| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 174 : | Ligne 174 : | ||

| − | Ensure plate is mounted parallel and at | + | Ensure plate is mounted parallel and at lowest point in slots</translate> |

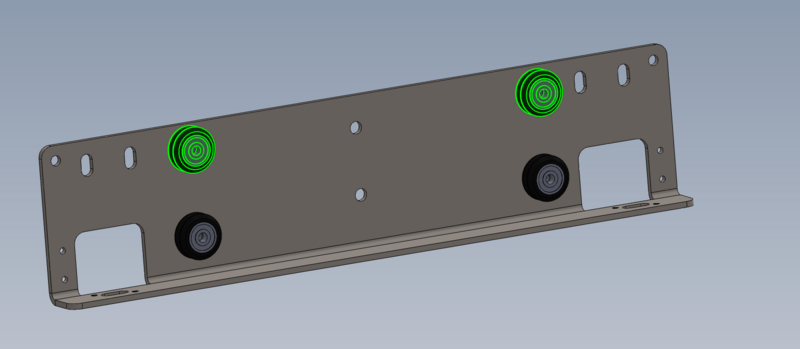

|Step_Picture_00=R0015288_Bench_Assemble_Transfer_slider_units_and_Cylinder_Rails_Screenshot_2023-09-20_153153.png | |Step_Picture_00=R0015288_Bench_Assemble_Transfer_slider_units_and_Cylinder_Rails_Screenshot_2023-09-20_153153.png | ||

|Step_Picture_01=R0015288_Bench_Assemble_Transfer_slider_units_and_Cylinder_Rails_Screenshot_2023-11-27_110240.png | |Step_Picture_01=R0015288_Bench_Assemble_Transfer_slider_units_and_Cylinder_Rails_Screenshot_2023-11-27_110240.png | ||

Version actuelle datée du 22 décembre 2023 à 09:42

bench assembly details for bench assembly of pneumatic transfer rails

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Warning!!

