| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 14 : | Ligne 14 : | ||

| − | '''The Jetter motor on the GZ axis has a brake. | + | '''The Jetter motor on the GZ axis has a brake. Releasing the brake without control could be harmful/dangerous.''' |

'''Use the Air Counterbalance rig to assist if necessary.''' | '''Use the Air Counterbalance rig to assist if necessary.''' | ||

| − | This assumes that the motors are connected to the Beckhoff | + | This assumes that the motors are connected to the Beckhoff drive and are free to move.</translate> |

}} | }} | ||

{{Materials}} | {{Materials}} | ||

Version du 23 avril 2023 à 14:33

Autoflow MK4 GY&GZ axis setup with Jetter Motors

Sommaire

- 1 Introduction

- 2 Étape 1 - Initial Preperation

- 3 Étape 2 - GY Axis:

- 4 Étape 3 - GZ Axis

- 5 Étape 4 - Counterbalance

- 6 Étape 5 - CX5203 Firmware Upgrade

- 7 Étape 6 - Drive Manager 2 and Support Jetter Files

- 8 Étape 7 - Basic Assumptions

- 9 Étape 8 - GY setup Motor

- 10 Étape 9 - GY Setup FeedBack

- 11 Étape 10 - GY Setup Scaling

- 12 Étape 11 - GY Setup Tuning

- 13 Étape 12 - GY Setup Commutation step 1 P-0-150

- 14 Étape 13 - GY Setup Commutation angles(if necessary to change)

- 15 Étape 14 - GZ Setup

- 16 Commentaires

Introduction

WARNING:

The Jetter motor on the GZ axis has a brake. Releasing the brake without control could be harmful/dangerous.

Use the Air Counterbalance rig to assist if necessary.

Étape 1 - Initial Preperation

Ensure that the profile support arm is held out of the way to avoid marking the blue infeed arm.

Étape 2 - GY Axis:

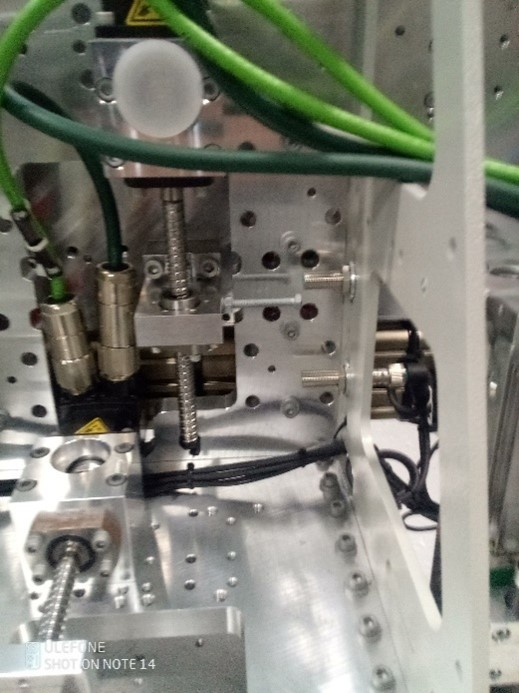

Check that proximity arm is in between the proximity sensor.

You should be able to turn the leadscrew by hand to move it.

Étape 3 - GZ Axis

Check that proximity arm is in between the proximity sensor

This has a brake and you can only turn the leadscrew by hand if the counterbalance is fitted.

Étape 4 - Counterbalance

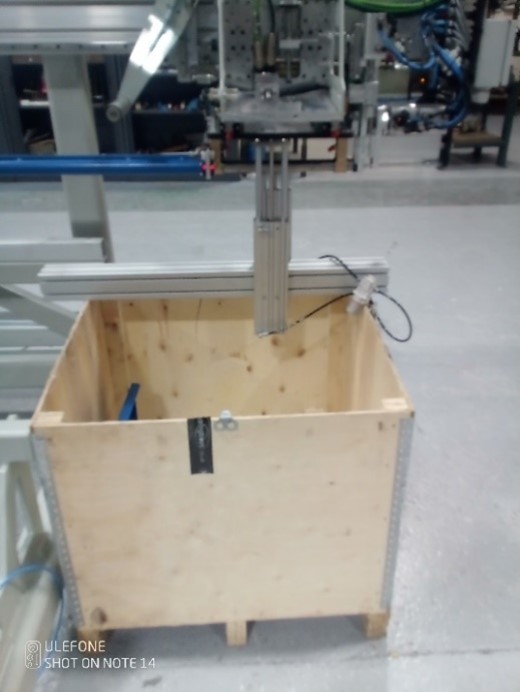

Counterbalance fitted under the carriage.

