| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 78 : | Ligne 78 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Assemble Cylinder assembly</translate> | |Step_Title=<translate>Assemble Cylinder assembly</translate> | ||

| − | |Step_Content=<translate>13 off | + | |Step_Content=<translate>13 off |

| + | |||

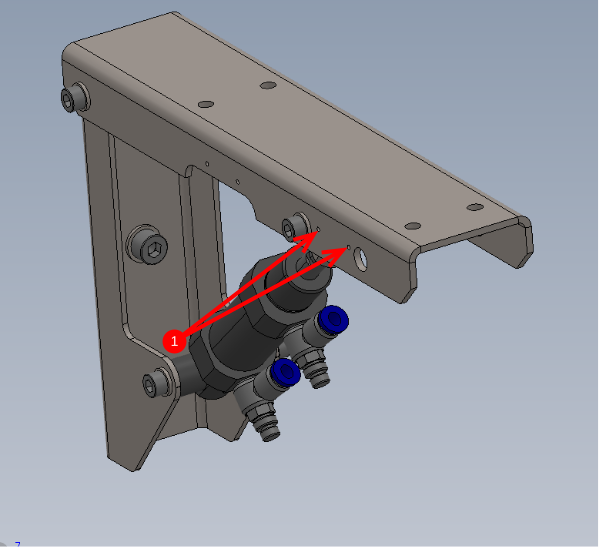

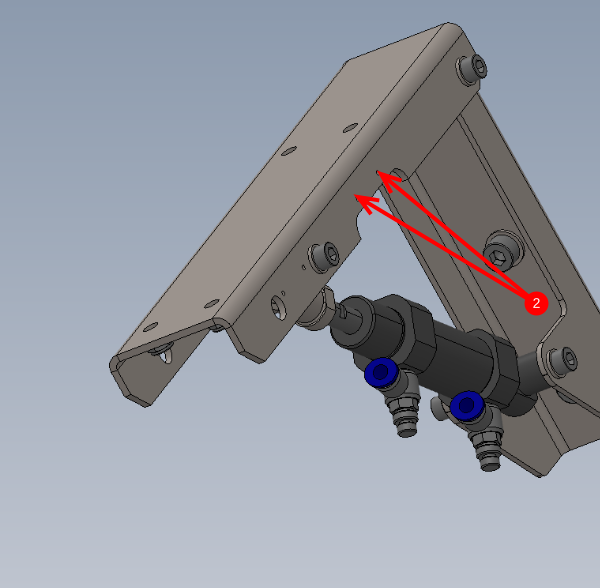

| + | {{Info|...All Flow regulator fittings P0001198 should be set at this point to the correct flow rate. To do this follow these steps | ||

| + | |||

| + | 1 Wind regulation screw clockwise until fully in. Do not overtighten, stop when light resistance is felt. | ||

| + | |||

| + | 2 Turn regulation screw exactly 2.5 turns anticlockwise to set flow rate}} | ||