- 4 Étape 3 - Check D0015573 for rework

- 5 Étape 4 - Air fittings to cylinders

- 6 Étape 5 - Attach cylinders

- 7 Étape 6 - Cut air pipes

- 8 Étape 7 - Connect Air pipes

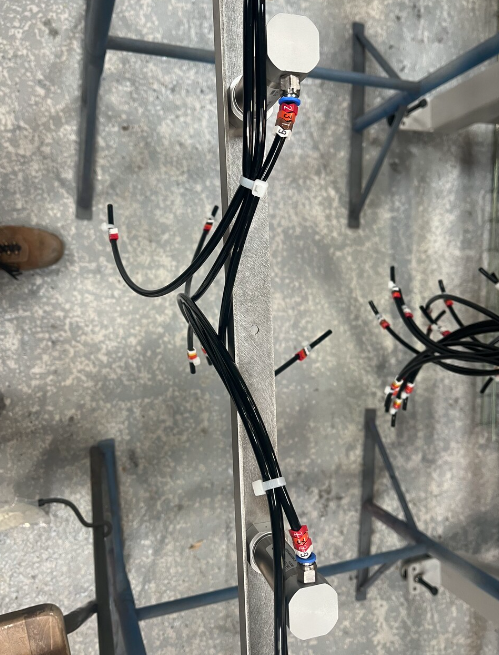

- 9 Étape 8 - Loom pipes

- 10 Étape 9 - Fit loom support spacer

- 11 Étape 10 - Assemble and fit concentric journal

- 12 Étape 11 - Assemble and fit Eccentric journal

- 13 Étape 12 - Attach to transfer rail

- 14 Étape 13 - Assemble drive journals concentric

- 15 Étape 14 - Assemble drive journals eccentric

- 16 Étape 15 - Attach drive rack

- 17 Étape 16 - Attach to cylinder rail

- 18 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Parts Required

B0001160 Delrin Dual V Wheel Kit x 48

B0001161 Spacer: Concentric - Delrin Dual V Wheel x 24

B0001162 Spacer: Eccentric - Delrin Dual V Wheel x 24

D0015255 Rack: Mod2 360 Long x 8

