| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 55 : | Ligne 55 : | ||

Pen mark all fasteners to show finalised</translate> | Pen mark all fasteners to show finalised</translate> | ||

| − | |Step_Picture_00= | + | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png |

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 18 juillet 2023 à 12:21

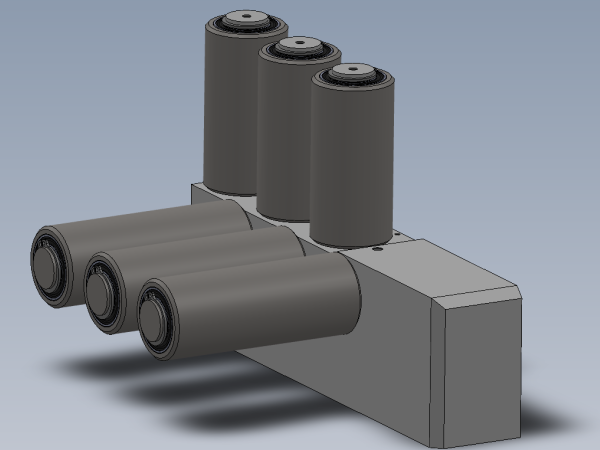

Correct build checks for assembly of R0000706 datum rollers

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Check fit of shafts in bearings

