| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 162 : | Ligne 162 : | ||

|Step_Picture_02=R0015101_Bench_Assemble_Take_Up_Assembly_Screenshot_2023-07-06_074019.png | |Step_Picture_02=R0015101_Bench_Assemble_Take_Up_Assembly_Screenshot_2023-07-06_074019.png | ||

|Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":643,"height":631,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.93,"scaleY":0.93,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/75/R0015101_Bench_Assemble_Take_Up_Assembly_Screenshot_2023-07-06_074019.png","filters":[]}],"height":589,"width":600} | |Step_Picture_02_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":643,"height":631,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.93,"scaleY":0.93,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/75/R0015101_Bench_Assemble_Take_Up_Assembly_Screenshot_2023-07-06_074019.png","filters":[]}],"height":589,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Lubrication</translate> | ||

| + | |Step_Content=<translate>4 off arms should be lubricated with grease gun and trojan grease via greasing point</translate> | ||

| + | |Step_Picture_00=R0015101_Bench_Assemble_Take_Up_Assembly_Screenshot_2023-11-08_084023.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 8 novembre 2023 à 09:41

Instructions to bench assemble take up parts

Introduction

Tools Required

Standard hex key set

Standard spanner set

Parts Required

D0008281 Takeup Boss Cap x 4

D0015581 Fixed Pivot Bracket x 4

D0015584 Cylinder Trunnion Plate x 1

D0015590 Takeup Arm ZX5 x4

D0015593 Takeup Arm Pin ZX5 x 4

D0015595 Takeup Arm Washer 4mm x 4

D0015596 Takeup Bearing Block Short x 4

D0015605 Fixed Pivot Bracket End Plate x 4