Adjust the pressure until you can turn the leadscrew of the GZ axis by hand. (6 bar)

.

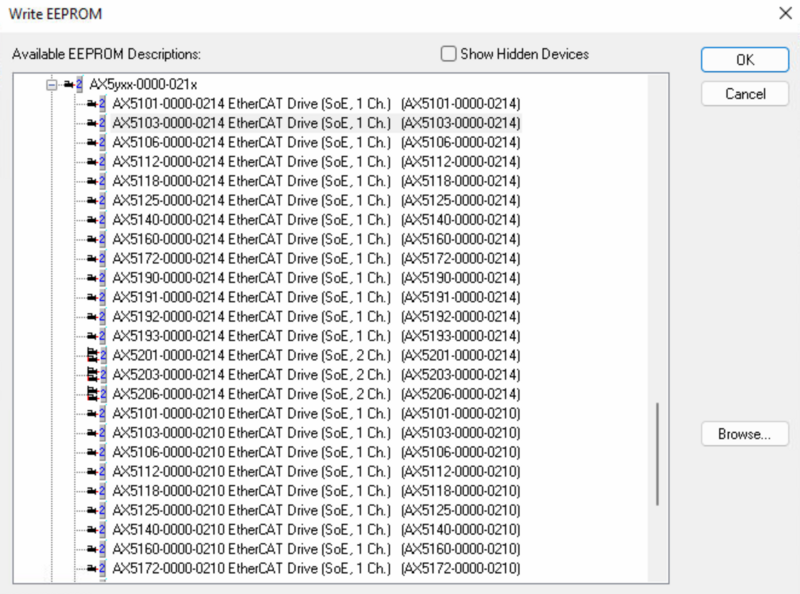

Étape 5 - CX5203 Firmware Upgrade

The firmware on the CX5203 must be high enought to be supported under Drive manager 2.

Because your have to remove and add drives back into a projecct crate a new projet just to update the drives.

