| [version en cours de rédaction] | [version en cours de rédaction] |

(Annulation des modifications 14468 de Gareth Green (discussion)) (Balise : Annuler) |

|

| (5 révisions intermédiaires par le même utilisateur non affichées) | |

(Aucune différence)

| |

Version actuelle datée du 24 septembre 2024 à 16:03

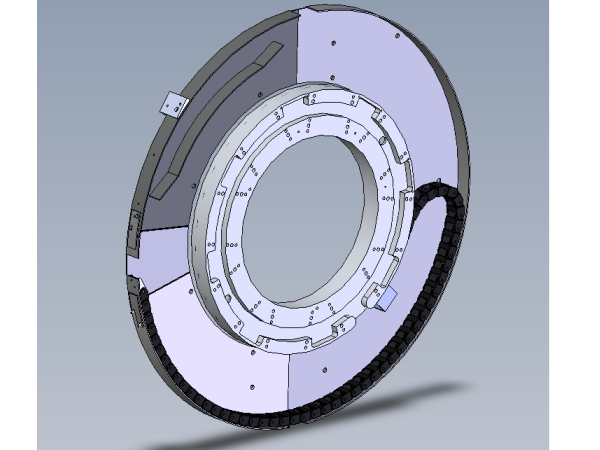

Installation of rotary energy chain and back plates

Sommaire

- 1 Introduction

- 2 Étape 1 - Adhesive

- 3 Étape 2 - Prepare 1st guide Section

- 4 Étape 3 - Fit Energy chain mounting bracket

- 5 Étape 4 - Prepare second section

- 6 Étape 5 - Prepare 3rd section

- 7 Étape 6 - Orientation

- 8 Étape 7 - Fit D0007817

- 9 Étape 8 - Fit D0003930

- 10 Étape 9 - Fit D0003985

- 11 Étape 10 - Fit locking screw to energy chain

- 12 Étape 11 - Modify plug and mount echain bracket

- 13 Étape 12 - Mount bracket

- 14 Étape 13 - Finalise energy chain cables

- 15 Étape 14 - Fit Access panel

- 16 Étape 15 - Add air ring main

- 17 Commentaires

Introduction

Tools Required

Standard set Hex keys

Standard socket set

Countersink bit and drill

Copper/hide hammer

Standard hss drill set

Parts Required

D0006210 pre assembled energy chain

D0003929 Access panel

D0003930 Circular guide

D0003985 Upper circular guard

D0007817 Circular guard

D0001171 plug bracket

P0001023 6mm y adapter x 9

P0000401 non return valveÉtape 1 - Adhesive

All bolts must have Loctite 243 adhesive applied unless otherwise stated.

All bolts must be marked with pen once completed to indicate adhesive and correct tension has been applied

