| [version en cours de rédaction] | [version en cours de rédaction] |

m (Gareth Green a déplacé la page Finalise wiring loom for Rotary head vers R0015295 Finalise wiring loom for Rotary head) |

|||

| (Une révision intermédiaire par le même utilisateur non affichée) | |||

| Ligne 9 : | Ligne 9 : | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate>Tools required</translate> | + | |Introduction=<translate>'''<u>Tools required</u>''' |

| + | |||

| + | |||

| + | Standard Hex keys | ||

| + | |||

| + | |||

| + | '''<u>Parts Required</u>''' | ||

| + | |||

| + | |||

| + | D0007788 inspection cover 8 off</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

Version actuelle datée du 23 juin 2023 à 12:22

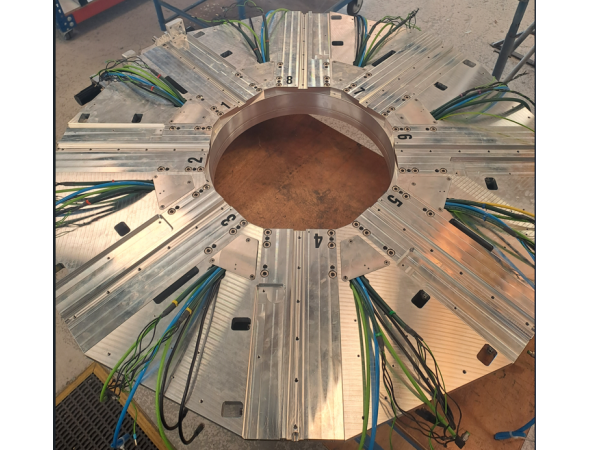

correct routing of cables ready for connection boxes

Sommaire

- 1 Introduction

- 2 Étape 1 - Wiring loom positioning Ethercat control

- 3 Étape 2 - Wiring loom positioning Ethercat power

- 4 Étape 3 - Wiring loom positioning 300hz power

- 5 Étape 4 - Fit Inspection covers on spindles 1,2,3,4,5,6 and 8

- 6 Étape 5 - Fit inspection cover to spindle 7

- 7 Étape 6 - Rotational check

- 8 Commentaires

Introduction

Tools required

Standard Hex keys

Parts Required

Étape 1 - Wiring loom positioning Ethercat control

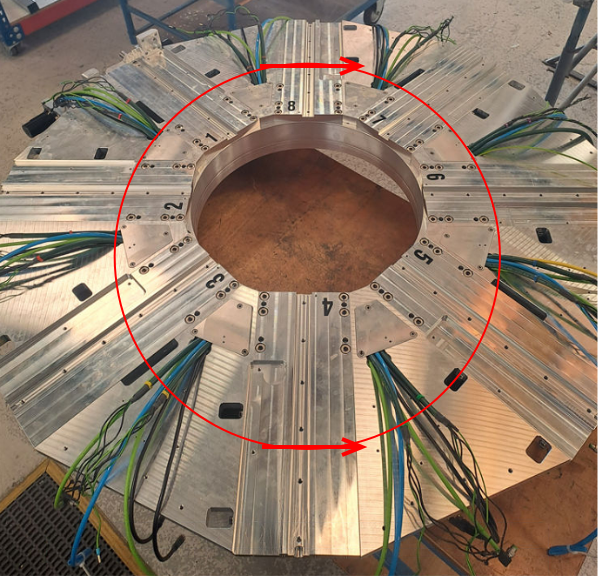

Cables must be adjusted between each spindle to ensure the cable lengths are correct .

