| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 6 : | Ligne 6 : | ||

|Tags=minable, maxable, optimising, trim | |Tags=minable, maxable, optimising, trim | ||

}} | }} | ||

| − | <translate>= Loading and Optimising = | + | <translate>=Loading and Optimising= |

A major feature of the flowline software is its ability to optimise a batch for the best use of profile. This is absolutely necessary on the flowline because: | A major feature of the flowline software is its ability to optimise a batch for the best use of profile. This is absolutely necessary on the flowline because: | ||

| Ligne 13 : | Ligne 13 : | ||

*When bar length measuring is used, the machine re-optimises on each bar length anyway. | *When bar length measuring is used, the machine re-optimises on each bar length anyway. | ||

| − | = Operations at the end of a bar = | + | =Operations at the end of a bar= |

The flowline cannot machine anything where the gripper is, or at the very end of the bar. To cope with this, the software looks at each piece to see if there are any operations near the ends – i.e. if this piece was at the end, the operation would be unmachinable. | The flowline cannot machine anything where the gripper is, or at the very end of the bar. To cope with this, the software looks at each piece to see if there are any operations near the ends – i.e. if this piece was at the end, the operation would be unmachinable. | ||

| Ligne 67 : | Ligne 67 : | ||

On optimisation, the optimiser sees that there is a large waste associated with putting a “mechanical” prep at the end of a bar, and will therefore try a different combination. If this is not possible (e.g. on a short offcut), the optimiser will allow for the waste at the start or end of the bar. | On optimisation, the optimiser sees that there is a large waste associated with putting a “mechanical” prep at the end of a bar, and will therefore try a different combination. If this is not possible (e.g. on a short offcut), the optimiser will allow for the waste at the start or end of the bar. | ||

| − | = Reducing the impact of minable and maxable = | + | =Reducing the impact of minable and maxable= |

| − | The value of minable and maxable is set </translate> | + | The value of minable and maxable is set as parameters in the shared parameters file sparams.saw. To stop or reduce the frequency of bars with minable / maxable waste: |

| + | |||

| + | # Move the drainage operations further "in" on the pieces so they are not close to the end and are therefore at least "minable" parameter value from the end of the piece | ||

| + | # Decrease the minable amount - if it is decreased too much, you may risk pieces not being clamped properly when they are machined | ||

| + | |||

| + | {{Warning|...Do not change minable or maxable half way through a batch. Always ensure the transfer table is clear of bars and exit both sides of the machine}} </translate> | ||

{{PageLang | {{PageLang | ||

|Language=en | |Language=en | ||

Version du 20 septembre 2019 à 14:05

Description and definition of minable and maxable on a Stuga flowline. Why and how this leads to larger trim and waste amounts at the start and end of the bar

Loading and Optimising

A major feature of the flowline software is its ability to optimise a batch for the best use of profile. This is absolutely necessary on the flowline because:

- The way that the machine is able to utilise profile is specialised and it is too difficult for another optimiser to manage. For example, when an arrow head is cut, the following piece has an arrow head on it already – this is a situation the optimiser will try to achieve because it saves profile and time

- The machine is unable to rout an operations or Y notch near the beginning and end of the bar – at the beginning the gripper is in the way, at the end the clamping is insufficient to support the profile. The on-board optimiser will try to avoid this situation by putting pieces with no end operations at the start and end of the bar. If this is not possible, the area will be earmarked as waste.

- When bar length measuring is used, the machine re-optimises on each bar length anyway.