Étape 2 - Prepare 1st guide Section

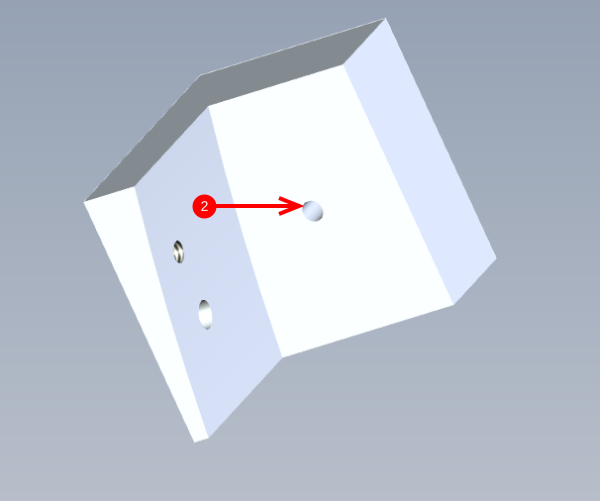

D0003985 needs preparing before fitting

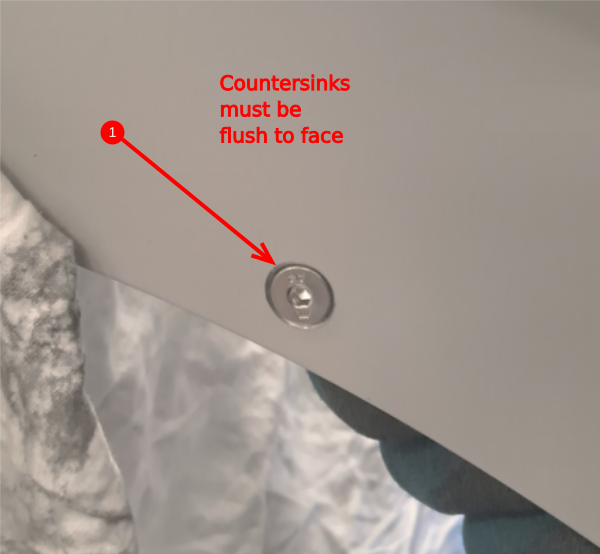

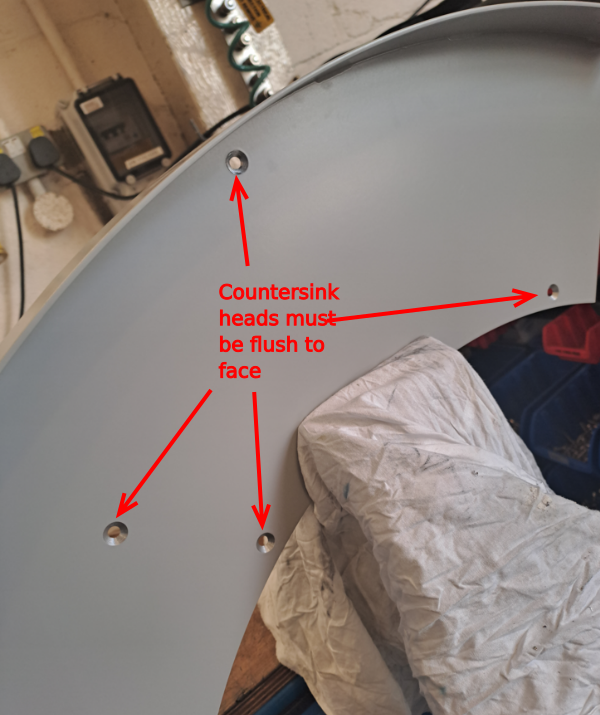

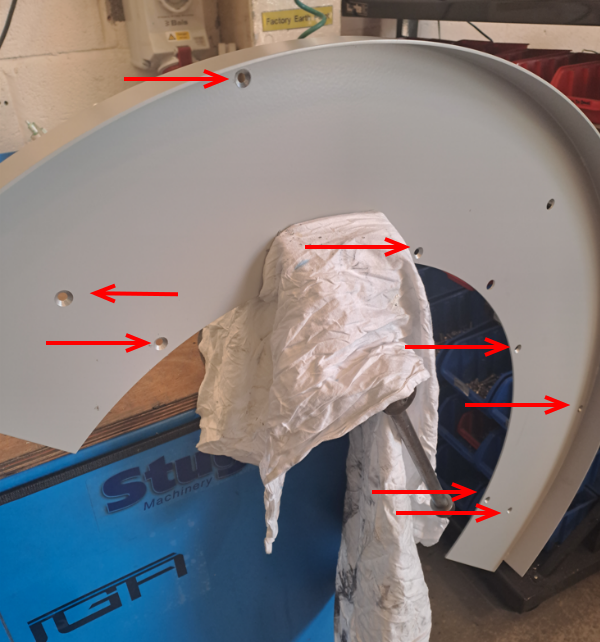

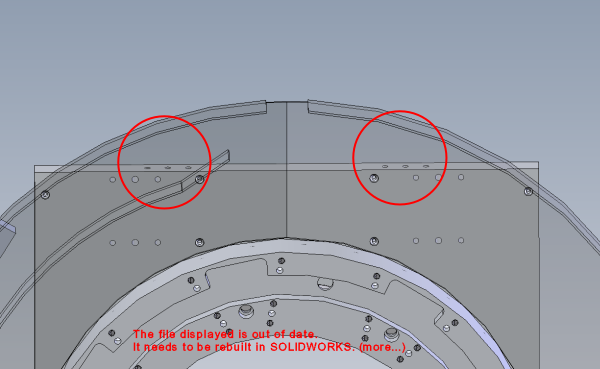

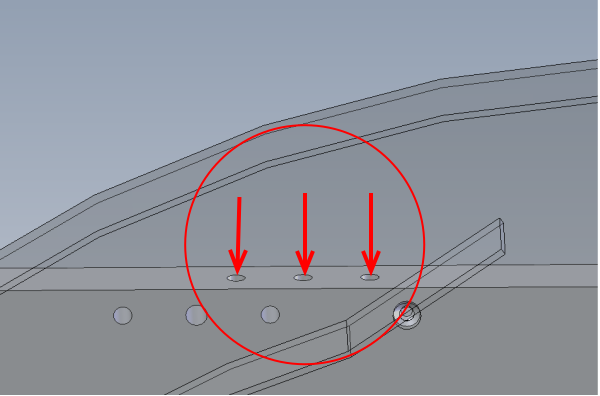