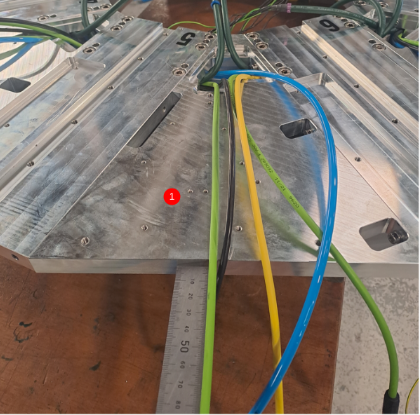

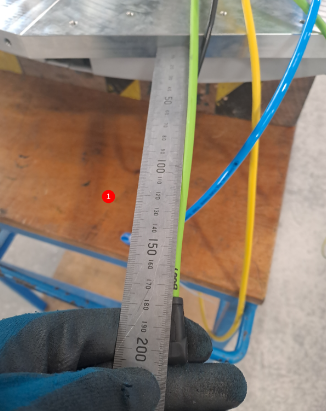

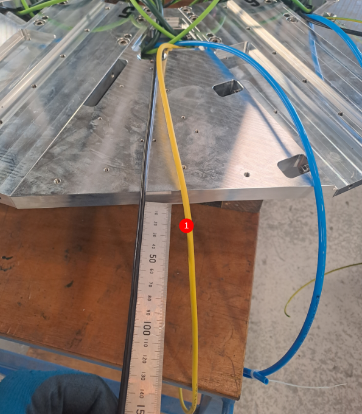

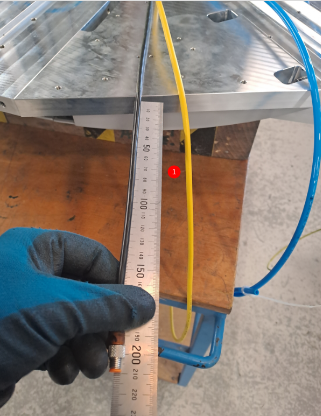

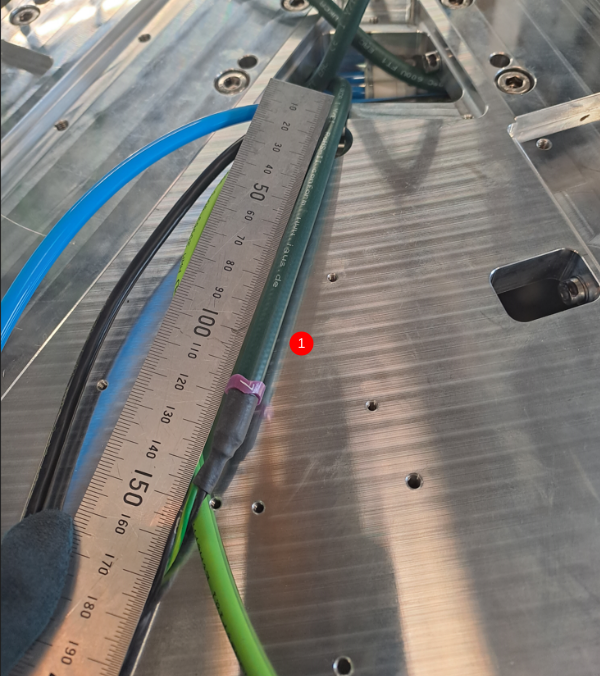

1 Start at cable point between 6 and 5 . Start with the light green ethercat cable with the right angle plug. Adjust so that 200mm is past the end of the spindle plate . See picture for detail.

2 Move to the next spindle connection between 5 and 4 and adjust the new right angled ethercat cable to match the length of the previous adjusted cable

3 Repeat this process working your way around the spindles to set all ethercat cables

Étape 2 - Wiring loom positioning Ethercat power

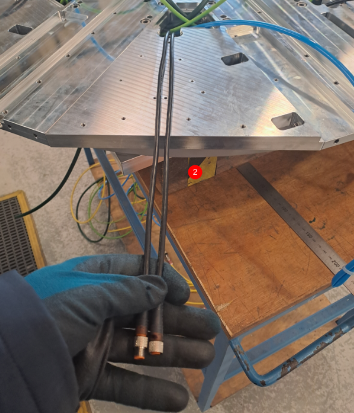

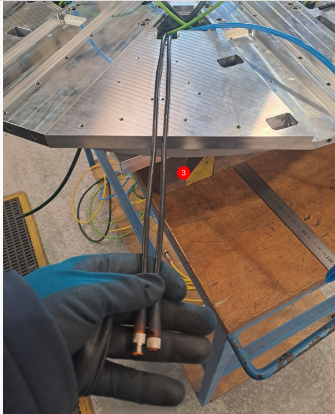

1 Start at cable point between 6 and 5 . Adjust black power cable to 200mm from edge of plate. See picture for details

2 Move to the next spindle connection between 5 and 4 and adjust the new black power cable to match the length of the previous adjusted cable

