Bench assembly details for R axis limit stop

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Fit bushes

- 4 Étape 3 - Assemble damper stop housings

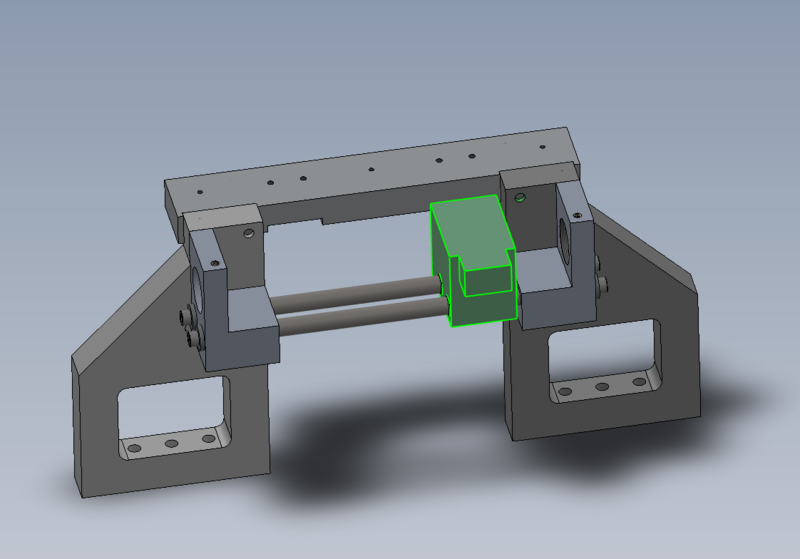

- 5 Étape 4 - Insert shafts and slide finger

- 6 Étape 5 - Fit Cross joiner

- 7 Étape 6 - Fix shafts

- 8 Étape 7 - Quality check

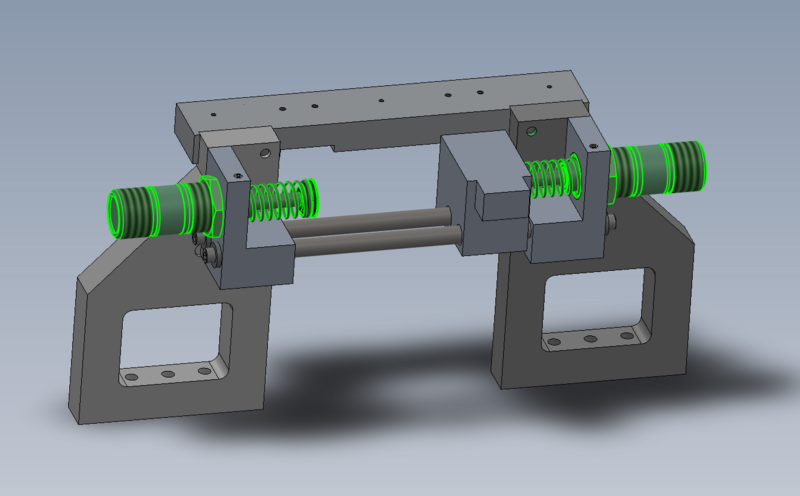

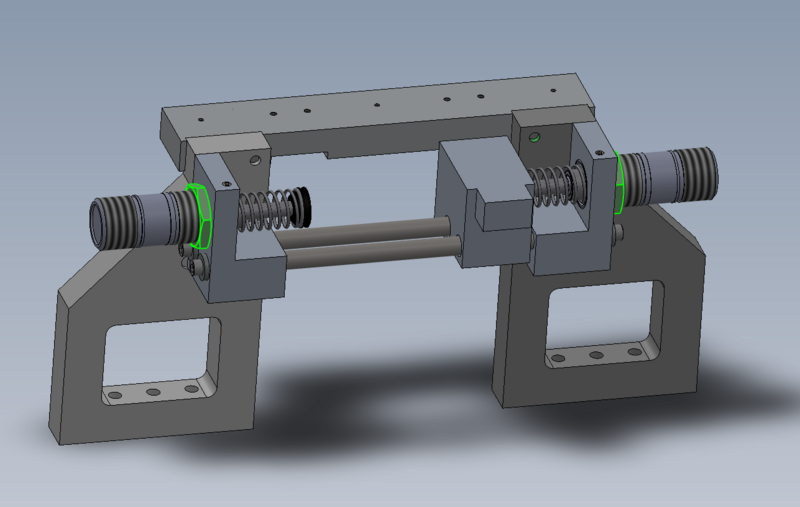

- 9 Étape 8 - Fit dampers

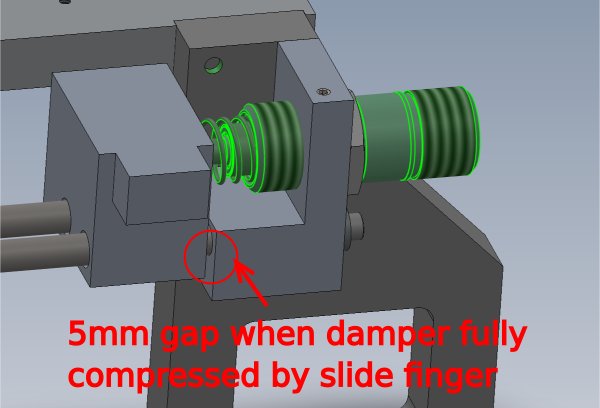

- 10 Étape 9 - Damper setting

- 11 Étape 10 - Fix datum sensor block

- 12 Étape 11 - Set Sensor

- 13 Étape 12 - Ensure all bolts are finalised

- 14 Commentaires

Introduction

Tools Required

Standard hex key set

38mm spanner

Parts Required

B0000122 Glacier Bush 12 D 14 D 15 Long x 4

D0007454 Stop Sub Base OH (D8377) x 1

D0007455 Stop Damper Housing OH (D8378) x 1

D0008377 Stop Sub Base (D7454) x 1

D0008378 Stop Damper Housing (D7455) x 1

D0008380E Stop Slide Finger ZX4 Mk5 x 1

D0008383 Cross Joiner x 1

D0010756 Proximity Switch Mounting Block Reduced Size x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 1

H0008379 Shaft 12mm: 263mm R Axis Limit Stainless x 2

P0000235 MC Series self compensating Damper x 2

Étape 1 - Unless otherwise stated

All bolts must have Loctite 243 adhesive applied unless otherwise stated.

All bolts must be marked with pen once completed to indicate adhesive and correct tension has been applied

