| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 99 : | Ligne 99 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Name all EtherCAT devices according to network</translate> | |Step_Title=<translate>Name all EtherCAT devices according to network</translate> | ||

| − | |Step_Content=<translate>Click twice on each device (not double click) to enable the device to be renamed | + | |Step_Content=<translate>{{Warning|...Do not start this step until the EtherCAT network is fully verified. You will waste a lot of time if you ignore this!}} |

| + | |||

| + | |||

| + | Click twice on each device (not double click) to enable the device to be renamed | ||

rename to [https://stuga.dokit.app/wiki/Naming_Conventions_for_Electrical_Components convention]</translate> | rename to [https://stuga.dokit.app/wiki/Naming_Conventions_for_Electrical_Components convention]</translate> | ||

Version du 20 novembre 2019 à 15:48

How to create a new TwinCAT3 Project from scratch

Sommaire

- 1 Étape 1 - Start a new project

- 2 Étape 2 - Add PLC Project for Reset

- 3 Étape 3 - Add PLC Project for tcMulti

- 4 Étape 4 - Ensure Correct Machine Commented in tcMulti project

- 5 Étape 5 - Add TwinSAFE project

- 6 Étape 6 - Add the route to the PLC

- 7 Étape 7 - Scan for Devices

- 8 Étape 8 - Check EtherCAT validity

- 9 Étape 9 - Name all EtherCAT devices according to network

- 10 Étape 10 - Add Drive Configurator

- 11 Étape 11 - Double check all IO references with someone else

- 12 Étape 12 - Activate configuration

- 13 Étape 13 - Add Axis Task

- 14 Étape 14 - Add Axes

- 15 Étape 15 - Map Axes

- 16 Étape 16 - Add Drive Configurator

- 17 Étape 17 - Map all IO

- 18 Étape 18 - Double check all IO references with someone else

- 19 Étape 19 - Activate configuration

- 20 Étape 20 - Add Axis Task

- 21 Étape 21 - Add Axes

- 22 Étape 22 - Map Axes

- 23 Commentaires

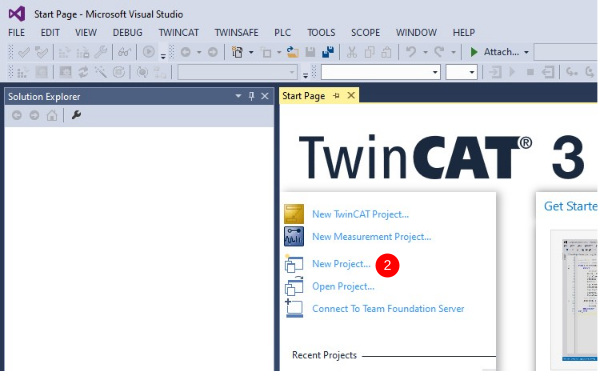

Étape 1 - Start a new project

- Open Visual Studio

- Click on New project

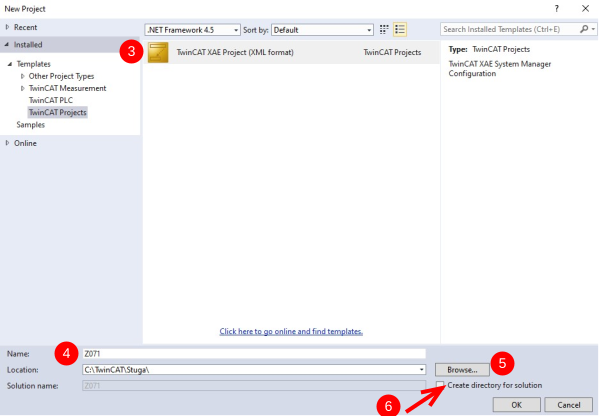

- Choose TwinCAT projects->TwinCAT XAE Project (xml format)

- Name is build number (no Suffix)