D0015551 Rack Mounting Plate x 8

D0015572 Slideway Connection Plate (2018) x 8

D0015573 Transfer Cylinder Bracket x 8

D0015576 Pneumatics Support Spacer x 8

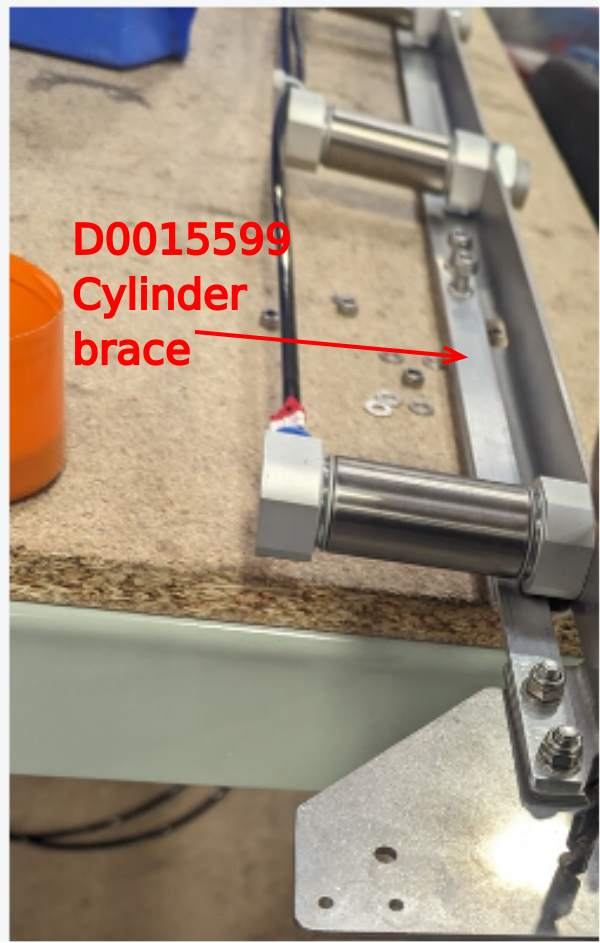

D0015599 Transfer Cylinder Bracket Brace x 8

P0000007 Straight Adaptor 6mm - 1/8 BSP tapered thread x 48

P0001111 Cylinder: Ø25 x 25S Cut Shaft x 48

R0015093 Bench Assemble Transfer Beam x 8

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts when finalised

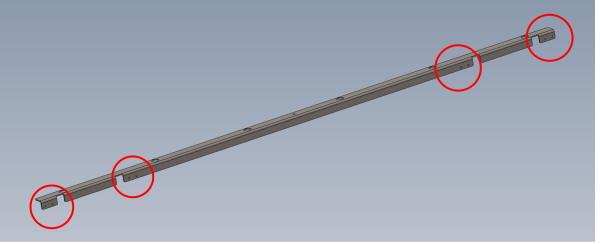

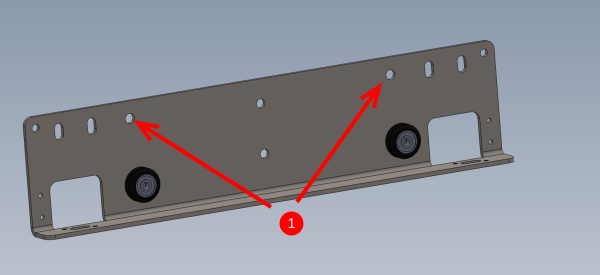

Étape 3 - Check D0015573 for rework

8 off Indicated holes should be 6.5mm clearance not M6 tapped

If holes are tapped, rework and drill to 6.5mm

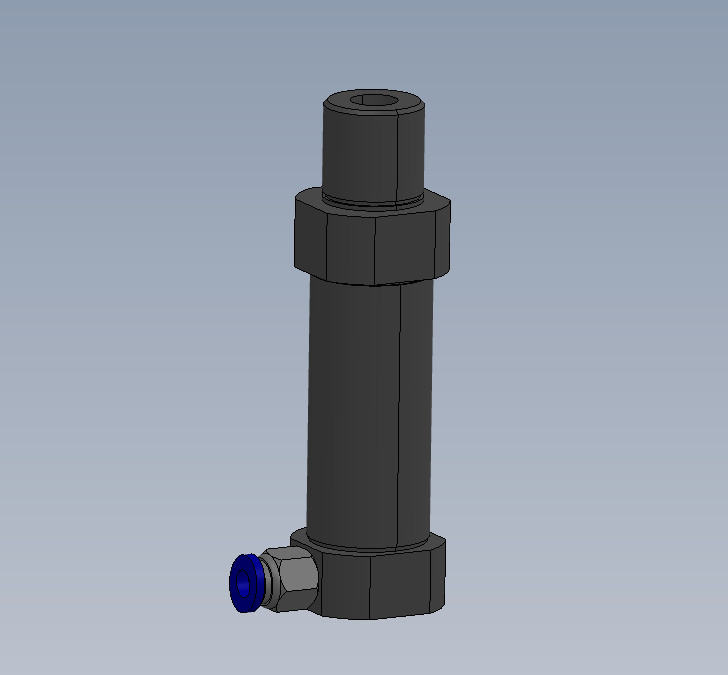

Étape 4 - Air fittings to cylinders

Attach P0000007 Straight Adaptor 6mm - 1/8 BSP tapered thread to P0001111 Cylinder: Ø25 x 25S Cut Shaft as shown

