| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 147 : | Ligne 147 : | ||

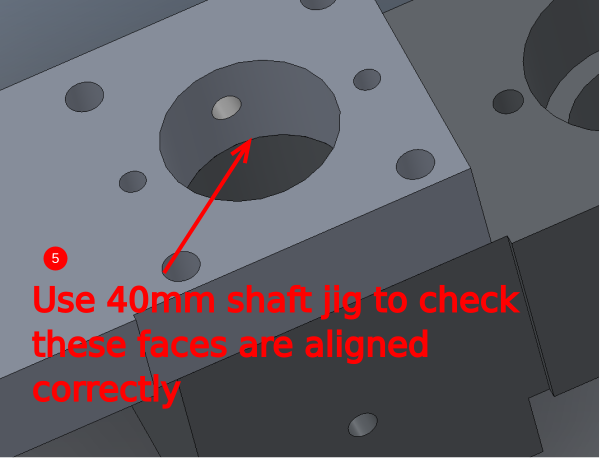

5 Check with 40mm shaft jig that alignment is correct and shaft can pass through assembled 40mm bore | 5 Check with 40mm shaft jig that alignment is correct and shaft can pass through assembled 40mm bore | ||

| + | |||

| + | {{Idea|...If 40mm shaft jig does not pass through assembled bores, emery tape can be used to manipulate bores. Only slight polishing should be required. Report any major adjustment required to supervisor}} | ||

