| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 28 : | Ligne 28 : | ||

D0002943 x 9 | D0002943 x 9 | ||

| − | |||

| − | |||

D0001254 x 9 | D0001254 x 9 | ||

| Ligne 39 : | Ligne 37 : | ||

D0001255 x 9 | D0001255 x 9 | ||

| − | + | H0007576 x 9 | |

B0000252 x 9 | B0000252 x 9 | ||

Version du 22 juin 2023 à 14:12

Instructions for bench assembling infeed arms

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Prepare main arm for assembly

- 4 Étape 3 - Attach runner strips and chain guide

- 5 Étape 4 - Add Location Spiral pin

- 6 Étape 5 - Assemble chain tensioner pinion

- 7 Étape 6 - Assemble slide unit

- 8 Étape 7 - Attach tensioner pinion

- 9 Étape 8 - Mount to loading arm

- 10 Étape 9 - Assembly support bars

- 11 Commentaires

Introduction

Tools Required

Circlip pliers internal and external

Standard hex key set

Standard spanner set

Standard Tap set

Parts Required

D0015456B x 9

D0001256 x 9

D0002943 x 9

D0001254 x 9

D0001253 x 9

D0002717 x 18

D0001255 x 9

H0007576 x 9

B0000252 x 9

D0007577 x 9

D0002999 x 9

D0015619 x 9

D0015620 x 9

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Pen mark all fasteners once finalised

Étape 2 - Prepare main arm for assembly

9 off

D0015456B load arm needs preparing before assembly.

All tapped holes require contaminants removing before assembly. Use appropriate taps to clean all threads on load arms