3 Repeat this process working your way around the spindles to set all power cables

Étape 3 - Wiring loom positioning 300hz power

1 Start at connection point with 3 power cables exiting . Set one cable as shown to 150mm

2 Use the previous set cable to adjust the next connection box cable to the same length

3 Repeat this until all power cables have been adjusted to the correct length

Étape 4 - Fit Inspection covers on spindles 1,2,3,4,5,6 and 8

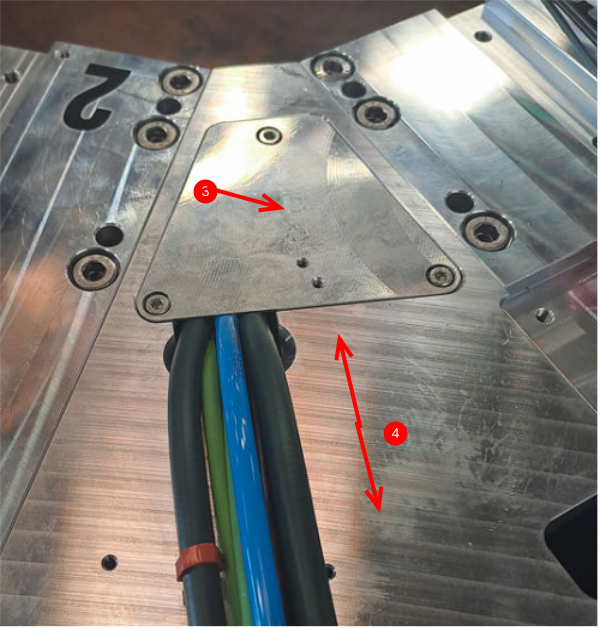

D0007788 inspection covers need fitting to captivate cables.

It is vital the cables are laid out in the correct way for spindle box routing later on.

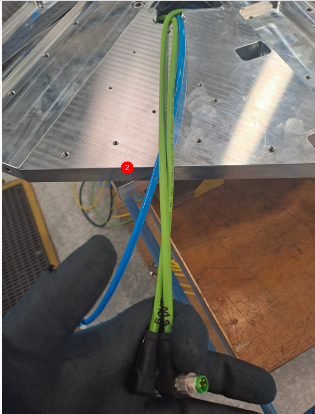

1 Lay the green ethercat cables to the left , and black power cables to the right as shown

2 Next, lay the two 300 hz cables on top with the blue air pipe between

3 Now fit inspection cover using m4 x 12 socket caps

4 Check that inspection cover hasn't trapped cables by checking to see if the loom of cables is able to move forward and back in the direction shown

