| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 137 : | Ligne 137 : | ||

If changes are evident , investigate !</translate> | If changes are evident , investigate !</translate> | ||

|Step_Picture_00=Zx5_Module_C_and_E_support_arm_alignment_quality-assurance-testing.png | |Step_Picture_00=Zx5_Module_C_and_E_support_arm_alignment_quality-assurance-testing.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit Blanking plug</translate> | ||

| + | |Step_Content=<translate>Fit M0001265 blanking plug to seal access hole once motor is fitted and checked</translate> | ||

| + | |Step_Picture_00=R0015314_Fit_Z_Axis_Drive_components_Screenshot_2024-12-18_135519.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 18 décembre 2024 à 14:57

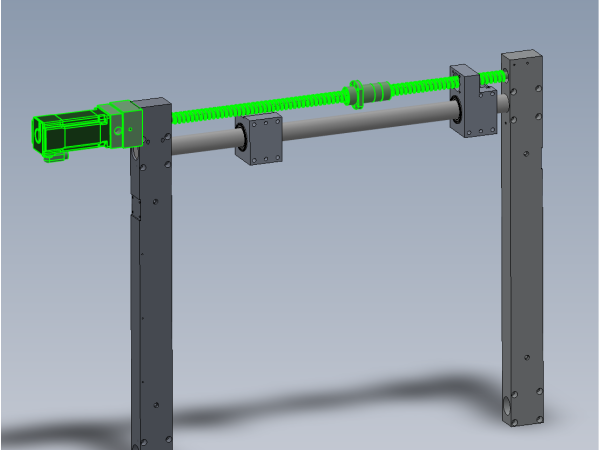

Fitting instructions for Y Axis drive

