| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 31 : | Ligne 31 : | ||

D0015363 Sensor Flapper Support Transfer SEE NOTE x 1 | D0015363 Sensor Flapper Support Transfer SEE NOTE x 1 | ||

| − | |||

| − | |||

E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn x 7 | E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn x 7 | ||

Version du 27 septembre 2023 à 10:23

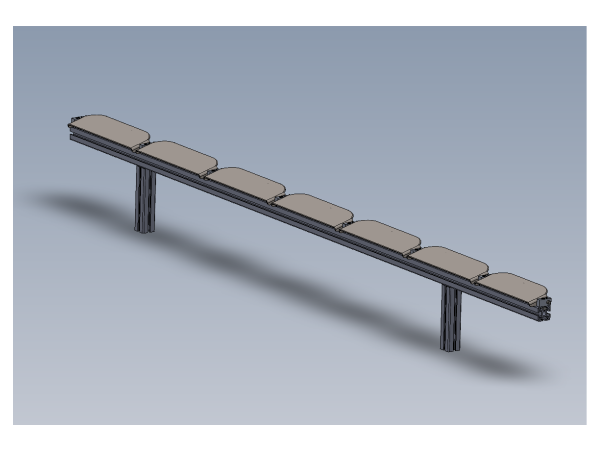

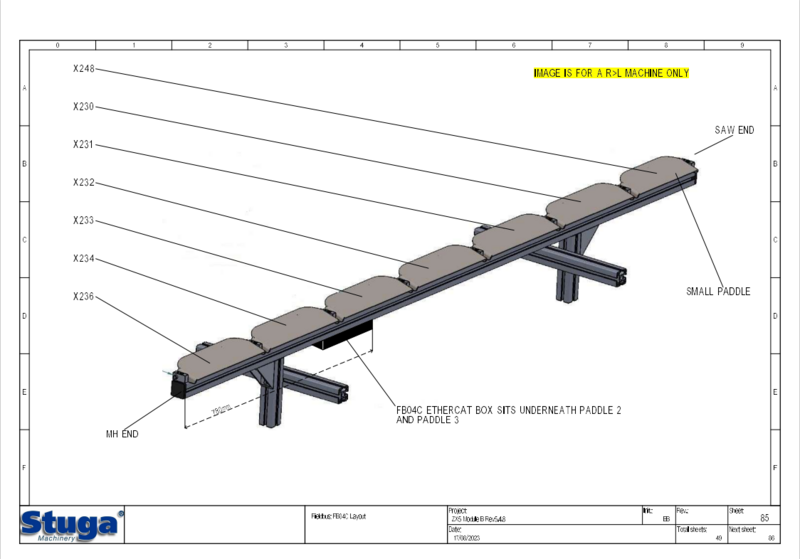

Bench assembly details for sensor rail

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Quality check

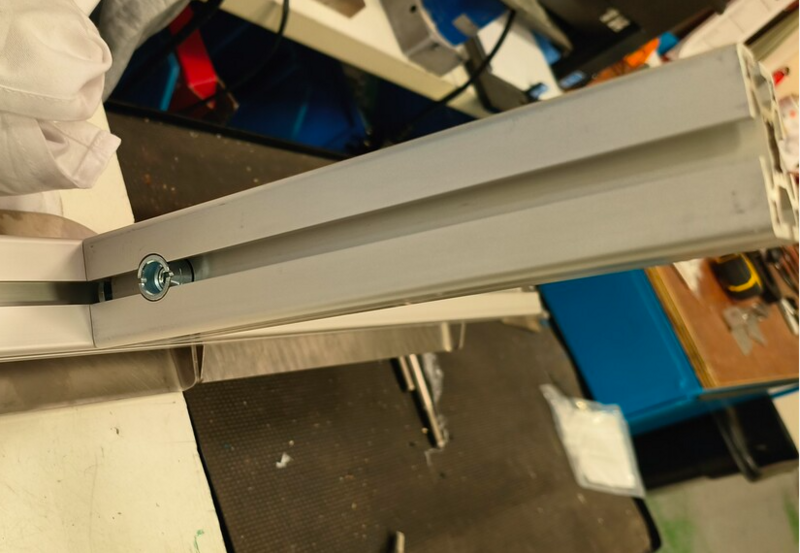

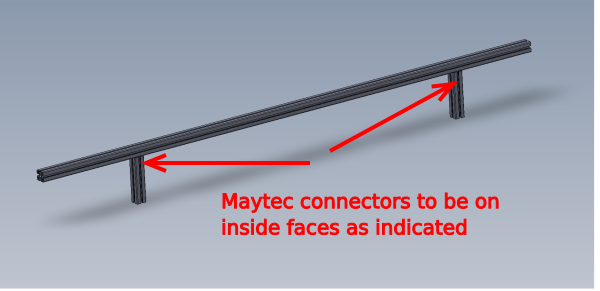

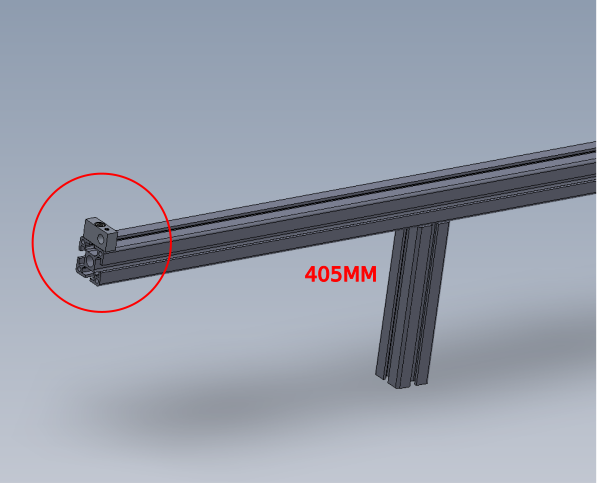

