| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=Laser_setup_LS1.jpg |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top",... ») |

m (GlennF a déplacé la page Laser setup vers Laser Setup on Flowline/ZX3 for Laser Holes : Machine applicable ) |

||

| (4 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 2 : | Ligne 2 : | ||

|Main_Picture=Laser_setup_LS1.jpg | |Main_Picture=Laser_setup_LS1.jpg | ||

|Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":11,"top":8,"width":640,"height":481,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.91,"scaleY":0.91,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/75/Laser_setup_LS1.jpg","filters":[]}],"height":449.63144963144964,"width":600} | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":11,"top":8,"width":640,"height":481,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.91,"scaleY":0.91,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/75/Laser_setup_LS1.jpg","filters":[]}],"height":449.63144963144964,"width":600} | ||

| − | |Description=<translate>Laser Setup on Flowline/ZX3</translate> | + | |Description=<translate>Laser Setup on Flowline/ZX3 for Laser Holes</translate> |

|Categories=Operation | |Categories=Operation | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| Ligne 10 : | Ligne 10 : | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate>How to Setup | + | |Introduction=<translate>'''How to Setup .''' |

| + | |||

| + | This will Cover the Basic Alignment of the receiver and Sender setup. | ||

| + | |||

| + | Focusing the Laser and Setting up the Receiver Sensitivity. | ||

| + | |||

| + | Always Make sure Laser Sender and Receiver are clean and both lenses have been wiped with a soft cloth first. | ||

| + | |||

| + | |||

<br /></translate> | <br /></translate> | ||

}} | }} | ||

{{Materials | {{Materials | ||

| − | |ItemList= | + | |ItemList={{ItemList |

|Item=Laser Focusing Spanner | |Item=Laser Focusing Spanner | ||

}}{{ItemList | }}{{ItemList | ||

| Ligne 25 : | Ligne 33 : | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate> | + | |Step_Title=<translate>Ensure Laser Receiver is setup at correct Height</translate> |

| − | |Step_Content=<translate>The | + | |Step_Content=<translate>The Protection plate screw holes can be used as a Guide to get the receiver aligned at the right height when the cover is off. Undo the locknuts on Receiver and move up/down as required Keeping the Lens Square to the Laser at all times.</translate> |

| − | |Step_Picture_00= | + | |Step_Picture_00=Laser_setup_LS3.jpg |

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Receiver should be aligned with centre of hole.</translate> |

|Step_Content=<translate>The laser receiver needs to be as square and as close to the center of the aluminium deflection plate</translate> | |Step_Content=<translate>The laser receiver needs to be as square and as close to the center of the aluminium deflection plate</translate> | ||

|Step_Picture_00=Laser_setup_LS2.jpg | |Step_Picture_00=Laser_setup_LS2.jpg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Check Path of Laser is Not Blocked and Square to beds.</translate> |

| − | |Step_Content=<translate>The | + | |Step_Content=<translate>The laser sender needs to have a clear path to the laser receiver, its really important that this is parallel and the beam does not bounce off the inside of any of the aluminium mounting block. Slacken off the Nuts above and below Laser to move up/down and side/side.</translate> |

| − | + | |Step_Picture_00=Laser_setup_LS1.jpg | |

| − | |||

| − | |Step_Picture_00= | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Checking Laser for position.</translate> |

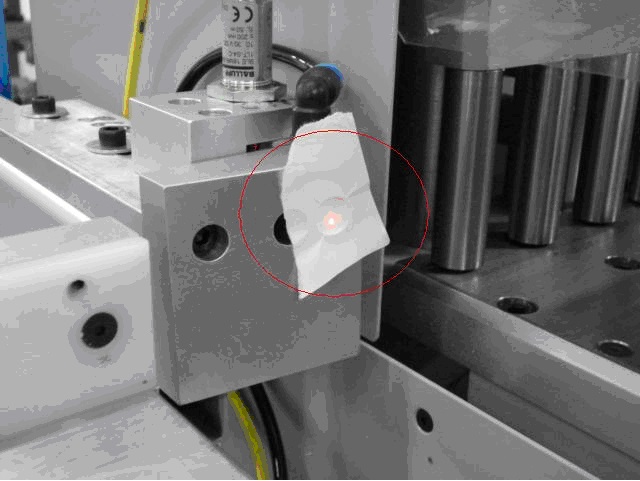

|Step_Content=<translate>Once you are happy that the laser sender and receiver are clean, parallel and you have no deflections place a profile label over the receiver hole and check you have a clear point to the laser and not a large spot with undefined edges.</translate> | |Step_Content=<translate>Once you are happy that the laser sender and receiver are clean, parallel and you have no deflections place a profile label over the receiver hole and check you have a clear point to the laser and not a large spot with undefined edges.</translate> | ||

|Step_Picture_00=Laser_setup_LS4.jpg | |Step_Picture_00=Laser_setup_LS4.jpg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Adjusting Laser Focus</translate> |

