| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 30 : | Ligne 30 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Unless otherwise stated</translate> | ||

| + | |Step_Content=<translate>Use loctite 243 on all fasteners | ||

| + | |||

| + | Use Loctite 572 on all threaded pneumatic connections | ||

| + | |||

| + | Pen mark all bolts to show finalised</translate> | ||

| + | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Attach Spherical bearings</translate> | |Step_Title=<translate>Attach Spherical bearings</translate> | ||

Version du 5 juillet 2023 à 09:56

Instructions for fitment of loader chain drive shafts

Introduction

Tools Required

Standard hex key set

Parts Required

B0000041 feather key 5 x 5 x 18 long

B0001152 Rigid Shaft Coupling Ø16

Pre Assembled R0015270 Bench assemble Shafts, bearings and sprockets

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

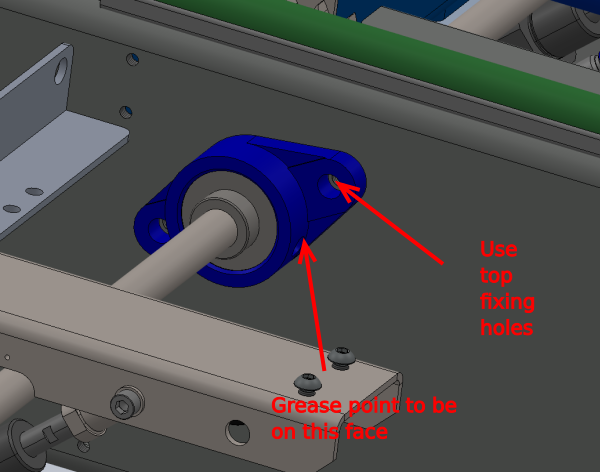

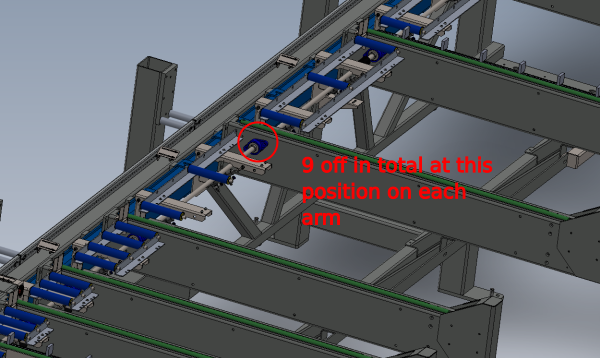

Étape 2 - Attach Spherical bearings

Attach 9 off B0001150 to load arms as shown . ensure correct position is used for mounting of bearings .

Use 2 off M8 x 30 socket countersink fasteners per bearing to align and fix to arms

Ensure greasing point of bearing is facing towards the front of the machine as shown