- 4 Étape 3 - Assemble Maytec frame

- 5 Étape 4 - Fit bushes

- 6 Étape 5 - Fit 1st Pivot

- 7 Étape 6 - Add dowel

- 8 Étape 7 - Fit 1st plate

- 9 Étape 8 - Fit 2nd plate

- 10 Étape 9 - Repeat for remaining plates

- 11 Étape 10 - Fit sensors

- 12 Étape 11 - Fit tie bases

- 13 Étape 12 - Assemble and mount Ethercat box

- 14 Étape 13 - Fit support angles

- 15 Étape 14 - Quality check

- 16 Étape 15 - Electrical connections if requested

- 17 Commentaires

Introduction

Tools Required

Standard hex key set

Parts Required

B0001099 Bush flange 10 i/d 12 o/d x 14

C0001018 EP2338-0001 EtherCAT Box 8 Configurable IO x 1

D0010167 Ethercat Mount Plate x 1

D0015353 Sensor Flapper Pivot x 8

D0015355 Sensor Flapper Plate (312) x 6

D0015357 Sensor Flapper Plate (270) x 1

D0015363 Sensor Flapper Support Transfer SEE NOTE x 1

E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn x 7

F0000537 dowel pin 10 x 40 x 8

M0001016 Angle 74 x 38 x 2

M0001209 Bracket m8 proximity sensor bracket 90 deg x 7

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts when finalised

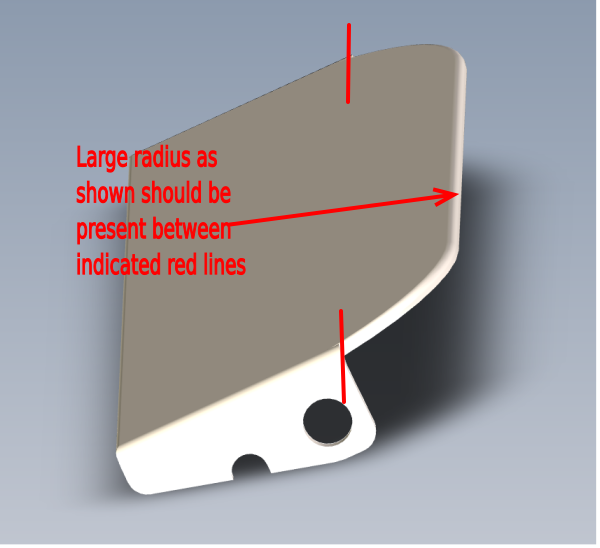

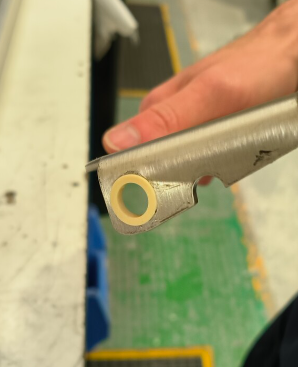

Étape 2 - Quality check

Check components

D0015355 Sensor Flapper Plate (312) x 6

D0015357 Sensor Flapper Plate (270) x 1

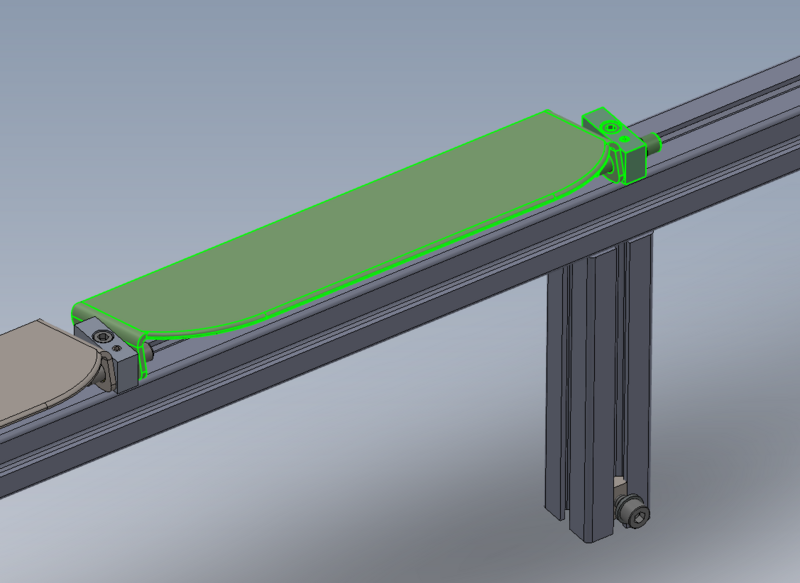

Ensure indicated have a radius on the indicated faces and are smooth and burr free

