| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 76 : | Ligne 76 : | ||

2 Rotate turntable to 45 and 135 degrees (full travel in both directions ) | 2 Rotate turntable to 45 and 135 degrees (full travel in both directions ) | ||

| − | 3 Clearance should be evident between saw blade and clamps in the area shown | + | 3 Clearance should be evident between saw blade and clamps in the area shown |

| + | |||

| + | Report to supervisor if contact is present | ||

Version du 29 janvier 2024 à 12:34

Fitting and assembly details for material clamps

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach Infeed clamp assembly

- 4 Étape 3 - Set position

- 5 Étape 4 - Check clearance to saw blade

- 6 Étape 5 - Fit outfeed clamp assembly

- 7 Étape 6 - Align clamps

- 8 Étape 7 - Finalise torque setting

- 9 Étape 8 - Recheck alignment

- 10 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

1 meter straight edge

Feeler gauges

Soft hammer

Engineers square

Parts Required

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

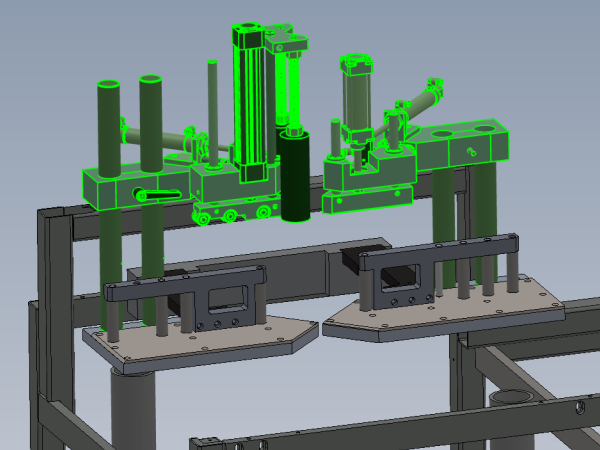

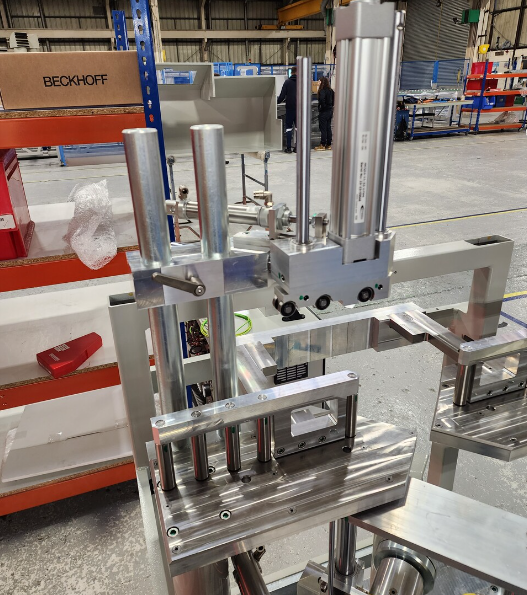

Étape 2 - Attach Infeed clamp assembly

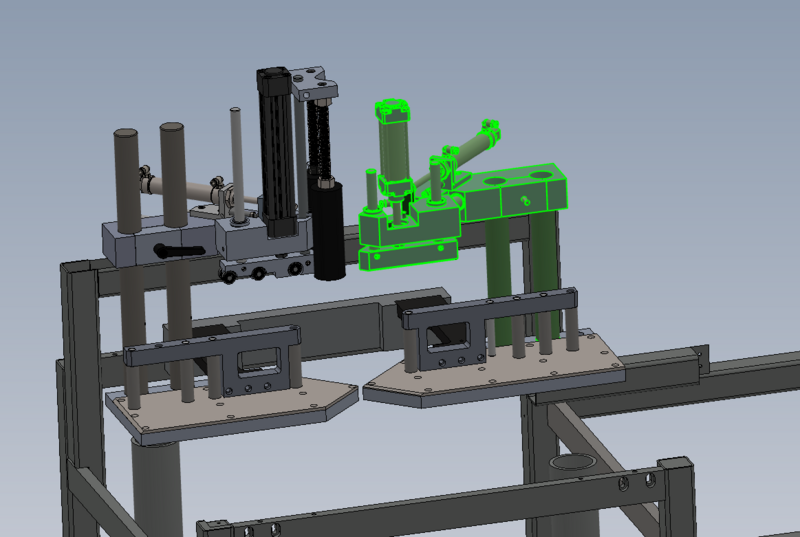

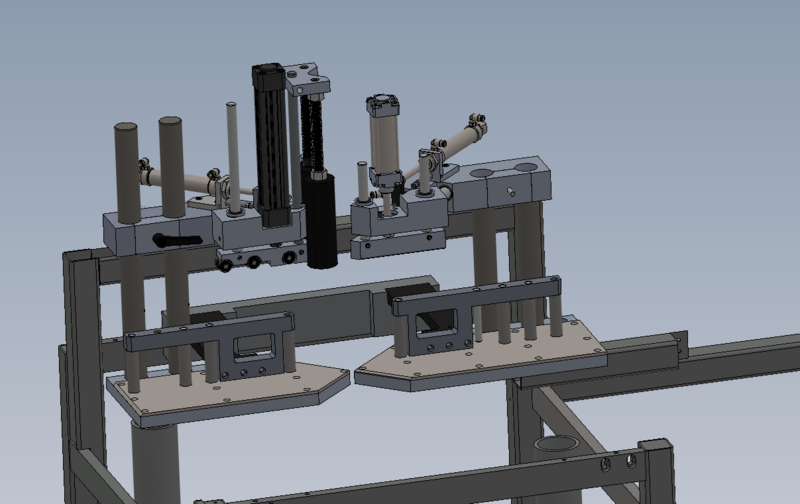

Attach infeed clamp assembly to infeed pad

Use 2 off M8 x 35 socket caps Do not use adhesive at this point

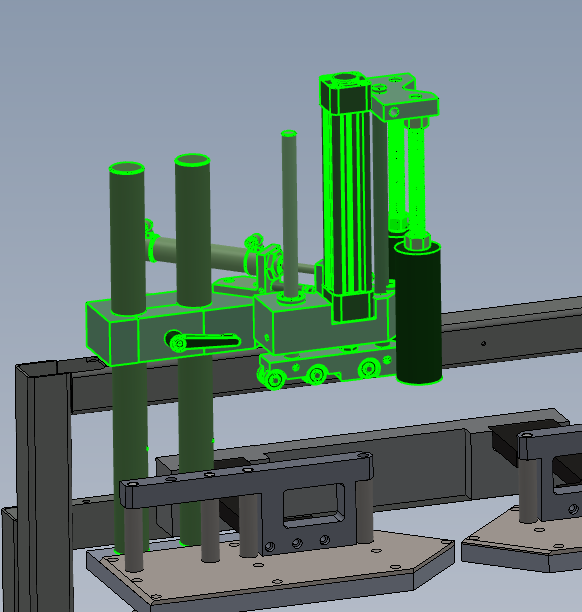

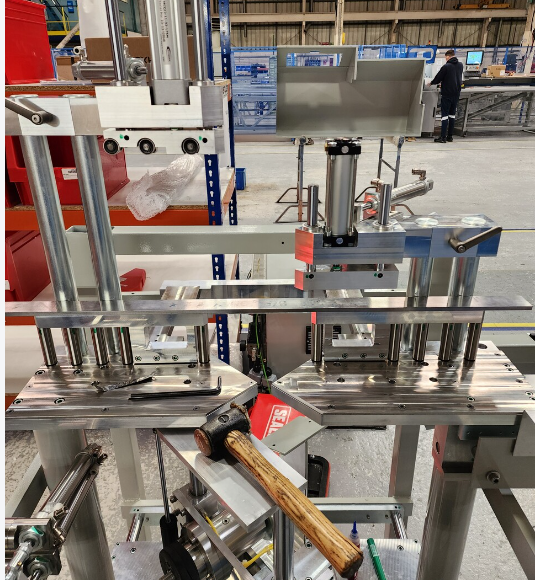

Étape 3 - Set position

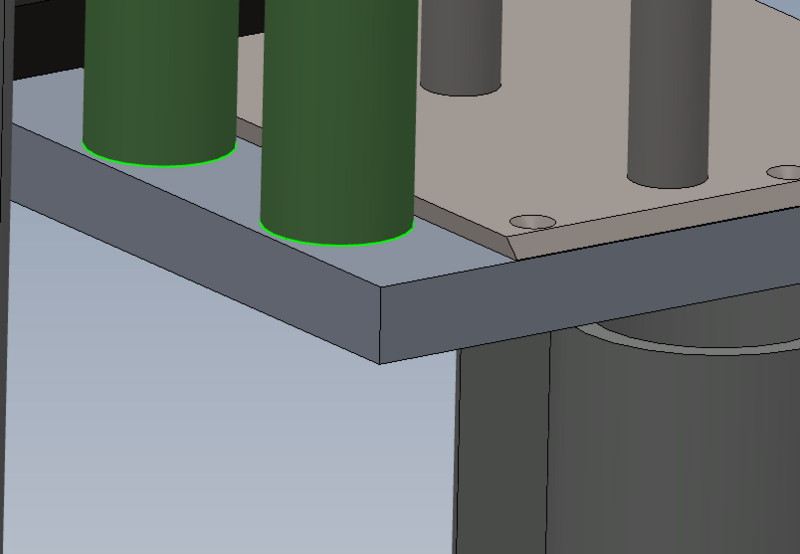