48 in total

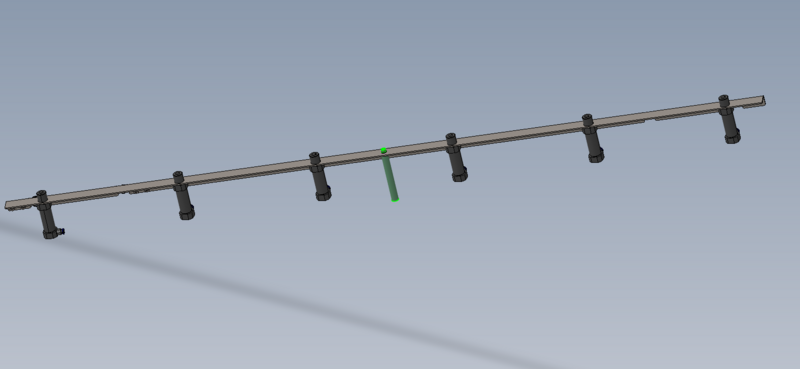

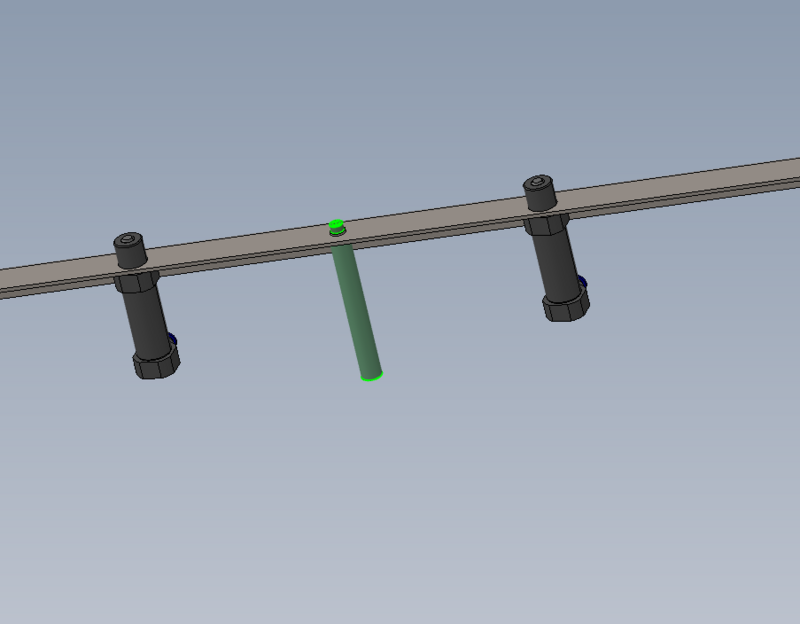

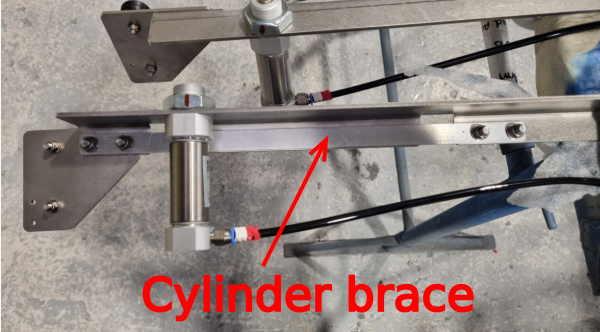

Étape 5 - Attach cylinders

Attach cylinders to D0015573 Transfer Cylinder Bracket as shown

Air fittings to face directions shown

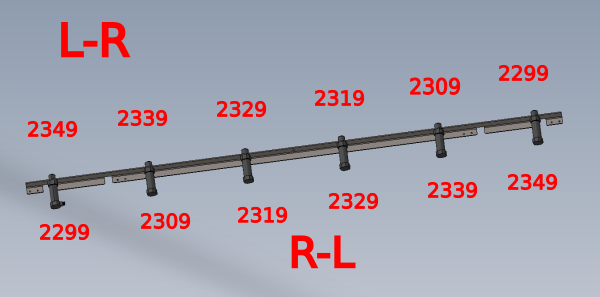

Étape 6 - Cut air pipes

cut and label the following pipes

8 off 6mm black pipes @ 1050mm labelled as 2349 both ends

8 off 6mm black pipes @ 800mm labelled as 2339 both ends

8 off 6mm black pipes @ 500mm labelled as 2329 both ends

8 off 6mm black pipes @ 500mm labelled as 2319 both ends

8 off 6mm black pipes @ 800mm labelled as 2309 both ends

8 off 6mm black pipes @ 1050mm labelled as 2299 both ends

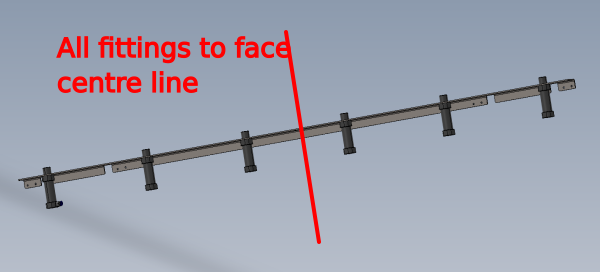

Étape 7 - Connect Air pipes

Connect air pipes as shown on each cylinder rail

L-R and R-L connections shown . Connect to suit handing of machine

Étape 9 - Fit loom support spacer

Fit D0015576 Pneumatics Support Spacer to each assembled rail using M6 x 16 socket caps and A form washer