Version du 4 juillet 2023 à 08:29

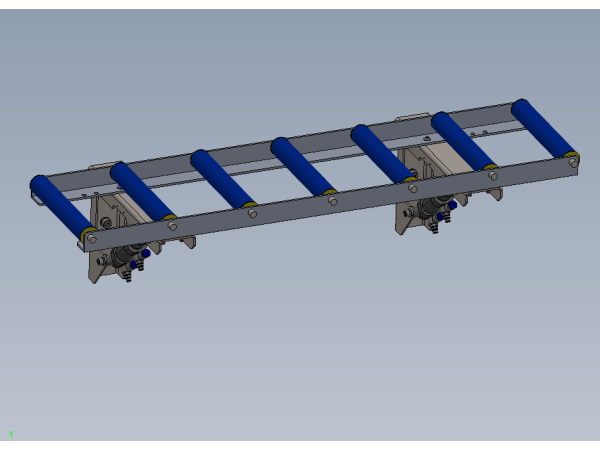

Instructions to bench assemble roller beds

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Assemble Cylinder assembly

- 4 Étape 3 - Check for rework

- 5 Étape 4 - Check for rework of following parts

- 6 Étape 5 - Fit bushes and mount cylinder

- 7 Étape 6 - Combine support arm and roller bracket

- 8 Étape 7 - Prepare M3 holes

- 9 Étape 8 - Assemble Large roller Table

- 10 Étape 9 - Fit rollers

- 11 Étape 10 - Assemble medium roller table

- 12 Étape 11 - Assemble small roller table

- 13 Étape 12 - Pneumatic pre assembly

- 14 Commentaires

Introduction

Tools Required

Standard Hex key set

Standard spanner set

Tape measure/Rule

8.2mm HSS drill

Drill

Parts Required

P0001110 x 13

P0000049 x 13

P0001198 x 26

D0015001 x 13

B0001103 x 26

D0015481 x 13

B0001220 x 26

D0015603 x 13

D0015010 x 26

D00150002 x 13

D0015603 x 13

D0015005 x 10

B0001092 x 45

D0015004 x 2

D0015003 x 4

D00155547 x 2

E0001120 x 2

P0000200 x 2

P0000160 x 2

P0001030 x 10Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

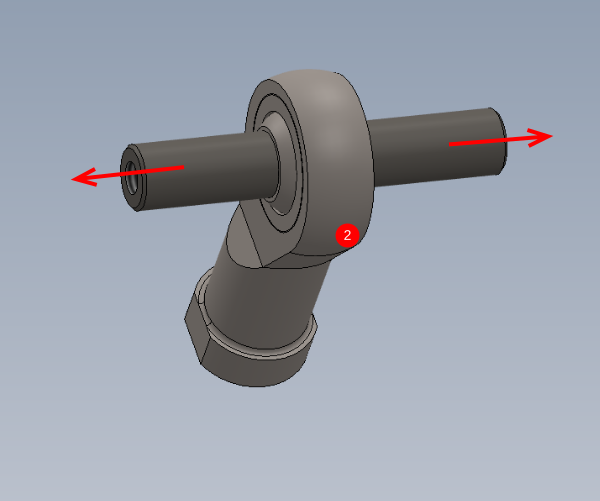

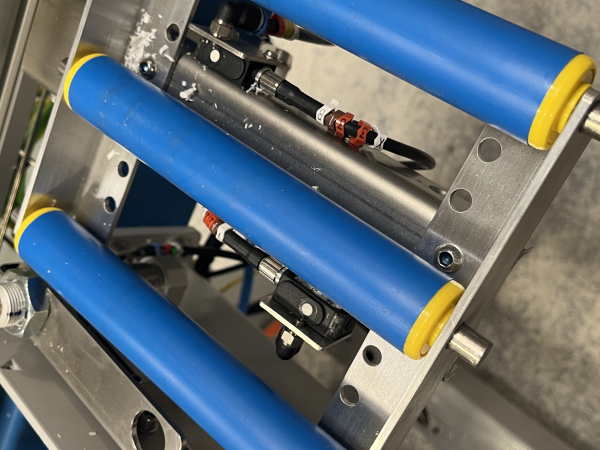

Étape 2 - Assemble Cylinder assembly

13 off

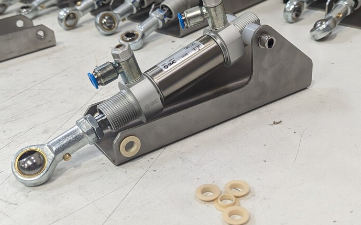

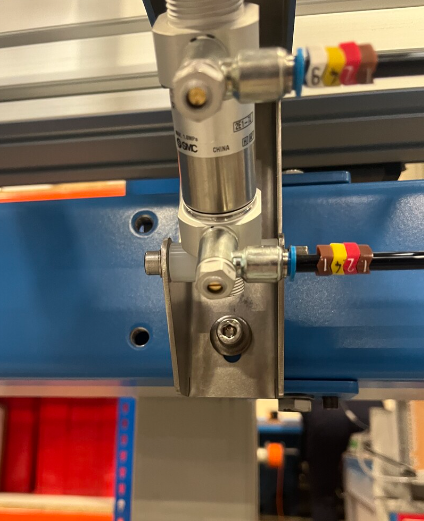