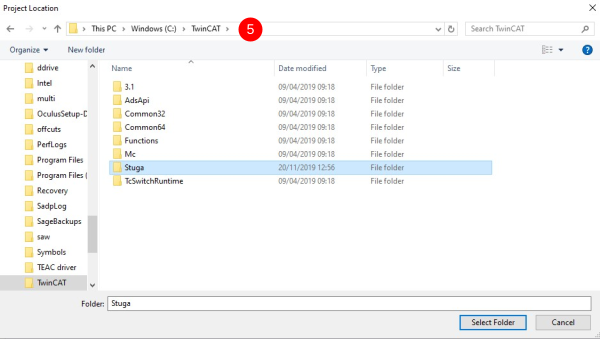

- Location is c:\TwinCAT\Stuga\

- Untick "Create Directory for solution"

This creates the template

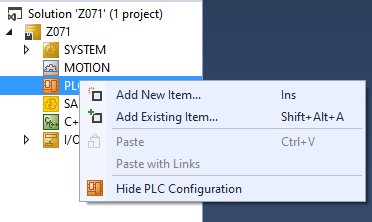

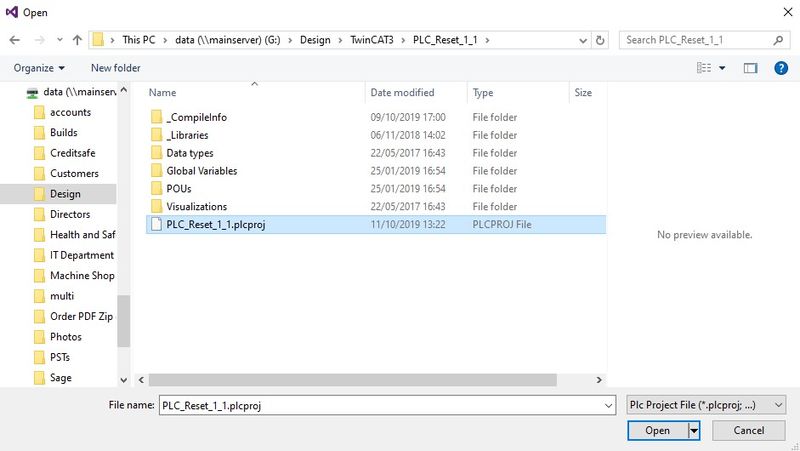

Étape 2 - Add PLC Project for Reset

- On PLC, right click and Add Existing Item

- Navigate to g:\Design\TwinCAT3\PLC_Reset_1_1

- Select the .Plcproj file

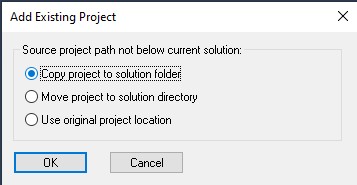

- Copy Project to solution file

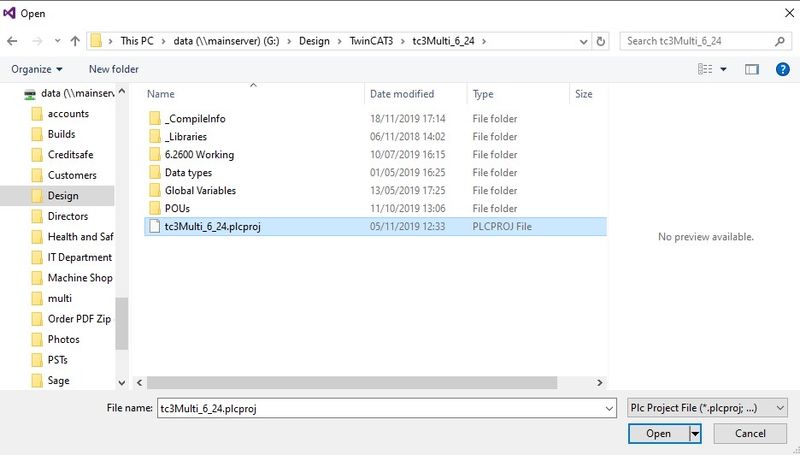

Étape 3 - Add PLC Project for tcMulti

- Add Existing Item

- Navigate to g:\Design\TwinCAT3\tcMulti_6_24

- Select the .Plcproj file