- 4 Étape 3 - Degrease and bearing fit

- 5 Étape 4 - Add circlip and fit roller

- 6 Étape 5 - Mount rollers

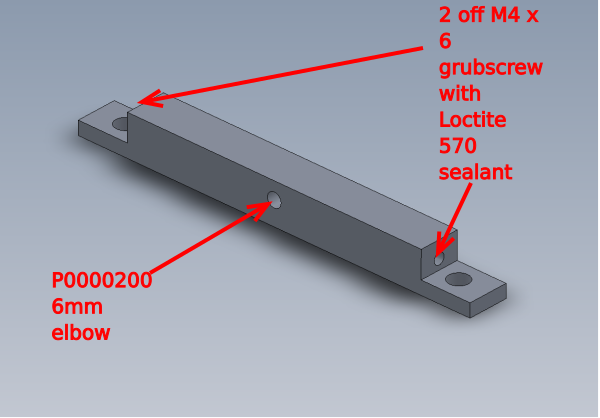

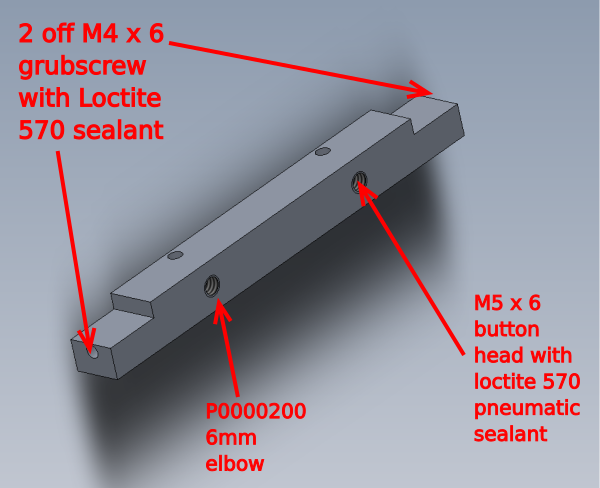

- 7 Étape 6 - Assemble Blower rails

- 8 Étape 7 - Mount blower rails

- 9 Étape 8 - Fit pipe work

- 10 Commentaires

Introduction

Tools required

External circlip pliers

Standard hex key set

Pipe cutters

Pneumatic identification numbers

Parts Required

B0000062 Circlip 20mm External x 6

D0001176 Washer : bearing shim x 3

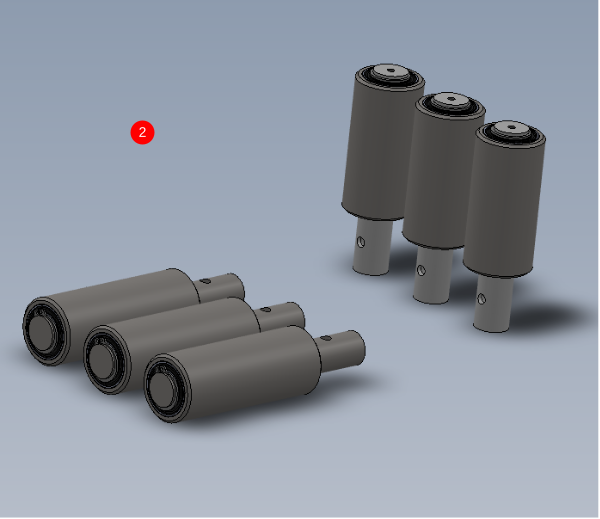

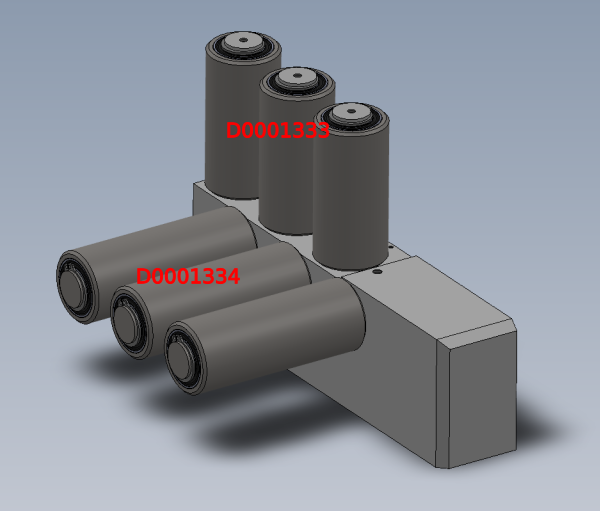

D0001333 Roller Ø40 x 80 c/w bearing x 3

D0001334 Roller Ø40 x 102 c/w bearing x 3

D0003108 Shaft 20mm: 146mm Clamp Roller Shaft x 3

D0007677 Infeed Base Rail (D2972) x 1

D0007942 Shaft 20mm: 119.4mm ZX Datum Roller Circlip x 3

D0010896 Infeed Clamp Blower Vert x 1

D0010897 Infeed Clamp Blower x 1

P0000053 6mm T (P16) x 1

P0000160 Fitting: Flow Controller In Line 6mm x 1Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

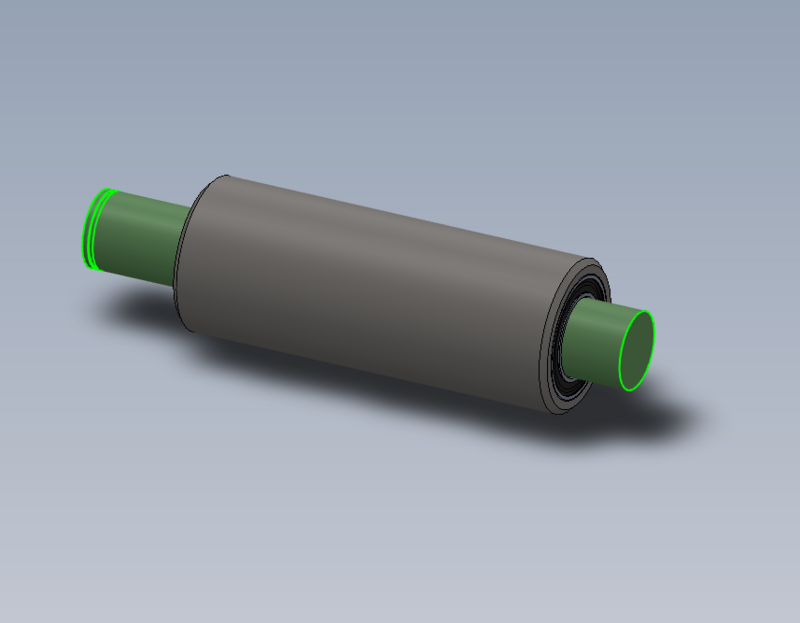

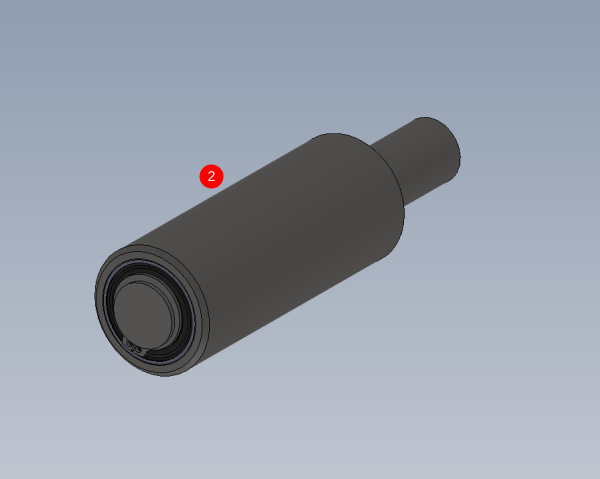

Étape 2 - Check fit of shafts in bearings

Check fit of following parts .

Shafts should pass through bearings with only slight resistance . All inner bearing faces should have contact to shaft and rotate when the shaft is turned

Proceed to step 4 if fit is correct

If shafts are tight check drawing and inspect size of shaft .

