cylinder mount bracket

Étape 8 - Assemble cylinders

fit 4 of P0000295 fittings to position cylinders

Fit 3 off P0000295 fittings to top clamp cylinders and 1 off straight P0000007

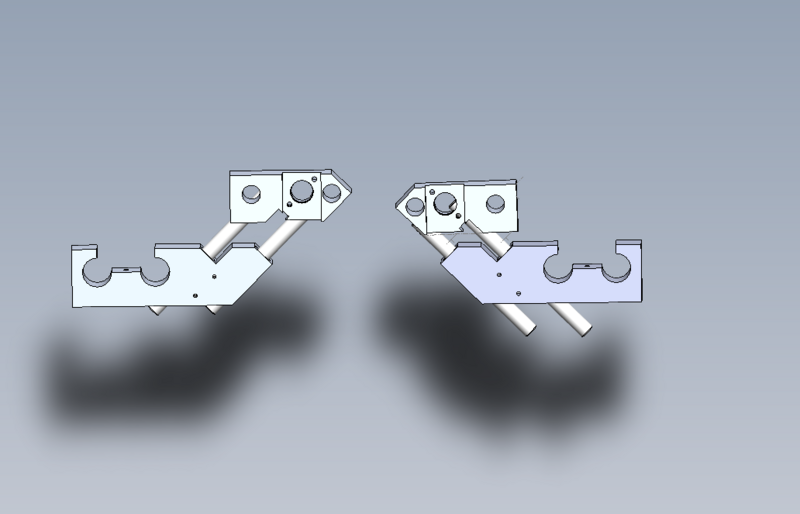

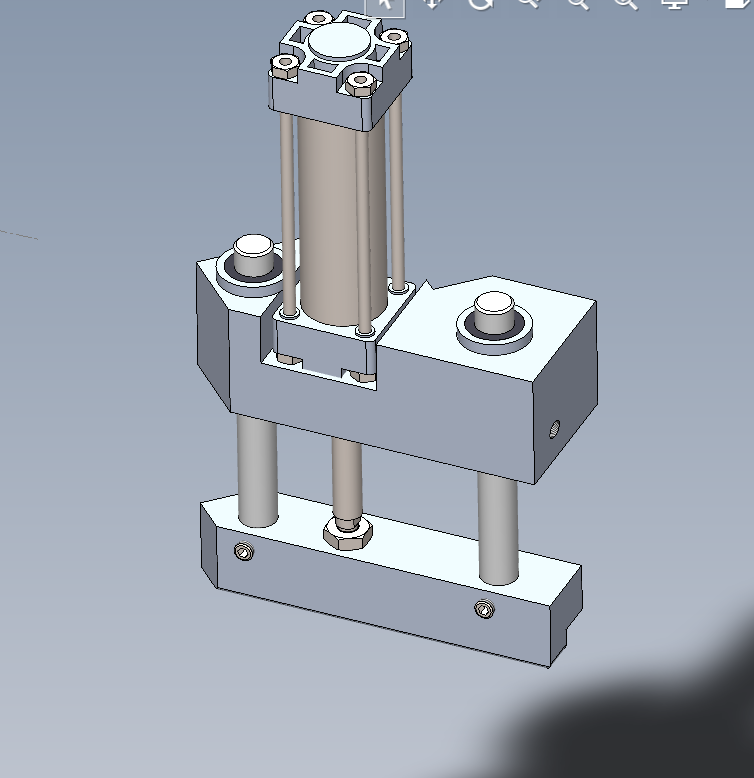

Étape 9 - Fit cylinder and align

Fit cylinder mount bracket to head

Fit cylinder mount plate to clamp head block

Fit cylinder to bracket

Contract cylinder and tension fixing points

ensure cylinder piston thread and nut are correct

Étape 10 - Fit clamp blocks

Fit pre build clamp pad assembly

Attach cylinder

Align and finalise cylinder fasteners

ensure cylinder piston thread is set correctly

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português