- Copy Project to solution file

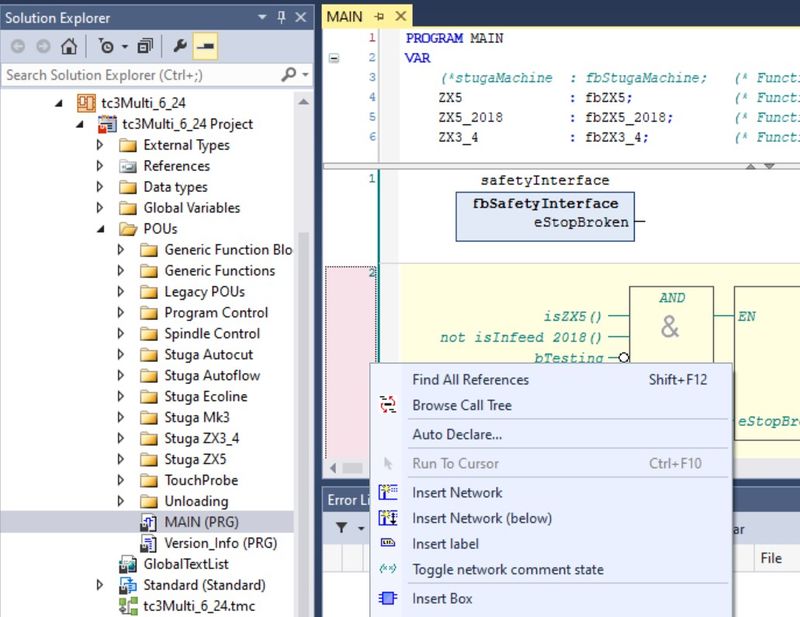

Étape 4 - Ensure Correct Machine Commented in tcMulti project

- Navigate to tcMulti_6_24 project->POUs->MAIN

- Scroll down to the machine types. The "comment State" can be toggled on and off by right clicking next to the step number on the left

- Your goal is to ensure the correct machine is highlighted and the incorrect ones are commented out (in green)

- Click Save All

Étape 5 - Add TwinSAFE project

Étape 6 - Add the route to the PLC

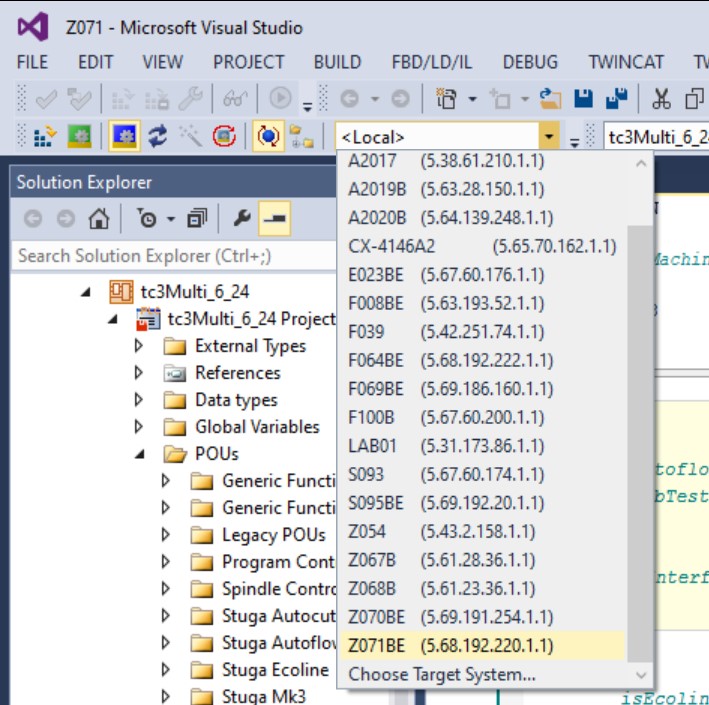

- From Dropdown box select the Build number (If it does not exist we will need to add a new route)