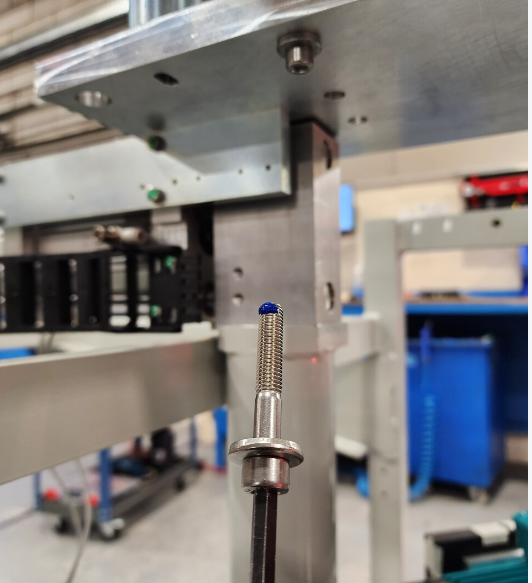

Use soft hammer to adjust pillar position to be flush with cut table

Check position using engineers square as shown

Add final tension to M8 securing fasteners

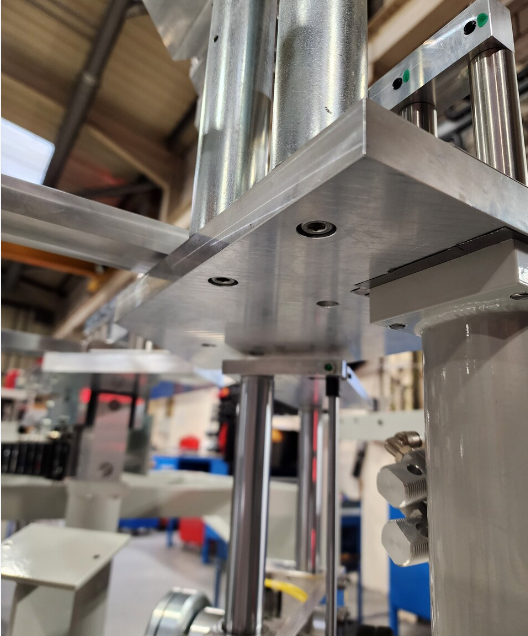

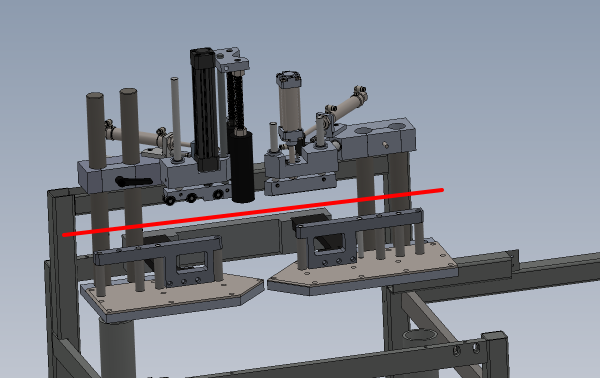

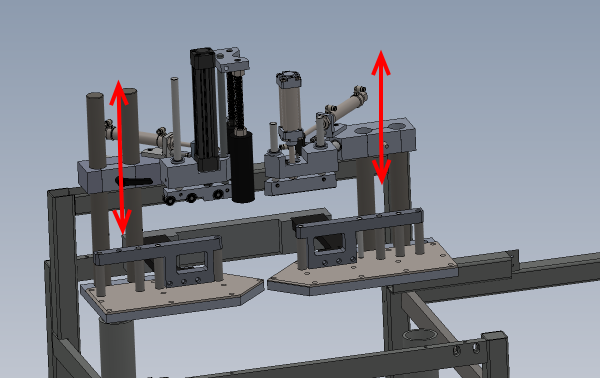

Étape 4 - Check clearance to saw blade

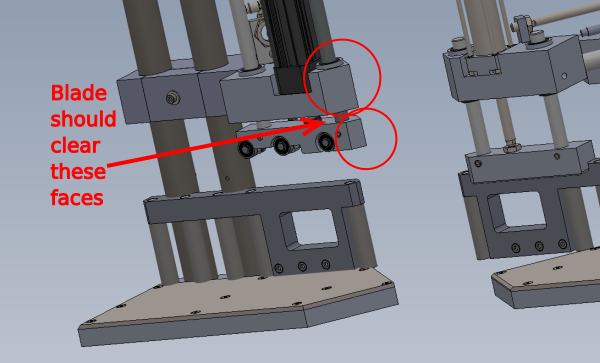

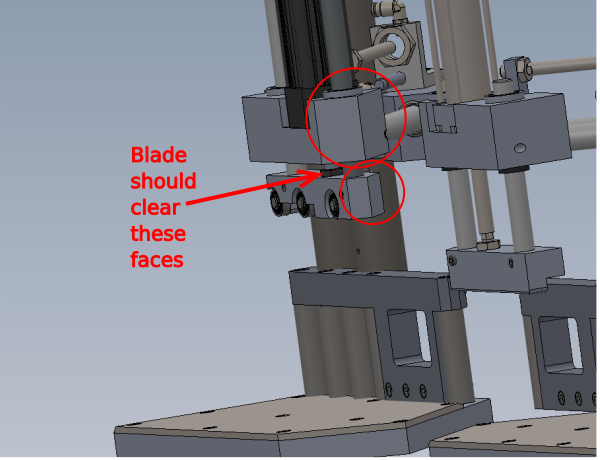

Clearance between clamps and saw blade must be checked. To do this

1 Lift saw blade to maximum height

2 Rotate turntable to 45 and 135 degrees (full travel in both directions )

3 Clearance should be evident between saw blade and clamps in the area shown

Report to supervisor if contact is present

Please take photos to show this check

Étape 5 - Fit outfeed clamp assembly

Fit outfeed clamp assembly to outfeed pad sing 2 off M8 x 50 socket caps and M8 motor plate washers

Do not use adhesive at this point

Étape 6 - Align clamps

Use 1 meter straight edge along pillars

Adjust OUTFEED CLAMP to set all 4 pillars to contact straight edge

Use feeler 0.002" /0.05mm gauge as maximum tolerance

Étape 7 - Finalise torque setting

Individually remove and apply adhesive to 4 off M8 fasteners and apply final tension setting to 40nm with torque wrench

Étape 8 - Recheck alignment

Recheck alignment once final tension is added to all fasteners

Check all clamps more freely up and down pillars when quip clamp has tension removed

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português