D0015736 Hard Stop Backplate x 1

D0015737 Hard Stop Shaft x 1

M0001077 Rubber bump stop M6 x 1

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 1

P0000049 Cylinder Spherical Bearing M10 x 1.25 x 1

P0001075 Trunnion Pin for CG1 Cylinder x 1

P0001076 Trunnion Bracket for CG1 x 1

P0001112 Cylinder 32 x 125s Locking

P0001198 Fitting: Speed Controller 1/8" x 6mm Tube

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

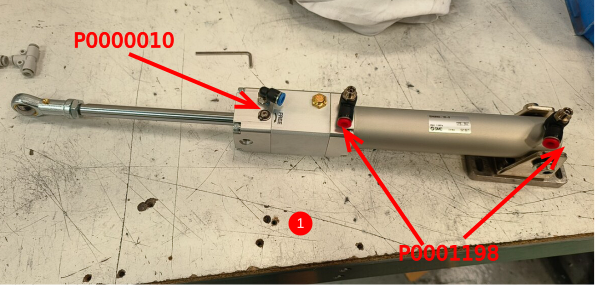

Étape 2 - Assemble cylinder unit

1 Fit air fittings PP0001198 2 off and P0001198 1 off as shown

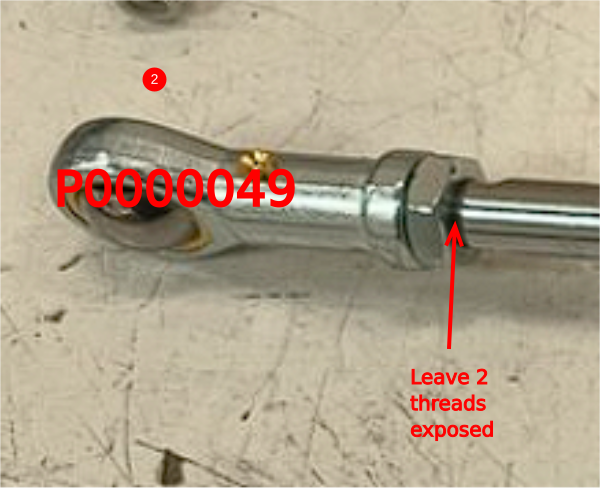

2 Attach P0000049 Cylinder Spherical Bearing to cylinder,use adhesive and finalise lock nut . Leave 2 threads exposed

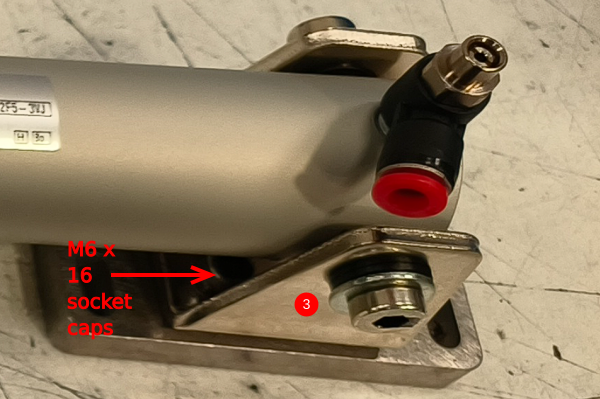

3 Attach Cylinder clevis end using parts

P0001075 Trunnion Pin for CG1 Cylinder x 1