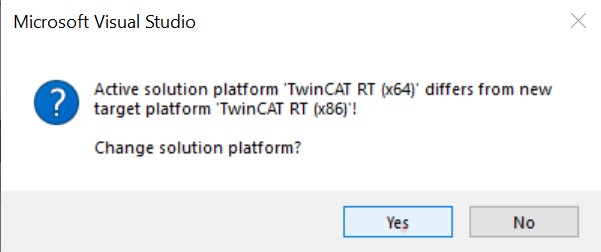

- If there is a request for a platform change, click Yes

- On success, the Route dropdown will not read Error

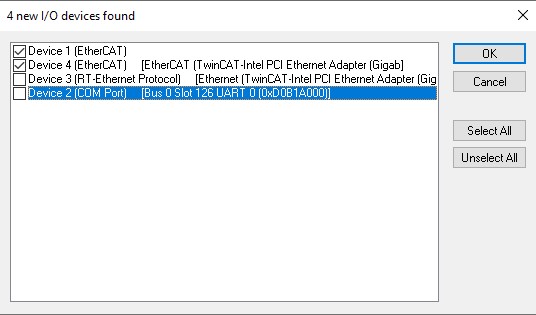

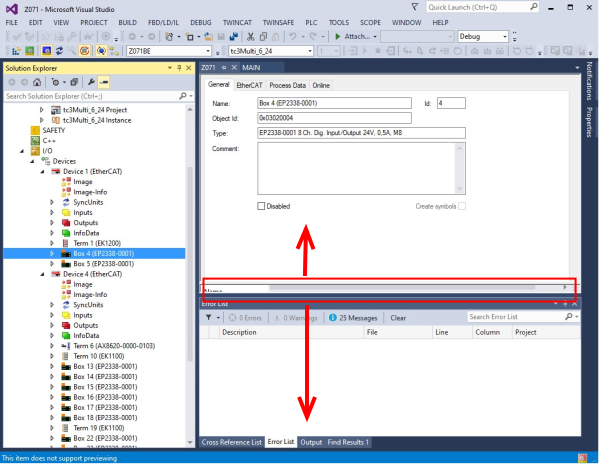

Étape 7 - Scan for Devices

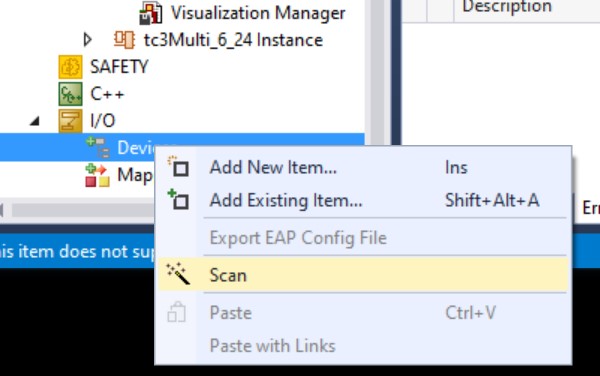

- Expand IO

- Right click on devices, Scan

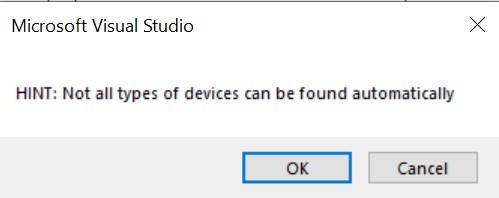

- Click OK on the Hint:

- Untick RT-Ethernet

- Untick COM-Port

- Just have the EtherCAT ports

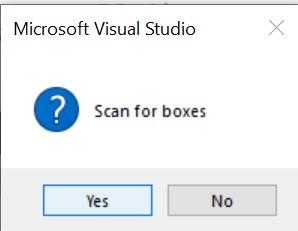

- Scan for boxes - Yes

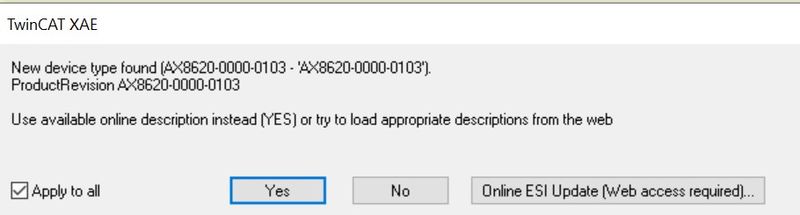

- If there is a request for New Device Type, Click Apply to All, Click Yes

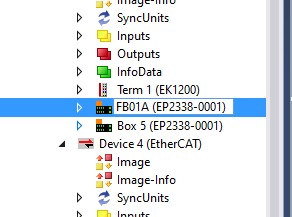

Étape 8 - Check EtherCAT validity

Check the Devices and boxes match the expected EtherCAT setupRepeat steps 7 and 8 until the physical network matches the scanned networkYou may need to Right Click->scan Boxes on the second device if the EtherCAT boxes do not appear

Étape 9 - Name all EtherCAT devices according to network

Click twice on each device (not double click) to enable the device to be renamed

rename to convention

Étape 10 - Add Drive Configurator

Étape 11 - Double check all IO references with someone else

Any mistakes made will save hours if spotted here

Étape 13 - Add Axis Task

Axis task may need to be added under the MOTION tree:

- Add New Item

- NC/PTP Configuration

- Leave the Name as default

Étape 14 - Add Axes

If the axes do not exist under MOTION->NC Task->Axes, add them

- Right Click Add axis

- Name to convention nn Axis

Repeat for each axis on machine

Étape 15 - Map Axes

- Double click an axis

- Settings tab

- Click Link To IO

- Connect to associated Drive

Repeat for each axis

Étape 16 - Add Drive Configurator

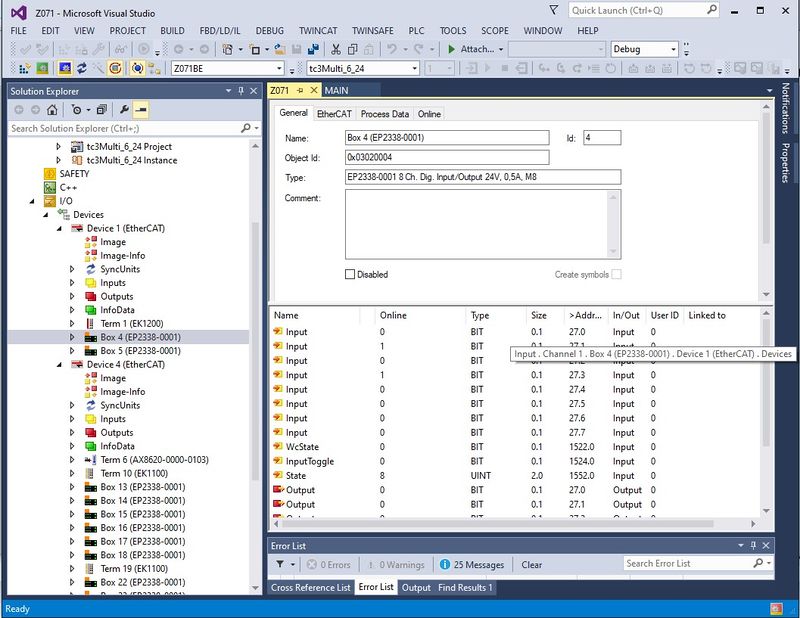

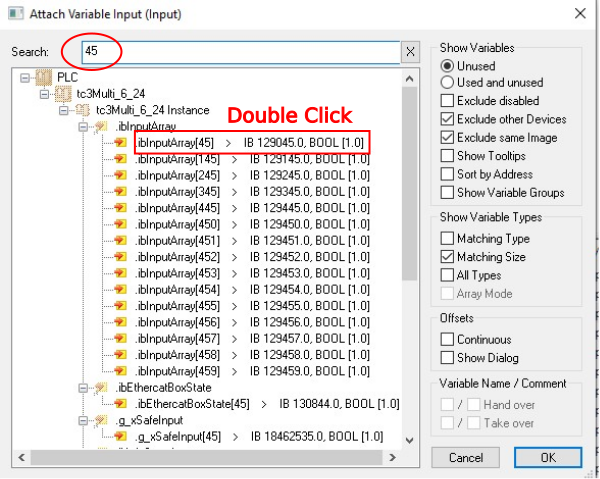

Étape 17 - Map all IO

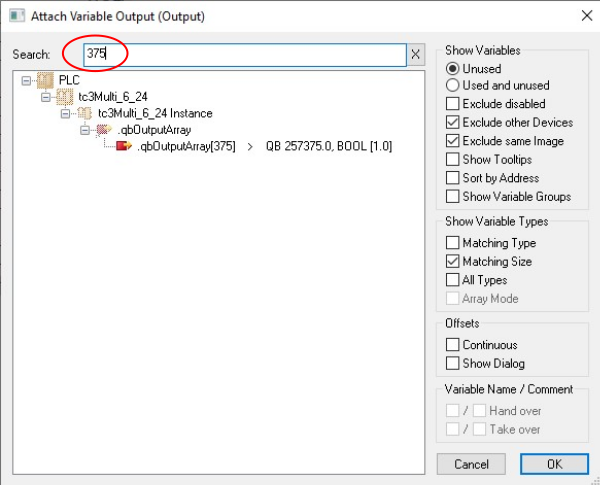

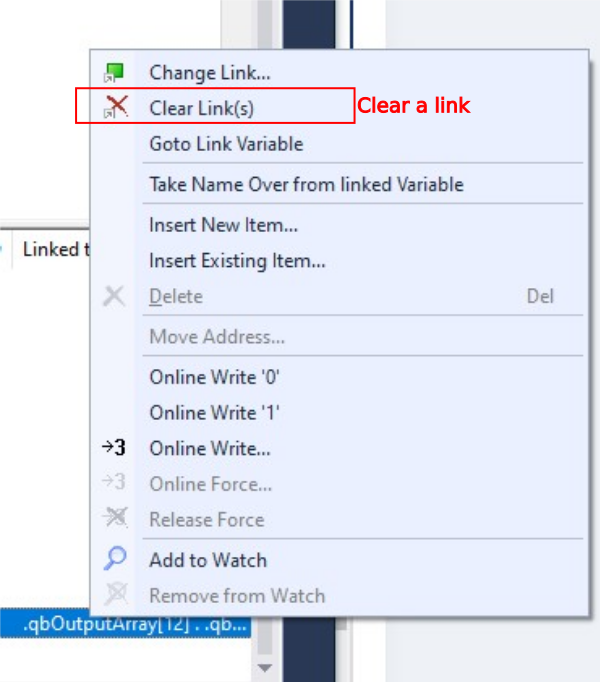

Using the circuit diagrams, link all the IO refs up to the inputs and outputs

- Double click on the slices and Field Bus boxes in turn

- Ensure you can see the Input / output channels (may need some resizing

- Double click on the relevant IO channel

- Type the number in the box

- For Inputs, use ibInputArray and match the number. outputs use qbOutputArray

Repeat for all IO

Étape 18 - Double check all IO references with someone else

Any mistakes made will save hours if spotted here

Étape 20 - Add Axis Task

Axis task may need to be added under the MOTION tree:

- Add New Item

- NC/PTP Configuration

- Leave the Name as default

Étape 21 - Add Axes

If the axes do not exist under MOTION->NC Task->Axes, add them

- Right Click Add axis

- Name to convention nn Axis

Repeat for each axis on machine

Étape 22 - Map Axes

- Double click an axis

- Settings tab

- Click Link To IO

- Connect to associated Drive

Repeat for each axis

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português