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Fit Y axis sleeve assembly

- 4 Étape 3 - Fit stepper housing block

- 5 Étape 4 - Position leadscrew

- 6 Étape 5 - Fit bearings

- 7 Étape 6 - Final leadscrew position

- 8 Étape 7 - Temporary fix leadscrew nut

- 9 Étape 8 - Check movement

- 10 Étape 9 - Fit servo adapter block

- 11 Étape 10 - Fit servo motor

- 12 Étape 11 - Finalise servo adapter block

- 13 Étape 12 - Re fit servo motor

- 14 Étape 13 - Fit keyway locking grubscrew

- 15 Étape 14 - Check movement

- 16 Étape 15 - Fit Blanking plug

- 17 Étape 16 - Remove leadscrew nut fixing

- 18 Commentaires

Introduction

Tools Required

Standard hex key set

External circlip pliers

Parts Required

B0000344 Circlip 15mm External x 1

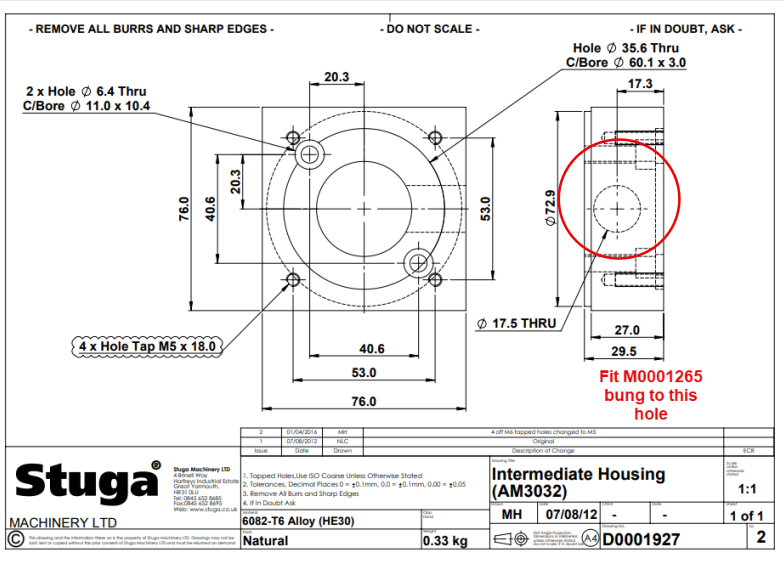

D0001927 Intermediate Housing (AM3032) x 1

D0006487 Y Stepper Housing x 1