|Step_Content=<translate>The laser clarity can be adjusted using the spanner supplied, keep turning Clockwise or Anticlockwise until a Very Clear Red Dot of approx 1mm Diameter is shown on Paper in front of receiver hole. | |Step_Content=<translate>The laser clarity can be adjusted using the spanner supplied, keep turning Clockwise or Anticlockwise until a Very Clear Red Dot of approx 1mm Diameter is shown on Paper in front of receiver hole. | ||

| Ligne 54 : | Ligne 60 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

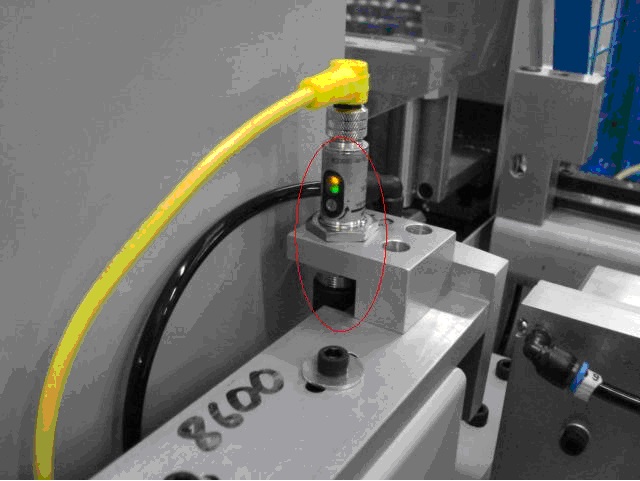

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Adjusting Receiver sensitivity</translate> |

|Step_Content=<translate>Finally the laser receiver sensitivity needs to be checked. Unscrew the adjusting screw (AntiClockwise) until the GREEN Led goes RED. . | |Step_Content=<translate>Finally the laser receiver sensitivity needs to be checked. Unscrew the adjusting screw (AntiClockwise) until the GREEN Led goes RED. . | ||

| Ligne 61 : | Ligne 67 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Other</translate> |

|Step_Content=<translate>As for software there are a few more things to think about. | |Step_Content=<translate>As for software there are a few more things to think about. | ||

| − | * Multihead | + | *Multihead |

| − | ** Z axis position of the Laser Hole files. | + | **Z axis position of the Laser Hole files. |

| − | ** Laser Holes getting done as slots for bent profiles. | + | **Laser Holes getting done as slots for bent profiles. |

| − | ** Speed control to keep slots/holes Clean. | + | **Speed control to keep slots/holes Clean. |

| − | * Saw | + | *Saw |

| − | ** Good Drive tuning, need following error of +/- 0.1mm on speed of 300mm/sec | + | **Good Drive tuning, need following error of +/- 0.1mm on speed of 300mm/sec |

| − | ** Laser hole Size Parameter - Should be 10mm | + | **Laser hole Size Parameter - Should be 10mm |

| − | ** Laser hole Tolerance should be no more than 1.2 (10-1.2=8.8mm) | + | **Laser hole Tolerance should be no more than 1.2 (10-1.2=8.8mm) |

| − | ** Drive speeds/Acceleration/Deceleration,etc | + | **Drive speeds/Acceleration/Deceleration,etc |

| − | ** Blower for Laser holes.</translate> | + | **Blower for Laser holes.</translate> |

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

Version actuelle datée du 27 mars 2020 à 11:09

Laser Setup on Flowline/ZX3 for Laser Holes

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Étape 1 - Ensure Laser Receiver is setup at correct Height

- 4 Étape 2 - Receiver should be aligned with centre of hole.

- 5 Étape 3 - Check Path of Laser is Not Blocked and Square to beds.

- 6 Étape 4 - Checking Laser for position.

- 7 Étape 5 - Adjusting Laser Focus

- 8 Étape 6 - Adjusting Receiver sensitivity

- 9 Étape 7 - Other

- 10 Commentaires

Introduction

How to Setup .

This will Cover the Basic Alignment of the receiver and Sender setup.

Focusing the Laser and Setting up the Receiver Sensitivity.

Always Make sure Laser Sender and Receiver are clean and both lenses have been wiped with a soft cloth first.

- Pièces et outils

Pièces et outils

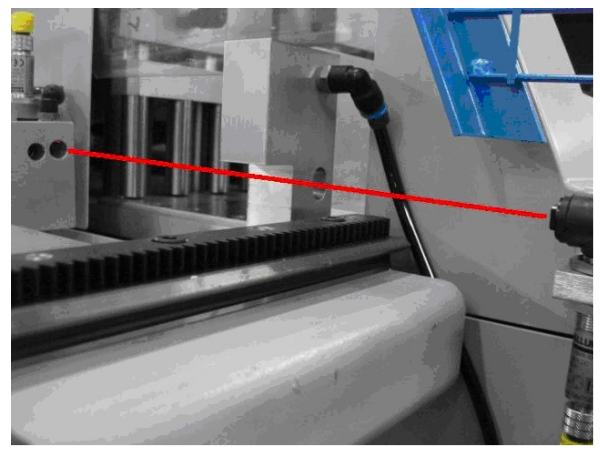

Étape 1 - Ensure Laser Receiver is setup at correct Height

The Protection plate screw holes can be used as a Guide to get the receiver aligned at the right height when the cover is off. Undo the locknuts on Receiver and move up/down as required Keeping the Lens Square to the Laser at all times.

