| [version en cours de rédaction] | [version en cours de rédaction] |

m (Gareth Green a déplacé la page R0015305 Install Wiring loom for Rotary Ring vers R0015305A Install Wiring loom for Rotary Ring : New revision ) |

|

(Aucune différence)

| |

Version actuelle datée du 24 septembre 2024 à 17:44

Installation of wiring loom and captivating spindle bases

Sommaire

- 1 Introduction

- 2 Étape 1 - Quality

- 3 Étape 2 - Quality Check

- 4 Étape 3 - Start Wiring loom installation

- 5 Étape 4 - Fit spindle plate 6

- 6 Étape 5 - Fit Spindle plate 5

- 7 Étape 6 - Fit Spindle plate 4

- 8 Étape 7 - Fit Spindle plate 3

- 9 Étape 8 - Fit Spindle plate 2

- 10 Étape 9 - Fit Spindle plate 1

- 11 Étape 10 - Fit Spindle plate 8

- 12 Étape 11 - Fit Spindle plate 7

- 13 Étape 12 - Fit dowels to spindle plates

- 14 Étape 13 - Add final fasteners

- 15 Étape 14 - Add anti drift marks

- 16 Étape 15 - Prepare back plates

- 17 Étape 16 - Fit back plate 1

- 18 Étape 17 - Fit back plate 2

- 19 Commentaires

Introduction

Tools Required

Standard hex key set

Ball pein hammer

6mm drift/punch

Drill driver

6mm hex drill attachment

Parts Required

D00000291 spindle plate x 8

M0000025 Ident numbers x 1

D0007703 r stop pin x 1

D0007990 cylinder anchor x 1

D0007777 Trunking backplate x 2Étape 1 - Quality

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Quality Check

Check D0000291 spindle base has M4 hole tapped all the way through the plate. Rework if not

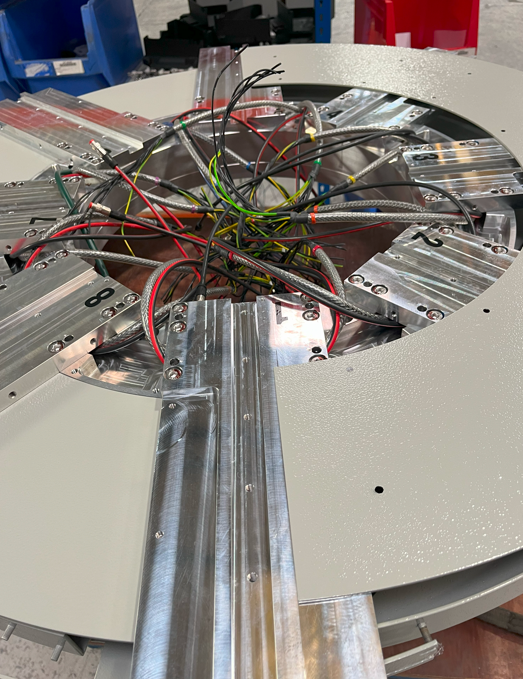

Étape 3 - Start Wiring loom installation

1 Segregate cables and 6mm blue pipe as shown

2 Use pre made cable identified as 6 and 7 and lay between 2 points shown

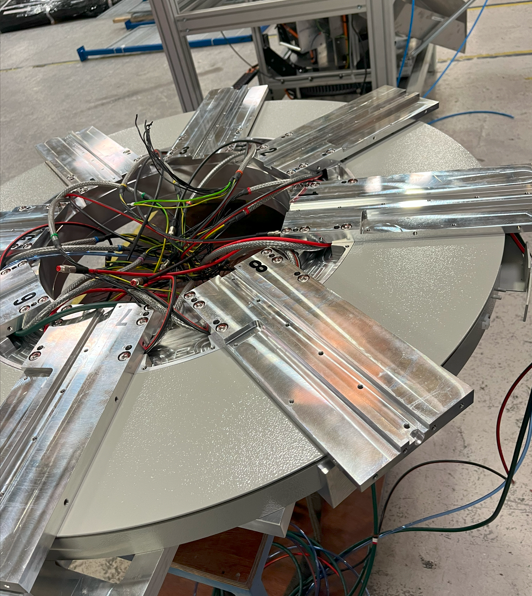

Étape 4 - Fit spindle plate 6

1 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps in opposing corners

2 Fit M0000025 number ident (number 6)

Étape 5 - Fit Spindle plate 5

1 Retrieve pre marked ethercat cable marked SP5-SP6

2 Retrieve pre marked power cable marked 5-6

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP5 and 5 exit to left

Ensure SP6 and 6 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 5)