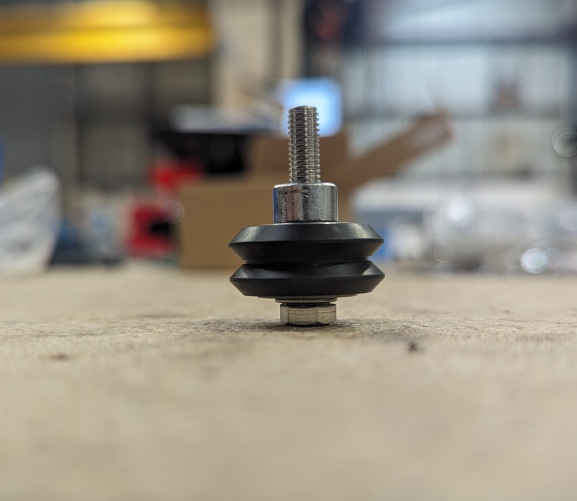

Étape 10 - Assemble and fit concentric journal

8 off in total

Fit concentric journal as shown to D0015572 Slideway Connection Plate

Assemble in this order

M5 x 30 set bolt- M5 A form washer- Delrin wheel assembly B0001160- spacer B0001161 - Main assembly - A form washer- M5 Nyloc nut

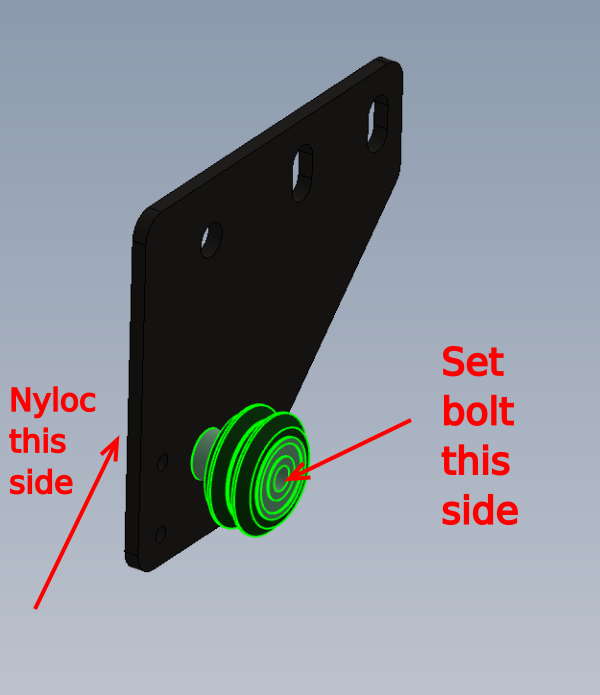

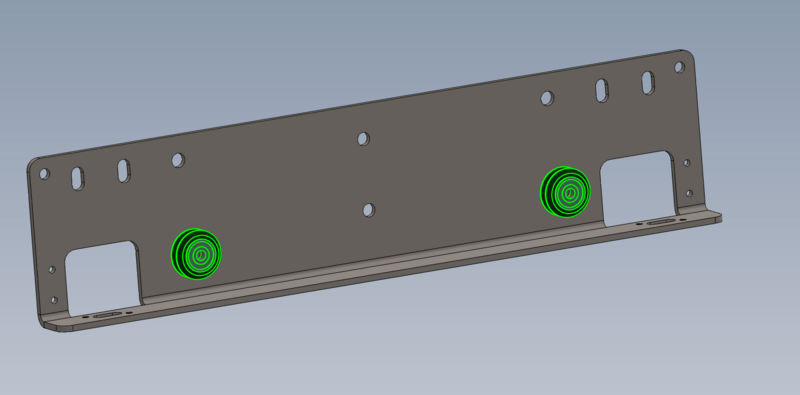

Étape 11 - Assemble and fit Eccentric journal

8 off

