| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Description=<translate>instructions to check parts and prepare for fitting</translate> |Categories=Production |Difficulty=Medium |Duration=1 |Duration-type... ») |

|||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

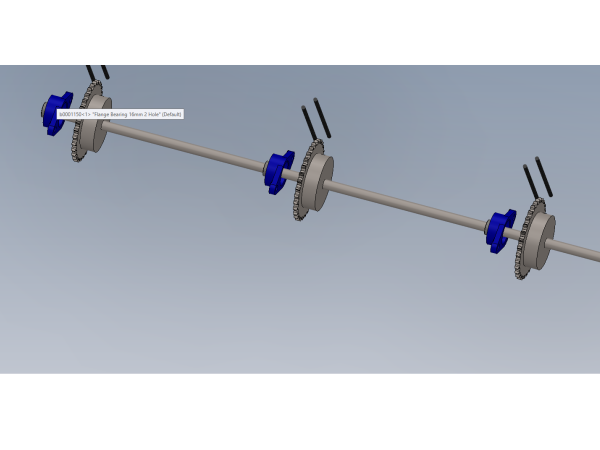

| + | |Main_Picture=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_16.png | ||

| + | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-4,"top":65,"width":1439,"height":736,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.42,"scaleY":0.42,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/4/4c/Bench_assemble_Shafts_bearings_and_sprockets_R0015077B_Screenshot_16.png","filters":[]}],"height":450.32119914346896,"width":600} | ||

|Description=<translate>instructions to check parts and prepare for fitting</translate> | |Description=<translate>instructions to check parts and prepare for fitting</translate> | ||

|Categories=Production | |Categories=Production | ||

| Ligne 7 : | Ligne 9 : | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate></translate> | + | |Introduction=<translate>'''<u>Tools Required</u>''' |

| + | |||

| + | |||

| + | Emery tape 180 grit | ||

| + | |||

| + | FE10 solvent | ||

| + | |||

| + | Compressed air line | ||

| + | |||

| + | Cleaning cloth | ||

| + | |||

| + | |||

| + | '''<u>Parts Required</u>''' | ||

| + | |||

| + | |||

| + | D0015459B x 1 | ||

| + | |||

| + | D0015458B x 1 | ||

| + | |||

| + | B0001150 x 9 | ||

| + | |||

| + | B0001145 x 9</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Unless otherwise stated</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Use loctite 243 on all fasteners |

| + | |||

| + | Use Loctite 572 on all threaded pneumatic connections | ||

| + | |||

| + | Pen mark all bolts to show finalised</translate> | ||

| + | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Prepare shafts</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check for any burrs or damage . If present remove with emery tape |

| + | |||

| + | |||

| + | Clean shafts D0015459B and D0015458B with fe10 solvent and compressed air to remove any debris or contamination</translate> | ||

| + | |Step_Picture_00=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_13.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":705,"height":511,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.85,"scaleY":0.85,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/e/ea/Bench_assemble_Shafts_bearings_and_sprockets_R0015077B_Screenshot_13.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":392.5,"top":317,"width":183,"height":100,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-91.5,"x2":91.5,"y1":50,"y2":-50,"x2a":77.78561546524097,"y2a":-33.389290899158986,"x2b":70.11323250873241,"y2b":-47.429751709569636},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":301,"top":367,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":484,"top":267,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":131.5,"top":243,"width":3,"height":144,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-1.5,"x2":1.5,"y1":72,"y2":-72,"x2a":9.081688180188182,"y2a":-51.837708355983075,"x2b":-6.914840727461609,"y2b":-52.170969374892444},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":130,"top":315,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":133,"top":171,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":435,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

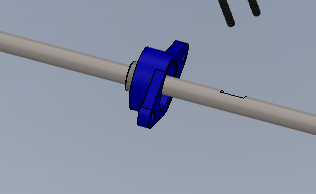

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Prepare bearings</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check for any internal burrs around tapped holes . If present remove with emery tape |

| + | |||

| + | |||

| + | Clean 9 off bearings B0001150 with fe10 solvent and compressed air to remove any debris or contamination | ||

| + | |||

| + | <br /></translate> | ||

| + | |Step_Picture_00=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_13.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":705,"height":511,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.85,"scaleY":0.85,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/e/ea/Bench_assemble_Shafts_bearings_and_sprockets_R0015077B_Screenshot_13.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":159.5,"top":245.5,"width":131,"height":81,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-65.5,"x2":65.5,"y1":40.5,"y2":-40.5,"x2a":52.69642470470462,"y2a":-23.177515776953303,"x2b":44.28190463234011,"y2b":-36.78618404213542},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":94,"top":286,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":225,"top":205,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":435,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

