| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 141 : | Ligne 141 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

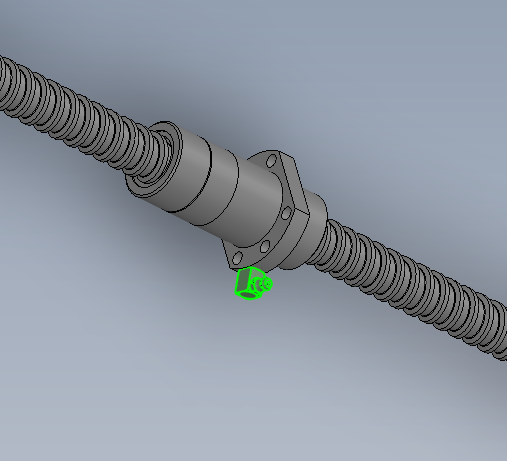

| − | |Step_Title=<translate>Fit Grease nipple</translate> | + | |Step_Title=<translate>Fit Grease nipple and check nut orientation n</translate> |

| − | |Step_Content=<translate>Fit B0000236 90 Deg Grease Nipple M6 ST/ST x 1 as shown</translate> | + | |Step_Content=<translate>Fit B0000236 90 Deg Grease Nipple M6 ST/ST x 1 as shown |

| + | |||

| + | |||

| + | Check Leadscrew nut is orientated correctly , rotate using leadscrew jig if incorrectly orientated</translate> | ||

|Step_Picture_00=R0000962E_Bench_assemble_Y_axis_Components_Screenshot_2023-07-18_104121.png | |Step_Picture_00=R0000962E_Bench_assemble_Y_axis_Components_Screenshot_2023-07-18_104121.png | ||