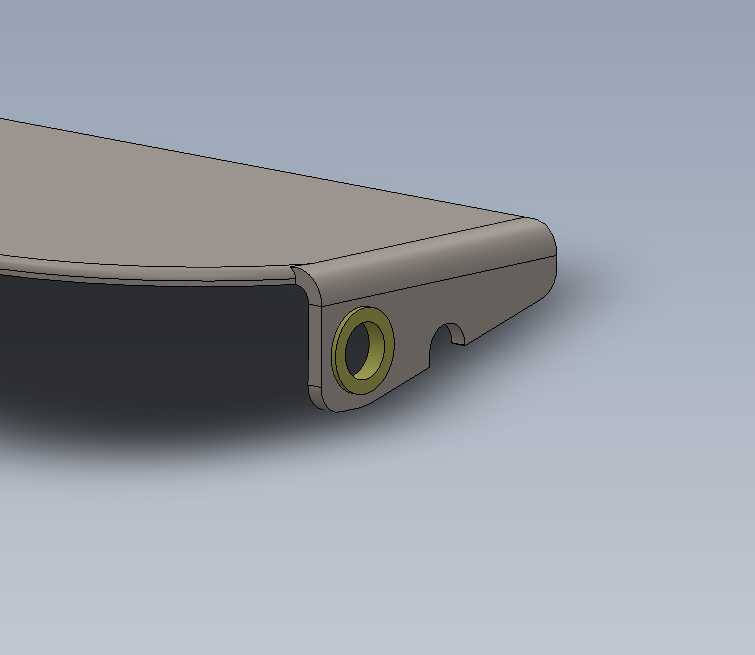

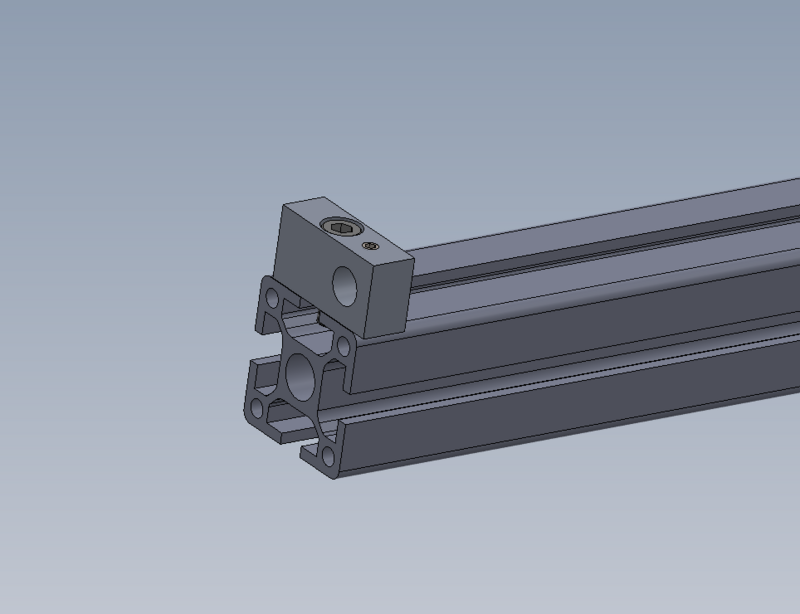

Étape 4 - Fit bushes

Fit B0001099 Bush flange 10 i/d 12 o/d x 14 into D0015355 Sensor Flapper Plate (312) x 6 and D0015357 Sensor Flapper Plate (270) x 1 as shown