Operations at the end of a bar

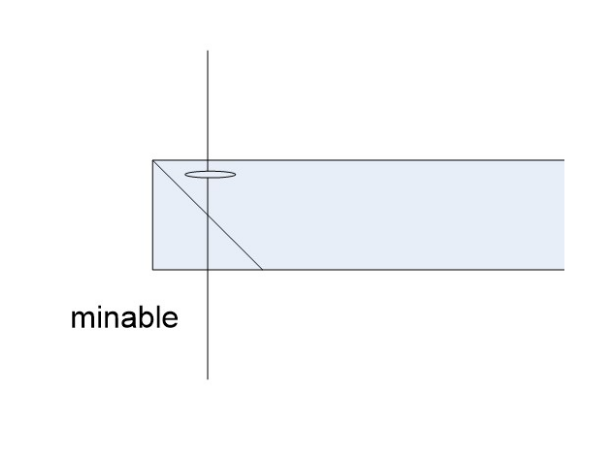

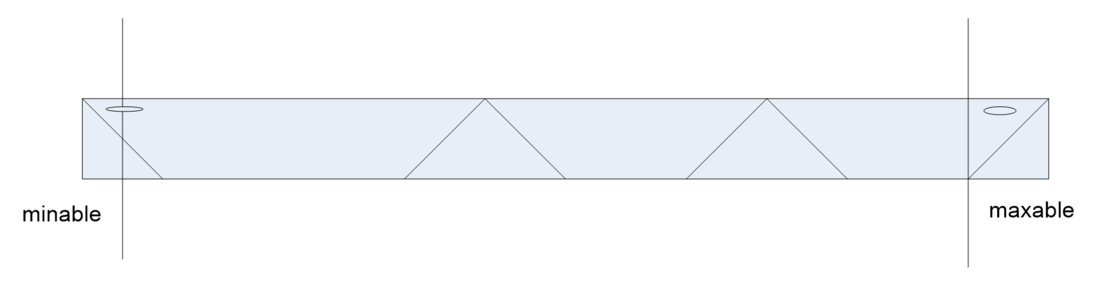

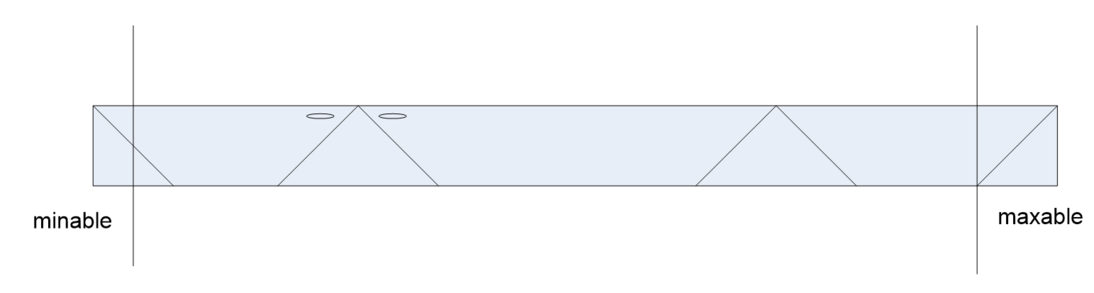

The flowline cannot machine anything where the gripper is, or at the very end of the bar. To cope with this, the software looks at each piece to see if there are any operations near the ends – i.e. if this piece was at the end, the operation would be unmachinable.

The unmachinable area at the gripper end is defined by the “minable” parameter in sparams.mul, the area at the end of the bar is defined by the “maxable” parameter.

If there is an operation on a piece that is in the minable / maxable area, the end prep is modified to a “mechanical” prep.

| Square Cut | | | Becomes | s |

| Mitre Cut | \ | Becomes | m |

| Mitre Cut | / | Becomes | i |

| Arrow Head Cut | > | Becomes | a |

In the above diagram:

| 1 | \ / | Becomes | m / |

| 2 | \ / | Becomes | \ / |

| 3 | \ / | Becomes | \ i |

On optimisation, the optimiser sees that there is a large waste associated with putting a “mechanical” prep at the end of a bar, and will therefore try a different combination. If this is not possible (e.g. on a short offcut), the optimiser will allow for the waste at the start or end of the bar.

Reducing the impact of minable and maxable

The value of minable and maxable is set as parameters in the shared parameters file sparams.saw. To stop or reduce the frequency of bars with minable / maxable waste:

- Move the drainage operations further "in" on the pieces so they are not close to the end and are therefore at least "minable" parameter value from the end of the piece

- Decrease the minable amount - if it is decreased too much, you may risk pieces not being clamped properly when they are machined

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português