Étape 5 - Fit inspection cover to spindle 7

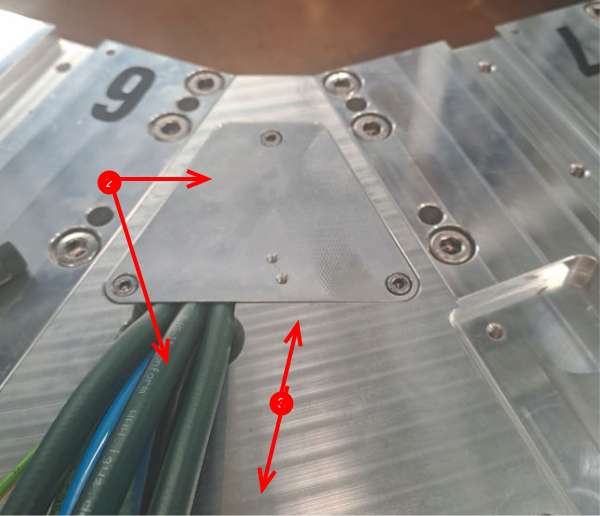

1 Position green ethercat cable, power cable and blue air pipe as shown

2 Lay off 300hz cables and earth on top and fit D0007788

3 Check cable movement is still present in the direction shown

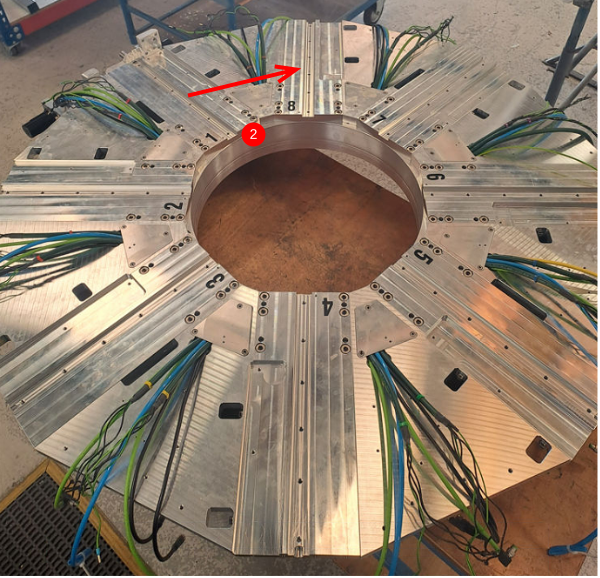

Étape 6 - Rotational check

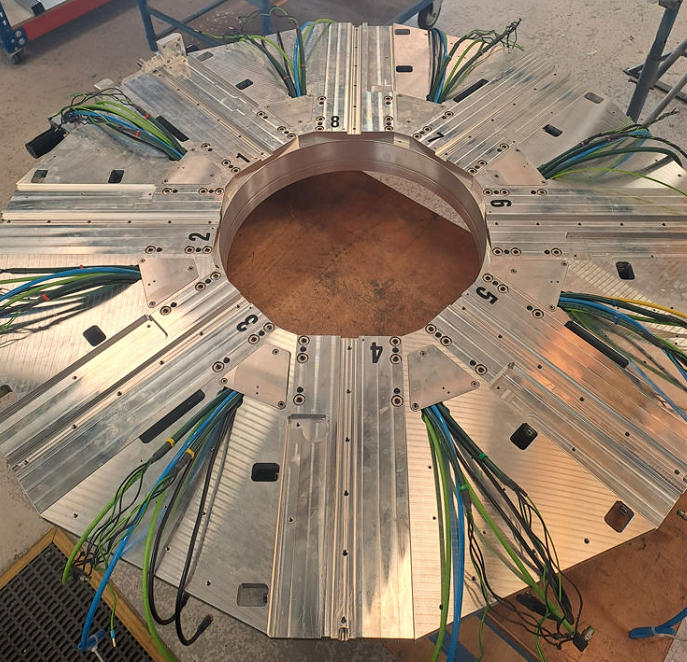

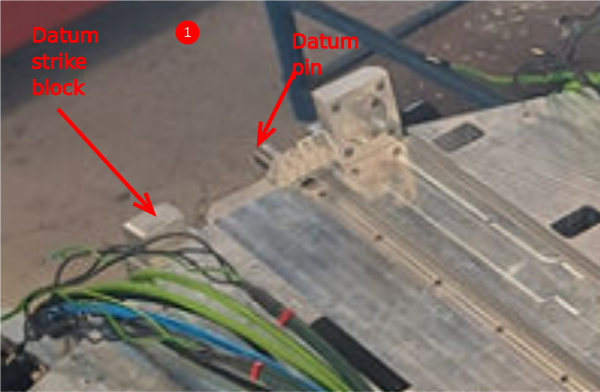

The full rotation of the rotary ring now needs to be checked

1 Start with ring in the position shown. The datum pin determines the start and finish point. The datum pin should be able to move freely to the datum strike block.

2 Now rotate the ring in the direction away from the strike block. 360 degrees of travel should be possible with the datum pin then contacting the other side of the datum strike block

Movement should be consistent in all degrees of travel

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português