Étape 5 - Fit 1st Pivot

Fit 1st D0015353 Sensor Flapper Pivot as shown

Fix with F0000299 m6 d nut and M6 x 20 socket cap

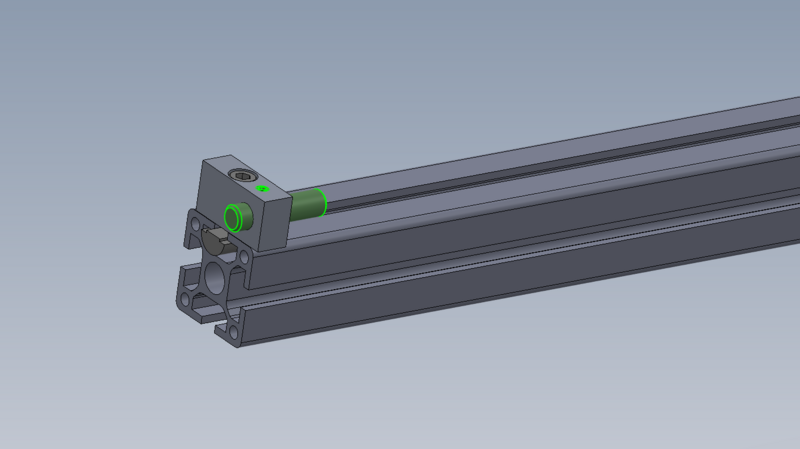

Étape 6 - Add dowel

Fit F0000537 dowel pin 10 x 40 as shown, leaving 5mm of protrusion

Secure with M5 x 12 kcp grubscrew

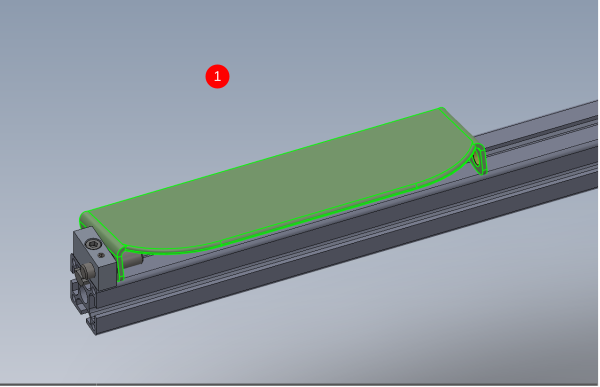

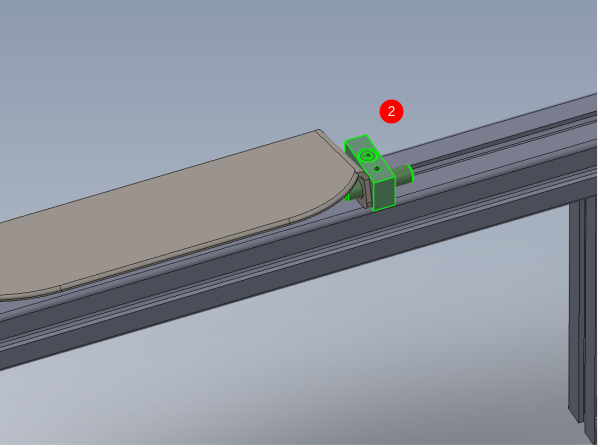

Étape 7 - Fit 1st plate

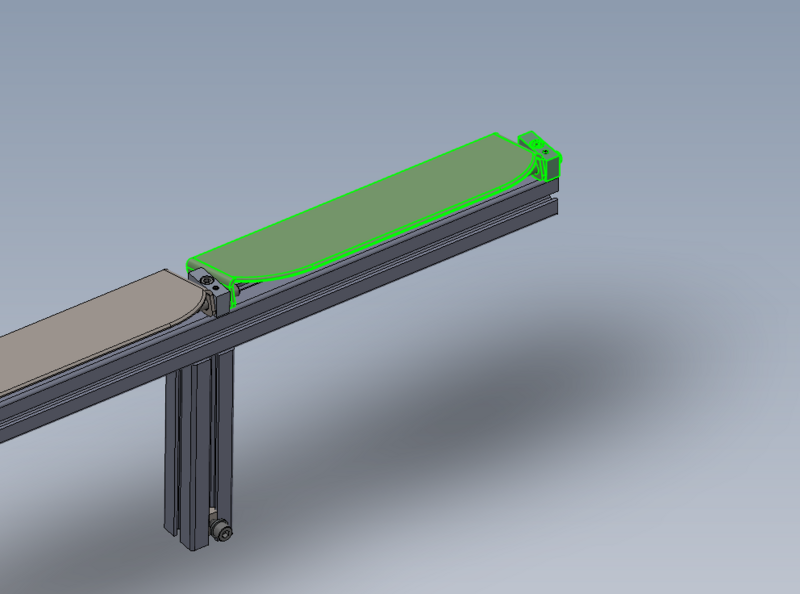

1 Position as shown D0015357 Sensor Flapper Plate

2 Captivate with pivot block and dowel as shown, using same fixings as previous pivot block . Ensure dowel sits central in pivot block.

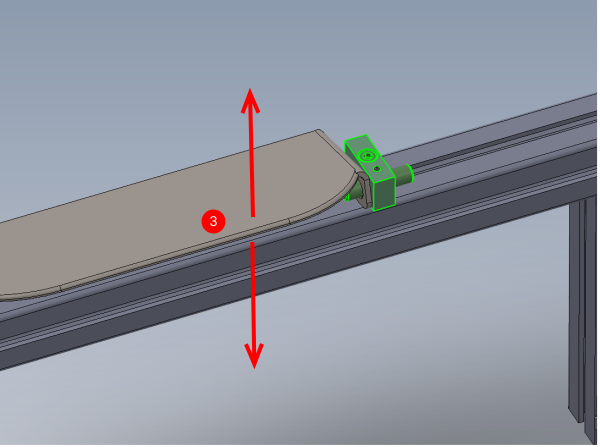

3 Ensure sensor plate is free to move in the direction shown when fitted. Leave as minimal gap as possible between pivot blocks and sensor plate

