| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 64 : | Ligne 64 : | ||

Pen mark all fasteners to show finalised</translate> | Pen mark all fasteners to show finalised</translate> | ||

|Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png | |Step_Picture_00=R0015086_Assemble_Pneumatics_on_to_electrical_cabinet_loctite_243.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Quality Check</translate> | ||

| + | |Step_Content=<translate>It is vital to check the correct pinion gear has been issued to build | ||

| + | |||

| + | |||

| + | D0001286B-2Mod should be issued | ||

| + | |||

| + | |||

| + | To check this is correct , perform a tooth count on the gear. If correct the gear will have 28 teeth it total | ||

| + | |||

| + | |||

| + | 8mm keyway should be present | ||

| + | |||

| + | |||

| + | Report any dicrepancy through he correct reporting method</translate> | ||

| + | |Step_Picture_00=R0000971E_Bench_Assemble_R_Axis_Gearbox_Screenshot_2024-09-05_143904.png | ||

| + | |Step_Picture_01=R0000971E_Bench_Assemble_R_Axis_Gearbox_Screenshot_2024-09-05_143652.png | ||

| + | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":540,"height":615,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.11,"scaleY":1.11,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/76/R0000971E_Bench_Assemble_R_Axis_Gearbox_Screenshot_2024-09-05_143652.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":314.5,"top":183.5,"width":67,"height":103,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":33.5,"x2":-33.5,"y1":-51.50021630485536,"y2":51.50021630485536,"x2a":-15.888475196768624,"y2a":39.09722496787677,"x2b":-29.300613995576306,"y2b":30.37286064481474},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":348,"top":132,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":281,"top":235,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":348.55,"top":86.78,"width":183.39,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.8,"scaleY":2.8,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"28 teeth in total ","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":472.5,"top":410,"width":9,"height":228,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":4.5,"x2":-4.5,"y1":114.00047881074778,"y2":-114.00047881074778,"x2a":-11.704918613350213,"y2a":-93.70049980152218,"x2b":4.2826306656606,"y2b":-94.33158462244633},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":477,"top":524,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":468,"top":296,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":475.08,"top":596.16,"width":159.96,"height":48.82,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.88,"scaleY":1.88,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"Single 8mm keywahay man","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":683,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 5 septembre 2024 à 14:41