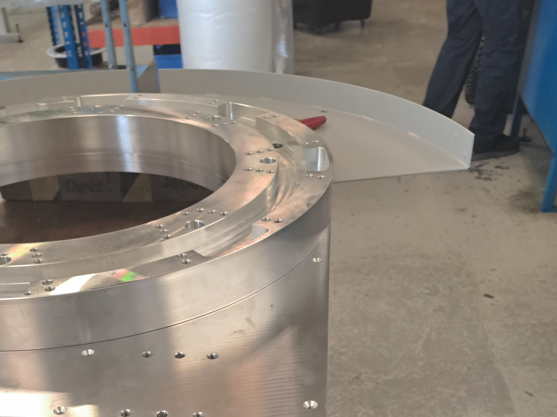

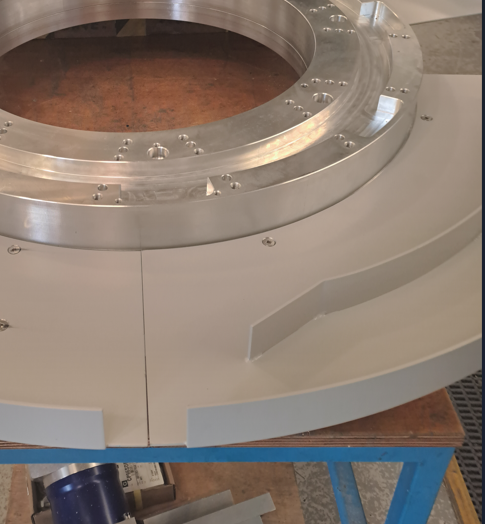

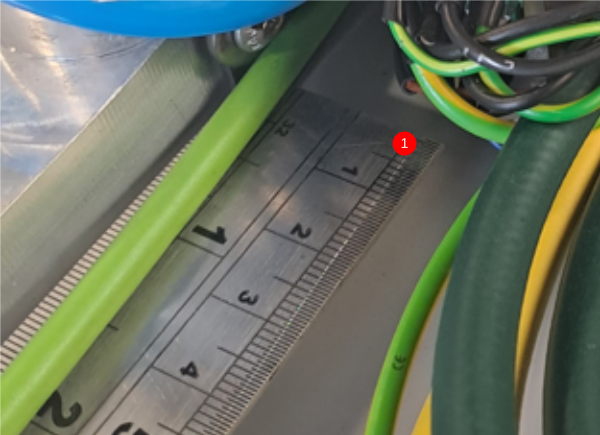

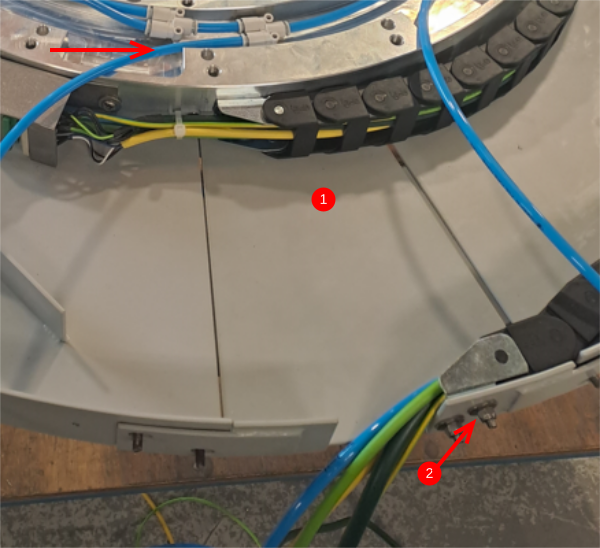

1 All back plates for the rotary trunking need to be checked for correct countersink depth. Any protrusion from main face will case energy chain failure