If shaft slides through easily, then follow step 3

D0001333 Roller Ø40 x 80 c/w bearing x 3

D0001334 Roller Ø40 x 102 c/w bearing x 3

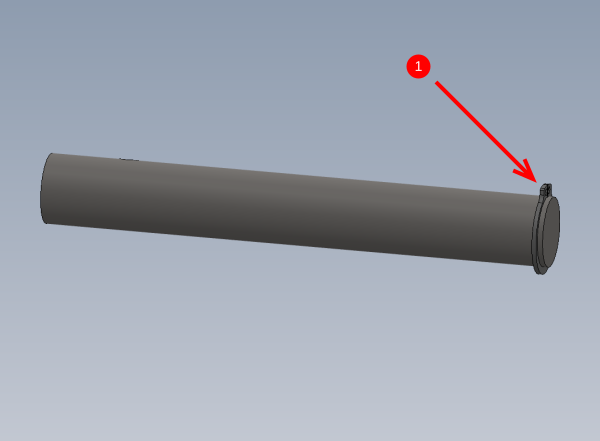

D0003108 Shaft 20mm: 146mm Clamp Roller Shaft x 3

D0007942 Shaft 20mm: 119.4mm ZX Datum Roller Circlip x 3

Étape 3 - Degrease and bearing fit

Thoroughly degrease all parts with FE10 solvent

1 Fit 20mm external circlip to shaft

2 Fit roller to shaft

3 Add 3 drops of Loctite 641 bearing retainer to indicated area and smear around the shaft

4 Move shaft to shown position and add 3 more drops of bearing fit to indicated face and smear around

5 Position roller against circlip and remove any excess bearing fit with rag

6 Leave roller in a vertical position to allow bearing fit to cure

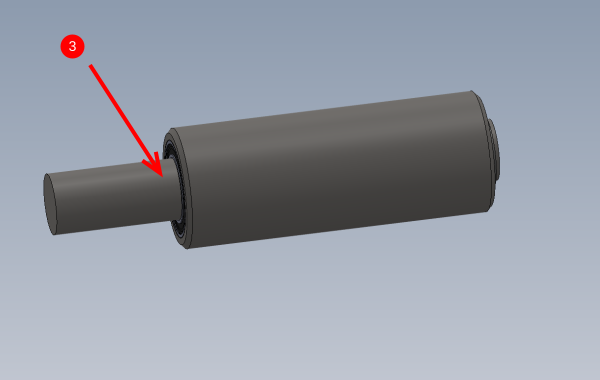

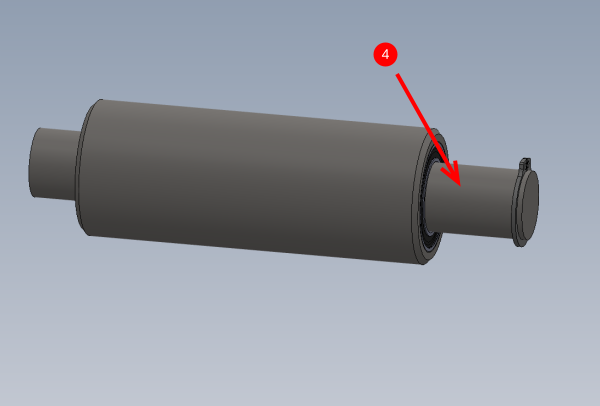

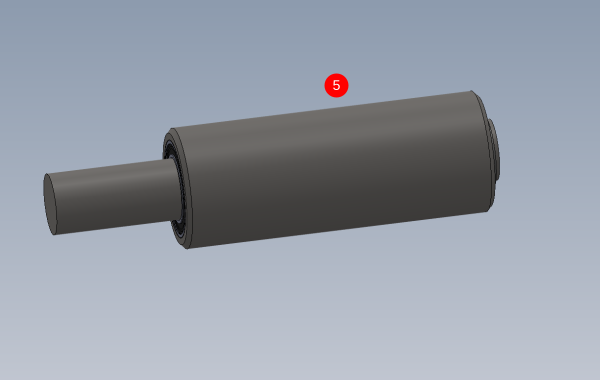

Étape 4 - Add circlip and fit roller

1 Fit 6 off 20mm external circlips to shafts as shown

2 Fit rollers to shafts

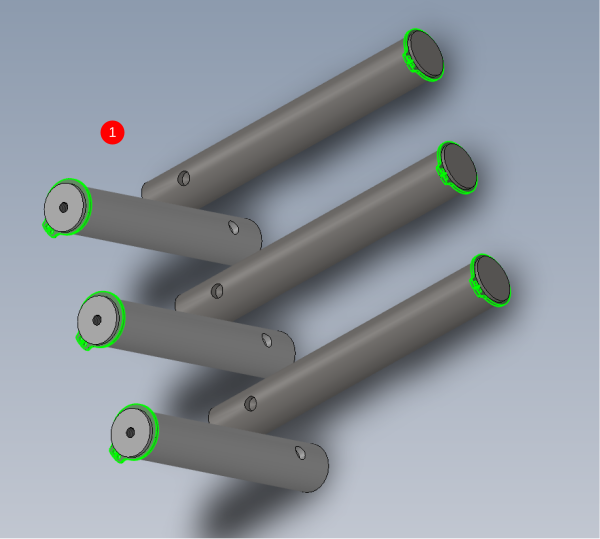

Étape 5 - Mount rollers

Fit rollers to D0007677 Infeed Base Rail (D2972) x 1 as shown and secure with M6 x 10 KCP grubscrews

Ensure dimples in shafts are located correctly to receive grubscrews

Étape 7 - Mount blower rails

PICTURES REQUIRED

Mount blower rails to roller assembly

Use m3 x 20 pan heads to mount D0010897

Use m5 x 12 socket caps and A form washers to mount D0018096 ( do not use adhesive on these fasteners )

Étape 8 - Fit pipe work

PICTURES REQUIRED

Attach pipework as shown

Pipe identification number is 3609

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português