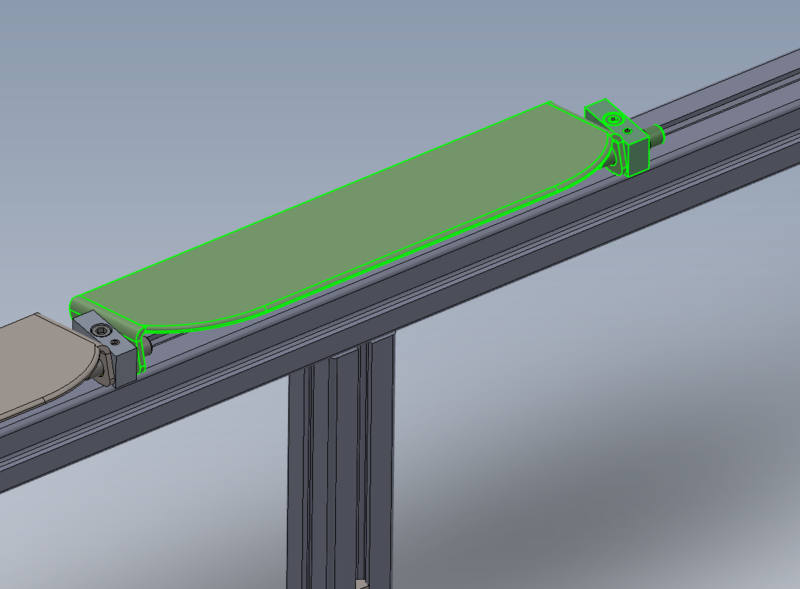

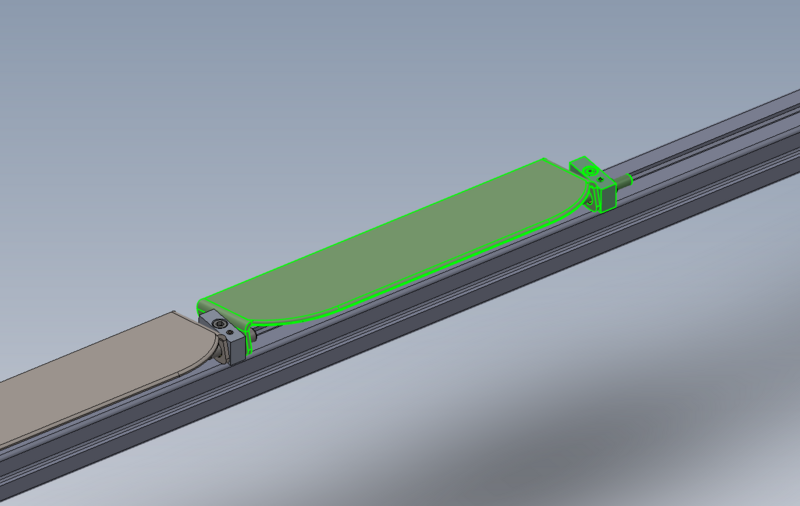

Étape 8 - Fit 2nd plate

Fit D0015355 Sensor Flapper Plate (312) and fix with same method as previous steps