Check and if proud, use a countersink to increase depth

Étape 3 - Fit Energy chain mounting bracket

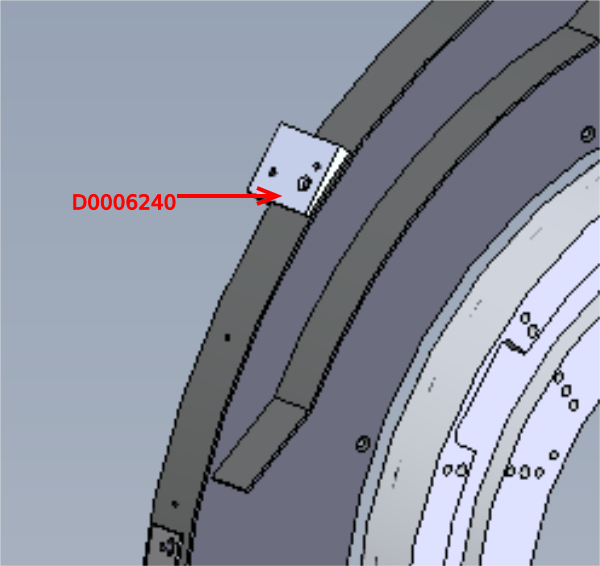

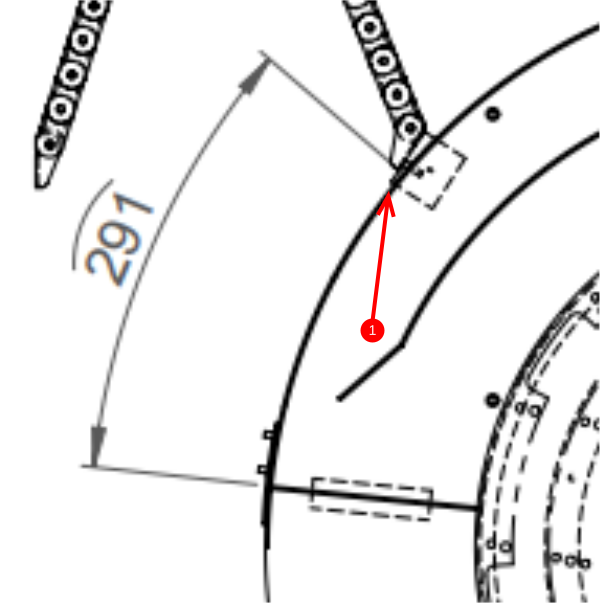

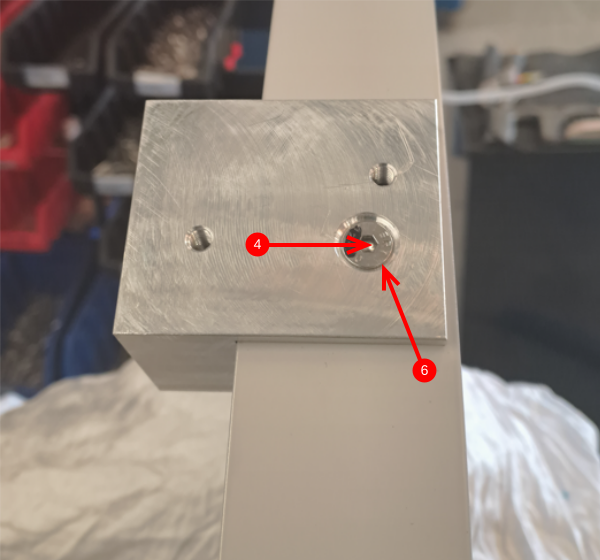

Mounting bracket D0006240 needs fitting to D0003985

1 Measure position of bracket onto circular guard (291mm)

2 Use a pointed m5 grubscrew screwed into bracket hole indicated, hold in position on guard, and use hide hammer to transfer position mark