R0000962E Bench assemble Y axis Components

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

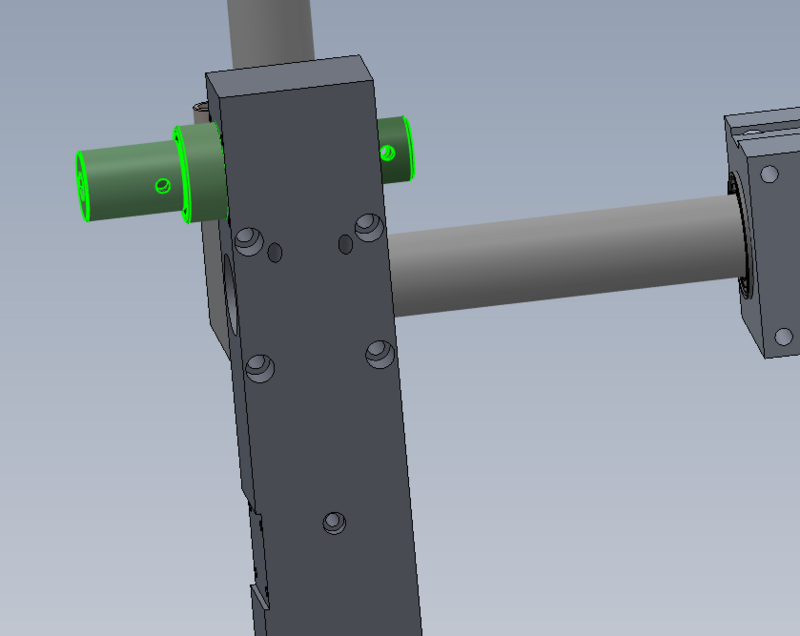

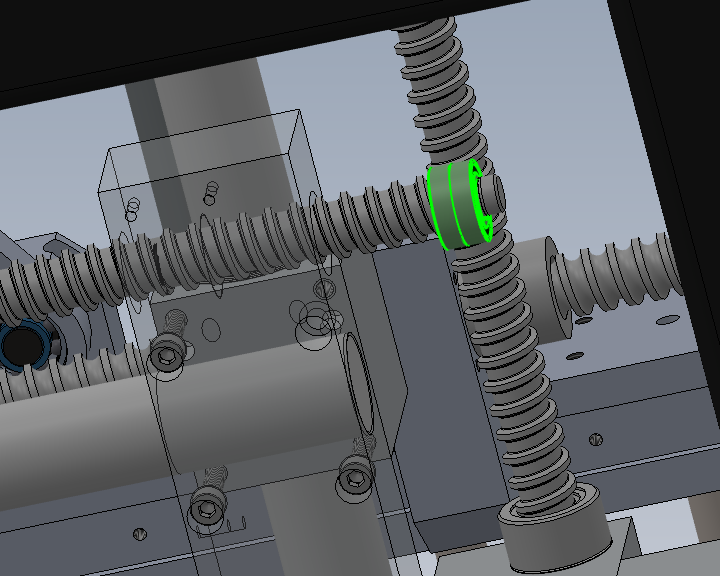

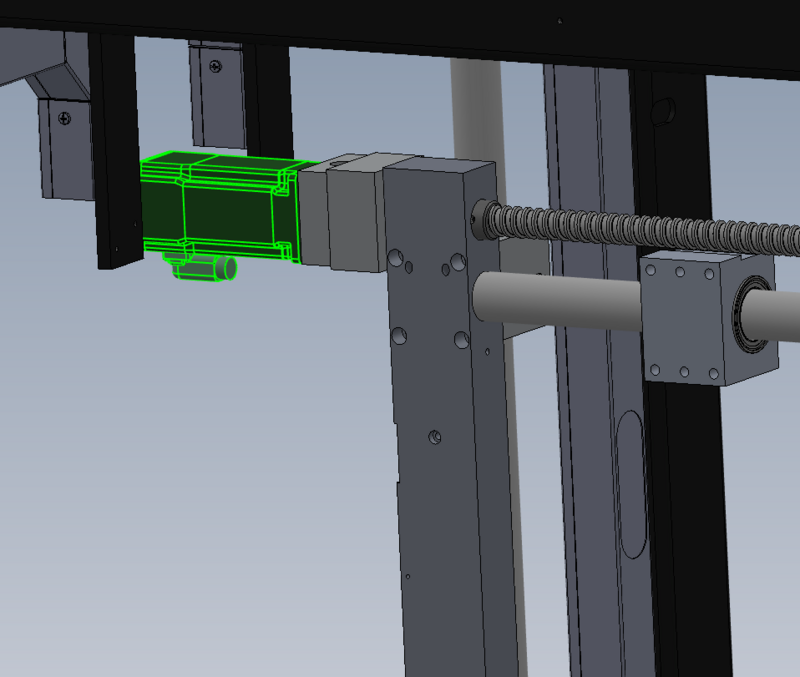

Étape 3 - Fit stepper housing block

Fit Y axis stepper housing block as shown

Ensure block is mounted square and true

Pay attention to bearing fit

If bearing is loose, used solvent and bearing fit adhesive

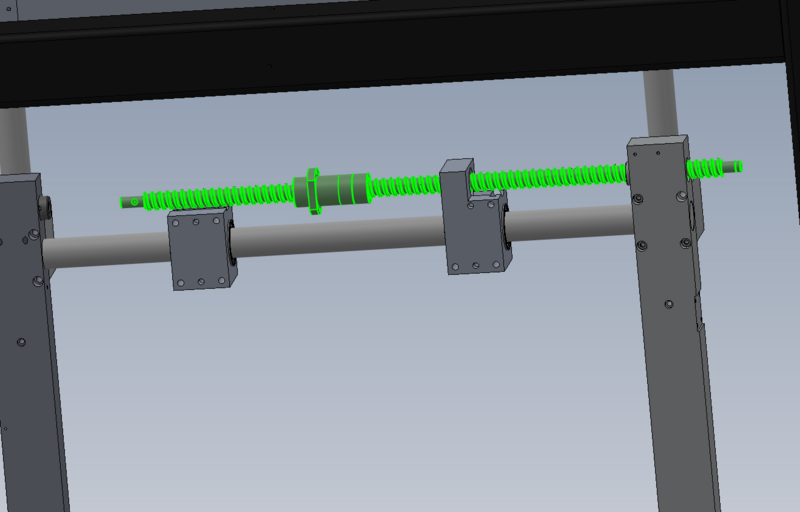

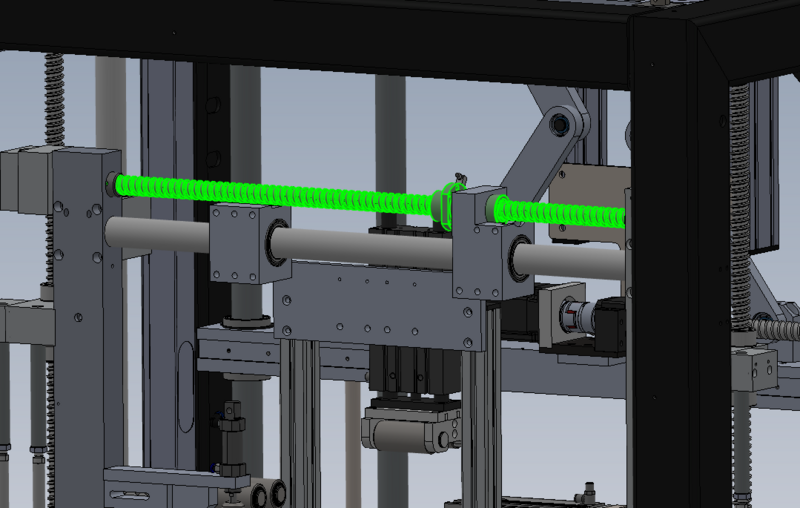

Étape 6 - Final leadscrew position

Slide leadscrew into final position

Add M8 x 12 kcp grubscrews to secure leadscrew to sleeve

Étape 7 - Temporary fix leadscrew nut

Temporarily fix position of leadscrew nut using 4 off M6 socket caps and a form washers

Étape 8 - Check movement

Check axis movement along entire length .