1 Fit 2 off P0001198 fittings to cylinder P0001110

2 Fit spherical bearing P0000049 to cylinder end , Do not add final tension to the nut

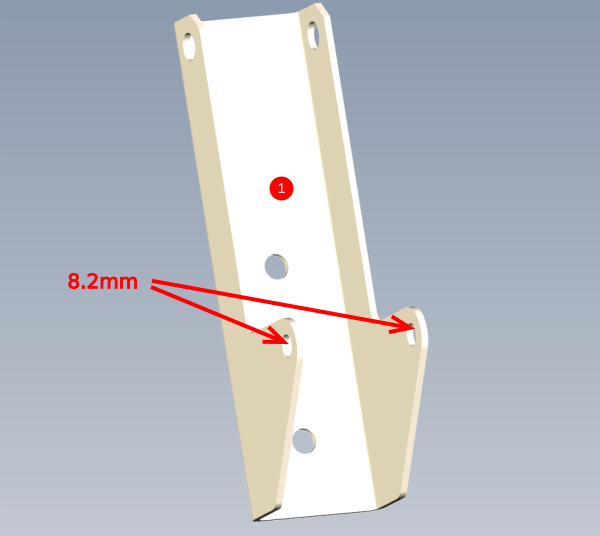

Étape 3 - Check for rework

13 off

Check part D00150001 has been supplied to new specification

Check indicated hole, should measure 8.2mm. If not open up with hand drill

Drawing change requested 06/06/23 to amend from 8mm to 8.2mm

Étape 4 - Check for rework of following parts

1 D0015006B indicated holes should measure as shown. Rework by hand if issued old spec

ECR raised 06/06/23

2 D0015002 rod end shaft . Check fit in P0000049 spherical bearing . Polish down diameter to allow shaft to pass through.

ECR raised 06/06.23 to improve tolerance of shaft to allow better fitment

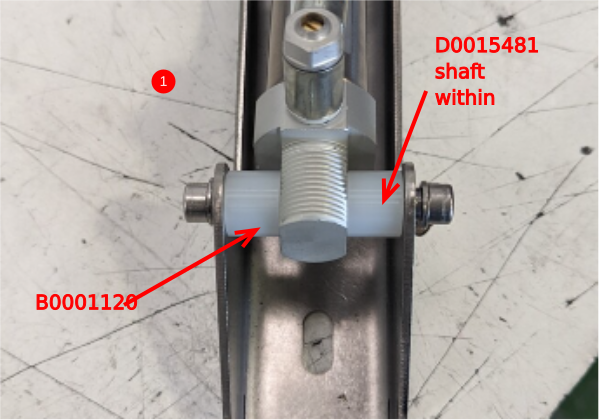

Étape 5 - Fit bushes and mount cylinder

13 off

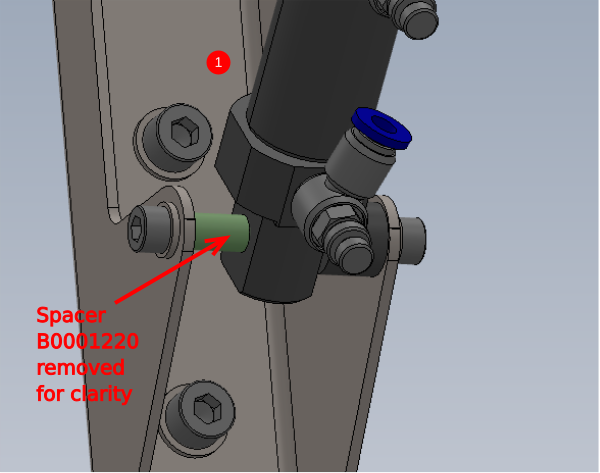

1 Combine D0015481 shaft and B0001220 spacer as shown to mount cylinder to bracket. Use M6 x 12 socket caps and A form washers to fasten

2 Fit 2 off B0001103 bushes to D0015006B

Étape 6 - Combine support arm and roller bracket

13 off

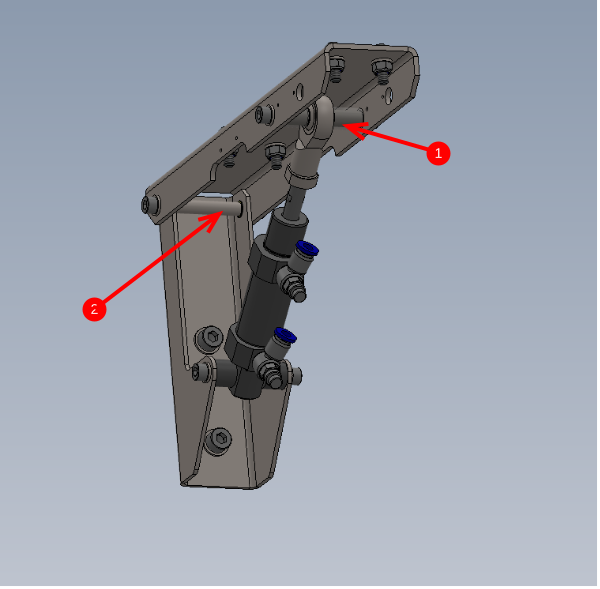

1 Fit 2 off D0015010 spacers, 1 off d0015002 shaft through spherical bearing and fix with 2 off m6 X 12 socket caps and A form washers