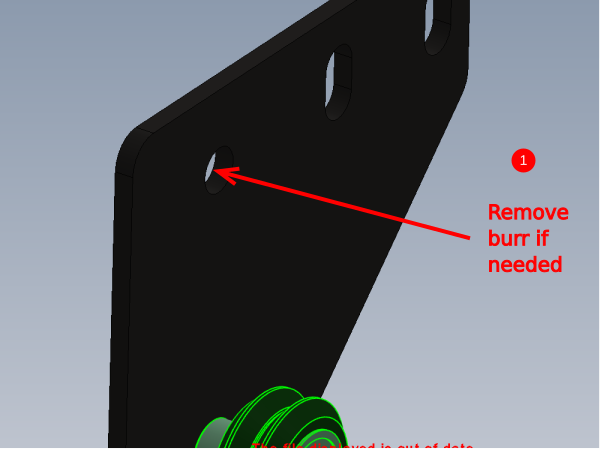

1 Check that part B0001162 sits flush into hole on mounting plate. It may be required to remove burrs from manufacture to achieve this

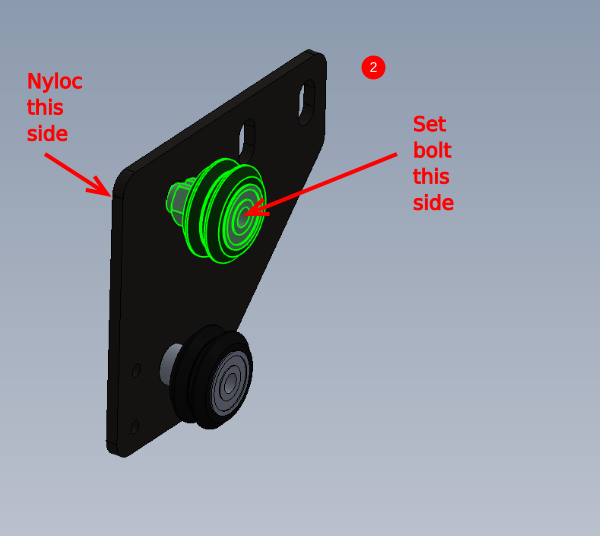

2 Attach delrin wheel in this order.

M5 x 30 Set bolt-M5 A form washer-Delrin Wheel (B0001160) -Eccentric cam(B0001162)- Assembly - M5 A Form Washer- M5 Nyloc nut

Do not add final tension to this wheel assembly as adjustment will be required at a later point