Movement should be free and consistent

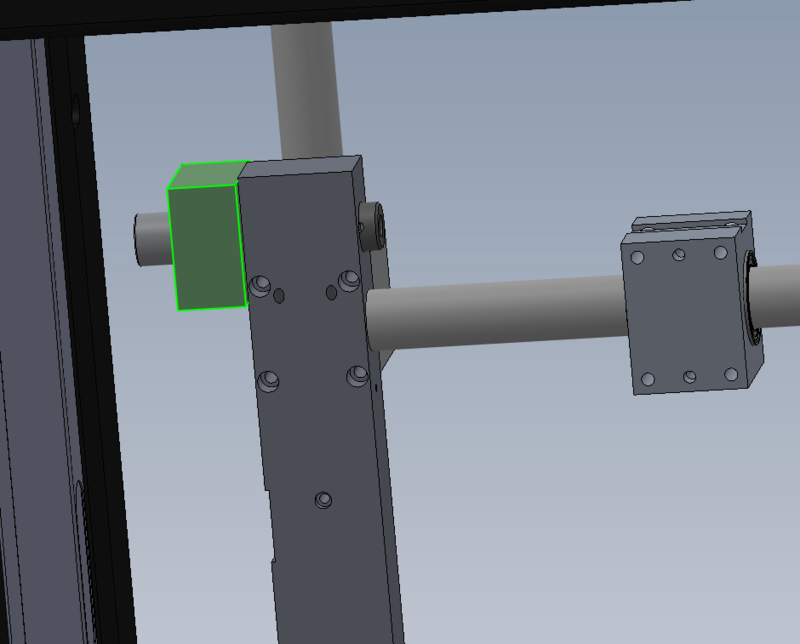

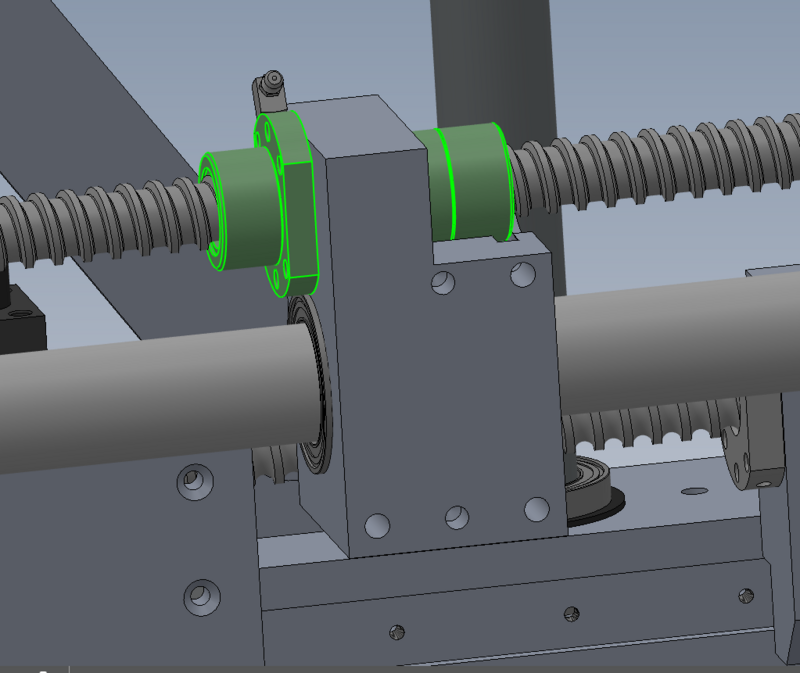

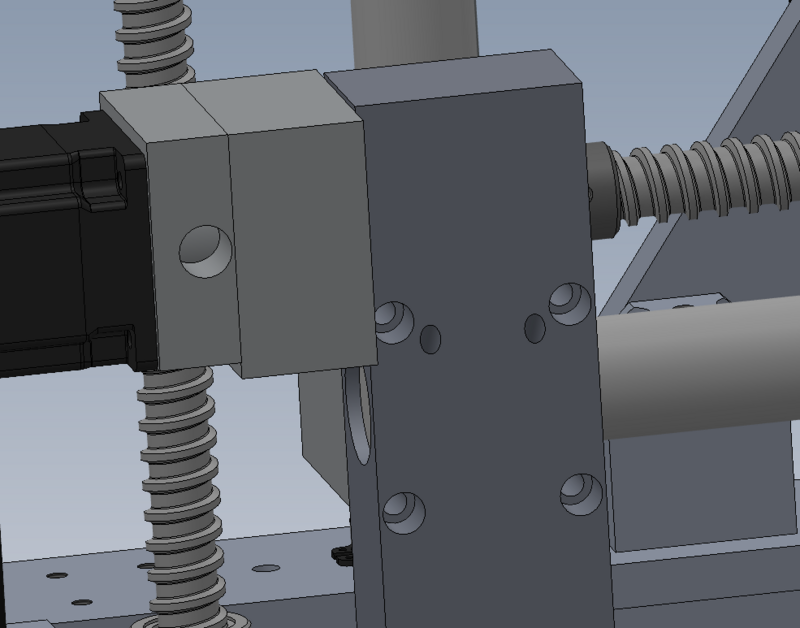

Étape 9 - Fit servo adapter block

Dry fit servo adapter block

do not add final tension to this block

Étape 10 - Fit servo motor

Fit servo motor to adapter block

Servo should fit easily into servo adapter block

~Adjust position of adapter block if fit is not correct

Étape 11 - Finalise servo adapter block

Remove servo motor and finalise fasteners on servo adapter block

Étape 12 - Re fit servo motor

Ensure motor is orientated correctly , servo plug facing down