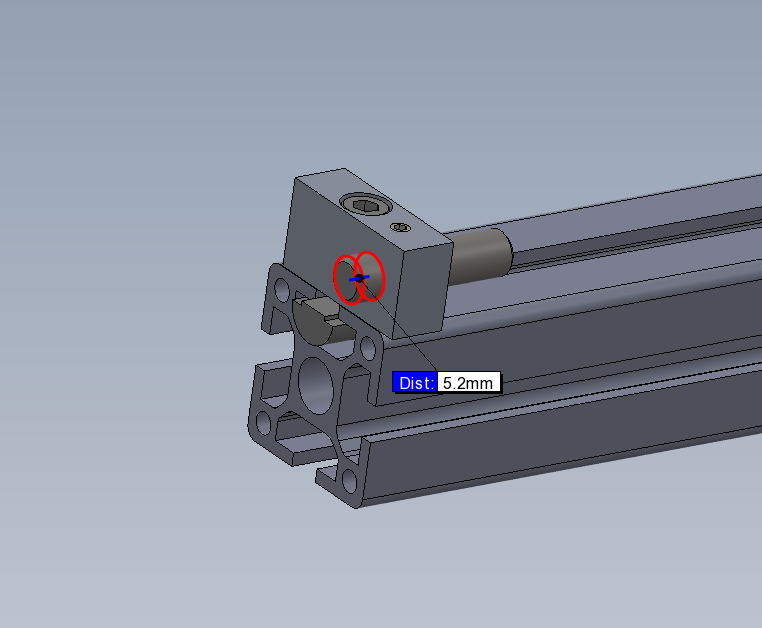

Étape 10 - Fit sensors

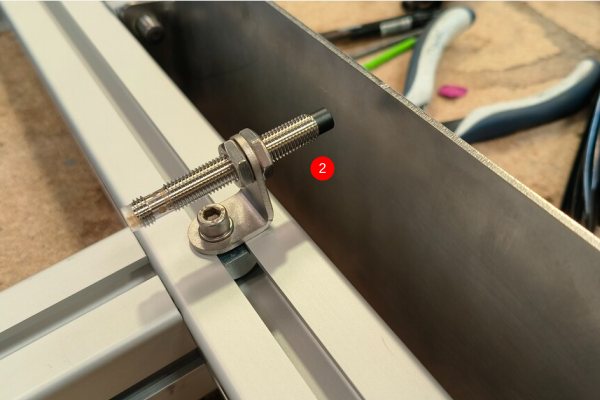

1 Fit 7 off M0001209 Bracket m8 proximity sensor bracket 90 deg. Position each bracket centrally beneath each sensor plate and orientate as shown

Use M5 fat D nut, M5 x 10 socket cap and A form washer to secure

2 Fit 7 off E0000336L Sensor: M8; 4mm, PNP N/O, M8 conn as shown .

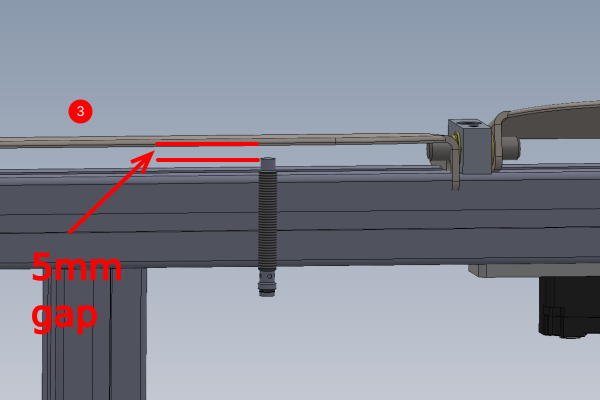

3 Set sensor gap to 5mm

With the sensor plate fully depressed in the direction shown, set sensor so 5mm gap is present

4 Secure 2 off lock nuts on sensor. Caution do not over tension, as this can lead to damage to sensor !

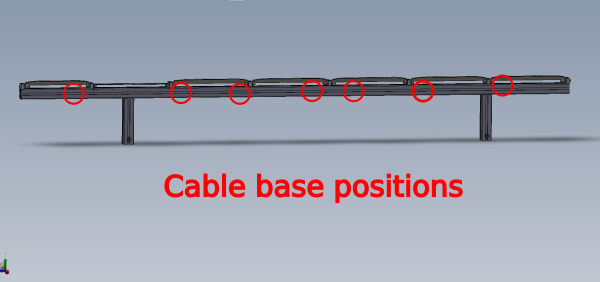

Étape 11 - Fit tie bases

Fit Cable tie bases using M5 x 10 button sockets an M5 fat D nuts at the positions shown

(cables shown are fitted at a later stage)