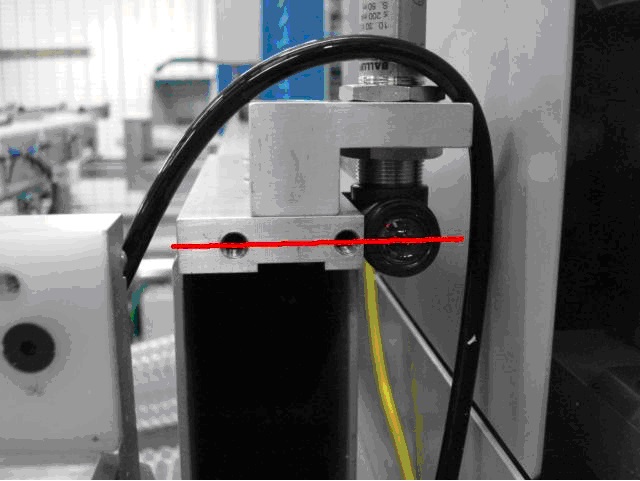

Étape 2 - Receiver should be aligned with centre of hole.

The laser receiver needs to be as square and as close to the center of the aluminium deflection plate

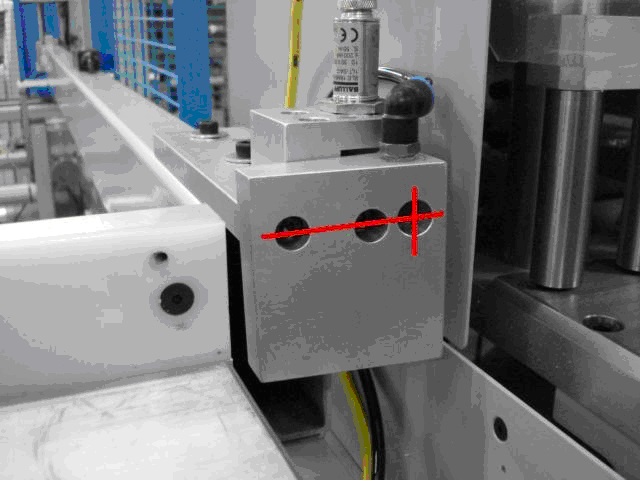

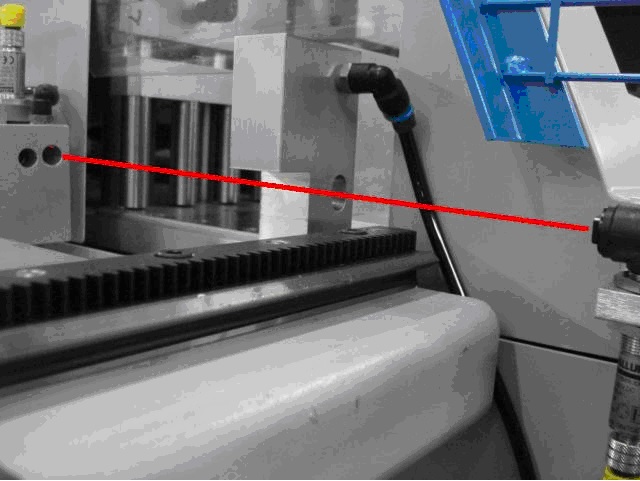

Étape 3 - Check Path of Laser is Not Blocked and Square to beds.

The laser sender needs to have a clear path to the laser receiver, its really important that this is parallel and the beam does not bounce off the inside of any of the aluminium mounting block. Slacken off the Nuts above and below Laser to move up/down and side/side.

Étape 4 - Checking Laser for position.

Once you are happy that the laser sender and receiver are clean, parallel and you have no deflections place a profile label over the receiver hole and check you have a clear point to the laser and not a large spot with undefined edges.

Étape 5 - Adjusting Laser Focus

The laser clarity can be adjusted using the spanner supplied, keep turning Clockwise or Anticlockwise until a Very Clear Red Dot of approx 1mm Diameter is shown on Paper in front of receiver hole.

Étape 6 - Adjusting Receiver sensitivity

Finally the laser receiver sensitivity needs to be checked. Unscrew the adjusting screw (AntiClockwise) until the GREEN Led goes RED. .

Then turn screw (Clockwise) until RED Led goes back to GREEN then turn a further 5 full turns the same way, the receiver sensitivity is now set

Étape 7 - Other

As for software there are a few more things to think about.

- Multihead

- Z axis position of the Laser Hole files.

- Laser Holes getting done as slots for bent profiles.

- Speed control to keep slots/holes Clean.

- Saw

- Good Drive tuning, need following error of +/- 0.1mm on speed of 300mm/sec

- Laser hole Size Parameter - Should be 10mm

- Laser hole Tolerance should be no more than 1.2 (10-1.2=8.8mm)

- Drive speeds/Acceleration/Deceleration,etc

- Blower for Laser holes.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português