<br /></translate> | <br /></translate> | ||

Version du 7 septembre 2023 à 12:57

Correct alignment protocol for subframe alignment

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Level Frame

- 4 Étape 3 - Instal Upper beam mount

- 5 Étape 4 - Level upper beam mount

- 6 Étape 5 - Install Z axis shafts

- 7 Étape 6 - Assemble centre platform

- 8 Étape 7 - Fit Centre platform

- 9 Étape 8 - Fit lower beam mounts

- 10 Étape 9 - Level lower beam mounts

- 11 Étape 10 - Align lower beam mounts

- 12 Étape 11 - Check shaft pitching

- 13 Étape 12 - Attach bottom plate

- 14 Étape 13 - Quality check

- 15 Étape 14 - Quality check

- 16 Étape 15 - continue to part 2 of dokit

- 17 Commentaires

Introduction

Tools Required

300mm engineers level

2 meter straight edge

1 meter straight edge

Standard hex key set

Standard spanner set

Z support jigs

Parts Required

D0000095 Bottom Plate x 2

D0006484 Front Tiebeam x 1

D0006485 Rear Tiebeam x 1

D0007681 Shaft Adjust Plate x 2

D0007683 Lower Beam Mount x 1

D0007684 Lower Beam Mount - Mirror x 1

D0007695 Platform (D8714) x 1

D0007787 Upper Beam Mount x 1

D0007835 Hard Stop x 2

D0008087 Z Servo Housing x 2

H0006025 Shaft 40mm: 939mm Flowline Y-axis x 2

H0007711 Shaft 40mm: 1350mm Microline Z (c/w M16 x 45 bolts) x 2

R0015296 Bench Assemble bearings Assemblies

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

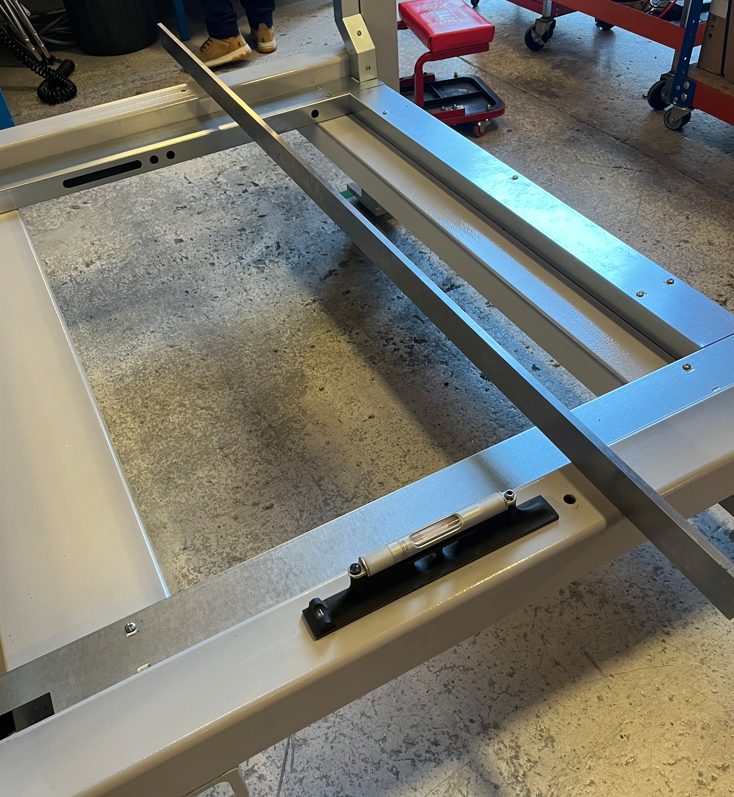

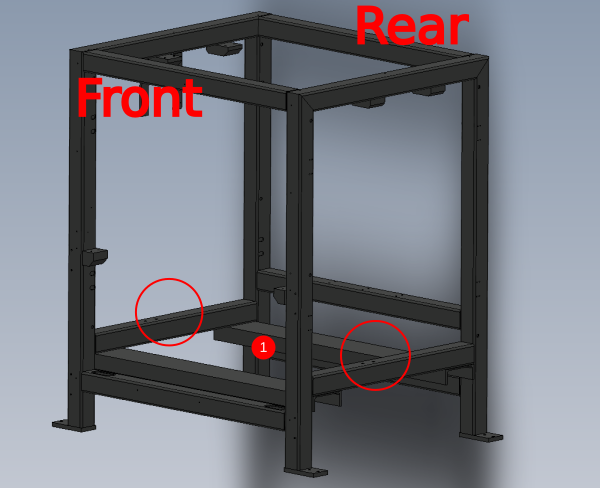

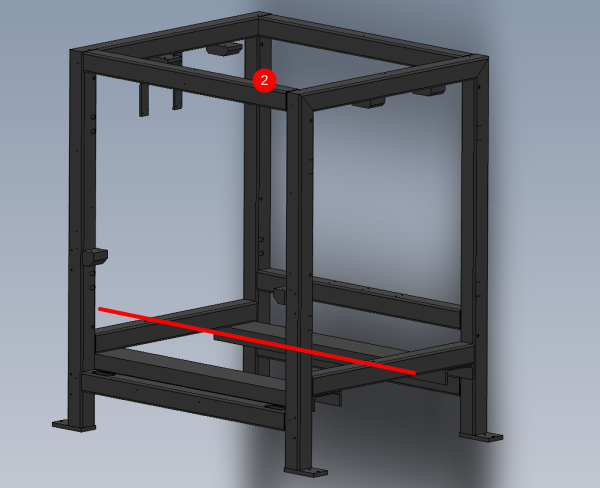

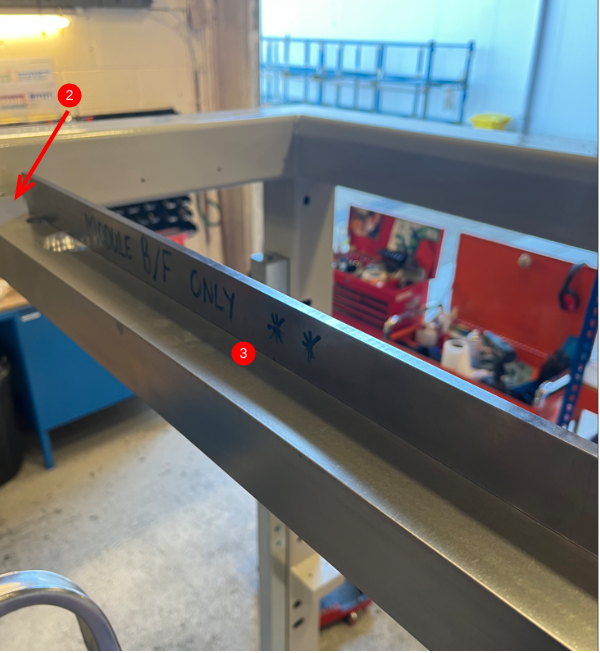

Étape 2 - Level Frame

1 Use engineers level to level frame at the indicated points . Any discrepancy between the two faces should be adjusted to be even both sides .

2 Use 2 meter straight edge and 300mm engineers level to level Y axis of machine at the indicated points

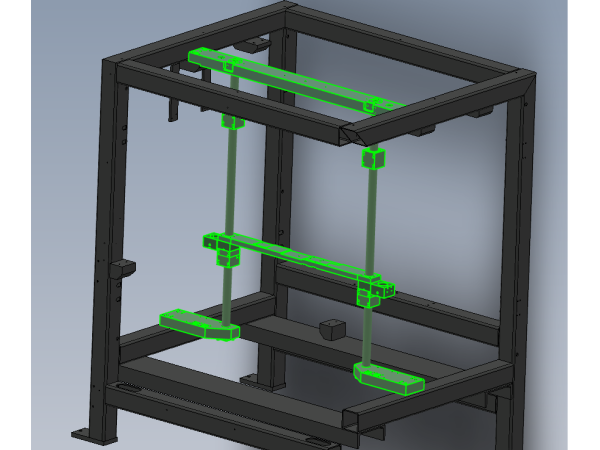

Étape 3 - Instal Upper beam mount

Mount and orientate D0007787 Upper Beam Mount x 1 as shown

Fix with M12 x 70 socket caps and A form washers , do not apply adhesive

Add 8 off M10 x 30 flat bottomed grubscrews

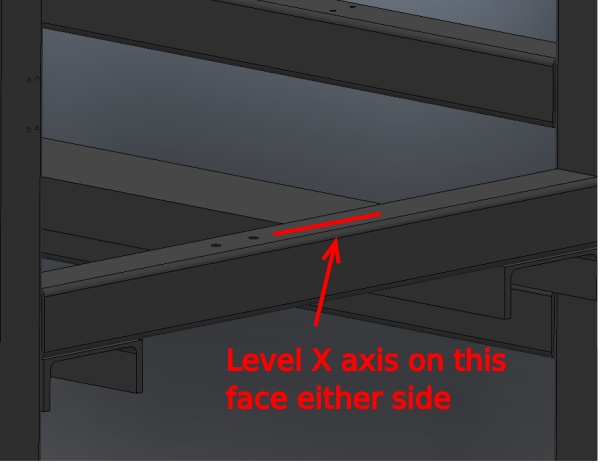

Étape 4 - Level upper beam mount

1 Level X axis on both sides of the beam at the indicated point using M10 grubscrews to adjust

2 Adjust Y Axis using grubscrews . only adjust one end up, as height needs to remain as close as possible to frame monting point.

Use 1 meter straight edge and engineers level

3 Check and adjust flatness by using 1 meter straight edge to gauge. Bias can be used on jacking grubscrews to manipulate the upper beam mount flat.