P0001076 Trunnion Bracket for CG1 x 1

Attach with M6 x 16 socket caps

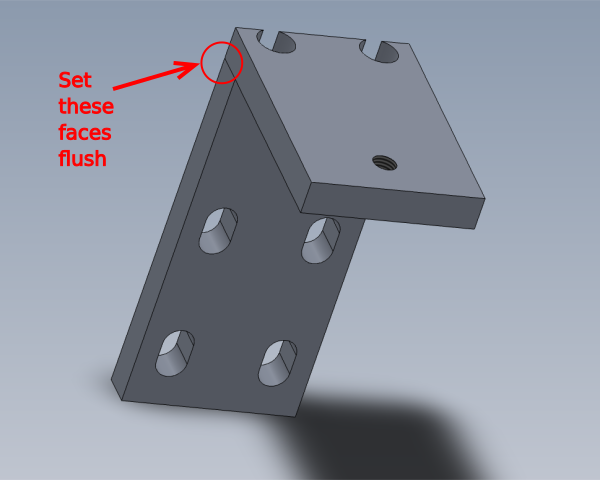

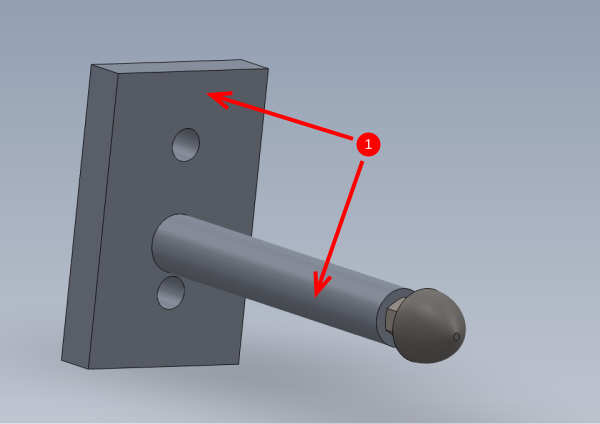

Étape 3 - Mounting bracket assembly

4 off

1 Combine D0015605 and D0015581 and fasten with 2 off M6 x 16 socket caps

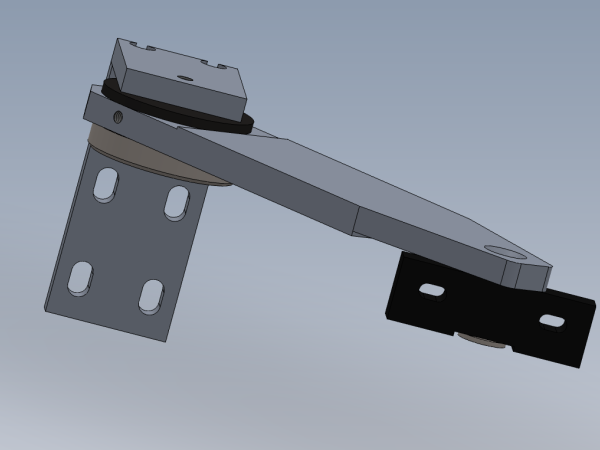

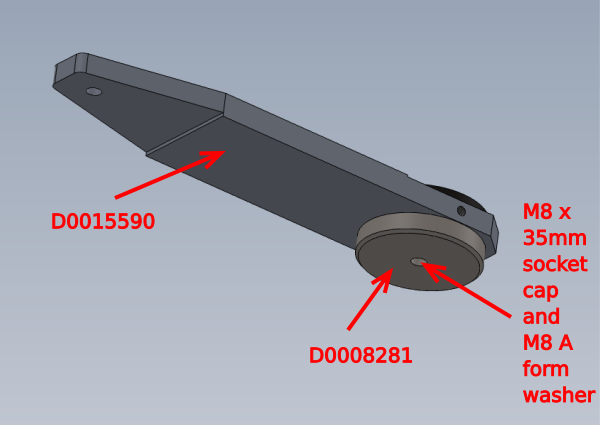

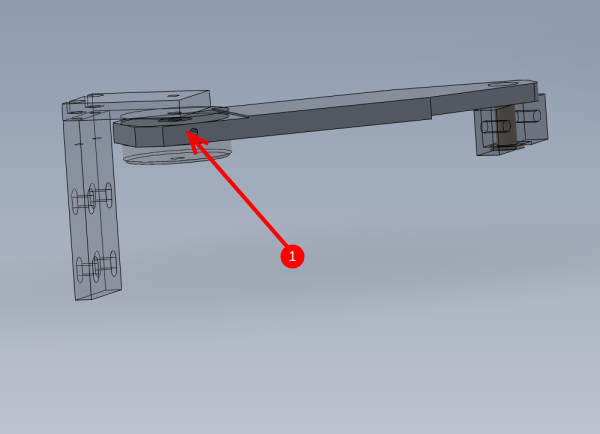

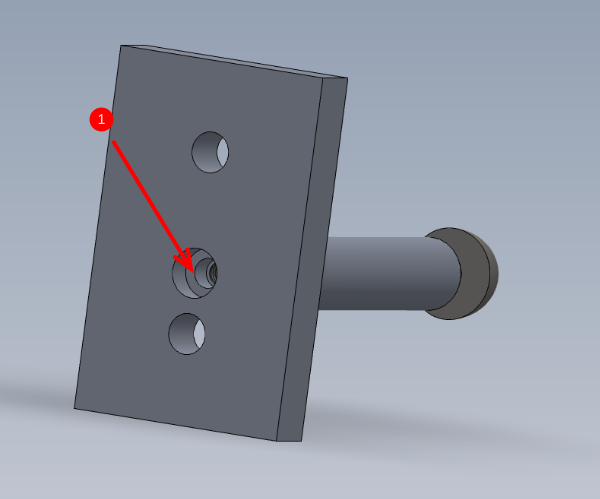

Étape 4 - Assemble arm

4 off

Assemble arm parts as shown

1 Add M6 straight grease nipple to indicated face

2 Add M6 x 10 grubscrew to indicated face

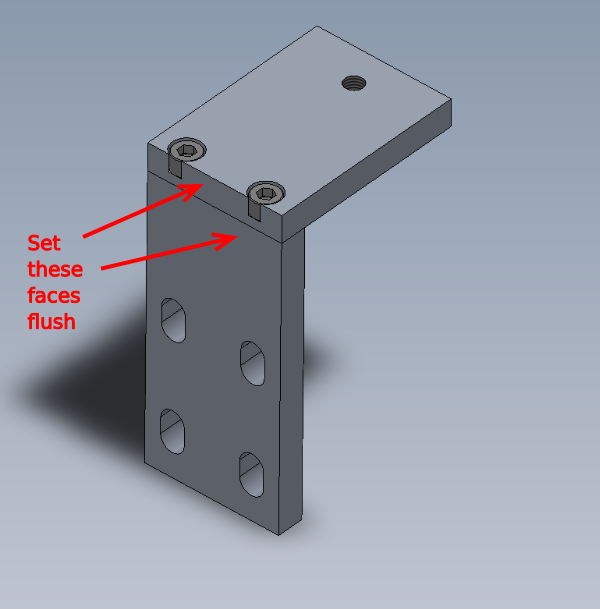

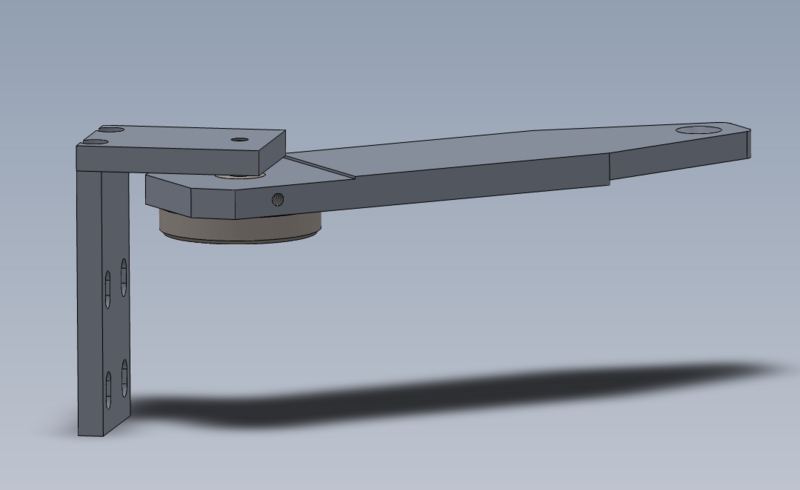

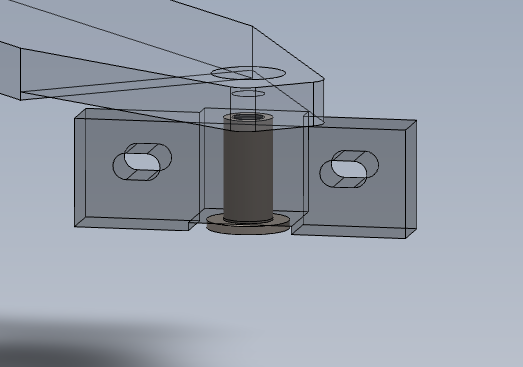

Étape 5 - Assemble arm to bracket

4 off

Use M8 x 40 socket cap with heavy M8 washer to combine parts as shown . Use loctite 270 on M8 socket cap

