| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 53 : | Ligne 53 : | ||

*The centralising feature means that any profile width inaccuracies are eliminated<br /> | *The centralising feature means that any profile width inaccuracies are eliminated<br /> | ||

| + | <br />{{#annotatedImageLight:Fichier:ZX5 Improvements and Upgrades 24872-web-115.jpg|0=200px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/4/4e/ZX5_Improvements_and_Upgrades_24872-web-115.jpg|href=./Fichier:ZX5 Improvements and Upgrades 24872-web-115.jpg|resource=./Fichier:ZX5 Improvements and Upgrades 24872-web-115.jpg|caption=|size=200px}} | ||

==Quad Plunge== | ==Quad Plunge== | ||

| − | {{#annotatedImageLight:Fichier:ZX5 Improvements and Upgrades | + | The standard setup of the ZX5 comes with two sets of double plunge heads, an upgrade on the ZX4's single plunge heads |

| − | == | + | <br /> |

| + | |||

| + | * Allows 10mm and 12.5mm tooling to be arranged in opposition for double plunge operations | ||

| + | * Reduces cycle time when both sizes of slot are required for trickle vents | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | <br />{{#annotatedImageLight:Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144213.jpg|0=400px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/0/04/ZX5_Improvements_and_Upgrades_Annotation_2019-09-26_14144213.jpg|href=./Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144213.jpg|resource=./Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144213.jpg|caption=|size=400px}}<br /> | ||

| + | |||

| + | == Infeed Loading Wheel == | ||

| + | A more reliable and faster loading method has been added which takes the best of the Flowline and ZX4 designs | ||

| + | |||

| + | * Direct drive | ||

| + | * Slipping clutch | ||

| + | * Reliable | ||

| + | * Eliminates profile marking | ||

| + | |||

| + | |||

| + | |||

=Software Enhancements= | =Software Enhancements= | ||

| + | {{#annotatedImageLight:Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144214.jpg|0=400px|hash=|jsondata=|mediaClass=Image|type=frameless|align=right|src=https://stuga.dokit.app/images/f/ff/ZX5_Improvements_and_Upgrades_Annotation_2019-09-26_14144214.jpg|href=./Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144214.jpg|resource=./Fichier:ZX5 Improvements and Upgrades Annotation 2019-09-26 14144214.jpg|caption=|size=400px}} | ||

| + | ==Laser Length Measuring== | ||

| + | The bars are roughly premeasured as they are loaded onto the backfence of the infeed table | ||

| + | |||

| + | * This allows the software to precompile the bar length and check if the expected length is loaded | ||

| + | * Improves cycle time on bar loading | ||

| + | * Sensor array is still used to get an accurate and secondary length reading. | ||

| + | |||

| − | |||

| − | |||

| − | =Drive Obsolescence=</translate> | + | |

| + | <br /> | ||

| + | ==Batch Timing and Production Reports== | ||

| + | The software constantly records the performance of the machine and a history is built up of the time taken for each and every operation | ||

| + | |||

| + | * Daily output emails can be configured to report on efficiency and idle time | ||

| + | * Estimated batch and sub batch machining times are displayed to the operator | ||

| + | |||

| + | =Drive Obsolescence= | ||

| + | The drive and controls partner for the ZX5 is Beckhoff. They have proven their reliability and longevity in the market place, and their willingness to support historical products. The ZX5 uses the very latest compact drives with their "OCT" One Cable Technology. Thsi has proved to be a far more relaible system, simply beacus of the reduction in the number of cables, connections and potential points of failure</translate> | ||

{{PageLang | {{PageLang | ||

|Language=en | |Language=en | ||

Version du 26 septembre 2019 à 15:14

This document is intended for existing users and owners of Stuga Flowlines to help explain the improvements and enhancements made to the flowline / ZX3 / ZX4 range of machines into out latest flagship product - the ZX5

A video of the machine in production can be seen here https://vimeo.com/279288374

Mechanical Enhancements

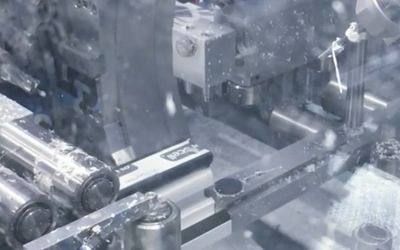

Twin V Notch Heads

Four dedicated, direct drive motors are used to power 4 V notch blades. The arrangement allows a front or rear V notch to be cut in one pass, as opposed to two passes (as on older Stuga machines). This reduces the cycle time of all V notch operations. Y notches are now carried out on the saw side of the machine (see Y Drive)