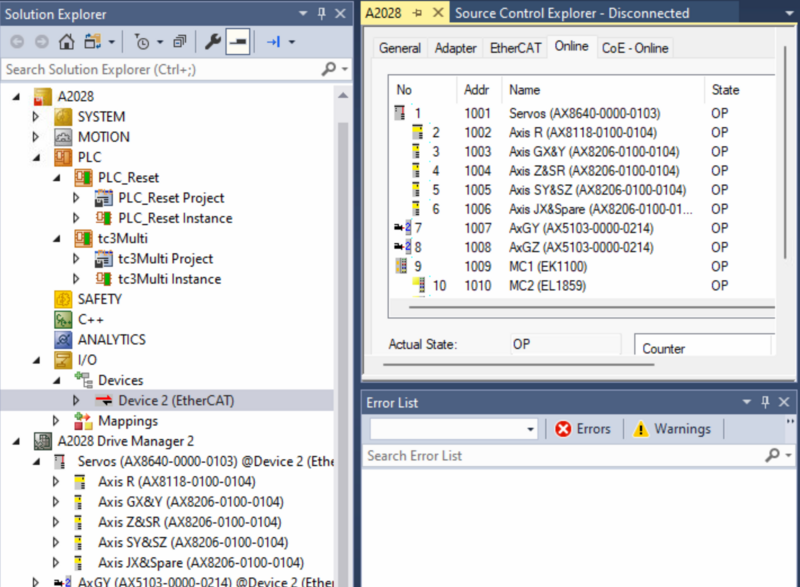

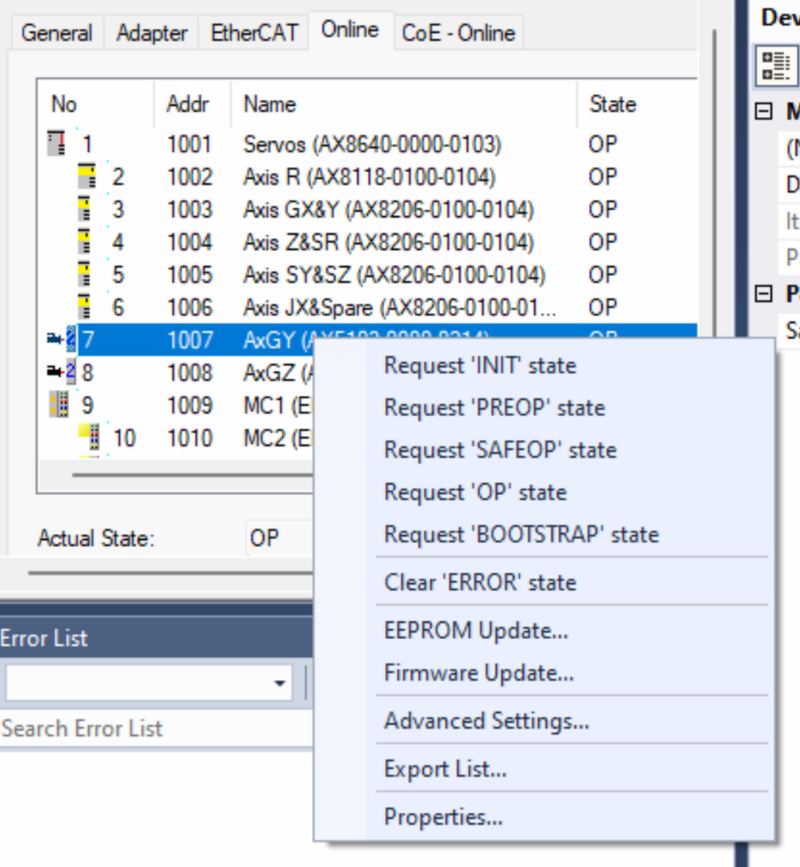

- Expand I/O -> Devices-> Device (EthercAT), Doble click and open the Onlne tab.

- Check the Dirve you are going to update is in OP state and right mouse click on it.

- Select FIRMWARE UP. Navidate to the location of the firmware. Normally C:\TwinCAT\Functions\TE5950-Drive-Manager-2\Firmware\AX5000

- Do the same process for the EEROM matching the version number.

- Check that you have the XML definition file for the version of firmware in C:\TwinCAT\3.1\Config\Io\EtherCAT\Beckhoff AX5xxx

- With this done you should be able to delete the drives and add them bak and check under drive manager 2

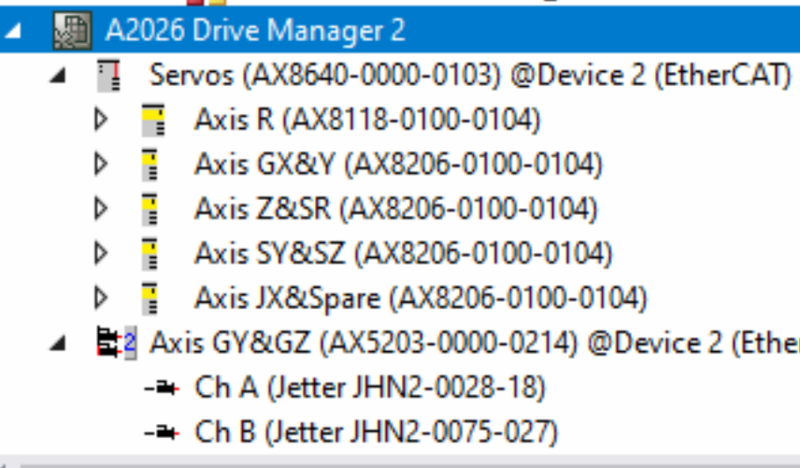

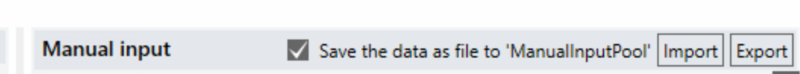

Étape 6 - Drive Manager 2 and Support Jetter Files

Ensure Drive Manager 2 is installed (Verion 1.1.60.0 minimum)

Copy the files from :