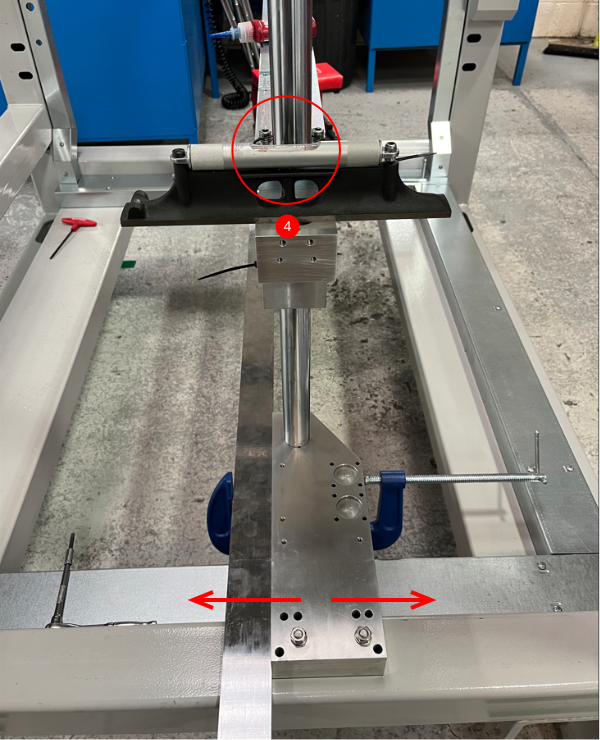

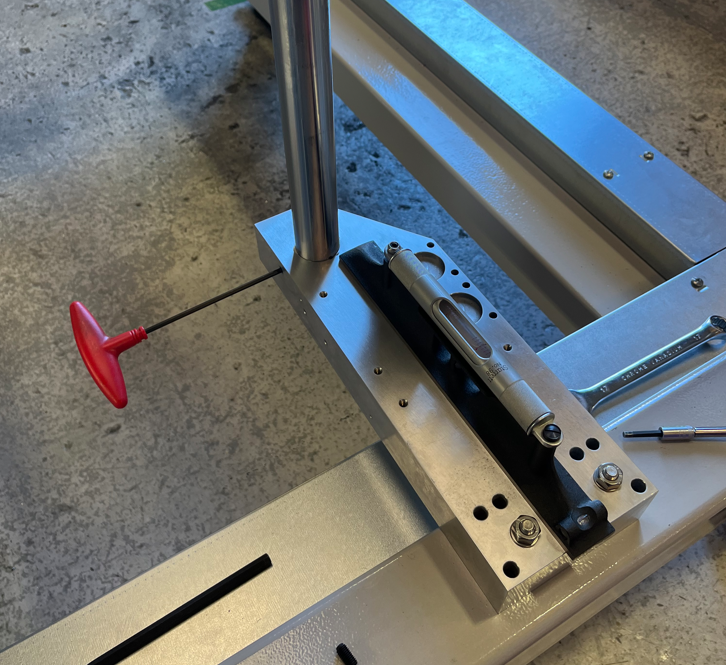

Étape 5 - Install Z axis shafts

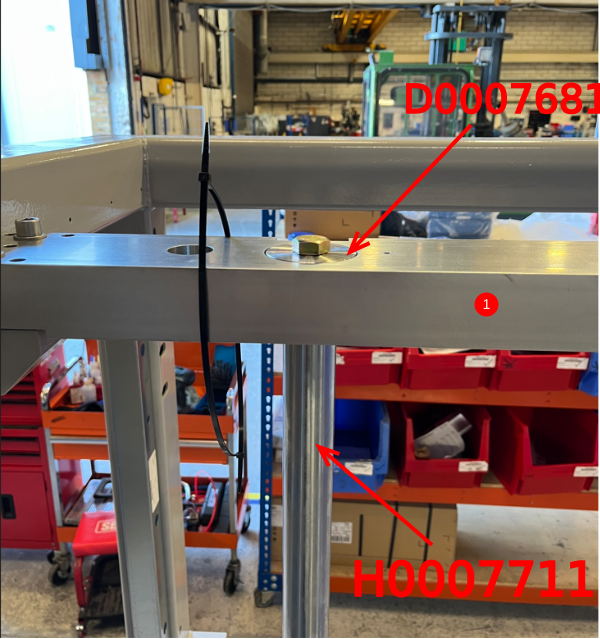

1 Mount H0007711 Shaft 40mm: 1350mm Microline Z (c/w M16 x 45 bolts) x 2

and suspend in place with M16 x 45 hex head bolts and D0007681 Shaft Adjust Plate x 2

Add 2 off large black tie wraps per side as shown

2 Fit 2 off bearing block from R0015296 Bench Assemble bearings Assemblies to z shafts orientated as shown.

M6 holes should face centre of machine and M8 holes and 8mm dowel holes should face front of machine