2 Fit 1 0ff D0015603 pivot shaft with 2 off M6 x 12 socket caps and A Form washers

Étape 7 - Prepare M3 holes

1 off only and mark for later Reference

1 Tap 2 off indicated holes M3

2 Tap 2 off indicated holes M3

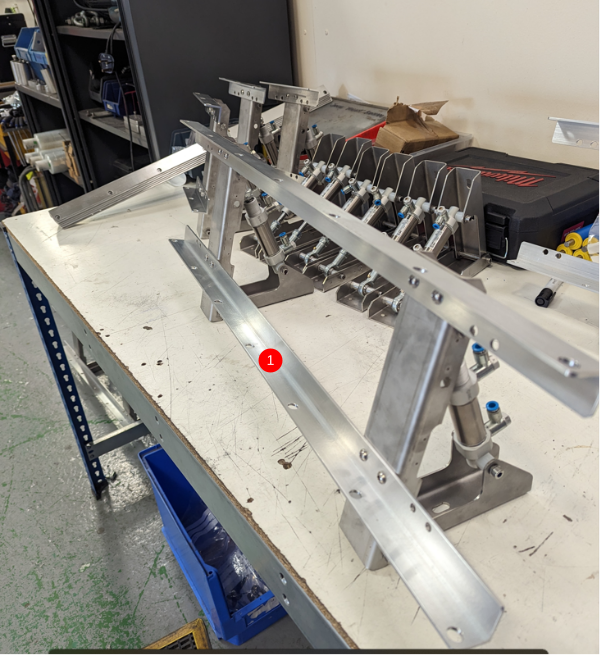

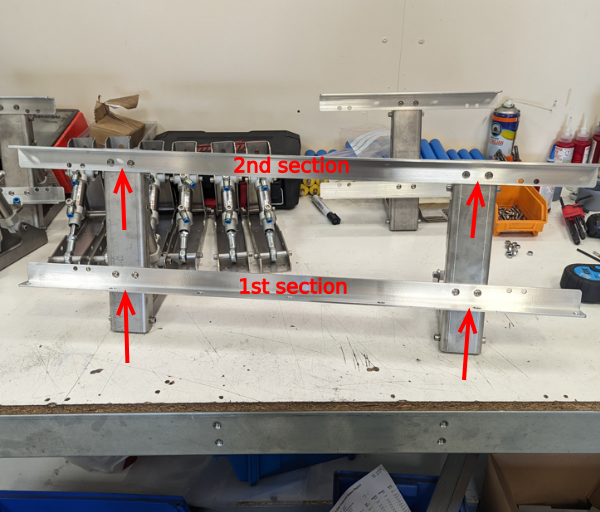

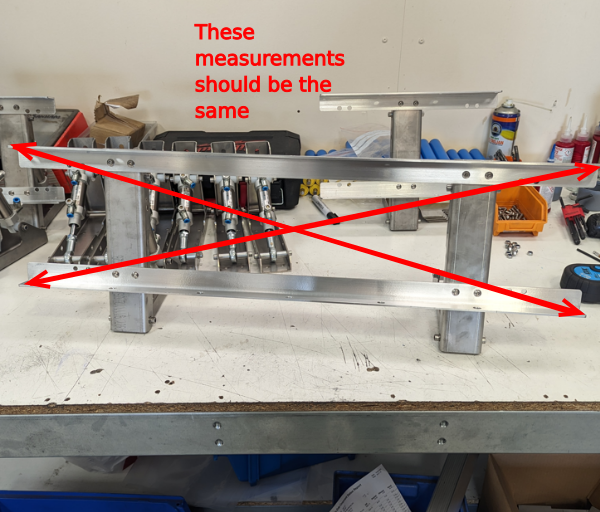

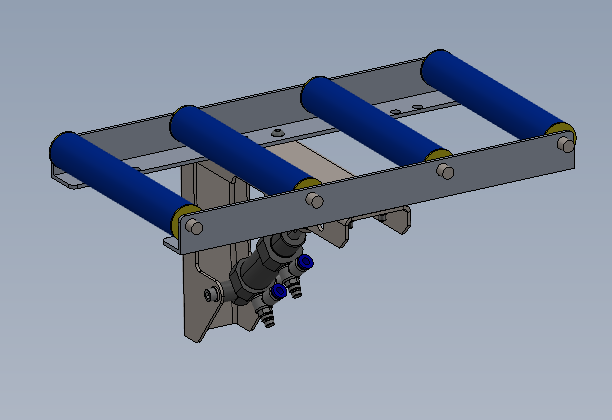

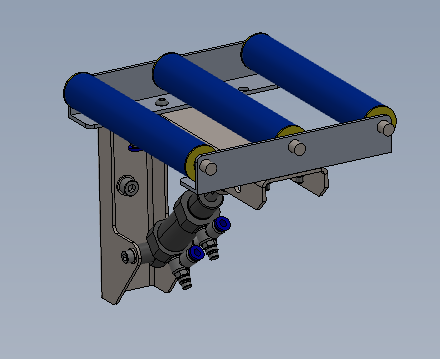

Étape 8 - Assemble Large roller Table

5 off to be assembled

1 Mount 2 off D0015005 to prebuild cylinder assemblies as shown

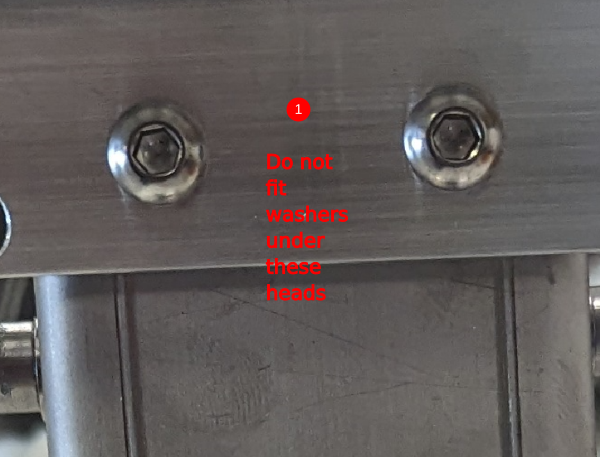

Use M6 x 20 button socket , A form washer and M6 nyloc nuts to fix.

Do not use washer under head of button head screw, on use on on nut side

2 Adjust the 2 off D0015005

1st section pushed against edge of clearance hole in direction shown

2nd section pushed in same direction