}} | }} | ||

Version du 18 septembre 2023 à 12:10

Instructions for assembling components

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Check fit of D0001926

- 4 Étape 3 - Fit bearing

- 5 Étape 4 - Tension drive coupling

- 6 Étape 5 - Finalise

- 7 Étape 6 - Check fit of leadscrew to coupling

- 8 Étape 7 - Check bearing fit

- 9 Étape 8 - Fit Grease nipple and check nut orientation n

- 10 Commentaires

Introduction

Tools Required

Standard hex key set

Fine emery tape

solvent

Standard drill set

Parts Required

B0000086 Ball Bearing 15 D 32 D 9 Long + seals x 2

B0000139 Double Angular Bearing 20 D 47 D 20.6 Long + seals x 1

B0000236 90 Deg Grease Nipple M6 ST/ST x 1

C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

D0001926 Servo Drive Coupling M20 (Ø14mm) Beckhoff x 1

D0006488 Y Leadscrew Sleeve x 1

H0007789 Y Leadscrew x 1

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Check fit of D0001926

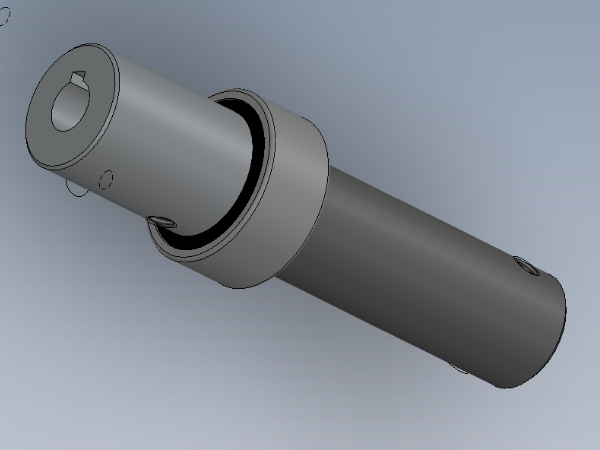

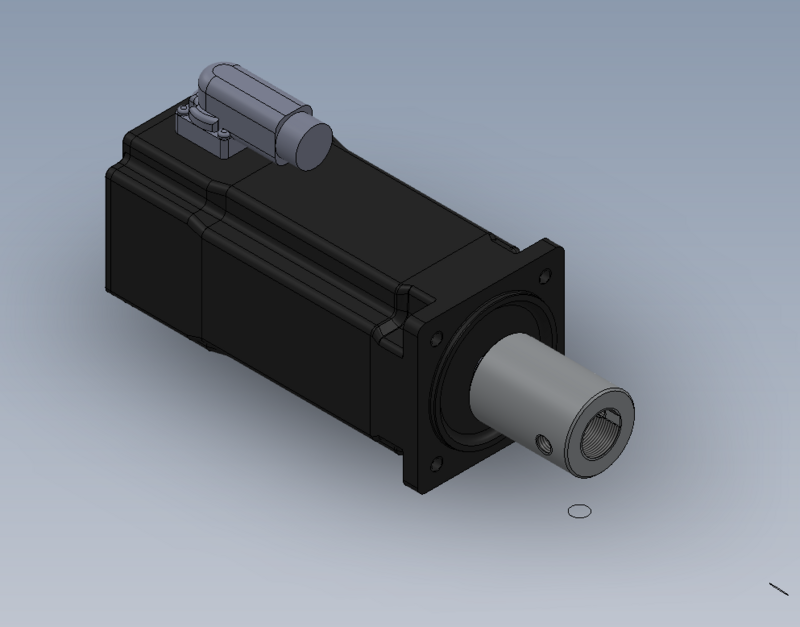

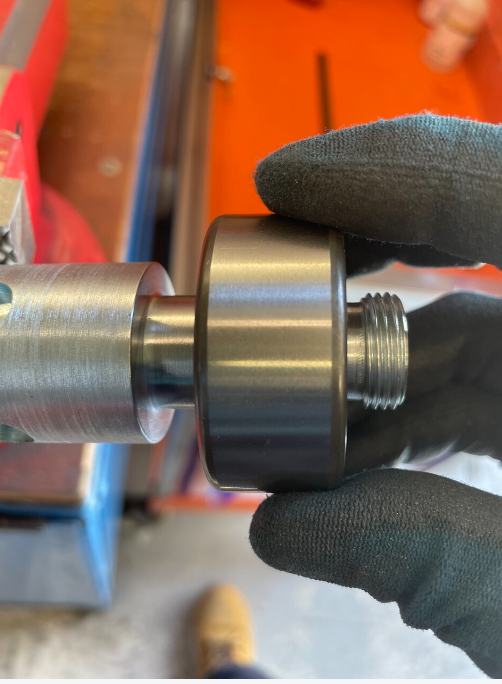

Ensure D0001926 Servo Drive Coupling M20 (Ø14mm) Beckhoff x 1

fits onto C0001122K Servo Motor: Beckhoff AM8032-1E10 (Keyed) x 1

Fit should be a snug slide fit

Part can be reamed with hand reamer if fit is tight

Étape 3 - Fit bearing

1 Check and adjust fit of B0000139 Double Angular Bearing 20 D 47 D 20.6 Long + seals x 1 onto D0006488 Y Leadscrew Sleeve x 1

2 Fit should be a smooth press fit onto sleeve. Indicated face can be polished down with fine emery to obtain desired fit