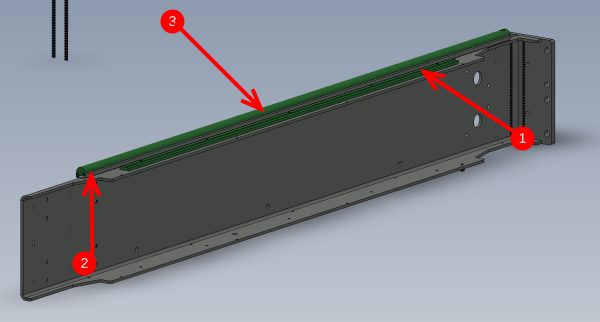

Étape 3 - Attach runner strips and chain guide

9 off

1 Attach chain guide D0001256 as shown using 5 off M4 x 12 socket caps

2 Attach lower channel D0002943 as shown using M5 x 10 button heads

3 Slide plastic guide into channel and fix with M5 x 12 socket cap and A form washer

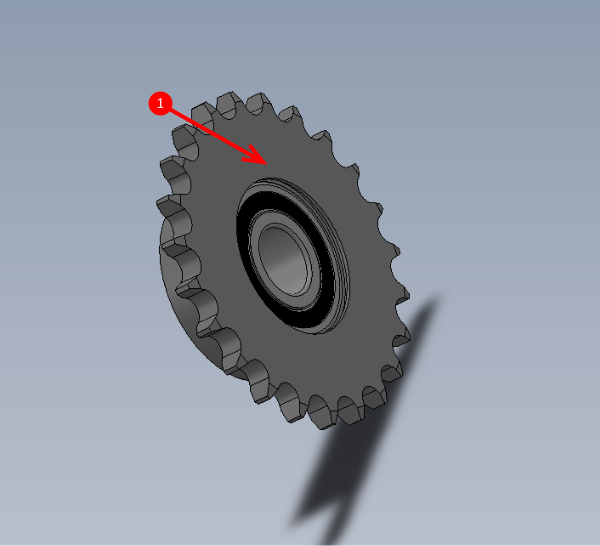

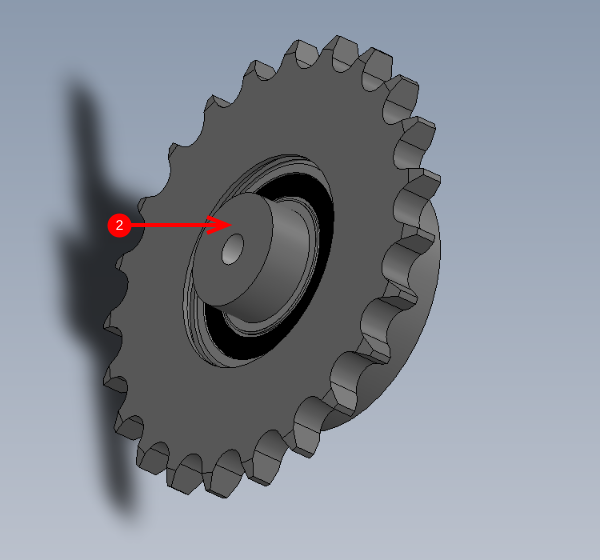

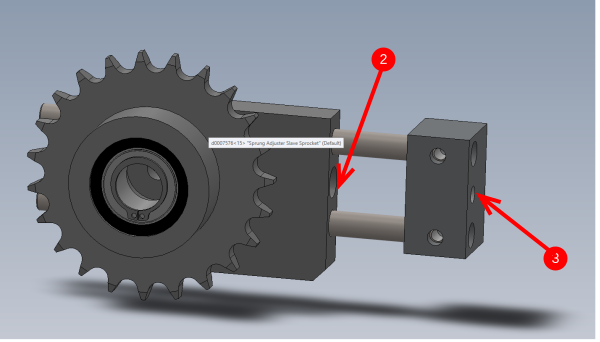

Étape 5 - Assemble chain tensioner pinion

9 off

1 Use press to fit bearing B0000252 to idler pinion D0007576. Ensure bearing fit is correct. If bearing is loose, degrease with FE10 solvent and use bearing fit to secure bearing . If bearing is tight, measure bore and report via NCR system if out of tolerance . Retain bearing with 47mm internal circlip

2 use press to insert D0007577 into bearing as shown. Ensure fit is correct. Use FE10 solvent and bearing fit if loose, if tight measure and inspect and report through NCR system. Fix in place with a 20mm external circlip

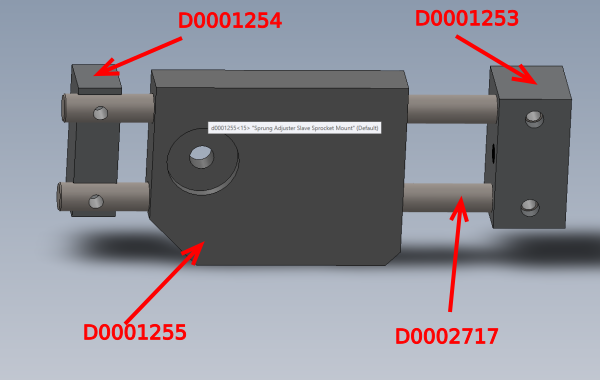

Étape 6 - Assemble slide unit

9 off

Assemble as shown the following with no fixings

D0001255

D0002717

D0001253

D0001254

Ensure D0001255 slides along shafts once assembled

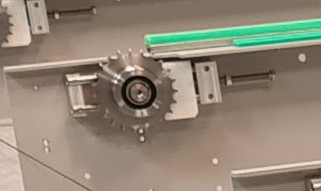

Étape 7 - Attach tensioner pinion

9 off

1 Attach tensioner pinion to assembly using M8 x 35 socket cap and M8 motorplate washer

2 Add D0002999 jacking insert into block

3 Add M8 x 100 set bolt and M8 nut to the indicated face

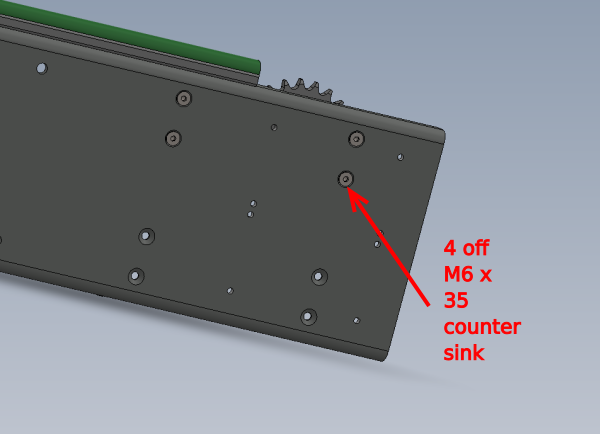

Étape 8 - Mount to loading arm

9 off

Use 4 off M6 x 35 countersink bolts to attach tensioner assembly to loading arm

Étape 9 - Assembly support bars

9 off

Combine as shown D0015619 and D0015620 using M8 x 30 socket caps, M8 heavy washers and M8 nyloc nuts

Orientate as shown in picture

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português