3rd Check parallel and adjust to correct

4th check squareness by taking corner measurements and adjusting if required

Once all above is achieved, finalise fasteners

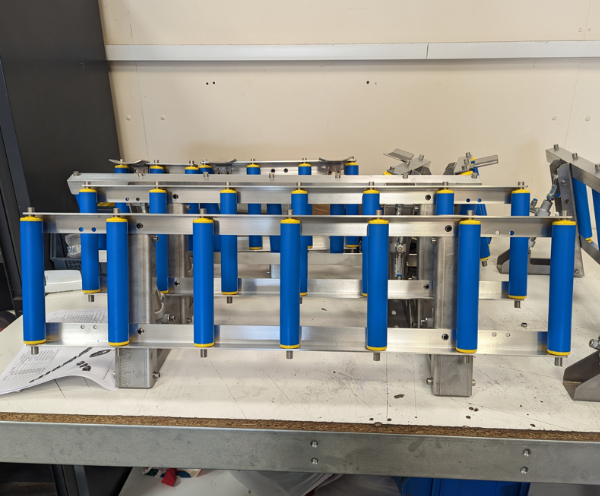

Étape 10 - Assemble medium roller table

Using same checks and setting as above assemble roller table with 4 rollers as shown

Étape 11 - Assemble small roller table

2 off

Using same checks and setting as above assemble 2 off roller tables with 4 rollers as shown,

Use the pre built cylinder bracket with m3 tapped holes for 1 off, and add 2 off Sensor E001120 ,2 off Blower P0000200 and 2 off bracket D0015547 as shown

Étape 12 - Pneumatic pre assembly

5 off

7 Roller bed assemblies with two cylinders require pneumatic pipe installation.

Use identification numbers as follows

1241 Home position

1249 Active position (down)

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português