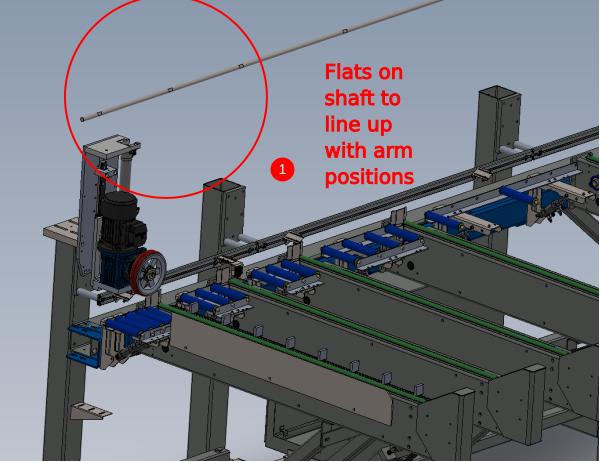

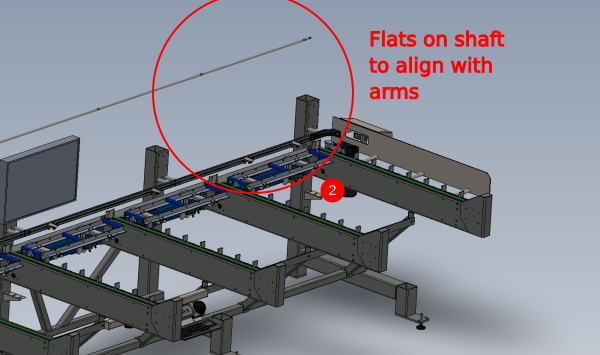

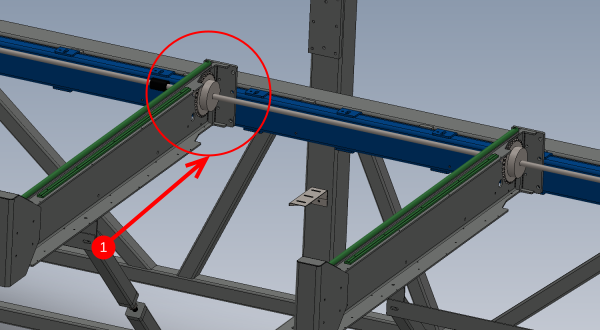

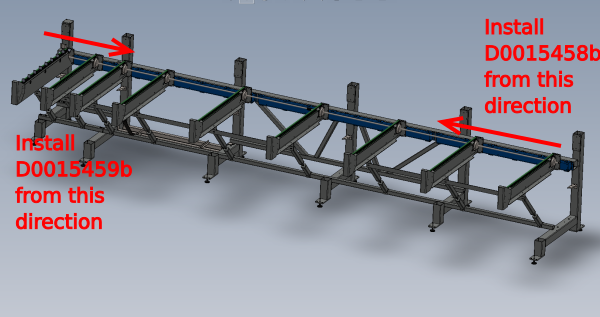

Étape 3 - Orientate drive shafts

Orientation of drive shafts is as follows

1 D0015459b orientated as shown

2 D0015458b orientated as shown

Each flat on the shafts if orientated correctly will align with an arm position on the frame

Étape 4 - Prepare sprockets

Prepare sprockets to fit when shafts are installed

Sprocket B0001145 will require adding to shaft as it is fitted to main frame. Each arm will have a sprocket fitted in the position shown (1)

Étape 5 - Fit shafts

Install shafts from the directions shown , adding the B0001145 sprockets in their correct positions, as the shafts pass through the bearings . Do not close the gap between the 2 shafts in the centre of the machine until the next step is observed

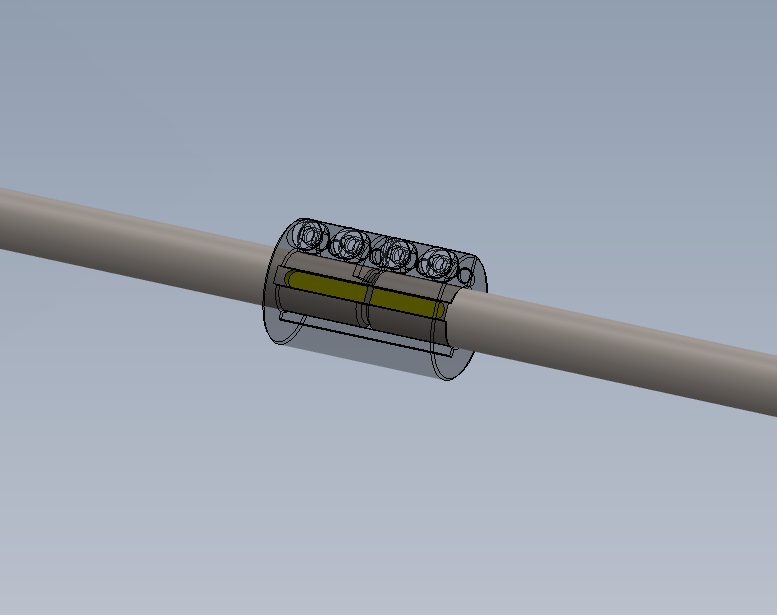

Étape 6 - Install Shaft Coupling

BFit shaft coupling B0001152 to one of shaft at the final stage of fitting.

Gap between shafts should be approximately 2mm

Once this is achieved fit 2 off b0000041 ( 1 to each shaft) align and tighten coupling in position

Overall position of the now combined drive shafts, bearing grubscrews and spockets will be finalised in a later dokit

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português