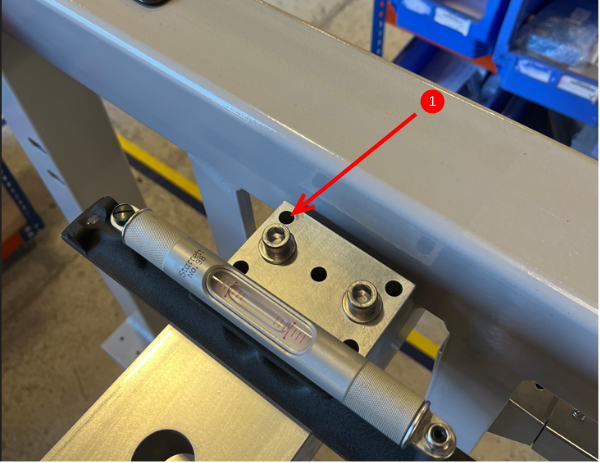

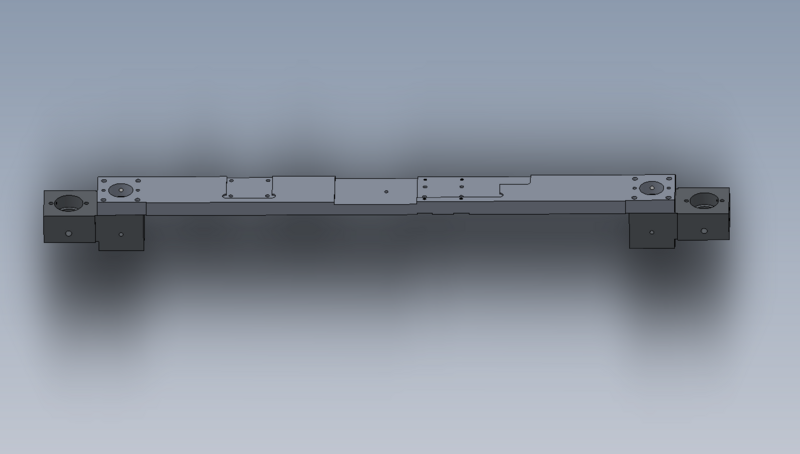

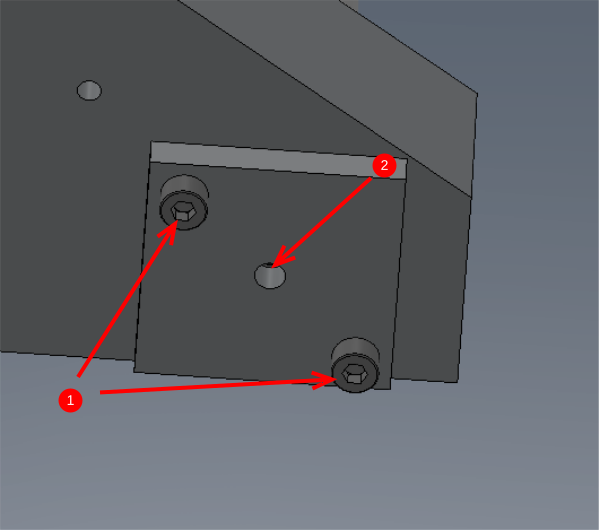

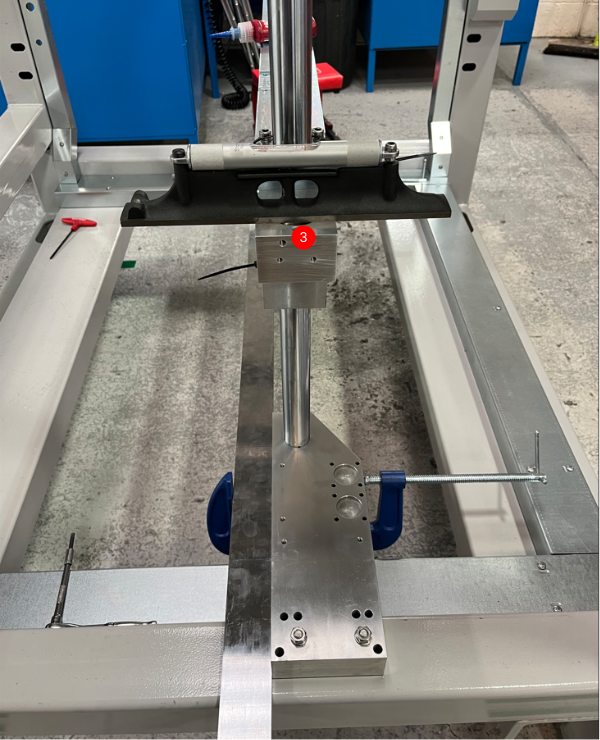

Étape 6 - Assemble centre platform

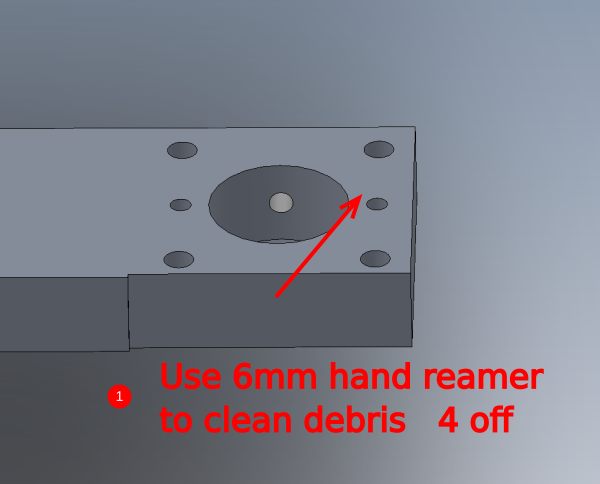

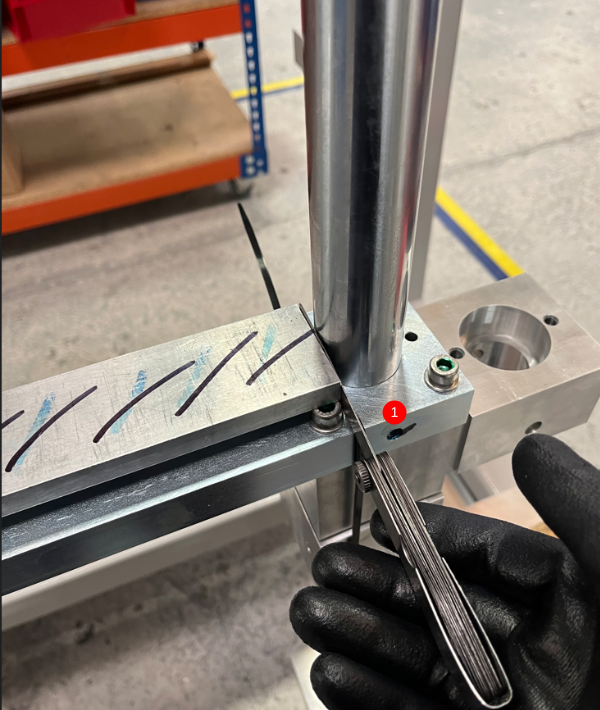

1 Prepare 6mm dowel holes indicated with 6mm reamer in D0007695 Platform

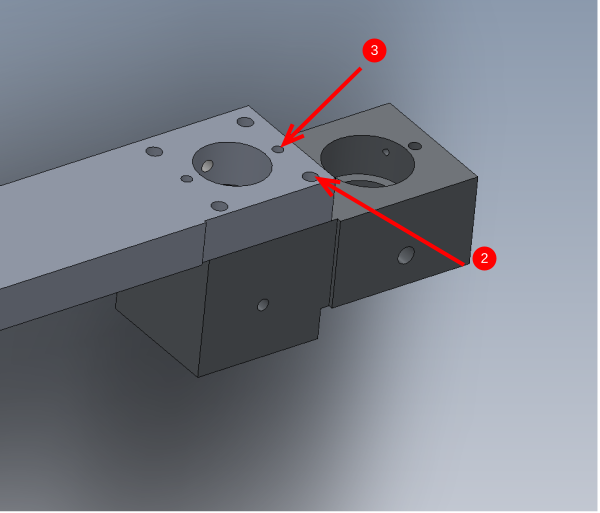

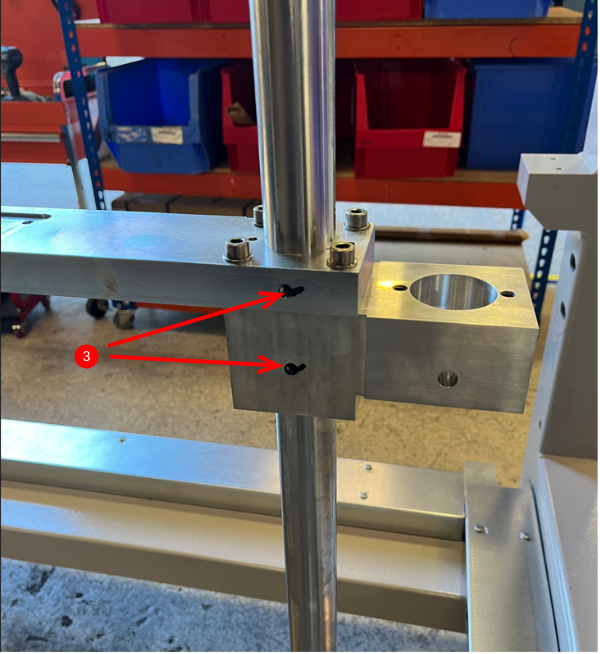

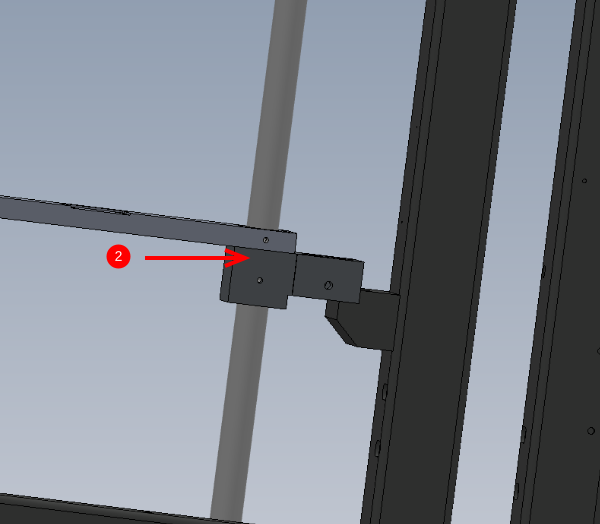

2 Lightly attach as shown 2 off D0008087 Z Servo Housing using 4 off M8 x 40 socket caps and A form washers per block

3 Fit 4 off 6mm x 30 dowel to align blocks

4 Finalise M8 socket caps

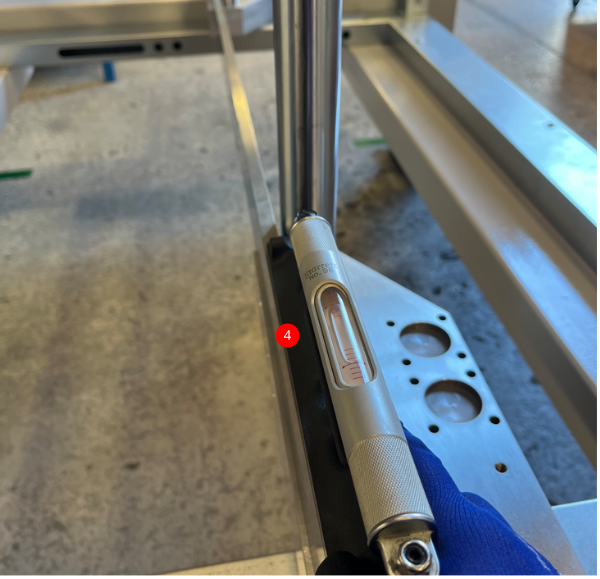