3 Drill to 6mm and fix bracket with m5x 16 cap head and large m5 washer

4 Drill 6mm through indicated hole

5 Fix with M5 x 16 countersink, large m5 washer and nyloc nut

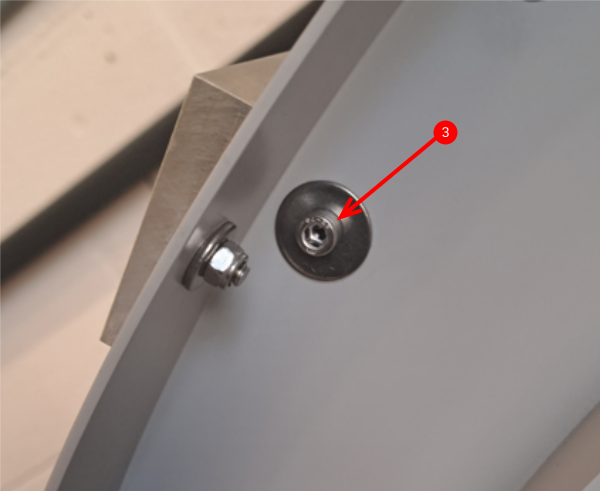

6 This countersink bolt head must be flush to block. If proud, use a countersink bit to increase depth

Étape 4 - Prepare second section

Check countersink holes in D0003930 are to the correct depth . Rework with countersink if fasteners sit proud.

Étape 5 - Prepare 3rd section

Check countersink holes in D0007817 are to the correct depth . Rework with countersink if fasteners sit proud.