G:\Design\TwinCAT3\Other Motor Definition Files

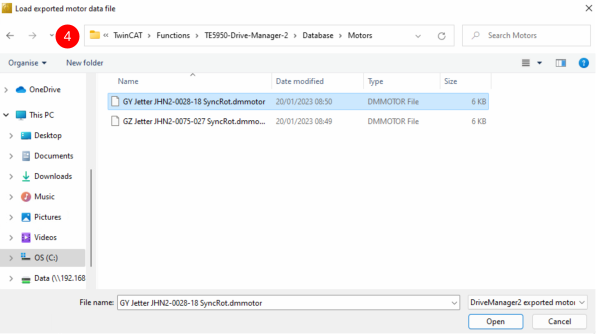

GY Jetter JHN2-0028-18 SyncRot.dmmotor

GZ Jetter JHN2-0075-027 SyncRot.dmmotor

to C:\TwinCAT\Functions\TE5950-Drive-Manager-2\Database\Motors

Étape 7 - Basic Assumptions

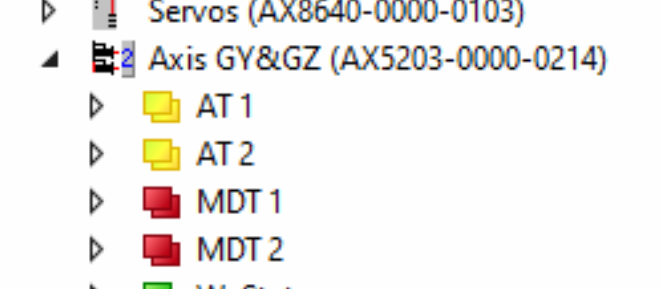

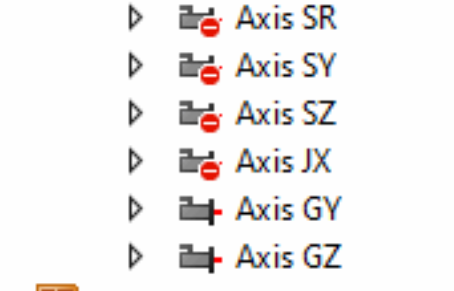

The Motors are connected to an AX5203 Drive

GY on the A channel

GZ on the B channel

The Drive is labelled GY & GZ

The channels are mapped to AXIS with appropriate names

A Driver Manager 2 Project exisits with the Drives in it.

