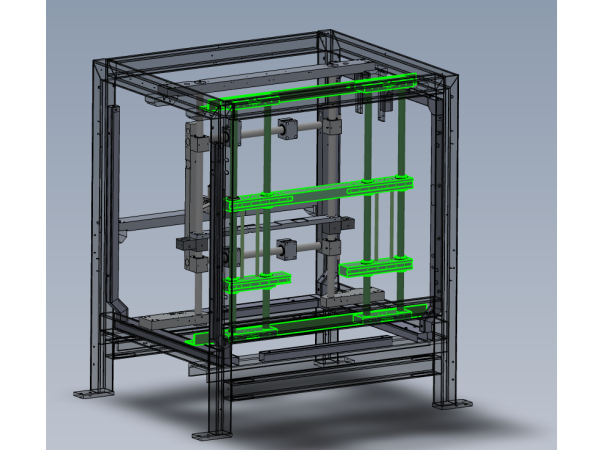

Installation criteria for V notch sub frame

Introduction

Tools Required

Standard hex key set

Standard Spanner set

Parallel setting blocks

600mm rule

1 meter straight edge

2 meter straight edge

12 " engineers level

12" engineers square

Parts Required

D0015151 Shaft End Washer x 8

D0015155 Vertical Spacer Bar x 4

D0015150 shaft 40mm zx v notch x 4

R0015035 Bench Assemble V Notch ComponentsÉtape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