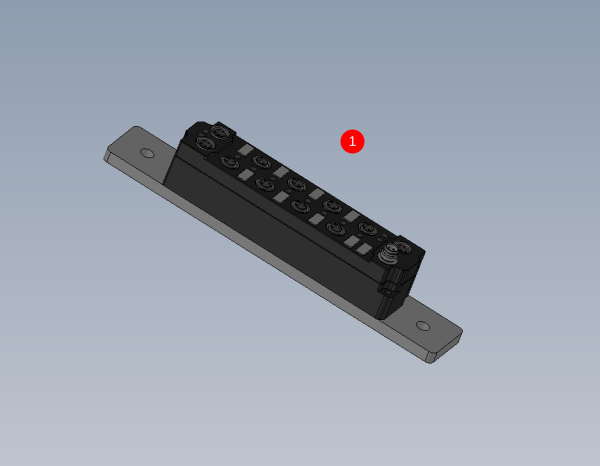

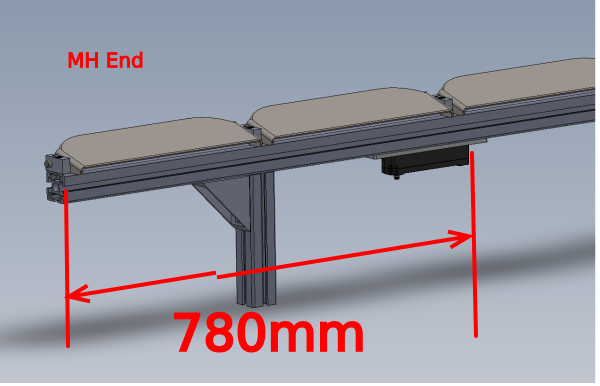

Étape 12 - Assemble and mount Ethercat box

1 Assemble C0001018 EP2338-0001 EtherCAT Box 8 Configurable IO onto D0010167 Ethercat Mount Plate x 1 as shown using M3 x 20 pan head fasteners

2 Fit to assembly Using 2 off M6 fat D nuts , M6 x 16 socket caps and A form washers at the position shown of 780 mm from indicated face to edge of ethercat box

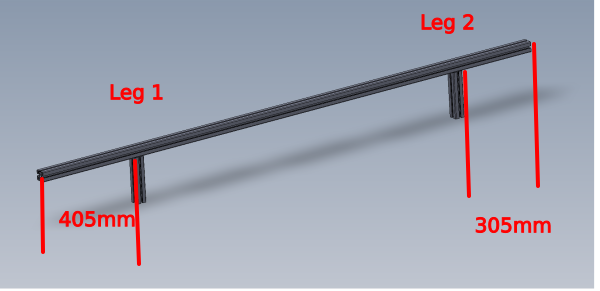

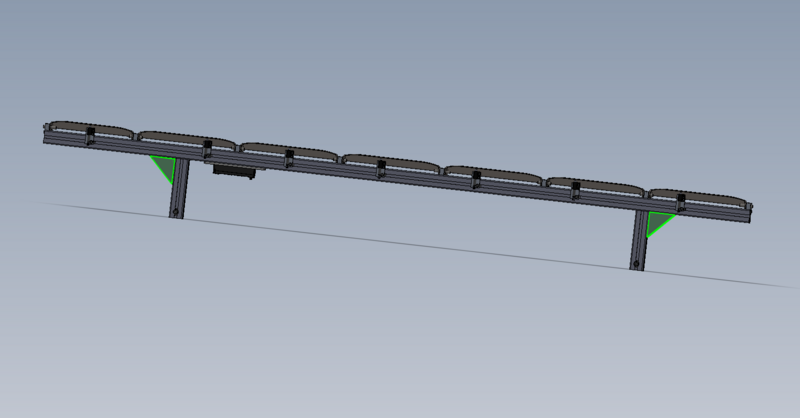

Étape 13 - Fit support angles

Fit 2 off M0001016 Angle 74 x 38 as shown

Fasten with M8 Fat D nut, M8 x 20 socket cap and Heavy M8 motor plate washers

Étape 14 - Quality check

Ensure all fasteners are double checked for correct tension, adhesive and identification to show finalised

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português