5 Check with 40mm shaft jig that alignment is correct and shaft can pass through assembled 40mm bore

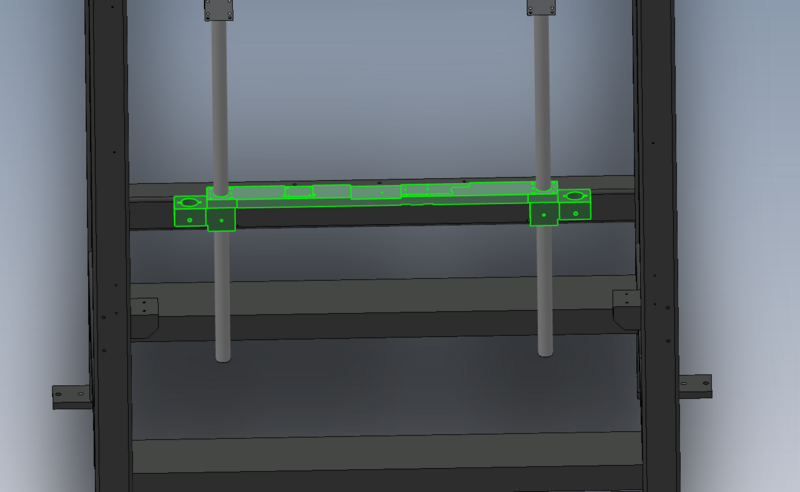

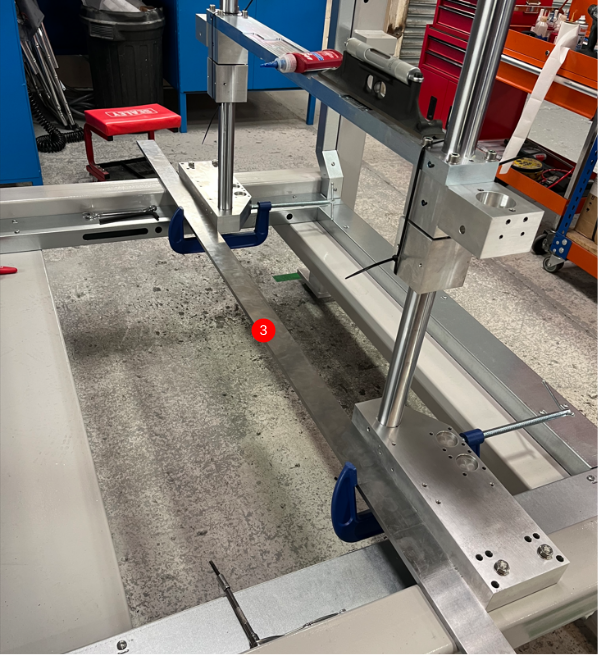

Étape 7 - Fit Centre platform

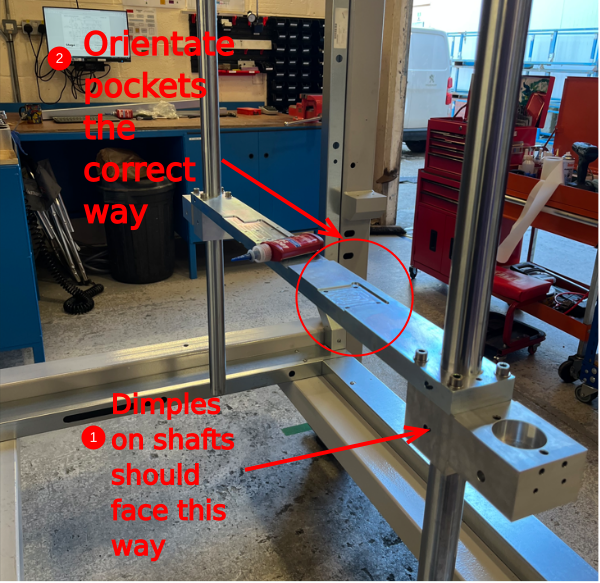

1 Ensure2 off dimples on each main vertical shaft are facing the rear of the machine

2 Slide into position centre platform assembly ensuring the correct orientation is achieved in regards to Machined pockets on the centre platform

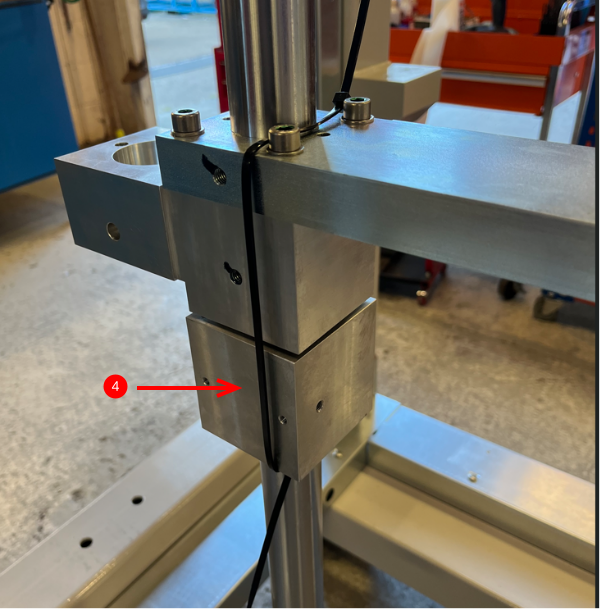

3 Align dimples to M8 tapped holes in crossmember and fix with 4 off M8 x 16 kcp grubscrew

4 Fit 2 off bearing block from R0015296 Bench Assemble bearings Assemblies as shown. Blocks should be orientated as previous fitted upper blocks