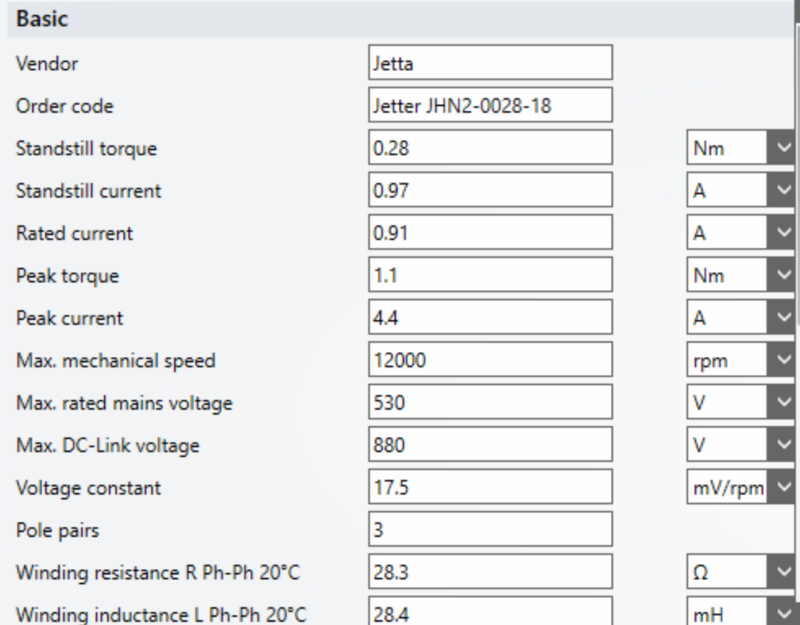

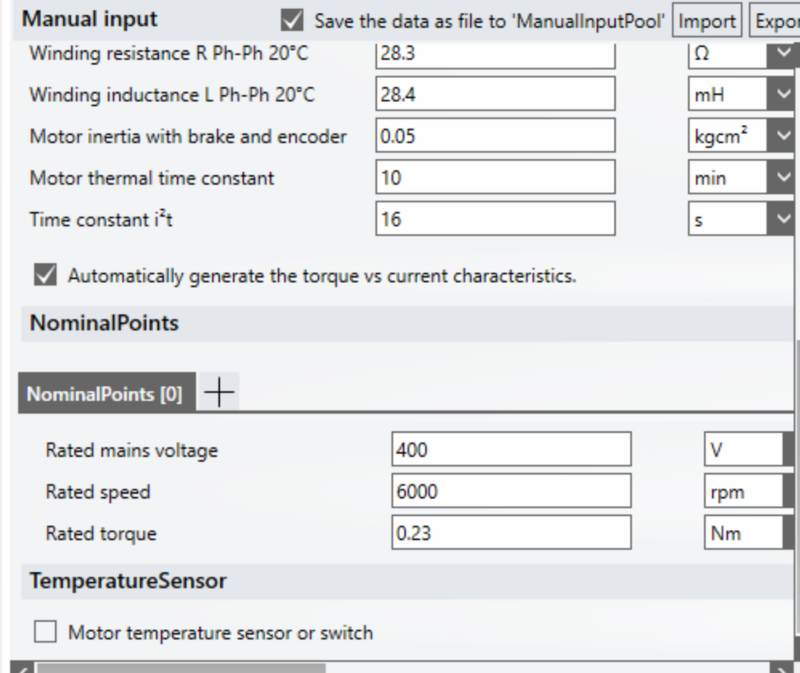

Étape 8 - GY setup Motor

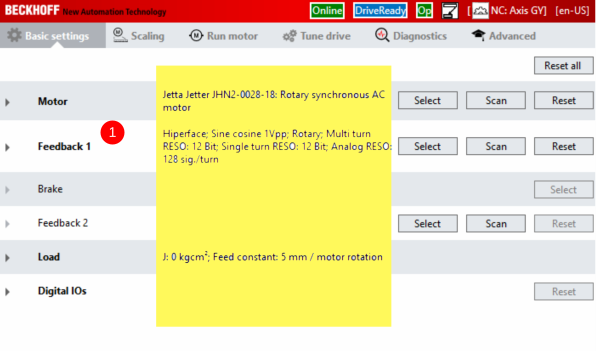

- Double click on GY axis (Ch A ) in drive manager 2 . You will not see the information highlighted yet.

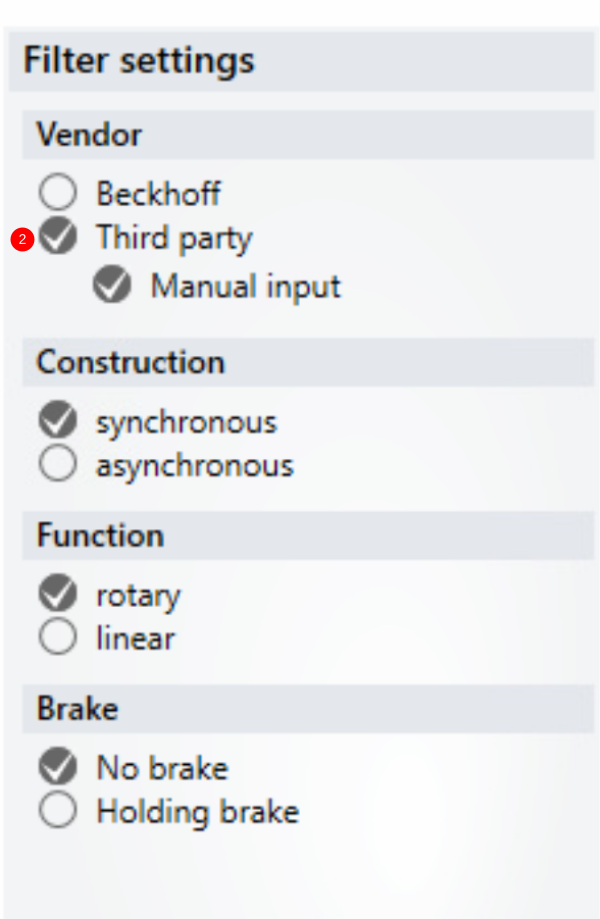

- For the Motor Press select then select the filter options.

- Select Import.

