| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=Finalise_wiring_loom_for_Rotary_head_Screenshot_2023-05-31_145134.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","... ») |

|||

| Ligne 45 : | Ligne 45 : | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 31 mai 2023 à 14:58

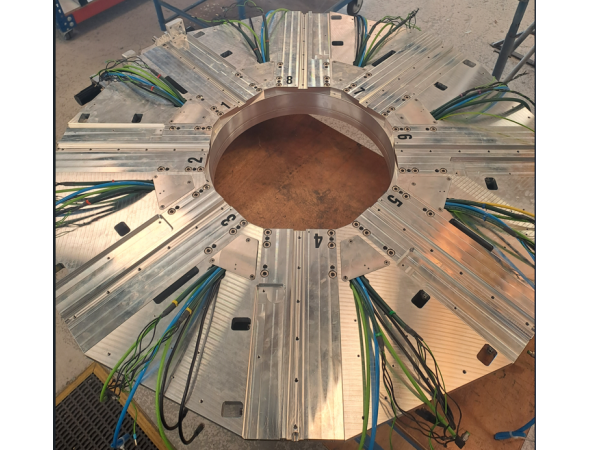

correct routing of cables ready for connection boxes

Introduction

Étape 1 - Wiring loom positioning Ethercat control

Cables must be adjusted between each spindle to ensure the cable lengths are correct .

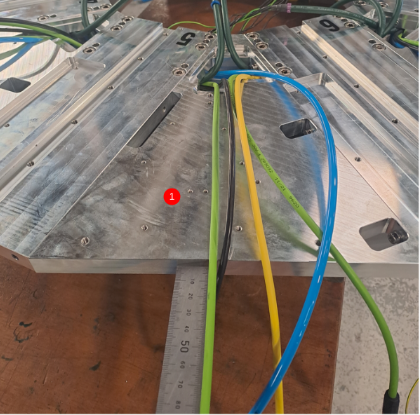

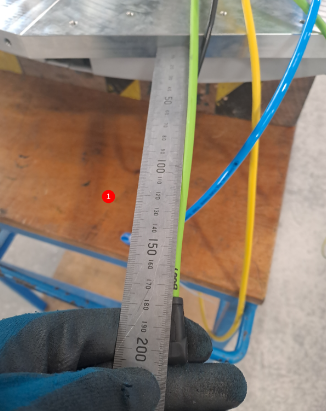

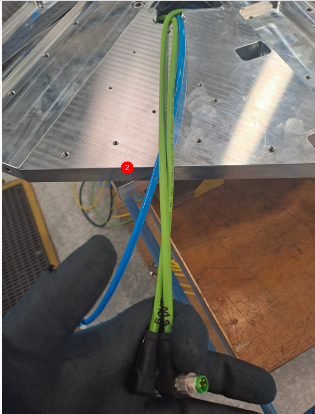

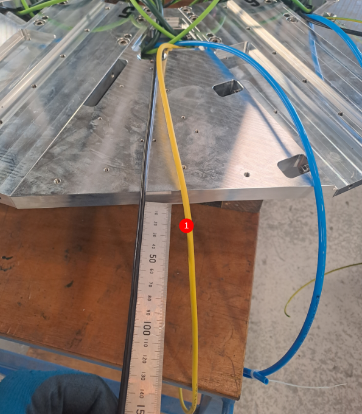

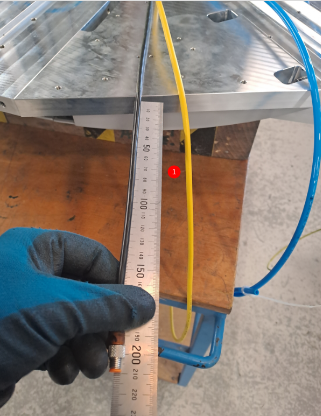

1 Start at cable point between 6 and 5 . Start with the light green ethercat cable with the right angle plug. Adjust so that 200mm is past the end of the spindle plate . See picture for detail.

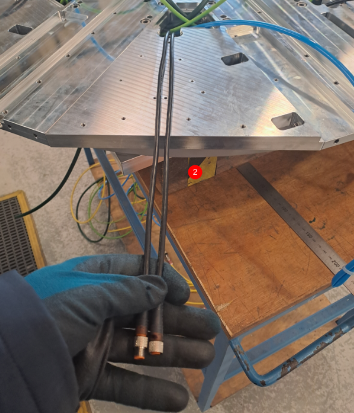

2 Move to the next spindle connection between 5 and 4 and adjust the new right angled ethercat cable to match the length of the previous adjusted cable

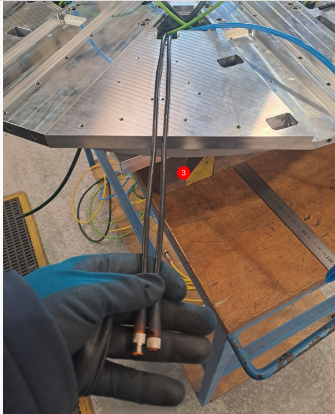

3 Repeat this process working your way around the spindles to set all ethercat cables

Étape 2 - Wiring loom positioning Ethercat power

1 Start at cable point between 6 and 5 . Adjust black power cable to 200mm from edge of plate. See picture for details

2 Move to the next spindle connection between 5 and 4 and adjust the new black power cable to match the length of the previous adjusted cable

3 Repeat this process working your way around the spindles to set all power cables

Étape 3 - Wiring loom positioning 300hz power

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português