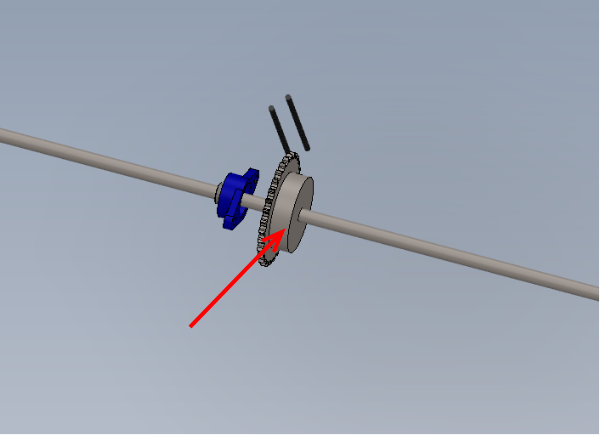

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Prepare Drive sprockets</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check for any internal burrs around tapped holes . If present remove with emery tape |

| + | |||

| + | |||

| + | Clean 9 off sprockets B0001145 with fe10 solvent and compressed air to remove any debris or contamination | ||

| + | |||

| + | <br /></translate> | ||

| + | |Step_Picture_00=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_13.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":705,"height":511,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.85,"scaleY":0.85,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/e/ea/Bench_assemble_Shafts_bearings_and_sprockets_R0015077B_Screenshot_13.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":236,"top":279.5,"width":92,"height":95,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-46,"x2":46,"y1":47.5,"y2":-47.5,"x2a":37.83340033393452,"y2a":-27.567447481714257,"x2b":26.33966747058311,"y2b":-38.698220359907204},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":190,"top":327,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":282,"top":232,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":435,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Check fit of bearings on shafts</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check that all bearings slide easily along the entire length of both shafts . |

| + | |||

| + | |||

| + | Any tight spots should be dressed down with emery tape, cleaned and retried. | ||

| + | |||

| + | |||

| + | Repeat until all bearings pass freely along both shafts</translate> | ||

| + | |Step_Picture_00=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_15.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

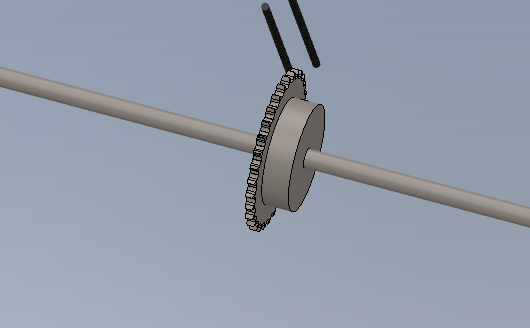

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Check fit of sprockets on shafts</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check that all sprockets slide easily along the entire length of both shafts . |

| + | |||

| + | Any tight spots should be dressed down with emery tape, cleaned and retried. | ||

| + | |||

| + | Repeat until all sprockets pass freely along both shafts</translate> | ||

| + | |Step_Picture_00=Bench_assemble_Shafts__bearings_and_sprockets_R0015077B_Screenshot_14.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Store prepared parts</translate> | ||

| + | |Step_Content=<translate>Store prepared shafts, sprockets and bearings ready for next stage</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 7 juin 2023 à 17:16

instructions to check parts and prepare for fitting

Introduction

Tools Required

Emery tape 180 grit

FE10 solvent

Compressed air line

Cleaning cloth

Parts Required

D0015459B x 1

D0015458B x 1

B0001150 x 9

B0001145 x 9Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

Étape 2 - Prepare shafts

Check for any burrs or damage . If present remove with emery tape

Clean shafts D0015459B and D0015458B with fe10 solvent and compressed air to remove any debris or contamination

Étape 3 - Prepare bearings

Check for any internal burrs around tapped holes . If present remove with emery tape

Clean 9 off bearings B0001150 with fe10 solvent and compressed air to remove any debris or contamination

Étape 4 - Prepare Drive sprockets

Check for any internal burrs around tapped holes . If present remove with emery tape

Clean 9 off sprockets B0001145 with fe10 solvent and compressed air to remove any debris or contamination

Étape 5 - Check fit of bearings on shafts

Check that all bearings slide easily along the entire length of both shafts .

Any tight spots should be dressed down with emery tape, cleaned and retried.

Repeat until all bearings pass freely along both shafts

Étape 6 - Check fit of sprockets on shafts

Check that all sprockets slide easily along the entire length of both shafts .

Any tight spots should be dressed down with emery tape, cleaned and retried.

Repeat until all sprockets pass freely along both shafts

Étape 7 - Store prepared parts

Store prepared shafts, sprockets and bearings ready for next stage

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português