| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 37 : | Ligne 37 : | ||

{{Tuto Step | {{Tuto Step | ||

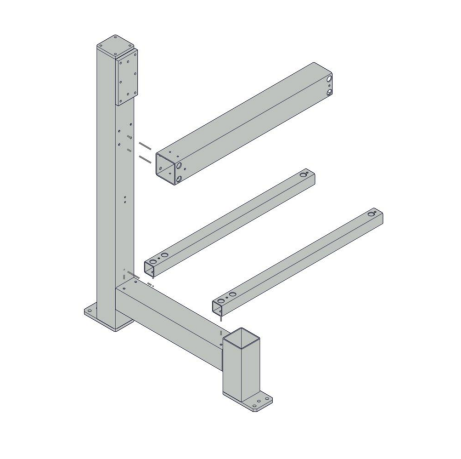

|Step_Title=<translate>Assembly Parts as shown</translate> | |Step_Title=<translate>Assembly Parts as shown</translate> | ||

| − | |Step_Content=<translate>The parts should be assembled as shown in the picture . | + | |Step_Content=<translate>The parts should be assembled as shown in the picture . |

| + | |||

| + | Use M10 x 25 socket caps and A form washers | ||

<br />{{Warning|...Adjustment will be required so only add fastenings with no adhesive at this stage , and do not tighten bolts}}<br /></translate> | <br />{{Warning|...Adjustment will be required so only add fastenings with no adhesive at this stage , and do not tighten bolts}}<br /></translate> | ||

Version du 31 juillet 2023 à 08:14

Assembly instructions for infeed module A extension section

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Assembly Parts as shown

- 4 Étape 3 - Set level on y axis

- 5 Étape 4 - Set level of X axis

- 6 Étape 5 - Setting alignment of assembly

- 7 Étape 6 - Tighten Fasteners

- 8 Étape 7 - Shimming if required

- 9 Étape 8 - Add adhesive

- 10 Étape 9 - Quality check

- 11 Commentaires

Introduction

instructions and parts required for fitting of frame extension

Parts required

Levelled infeed frame

D0015475 Infeed frame Extension leg 1 off

D0015476 Infeed frame Beam upper 1 off

D0015477 Infeed Extension Beam Lower 2 offÉtape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

Étape 2 - Assembly Parts as shown

The parts should be assembled as shown in the picture .

Use M10 x 25 socket caps and A form washers

Étape 3 - Set level on y axis

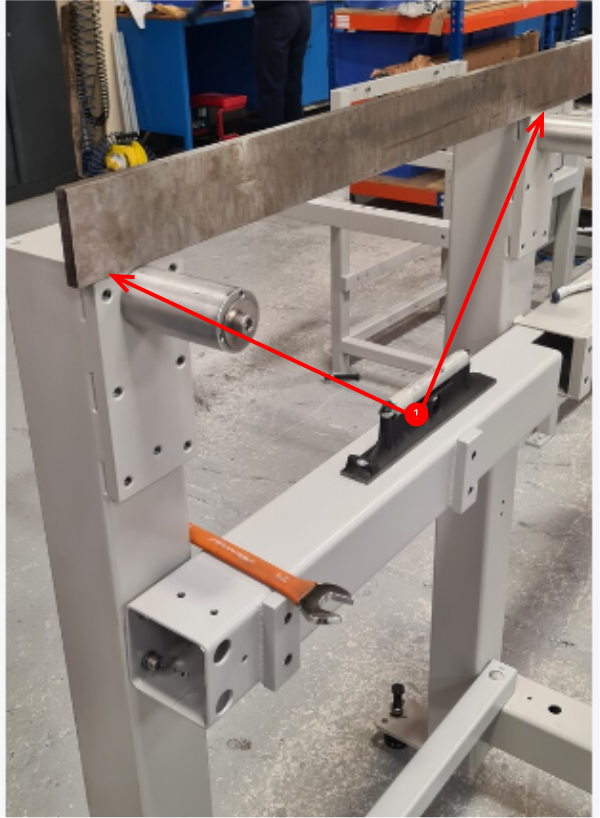

1 Fit levelling jig to frame extension section as shown

2 Use engineers level to adjust the level with the floor jacking bolts to set the jig level

Étape 4 - Set level of X axis

1 Use a metre straight edge to bridge between the top faces as shown

2 Use a engineers level to check level position of the extension section

3 Adjust jacking bolts to raise or lower the extension leg to achieve level

Étape 5 - Setting alignment of assembly

1 A wire line should be used as shown to check alignment. Movement in the direction shown by the arrow is what is being set in this step.