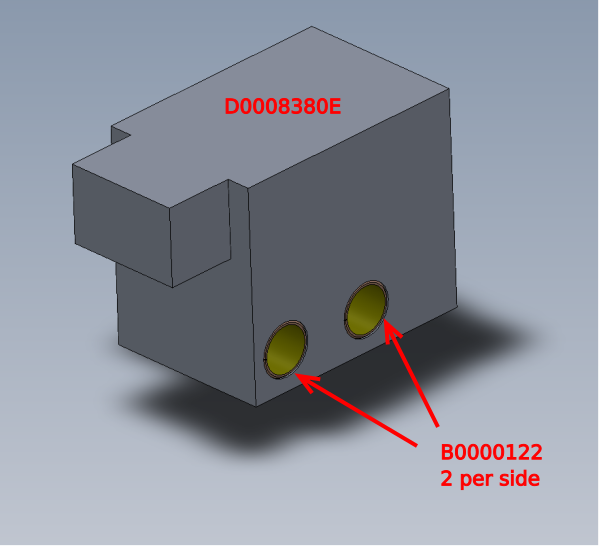

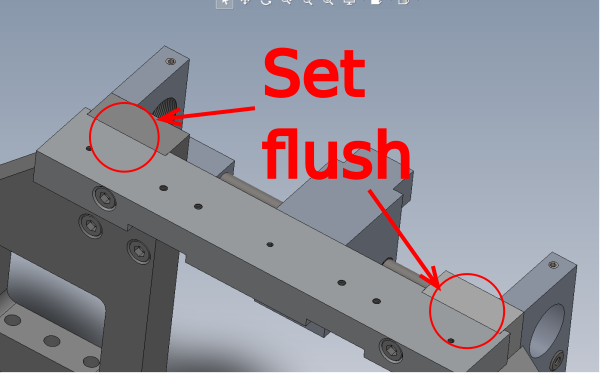

Étape 2 - Fit bushes

Fit 4 off B0000122 bushes to block D0008380E as shown

Bushes must be pushed flush to face

Check internal diameter of bushes once fitted by using 1 off H0008379 Shaft 12mm

If fit is tight, use 12mm hand reamer to clean bore to 12mm