Tru-loc Gripper System

A dual-tooth fixed gripper design accurately and reliably locates into the profile

- Tapered pins on both sides of machine ensure an accurate and reliable datum

- 2 holes and pins are used to cover all profile types - this eliminates the need for a "G" axis sideways movement on the gripper

- Elininates gripper slip

- Allows a more dynamic acceleration and deceleration on all x axis movements, therefore improving cycle time

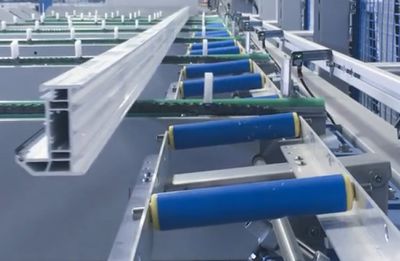

Roller beds

- All profile slideways on both sides of machine consist of roller beds

- Simple and inexpensive to replace if worn

- Profile slides with negligible friction

- No marking of profile on base

- Rollers lift and place profile onto transfer conveyors, reducing both profile marking and possibility of profile "tipping"

- Allows a more dynamic acceleration and deceleration on all x axis movements, therefore improving cycle time

Y Drive for Y notching

Y notching on Stuga flowline has always been a particularly difficult operation to maintain a necessary high accuracy due to many factors,. often outside of the machine's control

- Profile Extrusion Tolerances in profile width

- Profile length expansion in the time between machining and sawing (a 6 metre length expands by 1.2mm with just a 2 degree temperature rise)

- Linearity and accuracy of one side to the other

- Operator care and attention to detail

- Wear / backlash on linear axes

The Y drive system overcomes these issues by producing the entire Y cut in one operation in a similar way to an arrowhead.

- The saw centralising feature, widely recognised as a ideal way to overcome profile width tolerances when cutting arrow heads, now has an "offsetting" axis.

- This allows the saw to cut a square then mitre and vary the position of this to create Y notches of various depths

- Because this is done in one operation, there is no opportunity for a "line up" error between the machining side and the sawing side

- The toothed gripper is very important because allows the bar to be pulled back out of the way when creating the Y notch. This prevents the opposite prep getting created on the following piece on the bar

- The centralising feature means that any profile width inaccuracies are eliminated

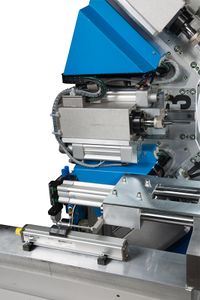

Quad Plunge

The standard setup of the ZX5 comes with two sets of double plunge heads, an upgrade on the ZX4's single plunge heads

- Allows 10mm and 12.5mm tooling to be arranged in opposition for double plunge operations

- Reduces cycle time when both sizes of slot are required for trickle vents

Infeed Loading Wheel

A more reliable and faster loading method has been added which takes the best of the Flowline and ZX4 designs

- Direct drive

- Slipping clutch

- Reliable

- Eliminates profile marking

Software Enhancements

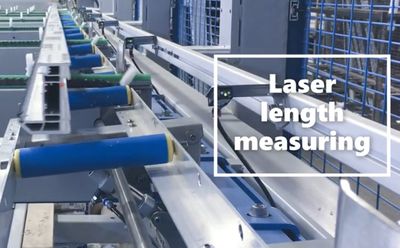

Laser Length Measuring

The bars are roughly premeasured as they are loaded onto the backfence of the infeed table

- This allows the software to precompile the bar length and check if the expected length is loaded

- Improves cycle time on bar loading

- Sensor array is still used to get an accurate and secondary length reading.

Batch Timing and Production Reports

The software constantly records the performance of the machine and a history is built up of the time taken for each and every operation

- Daily output emails can be configured to report on efficiency and idle time

- Estimated batch and sub batch machining times are displayed to the operator

Drive Obsolescence

The drive and controls partner for the ZX5 is Beckhoff. They have proven their reliability and longevity in the market place, and their willingness to support historical products. The ZX5 uses the very latest compact drives with their "OCT" One Cable Technology. Thsi has proved to be a far more relaible system, simply beacus of the reduction in the number of cables, connections and potential points of failure

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português