Étape 6 - Orientation

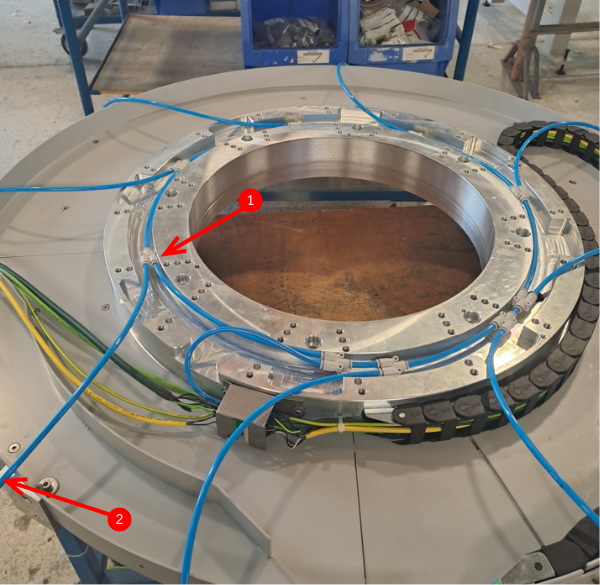

It is vital to achieve correct orientation of above parts

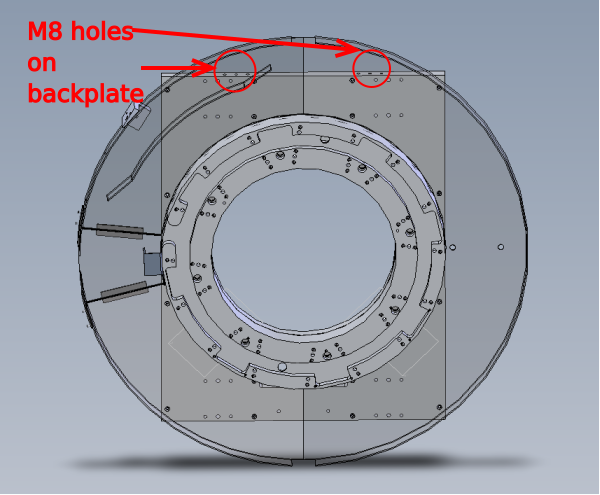

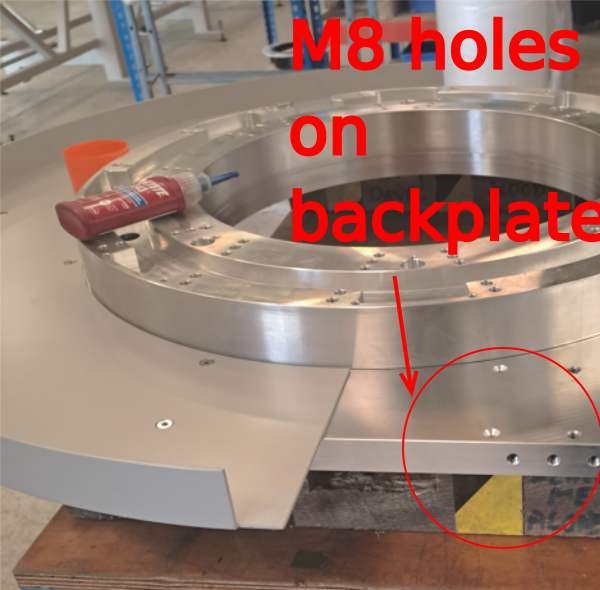

Use M8 holes indicated as reference point for fitting

Étape 10 - Fit locking screw to energy chain

Drill and tap m3 to plugged end ONLY of energy chain assembly

Use m3 x 6 pan head bolt to secure

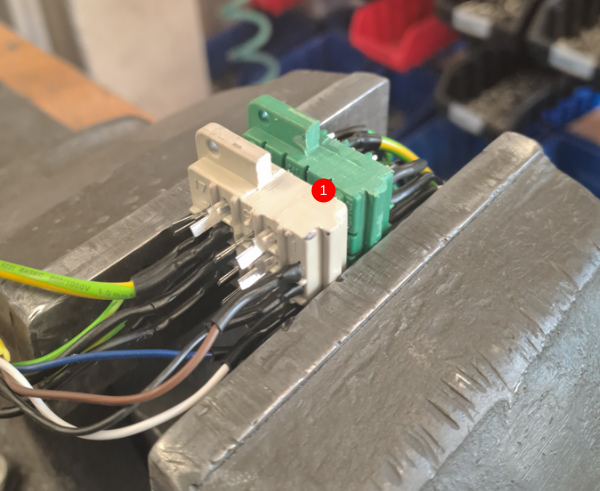

Étape 11 - Modify plug and mount echain bracket

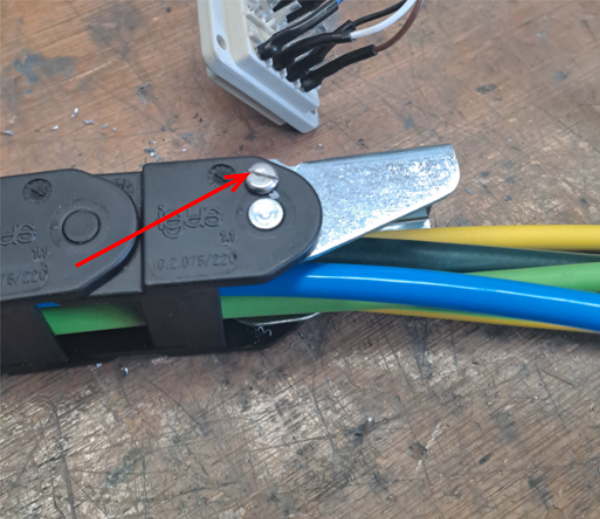

1 Modify plug to allow cable and pipe clearance as shown

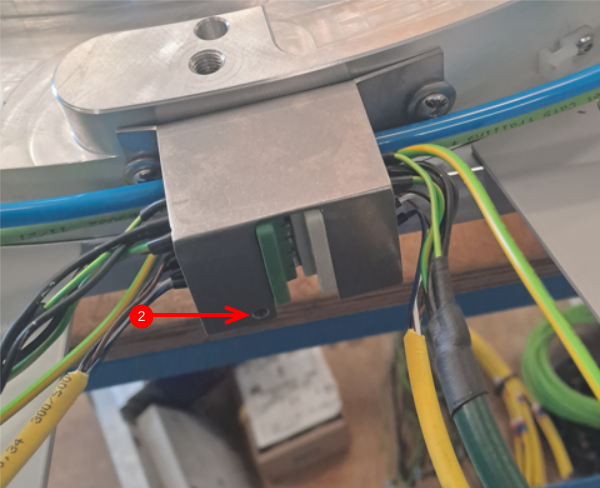

2 Modification is required to give access as indicated

