| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 30 : | Ligne 30 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Unless otherwise stated</translate> | ||

| + | |Step_Content=<translate>Use Loctite 243 on all fasteners | ||

| + | |||

| + | Pen mark bolts to indicate finalised</translate> | ||

| + | |Step_Picture_00=R0000712E_Rotary_Trunking_Screenshot_2023-05-31_084239.png | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Fit relay mounting plate</translate> | |Step_Title=<translate>Fit relay mounting plate</translate> | ||

Version du 2 juin 2023 à 12:19

Control installation

Introduction

Tools Required

Standard screwdriver set

Standard hex key set

Parts Required

E0000519 Relay x 8

A0000160 Relay base x 8

C0001018 Ethercat box x 8

D0010806 Mounting plate x 8Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Pen mark bolts to indicate finalised

Étape 2 - Fit relay mounting plate

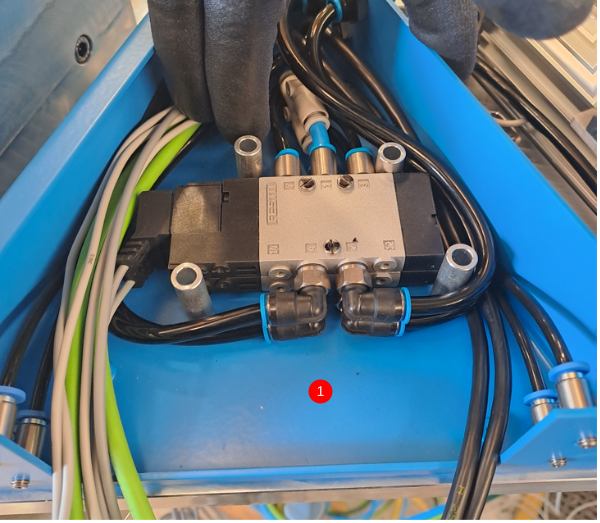

1 Segregate cables and pipes as shown in image

2 Mount D0010806 relay mounting base using 4 off M3x 25 pan head screws

3 Repeat for 7 off other connection boxes

Étape 3 - Mount Ethercat boxes

Use 2 off M3 x 20 countersink posi screws to mount C0001018 Ethercat boxes to all 8 connection boxes

Étape 4 - Adjust Pipes

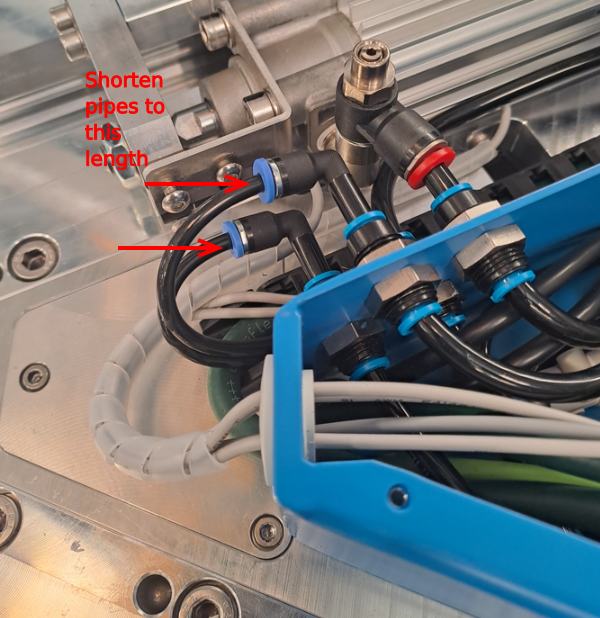

4 off connection boxes

4mm feed pipes to cylinders can now been adjusted in length to finalise

See image

Étape 5 - Check

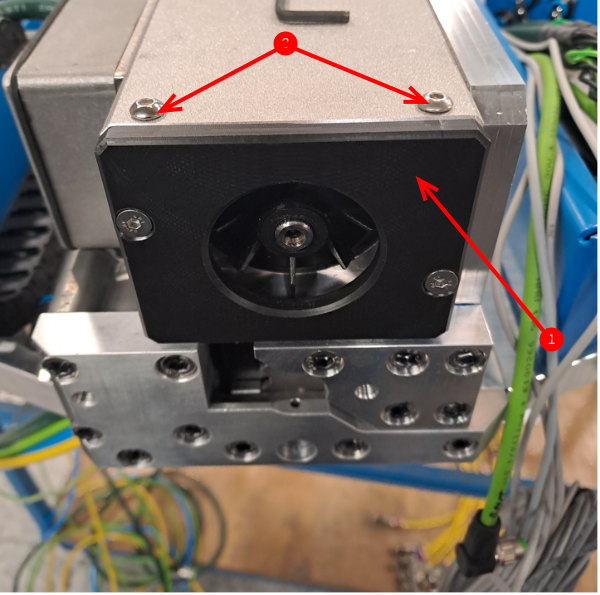

1 Motor replacement end caps D0010908 are fitted

2 Blanking m4 x 6 button screws are fitted to single slide spindle motors

Étape 6 - Relay bases and relays

Ensure E0000519 relays and A0000160 relay bases are stored with ring ready for handover

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português