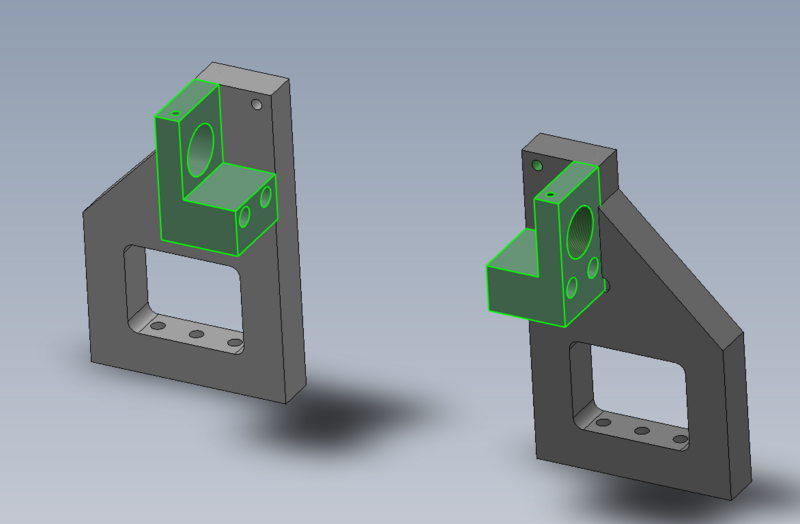

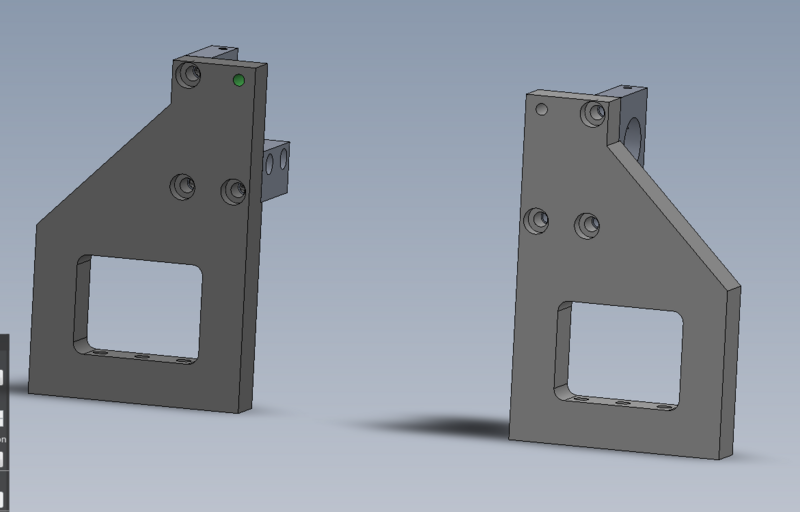

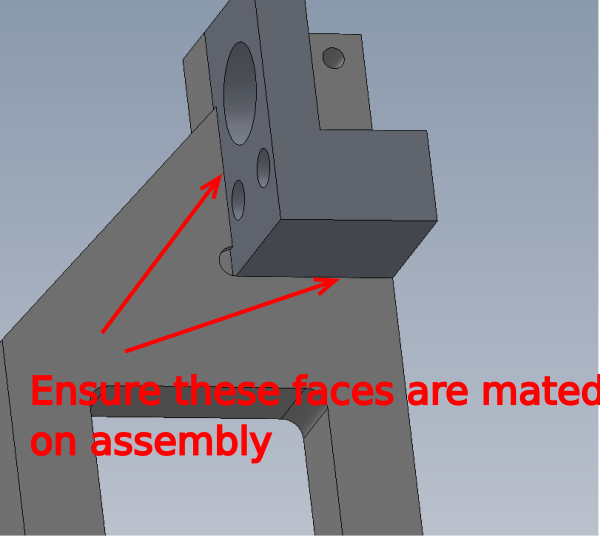

Étape 3 - Assemble damper stop housings

Use 6 off M8 x 30 socket caps to fix

D0007455 Stop Damper Housing OH to D0007454 Stop Sub Base OH

D0008378 Stop Damper Housing to D0008377 Stop Sub Base

Ensure indicated faces are mated together on assembly