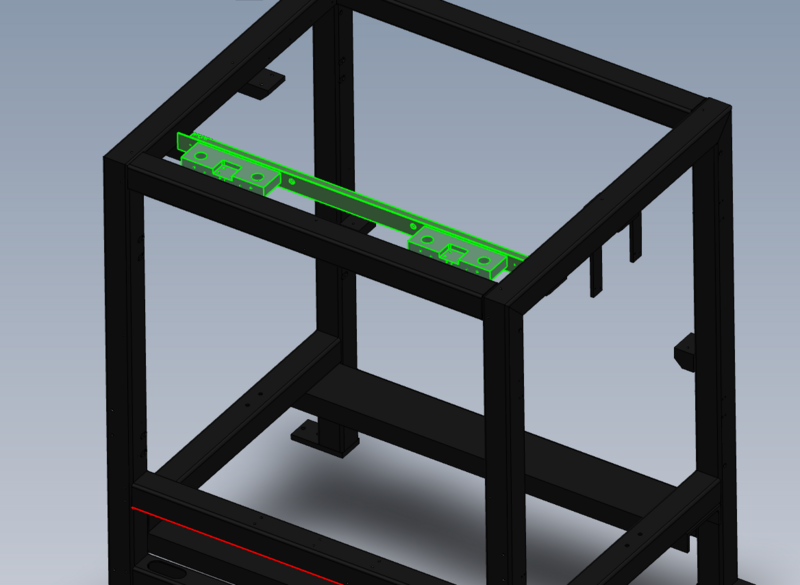

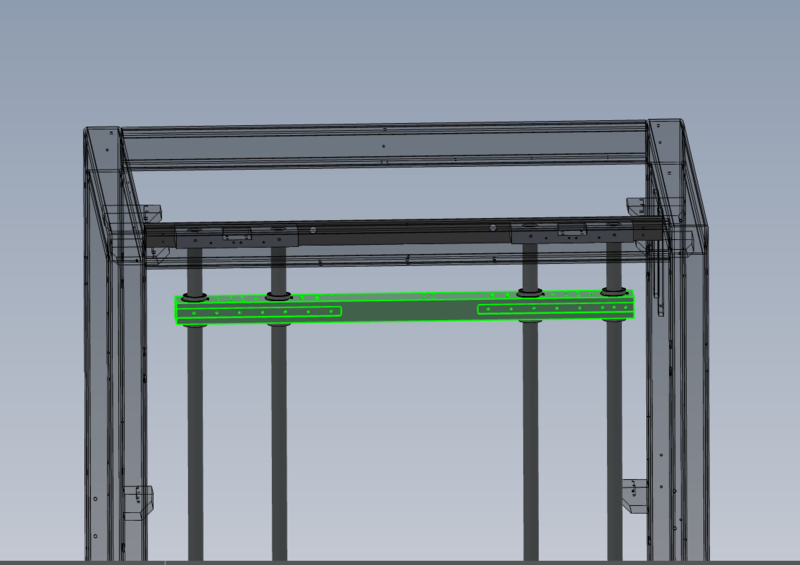

Étape 2 - Install top Mount

Position top mount as shown

1 Use 4 off M12 x 25 socket caps and A form washers to lightly fix in position

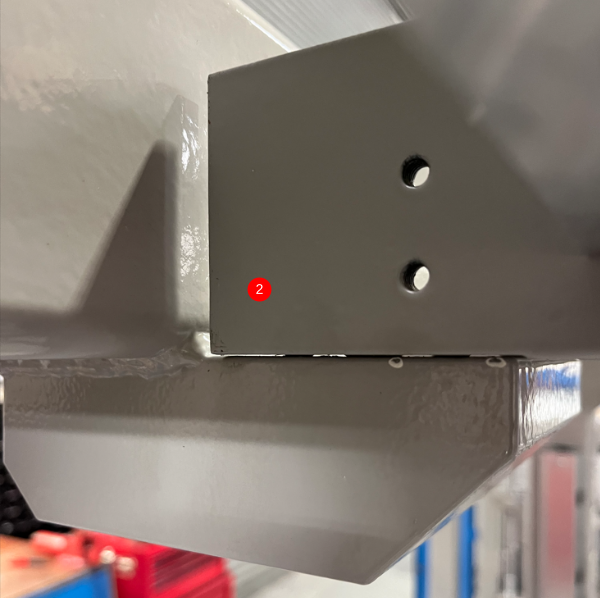

2 Adjust 8 off M10 grubscrews to lift mount approximately 1mm from face of mounting block

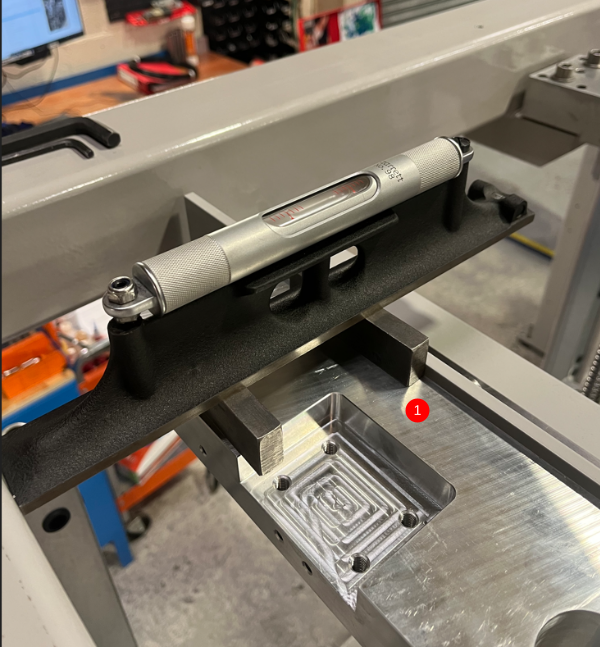

Étape 3 - Level top mount

1 Level X axis on both ends as shown using parallels and engineers level , Use M10 grubscrews to adjust

2 Level Y axis as shown , using 1 meter straight edge and parallels. Use M10 grubscrews to adjust

3 Ensure M12 socket caps are tight and recheck levels once set

Étape 4 - Fit shafts

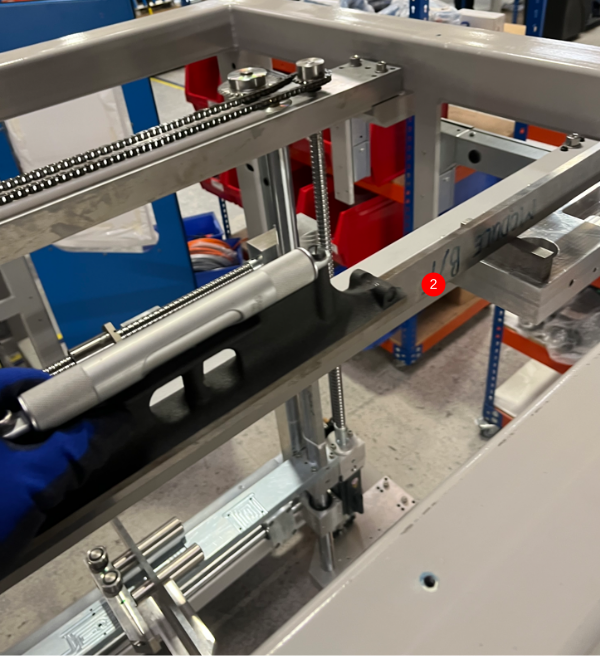

1 Fit 4 off D0015150 shaft 40mm zx v notch as shown , shafts must be staggered as shown

2 Captivate in position with M8 x 12 flat grubscrews in top mount blocks

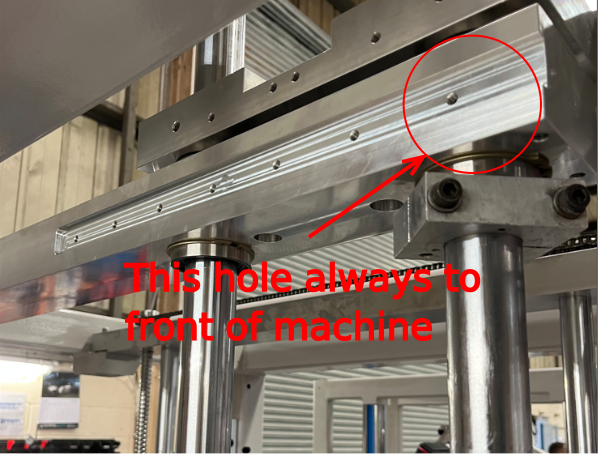

Étape 5 - Add top bearing block

Fit top bearing block as shown.

See photos for orientation

Fit shaft clamp to 1 off shaft to hold bearing block in position

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português