3 Attach chain bracket plug on end of cables at this end, with 2 off m5 x 10 button head and washers

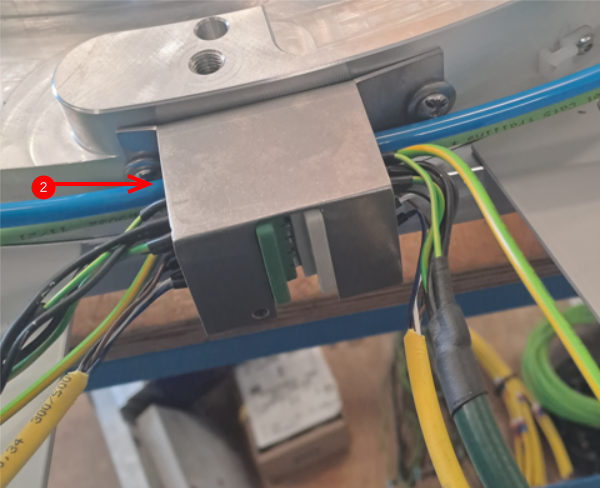

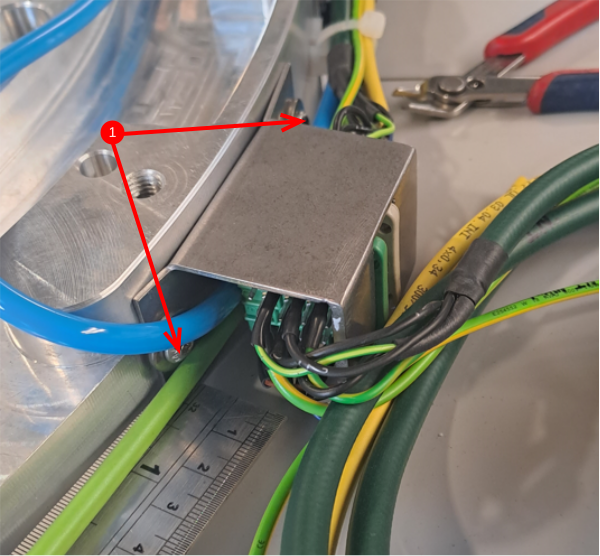

Étape 12 - Mount bracket

1 Mount bracket D0001171 using 2 off m5 x 10button heads and heavy washers

2 Captivate plug with m4 x 12 socket cap

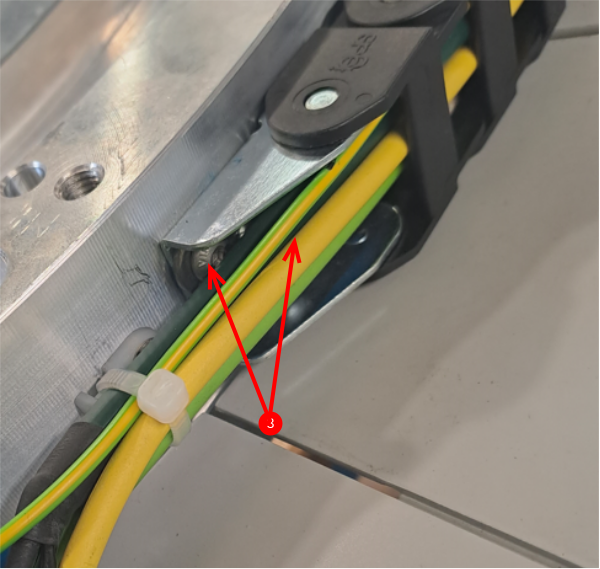

Étape 13 - Finalise energy chain cables

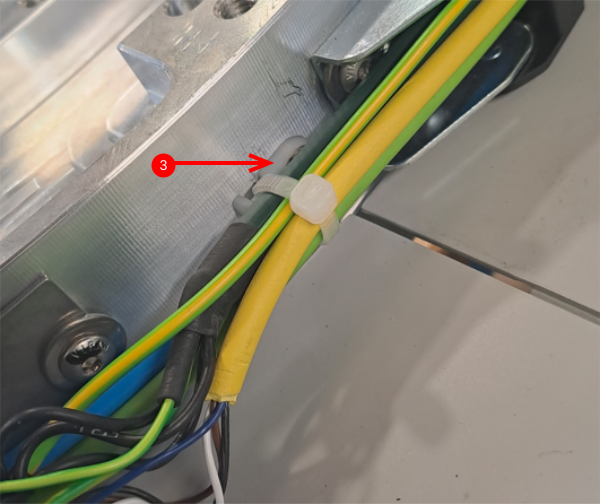

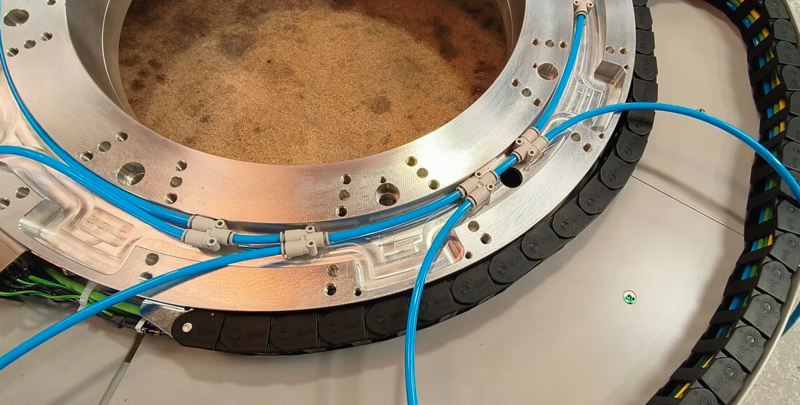

1 ensure 600mm of green ethercat cable is set

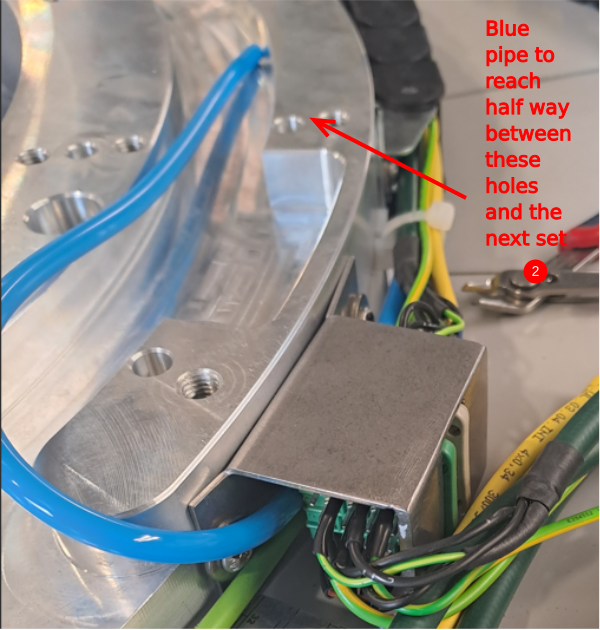

2 ensure 6mm blue pipe is set to position