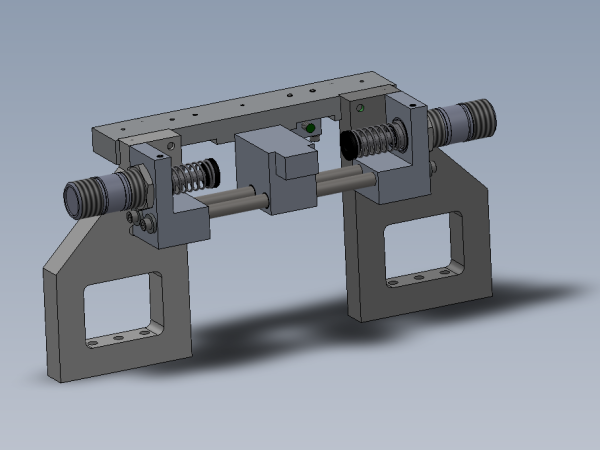

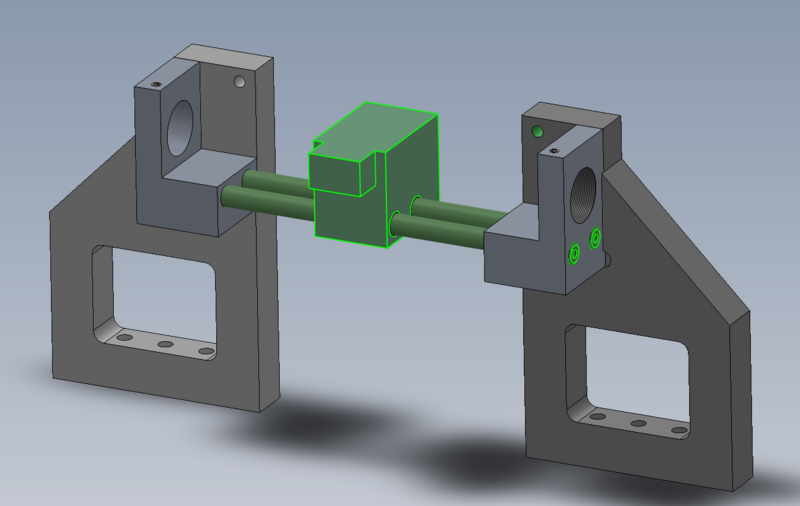

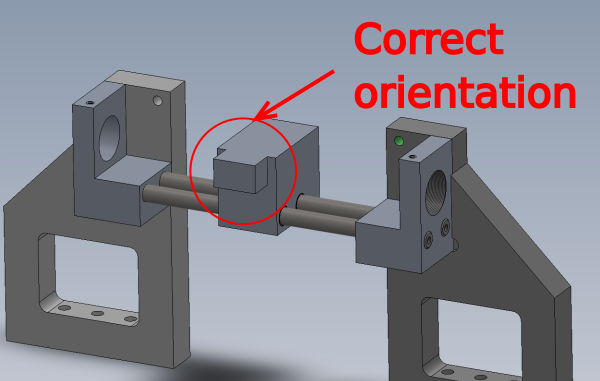

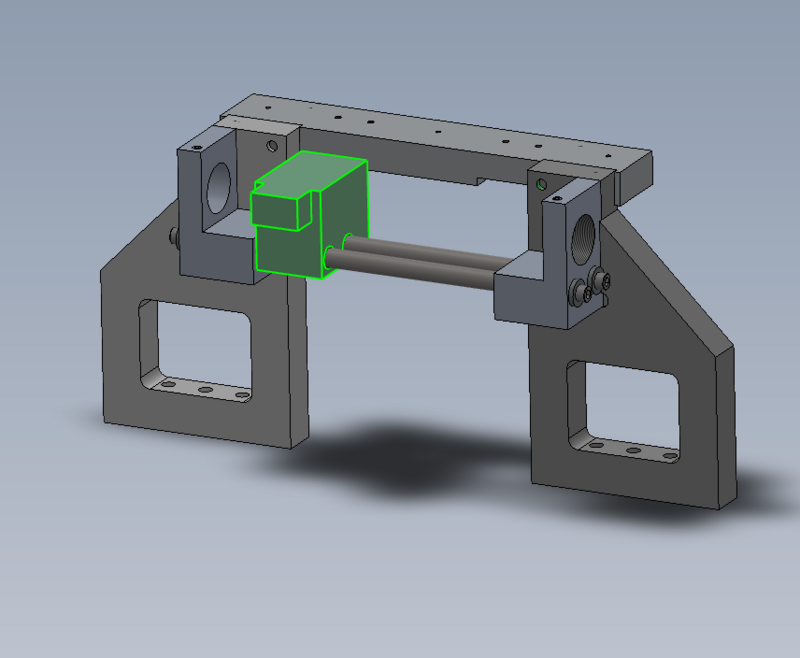

Étape 4 - Insert shafts and slide finger

Assemble as shown 2 off H0008379 Shaft 12mm: 263mm R Axis Limit Stainless x 2 and pre assembled slide finger block