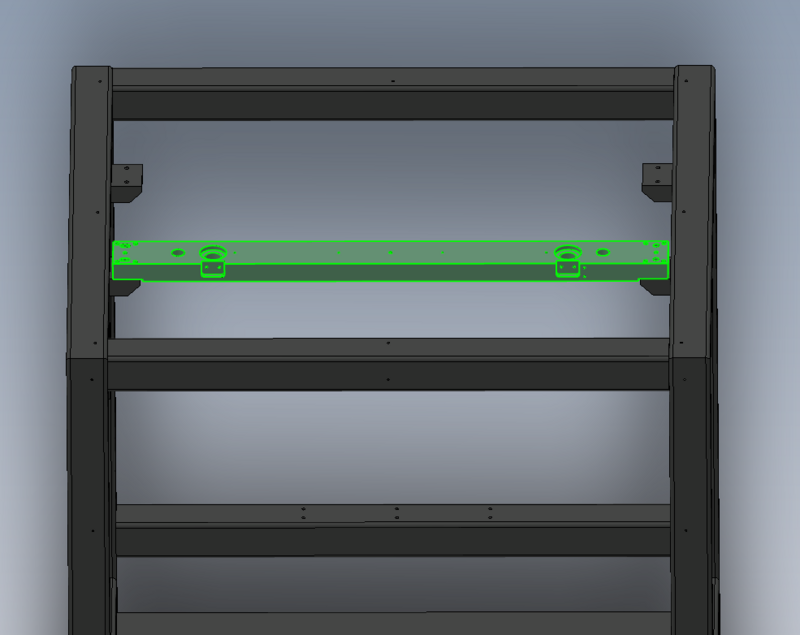

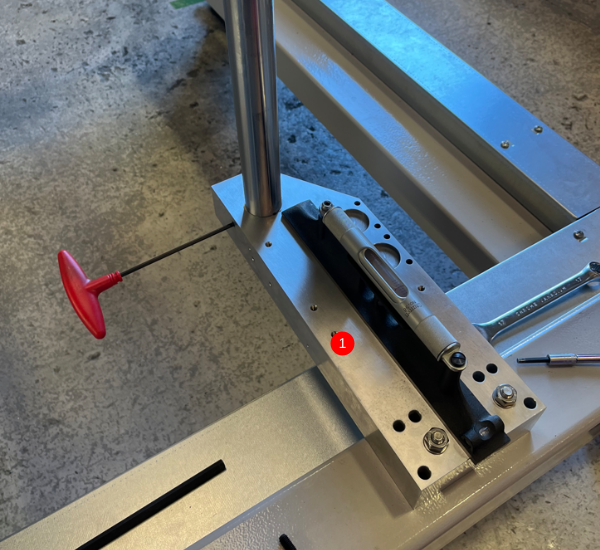

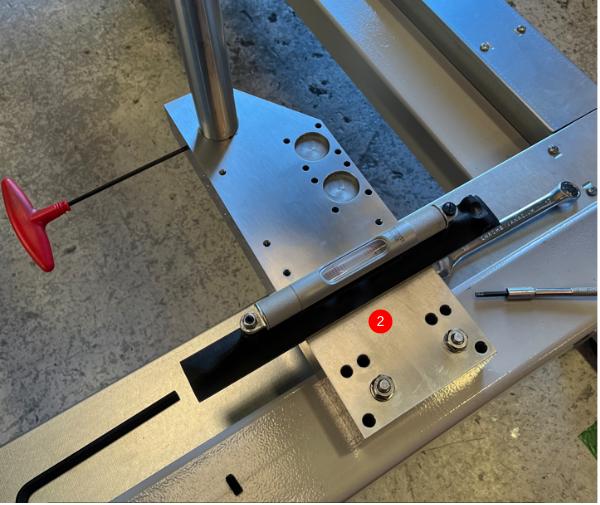

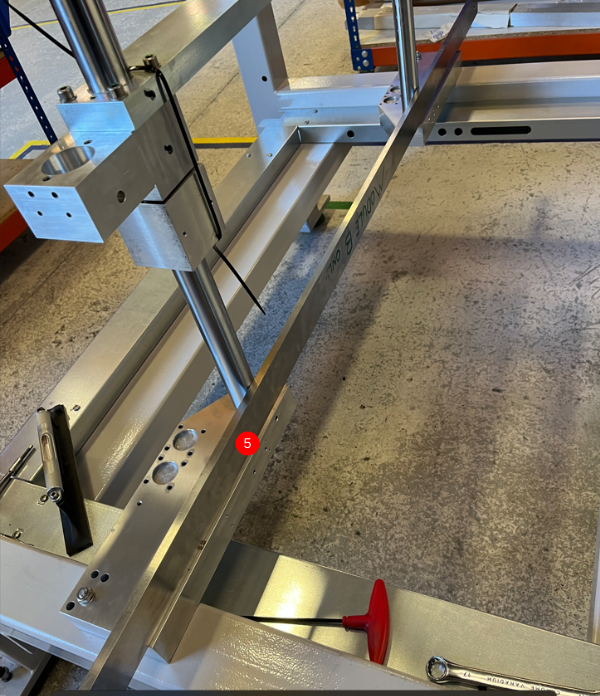

Étape 8 - Fit lower beam mounts

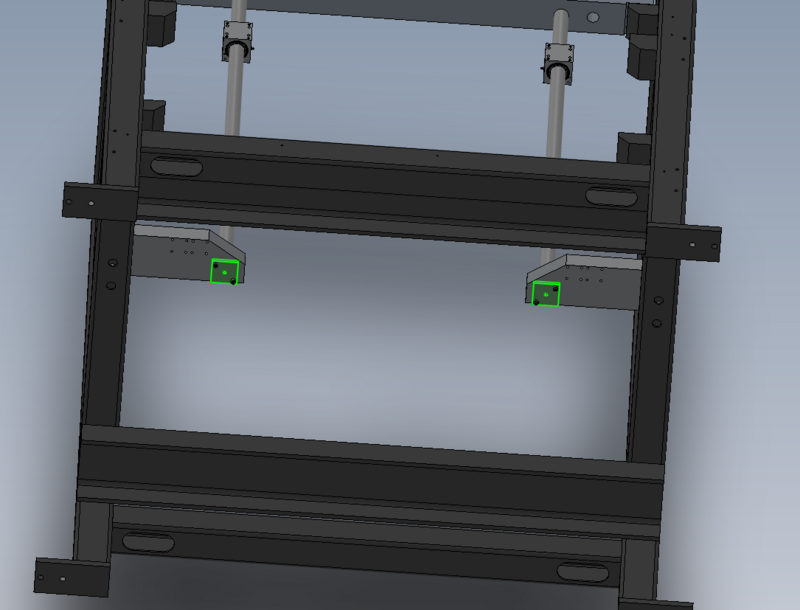

Fit

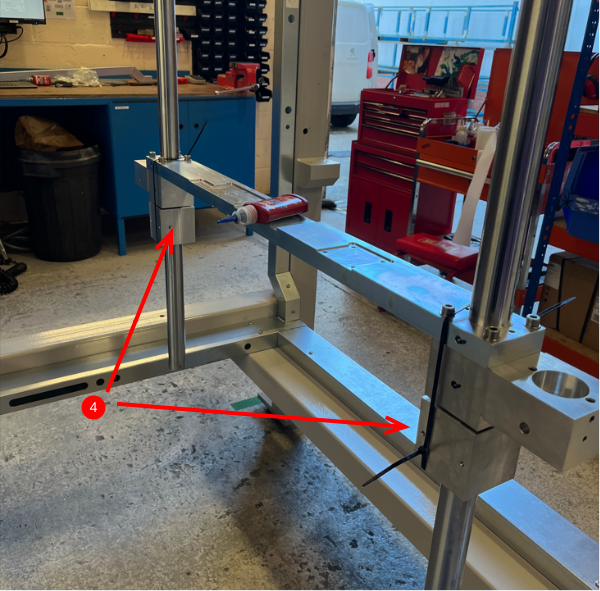

D0007683 Lower Beam Mount x 1

D0007684 Lower Beam Mount - Mirror x 1 as shown

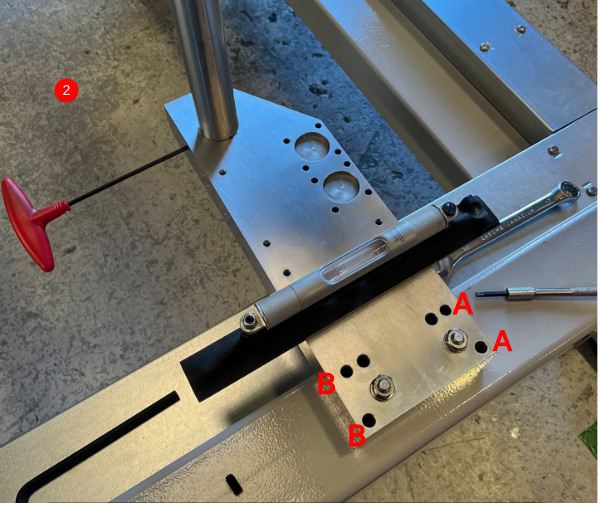

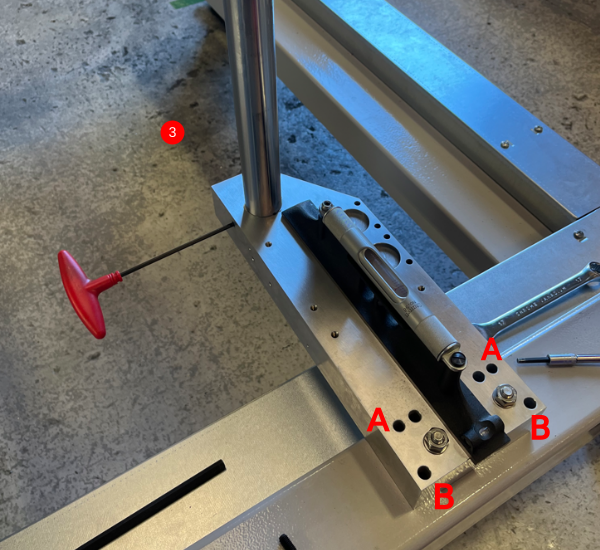

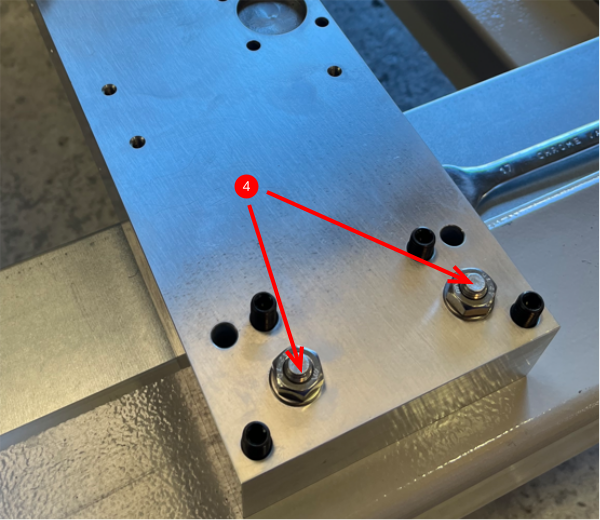

1 Use M10 x 70 socket caps , A form washers and standard M10 nuts to fix as shown