- Move to the folder C:\TwinCAT\Functions\TE5950-Drive-Manager-2\Database\Motors

- Select the GY and Open

- The parameters shold all mactch the screen shots.

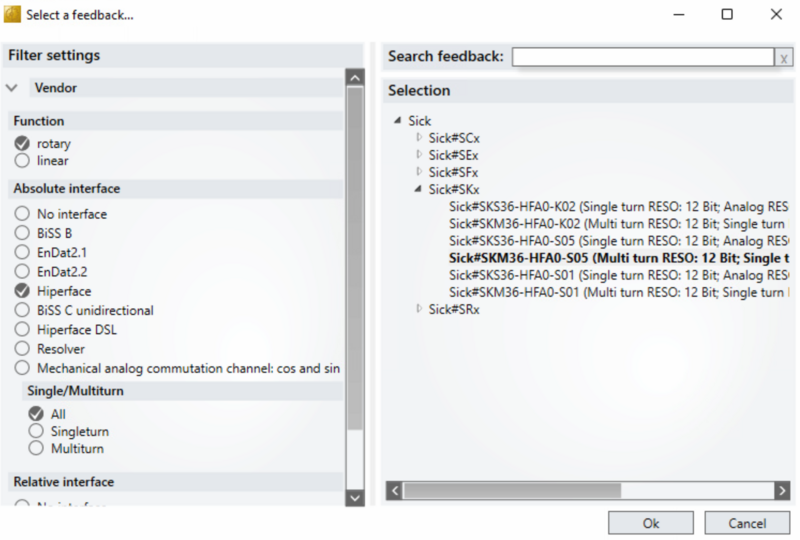

Étape 9 - GY Setup FeedBack

- From the Manager Scrren Press Select fo "Feedback 1"

- Under filter Select as shown (Hiperface being the important one)

- Expand Sick#SKx and select SKM36- HFA0-S05 and OK

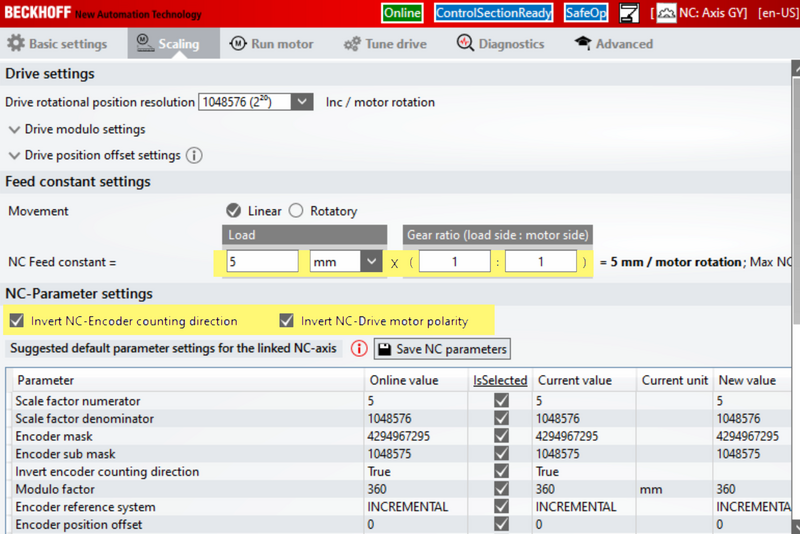

Étape 10 - GY Setup Scaling

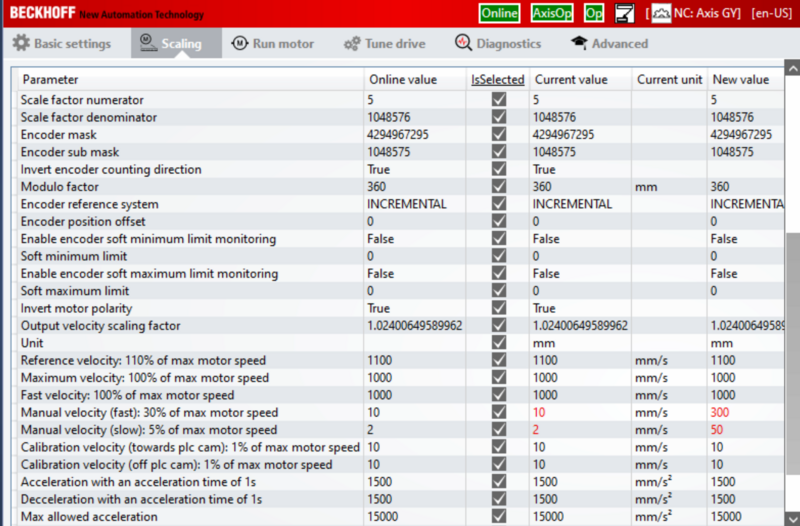

- Select the Scaling Tab

- Adjust the settings HightLighted.