Do not add fixings yet

Ensure slide finger is orientated the correct way

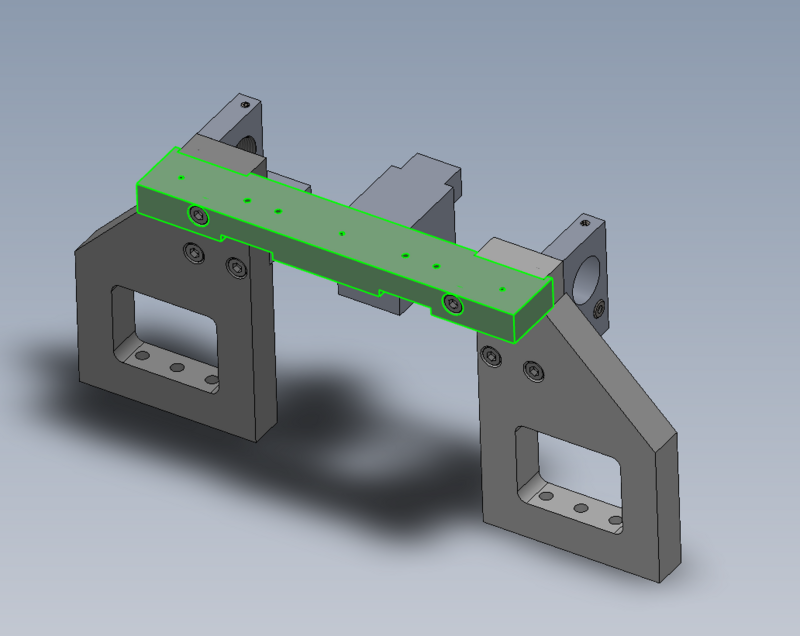

Étape 5 - Fit Cross joiner

Use 2 off M8 x 50 socket caps to fit D0008383 Cross Joiner as shown

Ensure indicated faces are set flush

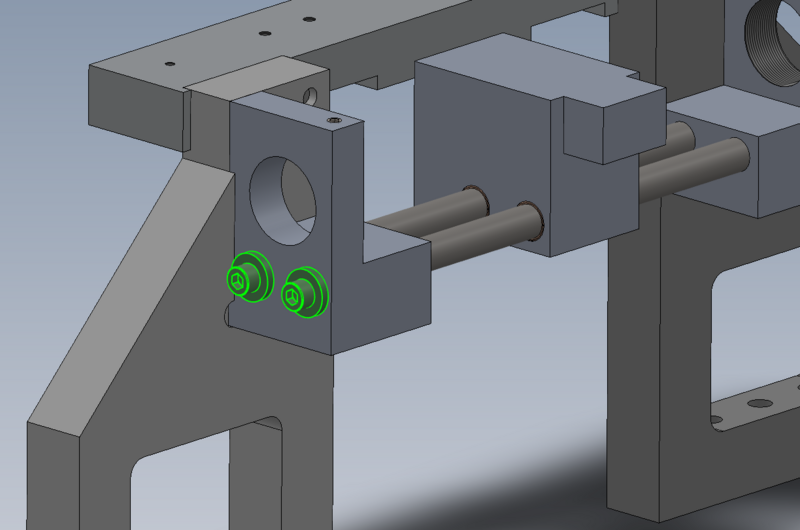

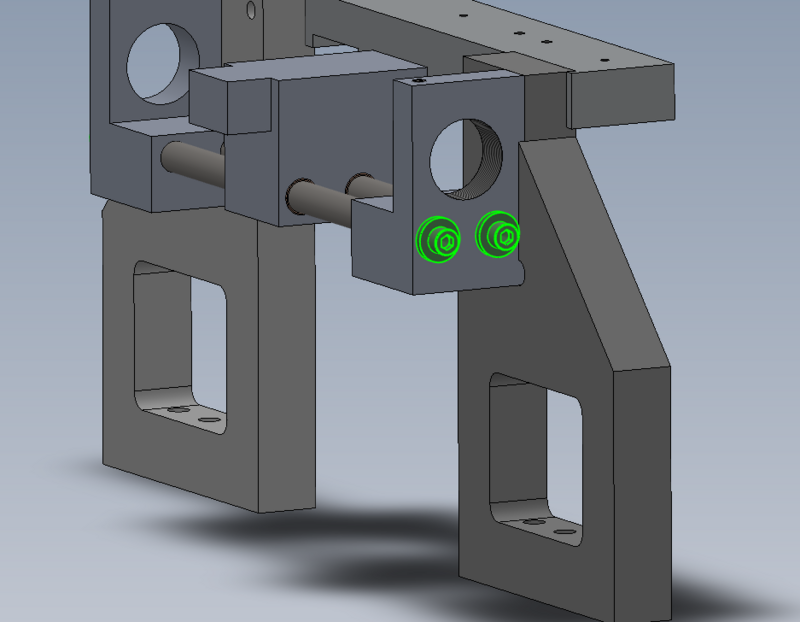

Étape 6 - Fix shafts

Use 4 off M6 x 16 socket caps and heavy M6 washers to fix shafts as shown

Note, slight shaft float will be present, this is normal

Étape 9 - Damper setting

Set dampers to the following spec

With damper fully compressed, a 5mm gap should be present at the indicated point