3 Ensure cable restraint is used once cable and pipe length are set ( M4 may need drilling )

Étape 14 - Fit Access panel

1 slide access panel into position

2 Fix energy chain to panel with m5 x 16 button heads, washers and nyloc nuts

Étape 15 - Add air ring main

1 Connect ring main as shown. Ensure fittings P0001023 are placed in the same locations as shown in picture

2 Cap off 8 off ends of air pipe as shown

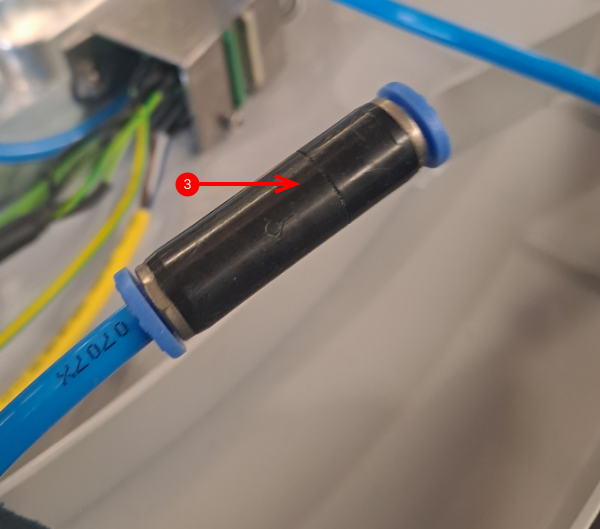

3 Add P0000401 to end of trailing 6mm blue pipe. Note orientation of non return valve

4 Purge system with air to perform pneumatic leak test. Once purged, system should hold pressure for minimum 1 hour

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português