2 Insert 4 off M10 x 30 flat bottomed jacking grubscrew as shown

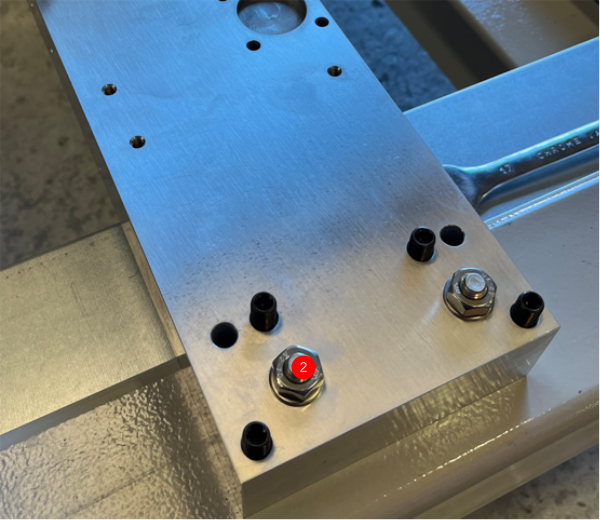

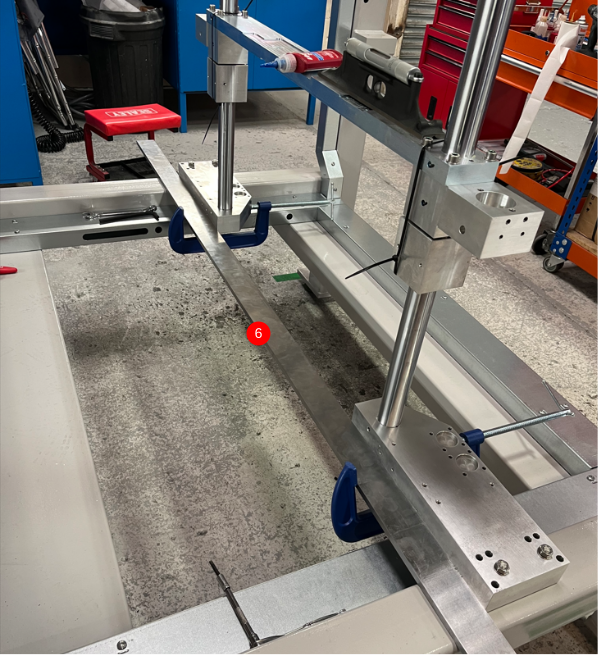

Étape 9 - Level lower beam mounts

1 Apply Medium tension to M10 socket caps and wind down M10 jacking grubscrews to touch on frame

2 Level X axis of block using pair A or B, never use all 4

3 Level Y axis of block using pair A or B, never use all 4

Repeat for other side

4 Level across beam mounts using 2 meter straight edge. Adjust lowest platform to correct any error . Always use all 4 jacking grubscrews turned exactly the same amount to raise platform to adjust