2 Move the frame in the indicated direction to achieve a straightness between all the uprights of the frame

Étape 6 - Tighten Fasteners

Now all Fasteners should be tightened and alignment and level Rechecked.

Sometimes due to the nature of the structure , it is possible movement will occur when tightening fixings

If this is the case , follow next step, if not proceed to step 7

Étape 7 - Shimming if required

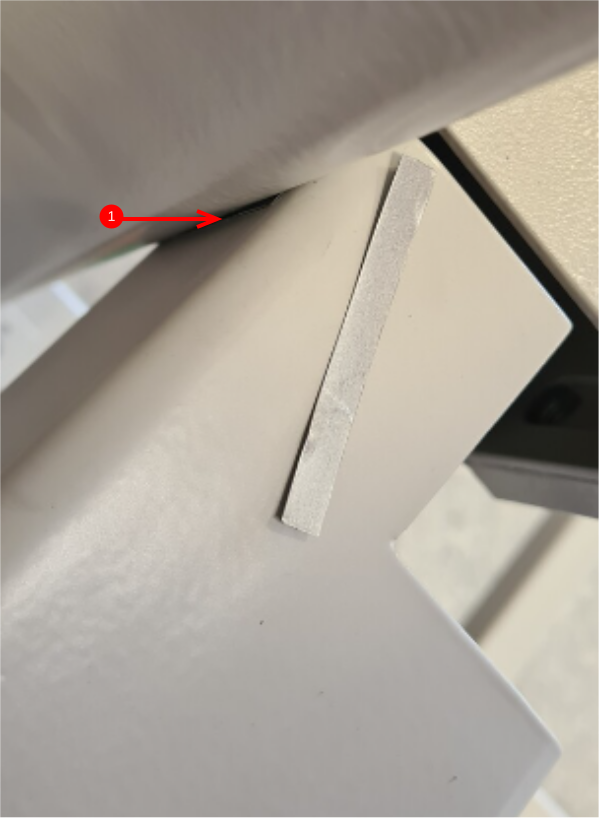

1 Shim can be added to the section as shown . This shim will correct the face of the box section to allow it to maintain alignment when tightened . Various sizes may be required. Trial and error is the only way to determine what size is required for this purpose

Shimming is complete when the fasteners are tightened and the alignment is not affected

Étape 8 - Add adhesive

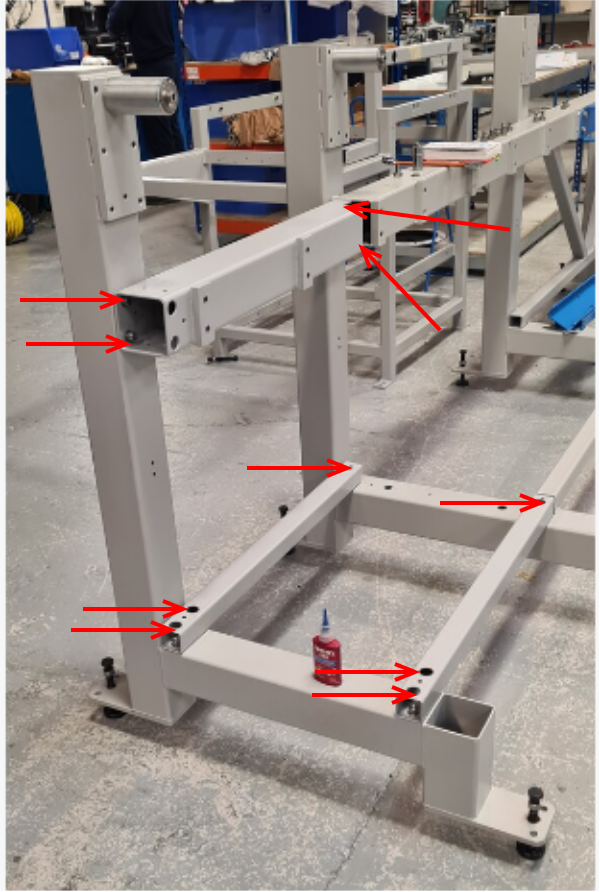

Remove all fasteners one by one, and add Loctite 243 to bolt, retighten and mark bolt heads as complete

Arrows indicate bolts to be finalised

Étape 9 - Quality check

Check all alignment and levels have remained after final fixings of fasteners

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português