- When Checking the INVERT boes you will get a request to activate it straight away. Do not both as you have to activate all setting down later.

- Before you save the NC Parameters Look at the values in red. If the new value is different to the Online value of the screen shot detick the is selected box so that it does not update.

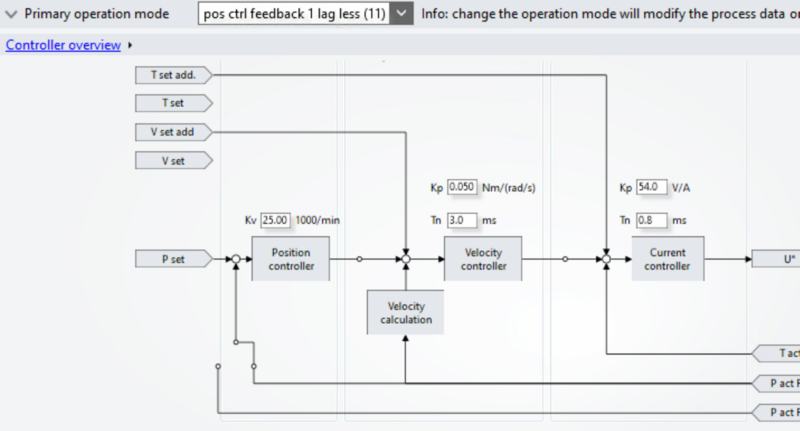

Étape 11 - GY Setup Tuning

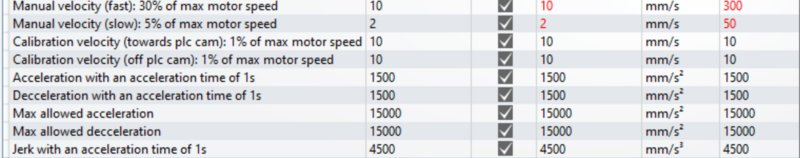

- Select the Tune Drive tab

- Set Kp = 0.02

- Set Kp=85.2

- Set Kv=25

- Set Tn=3.0

- Set Tn 0.8

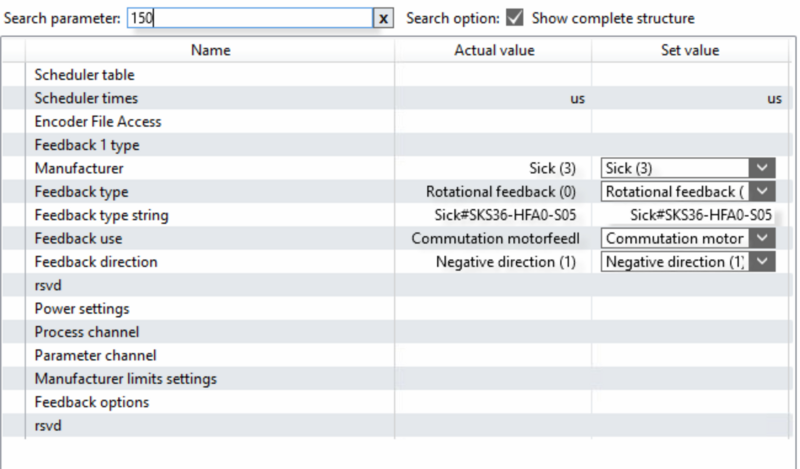

Étape 12 - GY Setup Commutation step 1 P-0-150

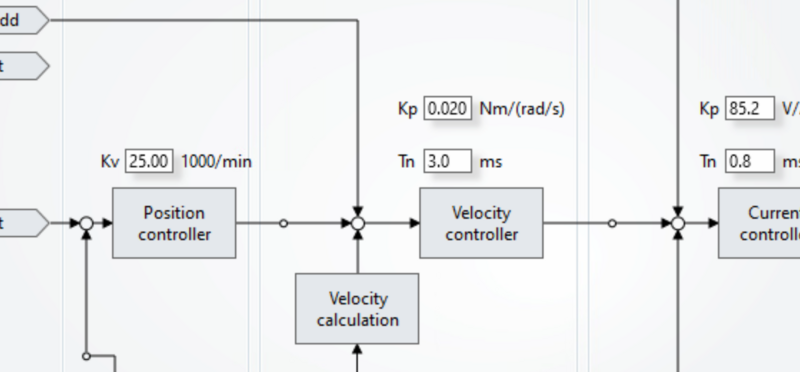

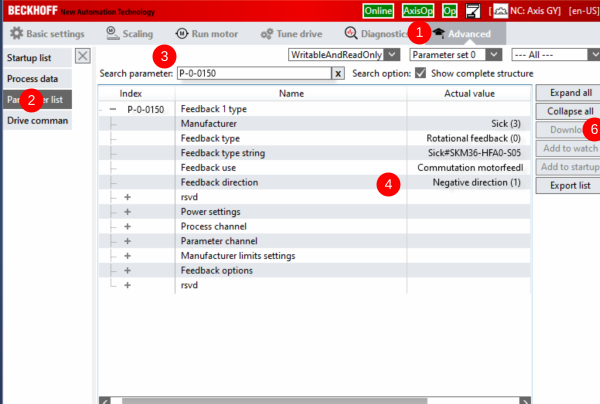

- Select th Advance tab

- Select Prameter List

- In search Type P-0-150

- Check the settings

- You may have to change the Feedback direction to Negative

- If you change it remeber to press download after the change

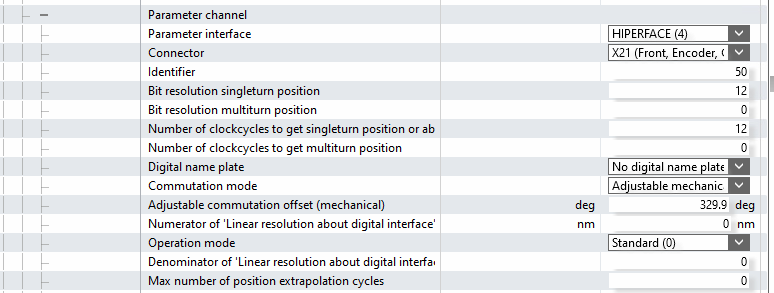