5 Once levelled, check no gaps are present on contact face of straightedge along both lower beam mounts

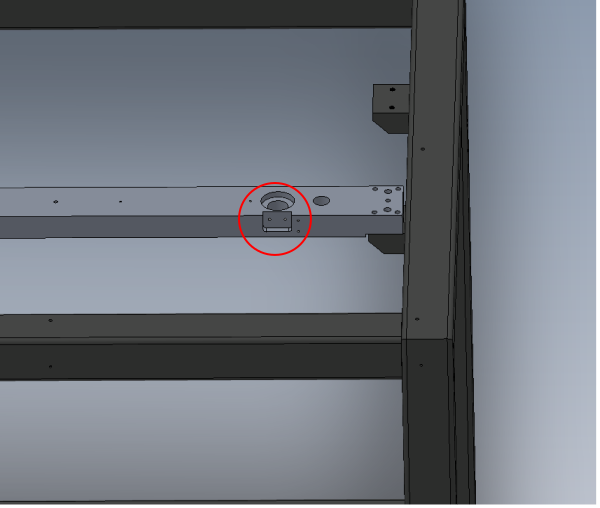

Étape 10 - Align lower beam mounts

1 Insert 1 off M8 x 16 kcp grubscrew per lower beam mount and apply light pressure with no adhesive

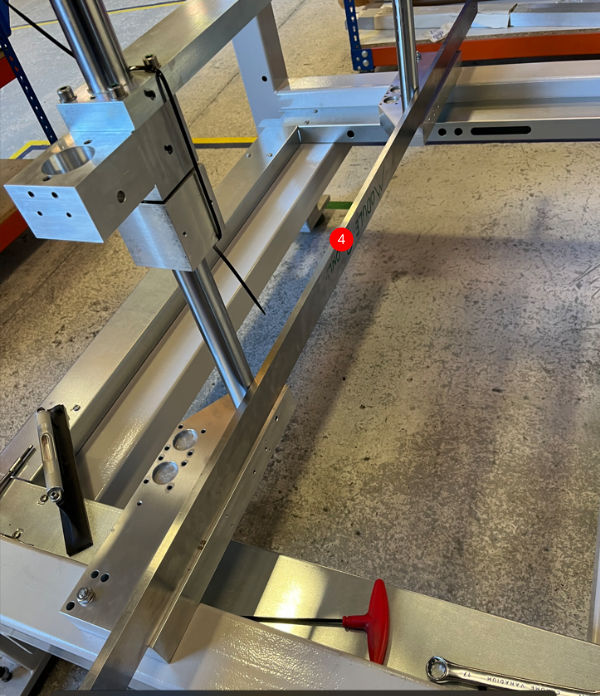

2 Release pressure on M10 socket caps that hold lower beam mounts in place

3 Use straight edge as indicated

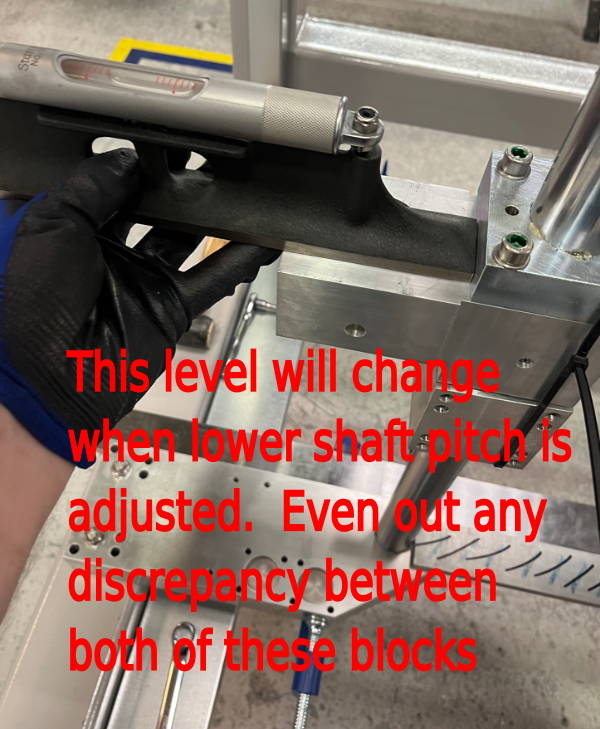

4 Adjust lower beam mount position using level as indicated . Once level is achieved, apply light pressure to M10 socket caps and repeat for other side

5 Adjust Lower beam mount position using a level as indicated . Repeat on other side

Étape 11 - Check shaft pitching

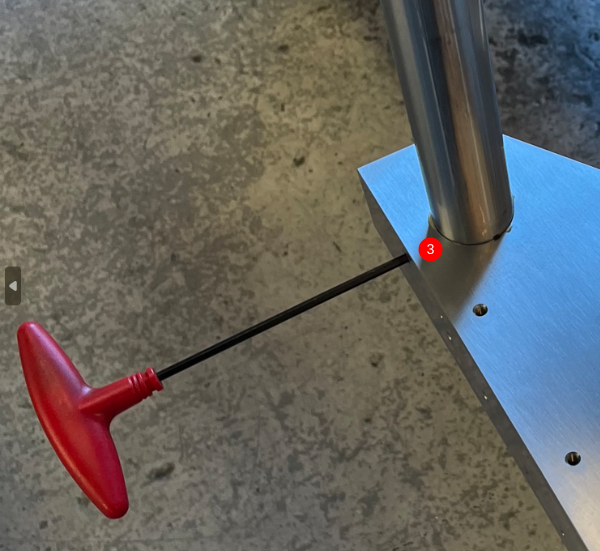

1 Use Z shaft slip gauge to measure pitch of shafts at upper point shown . Measure gap using feeler gauges

2 Check shaft pitching at lower point shown , this must be set to replicate upper measurement . Adjust lower beam mounts to adjust this measurement

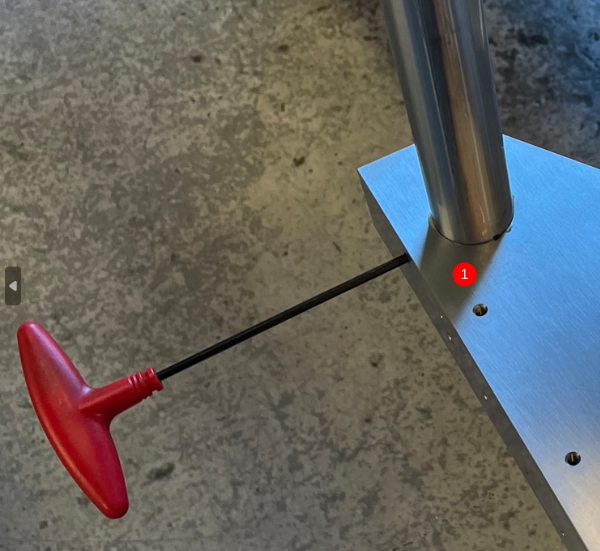

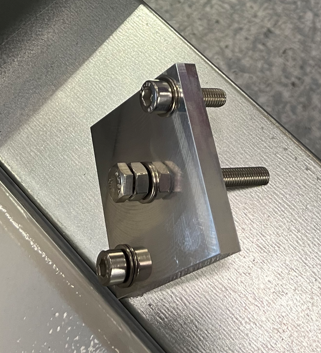

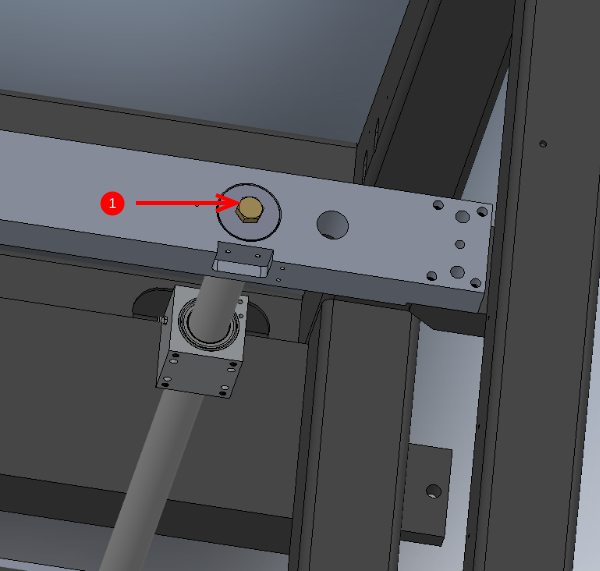

Étape 12 - Attach bottom plate

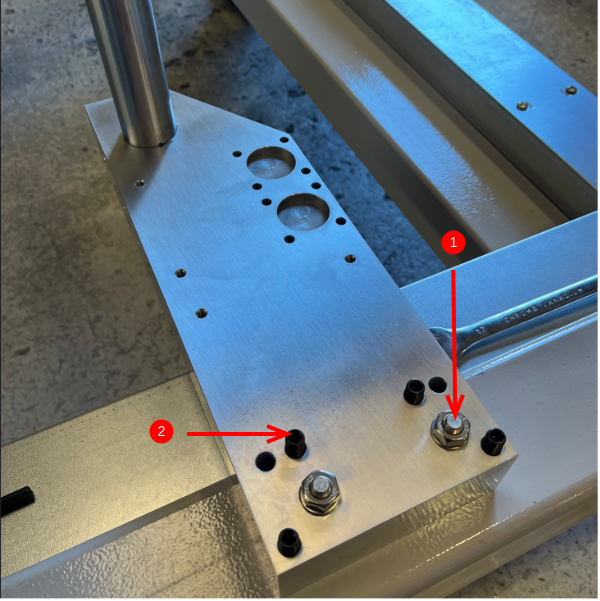

Attach 2 off D0000095 bottom plate as shown

1 Use 2 off M8 x 30 socket caps with A form washers to fix each plate .

2 Use M8 x 70 Set bolt with standard M8 nut and A form washer in central hole

3 Tension M8 nut only when level is on top of plate above so no movement occurs

Étape 13 - Quality check

Check the following points

1 Level Check

2 Level check

3 Level check

4 Level check

5 Alignment and Level check

6 Alignment check

Étape 14 - Quality check

Check the following

1 Z shaft M16 set bolts are glued and finalised

2 4 off Grubscrews are finalised

3 2 off grubscrews are finalised

4 M10 socket caps are finalised

Étape 15 - continue to part 2 of dokit

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português