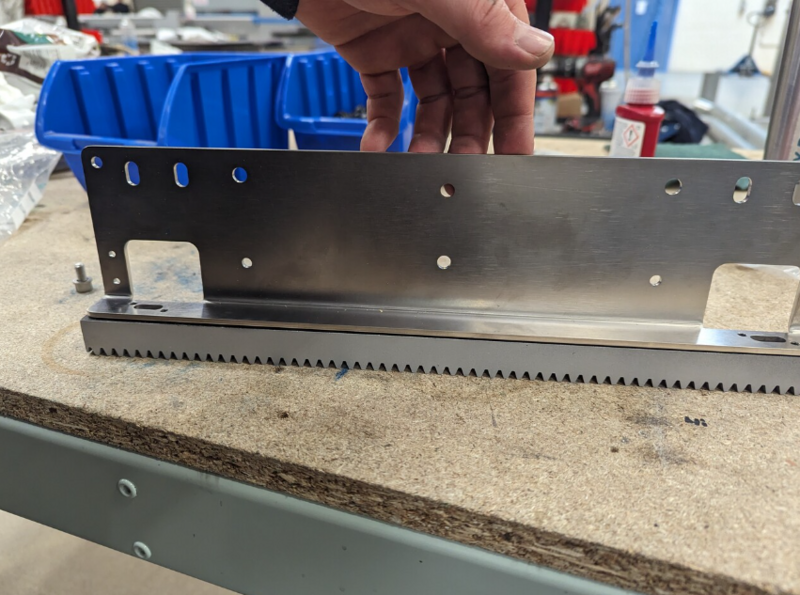

Étape 12 - Attach to transfer rail

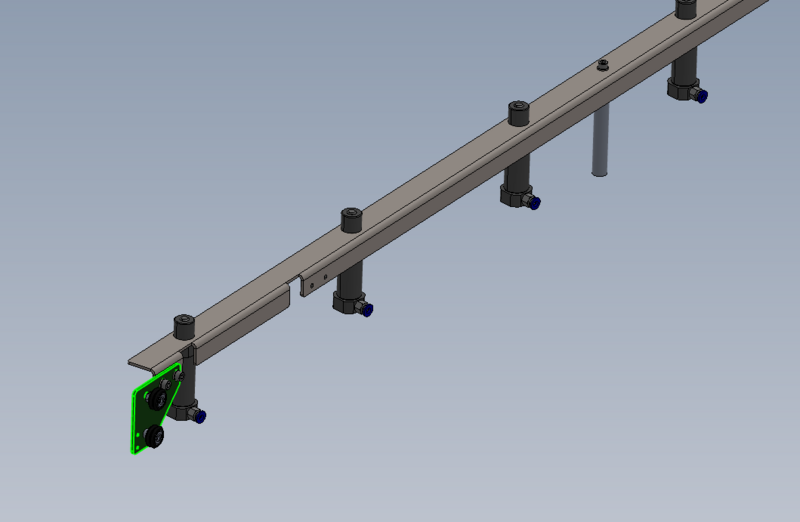

Combine D0015599 Transfer Cylinder Bracket Brace as shown

Use M6 x 20 socket caps, M6 a form washers and M6 nylocs to fix journal plate to transfer rail

Ensure plate is mounted parallel and at lowest point in slots

Étape 13 - Assemble drive journals concentric

8 off in total

Fit 2 off concentric journals as shown to D0015551 Rack Mounting Plate

Assemble in this order

M5 x 30 set bolt- M5 A form washer- Delrin wheel assembly B0001160- spacer B0001161 - Main assembly - A form washer- M5 Nyloc nut

Étape 14 - Assemble drive journals eccentric

1 Check that part B0001162 sits flush into hole on mounting plate. It may be required to remove burrs from manufacture to achieve this

2 Attach delrin wheel in this order.

M5 x 30 Set bolt-M5 A form washer-Delrin Wheel (B0001160) -Eccentric cam(B0001162)- Assembly - M5 A Form Washer- M5 Nyloc nut

Do not add final tension to this wheel assembly as adjustment will be required at a later point

Étape 15 - Attach drive rack

Do not apply adhesive to these bolts

Ensure racks have been treated with ZG-90 galv spray

8 off

Attach D0015255 Rack: Mod2 360 Long as shown.

Fix with M6 x 20 socket caps and A form washers

Once Rack is fixed to mounting plate, add 4 off m4 x 20 socket caps as shown

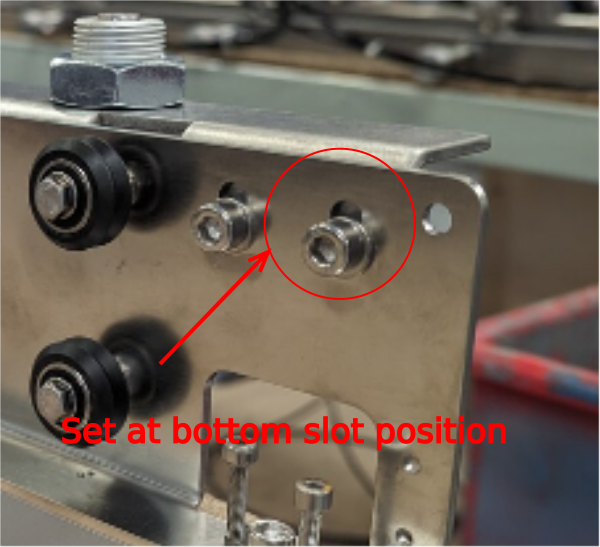

Étape 16 - Attach to cylinder rail

Attach assembly to cylinder rail as shown , using 4 off M6 x 12 socket caps and A Form washers

Ensure bottom of slot adjustment is used as shown

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português