Once bolt is finalised, check arm rotates smoothly when the bracket is held

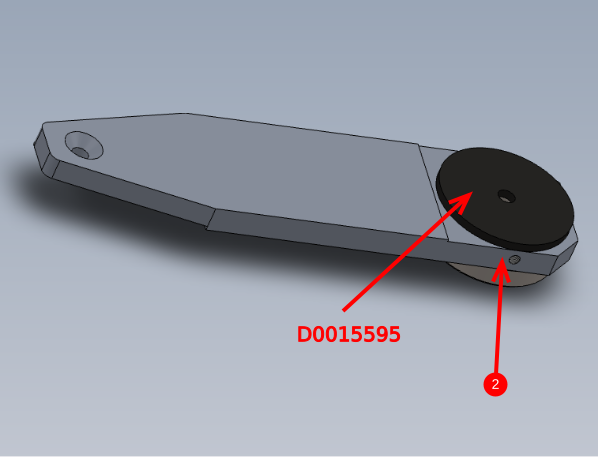

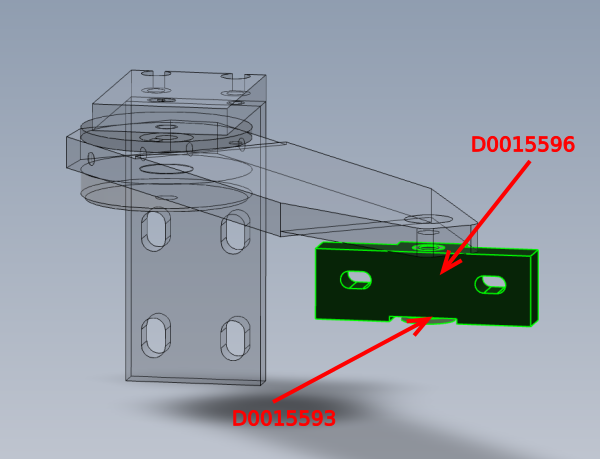

Étape 6 - Attach bearing block

4 off

Insert D0015593 pin into takeup bearing block D0015596 and secure to arm using M8 x 30 Countersunk bolt and use Loctite 270 to fix

Check that D0015596 block turns freely once fastened

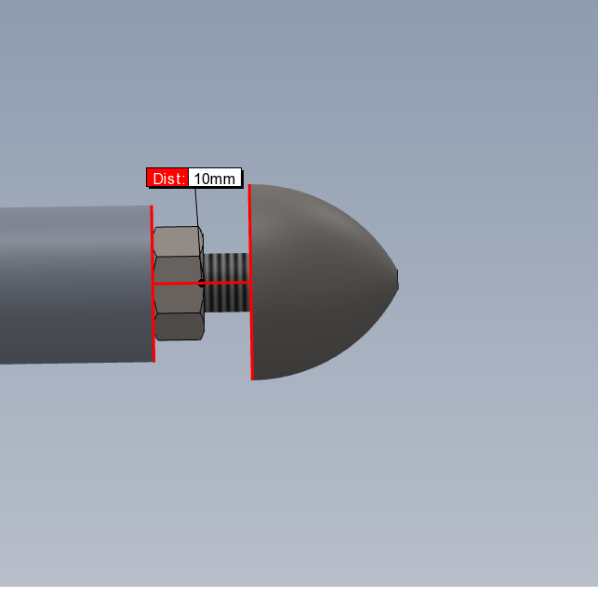

Étape 7 - Assemble bump stop

1 off

1 Mount D0015737 shaft to D0015736 Backplate using M6 x 16 socket cap

2 Attach bump stop M0001077 with M6 standard nut, use loctite 243 and set to dimension shown

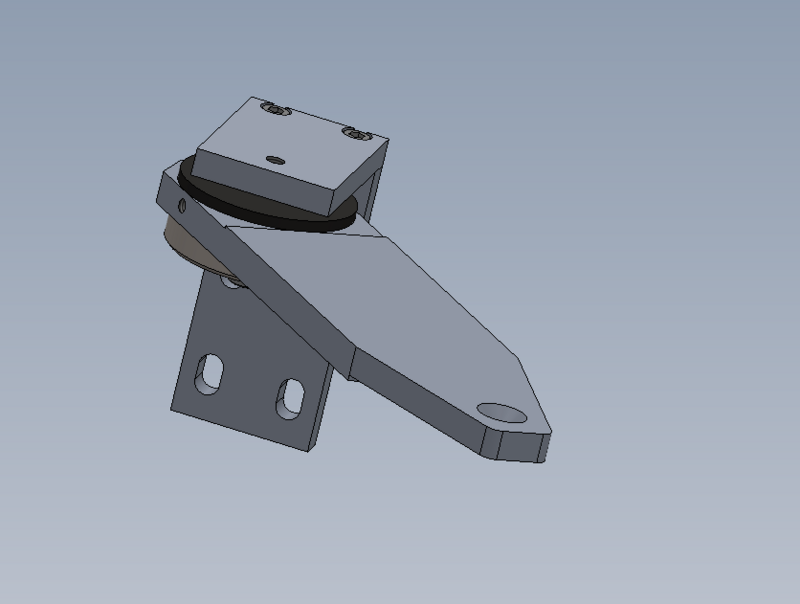

Étape 8 - Lubrication

4 off arms should be lubricated with grease gun and trojan grease via greasing point

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português