Finalise socket caps fixing motor to adapter block

Étape 14 - Check movement

Check Axis movement again. There should be no change in consistency of movement or force required

If changes are evident , investigate !

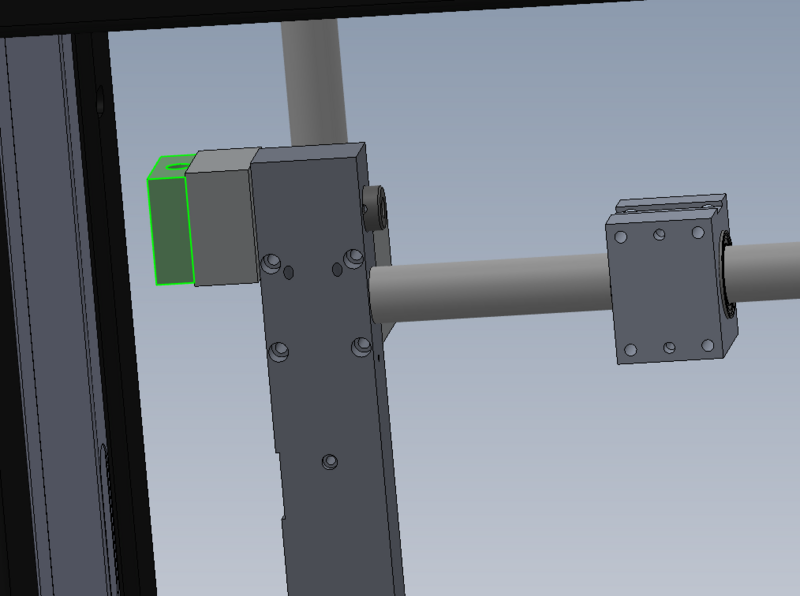

Étape 15 - Fit Blanking plug

Fit M0001265 blanking plug to seal access hole once motor is fitted and checked

Étape 16 - Remove leadscrew nut fixing

Remove 4 off fasteners attaching leadscrew nut to bearing block

This is required for rotary ring installation at a later stage

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português