Étape 4 - Tension drive coupling

1 Add m8 socket caps as shown to hold assembly in vice

2 Use 2 off m8 long socket caps and Standard M8 nuts and lock onto drive coupling .

Tension using long M8s as leverage

Étape 5 - Finalise

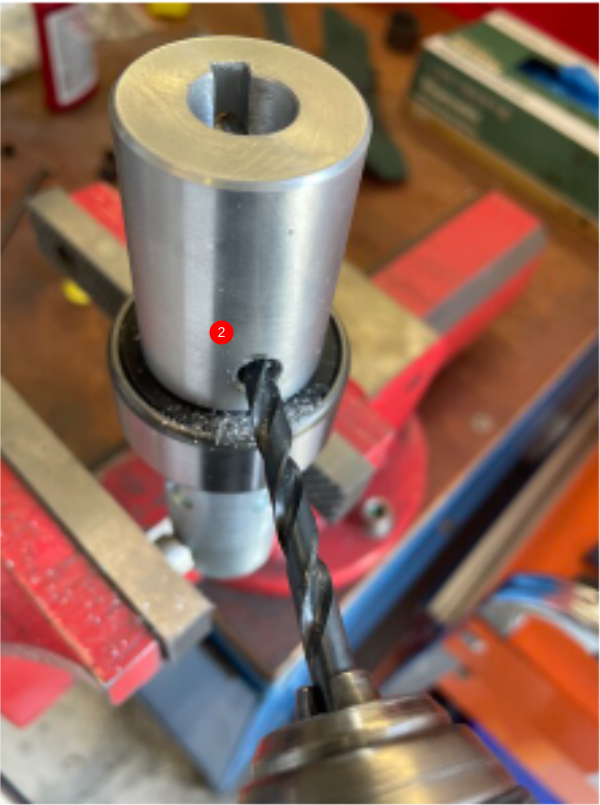

1 Remove 1 off Long M8 socket cap and tension an M8 x 12 kcp grubscrew into the hole (do not add adhesive )

2 Remove second Long M8 socket cap and dimple inner shaft using 6.8mm drill

Clean with compressed air and add M8x 8 kcp with adhesive and tension

3 Remove m8 x 12 kcp grub screw and repeat above step

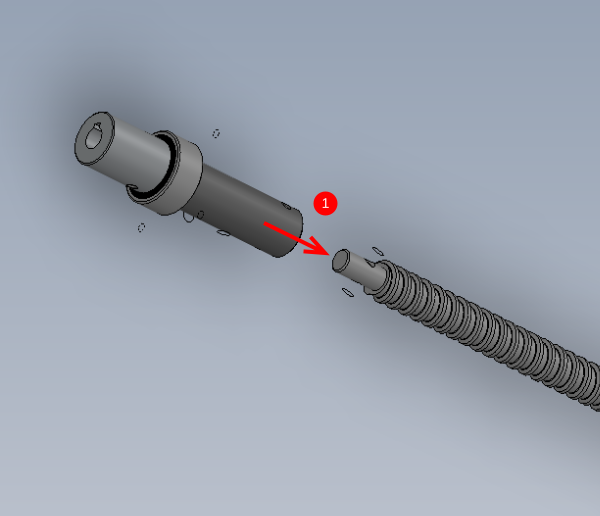

Étape 6 - Check fit of leadscrew to coupling

1 Check fit of coupling to leadscrew H0007789

2 Use reamer / Emery tape if fit is tight

Étape 7 - Check bearing fit

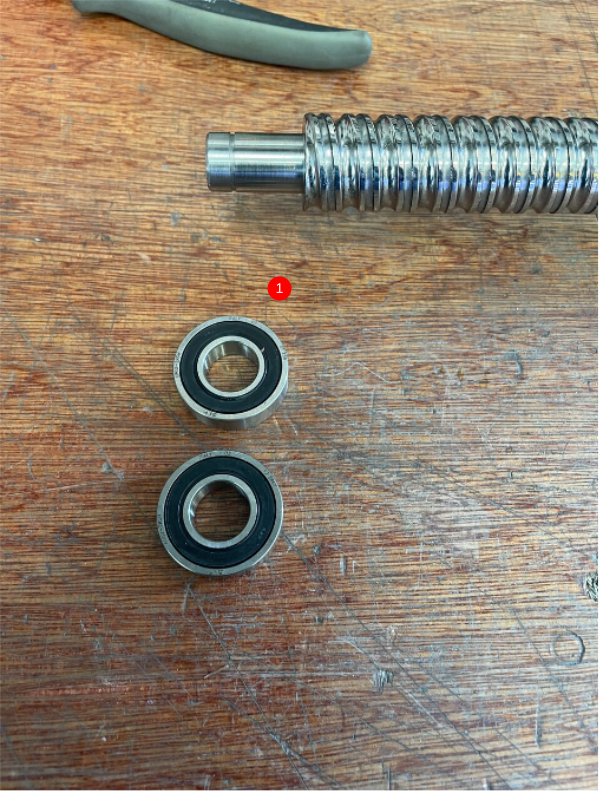

1 Check bearing B0000086 Ball Bearing 15 D 32 D 9 Long + seals fit is acceptable on leadscrew H0007789

2 Adjust with emery tape if fit is tight

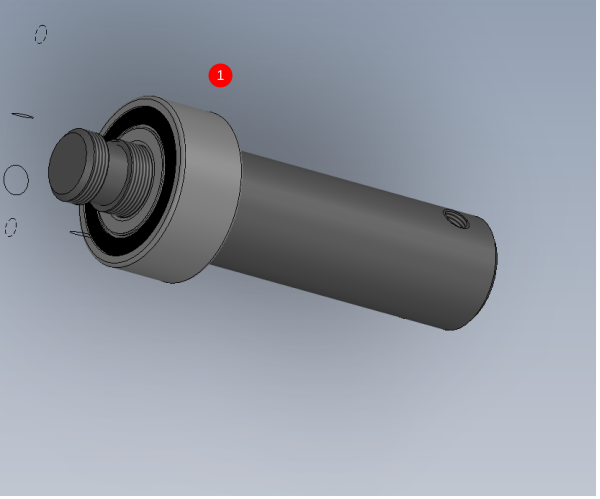

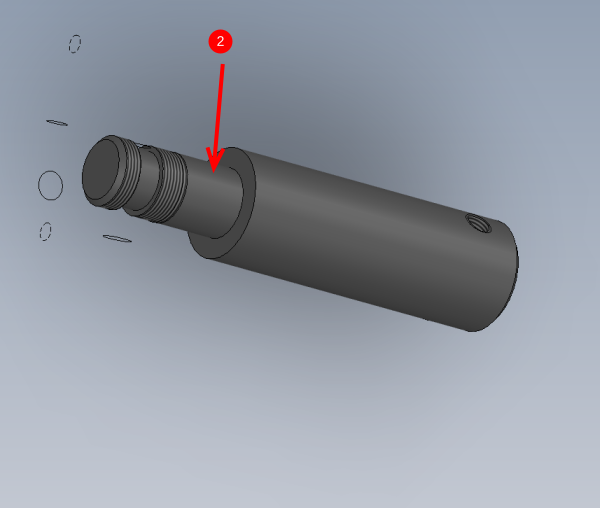

Étape 8 - Fit Grease nipple and check nut orientation n

Fit B0000236 90 Deg Grease Nipple M6 ST/ST x 1 as shown

Check Leadscrew nut is orientated correctly , rotate using leadscrew jig if incorrectly orientated

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português