- Expand the "Parameter chnannel"

- Make sure that Commutation mode = Adjustable mechanical offset.

- Make sure Adjust commutation offset (Mechanical) is 0.0 deg

- Go to P-0-0057 Electrical commutation offset and set a value of 340 deg

Étape 13 - GY Setup Commutation angles(if necessary to change)

There are two forms of commutation set up Mechanical and Electrical.

Mechical is going to be 0 degrees and we are going to adjust the electrial using the command P-0-0166

Étape 14 - GZ Setup

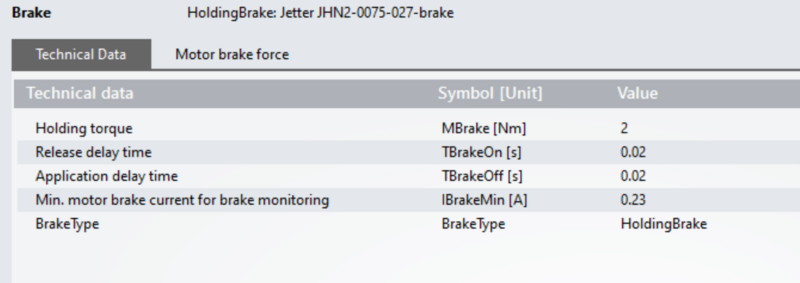

Repeat as for GY with the following changes:

1) Motor Set up - select the GZ jetter file

2) Feedback set to Sick#SKS36-HFA0-S05 (Single turn...)

3) Brake paramters should be as pure image

4) Sccaling as per GY

5) Tune drive settings as per image.

6) Commutation P-0-150 as per Image

P-0-0057 Electrical commutation offset and set a value of 0 deg

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português