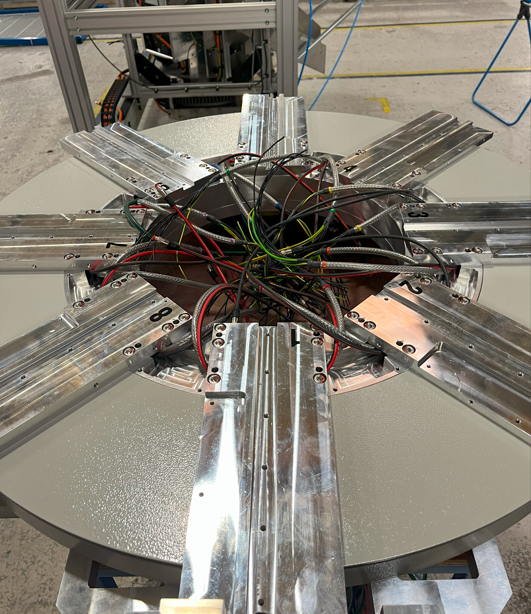

Étape 6 - Fit Spindle plate 4

1 Retrieve pre marked ethercat cable marked SP4-SP5

2 Retrieve pre marked power cable marked 4-5

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP4 and 4 exit to left

Ensure SP5 and 5 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 4)

Étape 7 - Fit Spindle plate 3

1 Retrieve pre marked ethercat cable marked SP3-SP4

2 Retrieve pre marked power cable marked 3-4

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP3 and 3 exit to left

Ensure SP4 and 4 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 3)

Étape 8 - Fit Spindle plate 2

1 Retrieve pre marked ethercat cable marked SP2-SP3

2 Retrieve pre marked power cable marked 2-3

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP2 and 2 exit to left

Ensure SP3 and 3 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 2)

Étape 9 - Fit Spindle plate 1

1 Retrieve pre marked ethercat cable marked SP1-SP2

2 Retrieve pre marked power cable marked 1-2

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP1 and 1 exit to left

Ensure SP2 and 2 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 1)

Étape 10 - Fit Spindle plate 8

1 Retrieve pre marked ethercat cable marked SP8-SP1

2 Retrieve pre marked power cable marked 8-1

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP8 and 8 exit to left

Ensure SP1 and 1 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 8)

Étape 11 - Fit Spindle plate 7

1 Retrieve pre marked ethercat cable marked SP7-SP8

2 Retrieve pre marked power cable marked 7-8

3 Lay both cables into chamber to the left of previous fitted plate

Ensure SP7 and 7 exit to left

Ensure SP8 and 8 exit to the right

4 Fit D0000291 spindle plate and lightly secure with 2 off M8 x 25 socket caps

5 Fit M0000025 ident number to spindle plate (number 7)

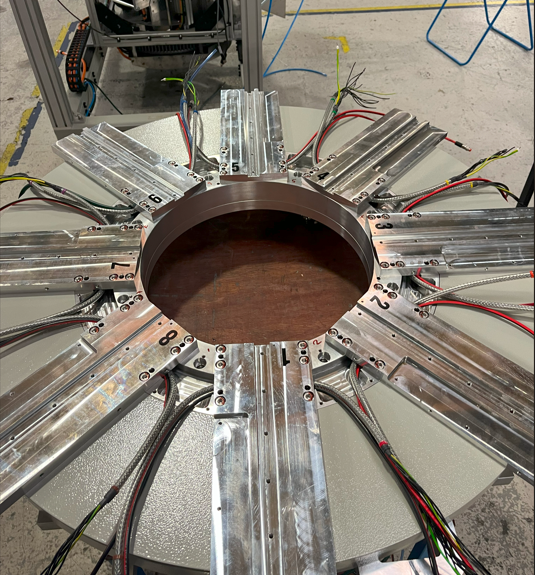

Étape 12 - Fit dowels to spindle plates

1 Ensure 2 off M8 x 25 sockets are only lightly tensioned. When fitting dowels spindle plates will need to move slightly to allow alignment to occur

2 Fit 4 off F0000042 8mm x 24mm dowel to each spindle plate. Start all 4 dowels into bores indicated , but do not drive flush

3 Use punch pin to drive dowels to approximately 10mm below spindle plate face

Étape 13 - Add final fasteners

1 Remove 2 off M8 x 25 socket cap fitted to each spindle plate

2 Fit 6 off M8 x 25 socket cap with adhesive to each spindle plate , do not wind bolt into thread

3 Use drill driver (torque setting 15) with 6mm hex attachment to drive all fasteners home

4 Finalise M8x25 socket caps by hand , and mark as completed

Étape 14 - Add anti drift marks

Each dowel hole (4 off per spindle plate, 32 in total) require anti drift dots adding to stop dowel slip in operation.

Use a centre punch and hammer, and add centre dot as indicated to slighty swage over top of dowel hole.

Repeat this for all dowel holes on spindle plates

Étape 15 - Prepare back plates

Prepare 2 off D0007777 trunking back plates for fitting

Check that a M5 countsunk bolt fits flush in all fixing holes.

If M5 countersunk sits above face, rework with Countersink to allow correct fitment

Étape 16 - Fit back plate 1

Trunking back plate 1 is positioned as shown

1 It should be fitted to the centre line of spindle plate 1 and 5, on the rear . (Picture shows fitted above for clarity of orientation only )

2 Slide back plate between spindle plates and lower trunking, and orientate as above.

3 Remove access cover to gain access to fit M5 x 10 countersunk bolts to fix backplate in position. Rotate ring to access all fastening points . 2 off fastening points will not be accessible at any point and are restricted by the energy chain mounting bracket and chain . These should be left unfixed at these points

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português