Set both sides to the same setting

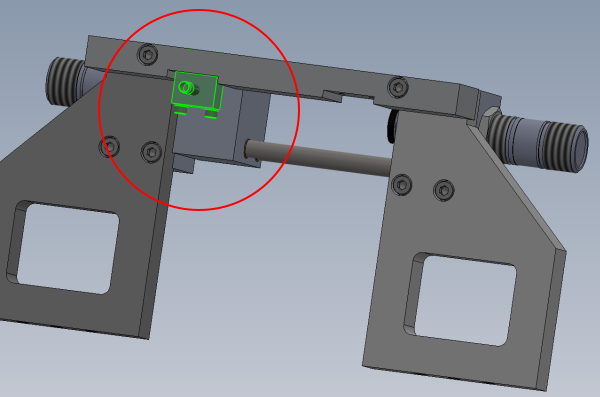

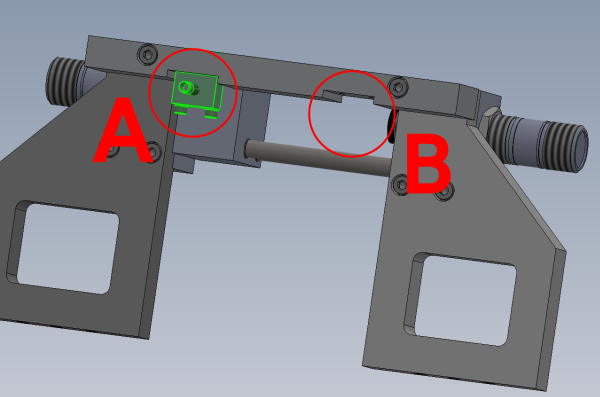

Étape 10 - Fix datum sensor block

Orientation

For R-L machines fit to point A

For L-R machines fit to point B

Use 2 off M5 x 40 socket caps with A form washers to secure D0010756 Proximity Switch Mounting Block as shown

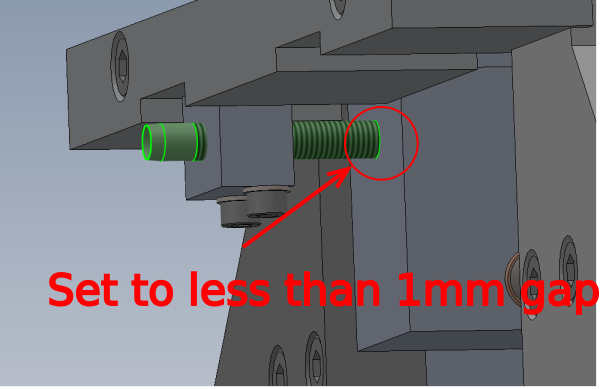

Étape 11 - Set Sensor

Adjust sensor to read indicated face.

Set gap to -1mm

Ensure sensor lock nut is not over tighten when finalising

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português