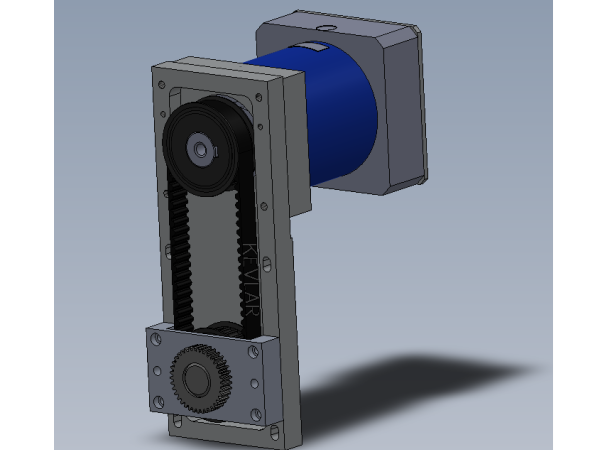

Assembly instructions for R axis gearbox

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Quality Check

- 4 Étape 3 - Assemble drive spigot

- 5 Étape 4 - fit key and pulley

- 6 Étape 5 - Attach to gearbox plate

- 7 Étape 6 - Gear box bung supplied with gearbox C0001211

- 8 Étape 7 - Check pulley fitment

- 9 Étape 8 - Fit Servo gearbox cap

- 10 Étape 9 - Couple and align gearbox and pinion assembly

- 11 Étape 10 - Align pulleys

- 12 Étape 11 - Remove pulley assembly

- 13 Étape 12 - Tension belt

- 14 Étape 13 - finalise position

- 15 Étape 14 - Quality check

- 16 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Tensioning jig

Standard HSS drill set

300mm rule

Parts Required

B0000062 Circlip 20mm External x 2

B0000092 Belt: Toothed 640-8MGT 20 (R Axis) (KEVLAR) x 1

B0000095 Bearing NR6004 2RS with snap ring (NSK) x 2

C0001211 Gearbox NP035s 5:1 x 1

D0000268 Rotary Drive Tooth Pulley x 1

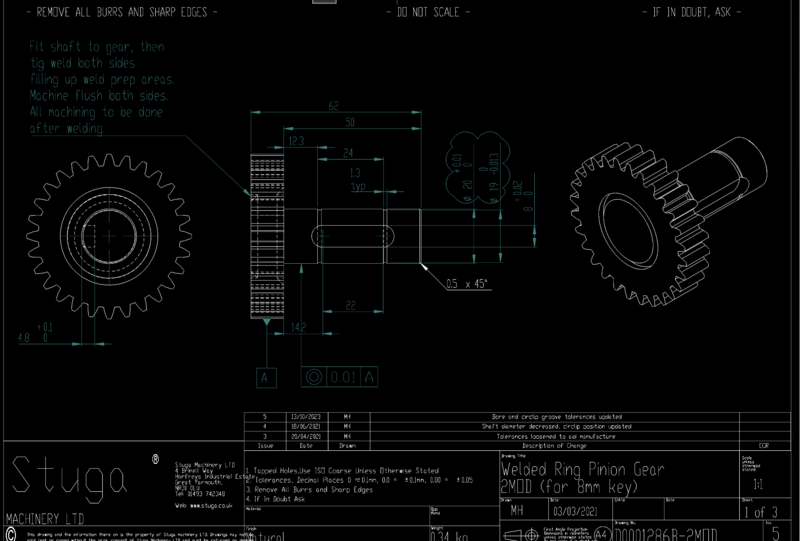

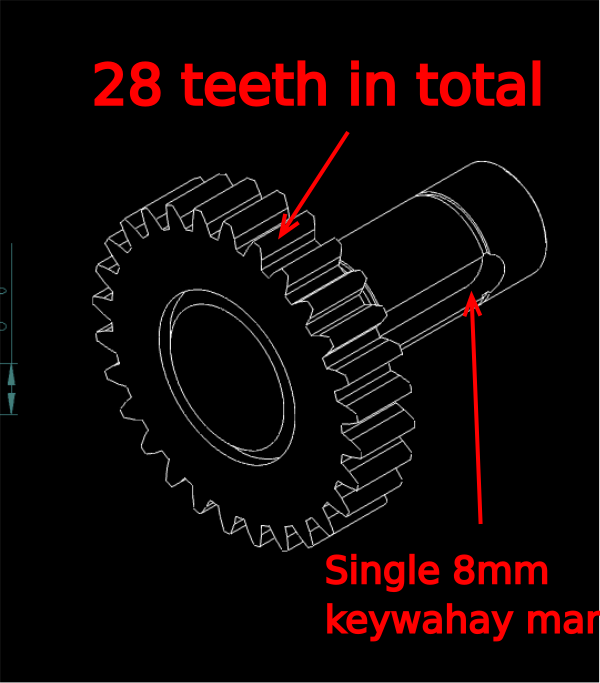

D0001286B-2MOD Welded Ring Pinion Gear 2MOD (for 8mm key) x 1

D0006058 Gearbox Plate x 1

D0006060 Spigot Cap x 1

D0007849 Servo gearbox cap x 1

D0008585B Rotary Ring Drive Pulley (for 8mm key) x 1

D0015801 Feather Key 8mm x 8mm x 22mm x 1

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

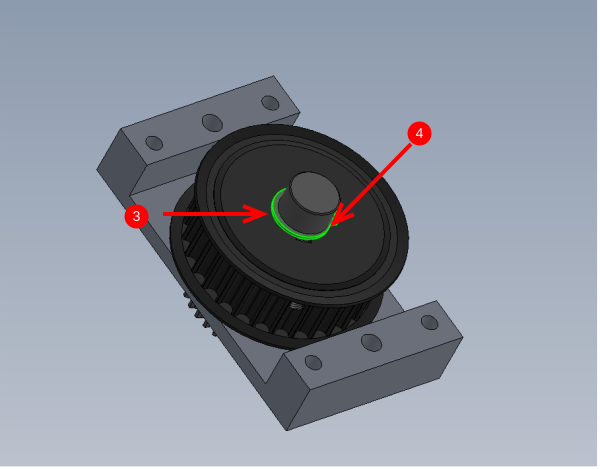

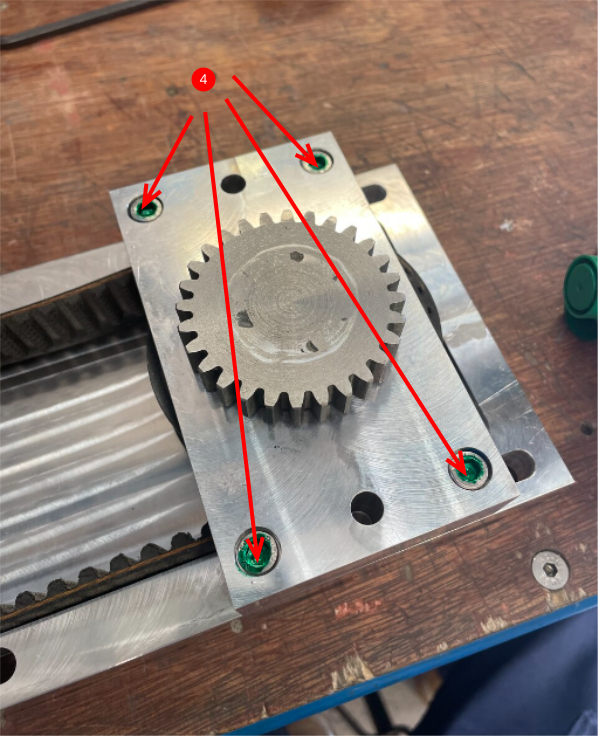

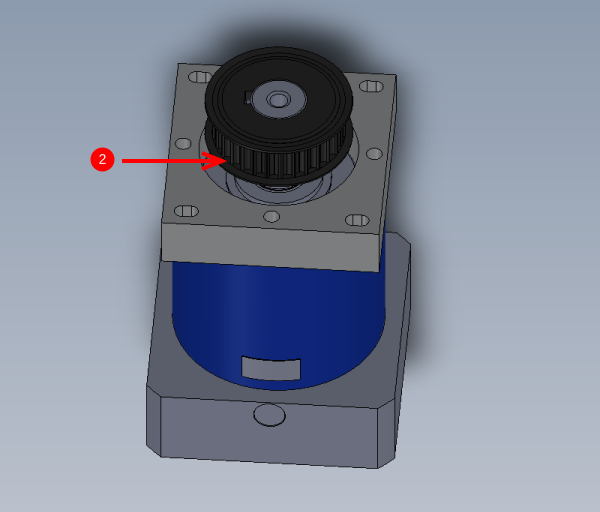

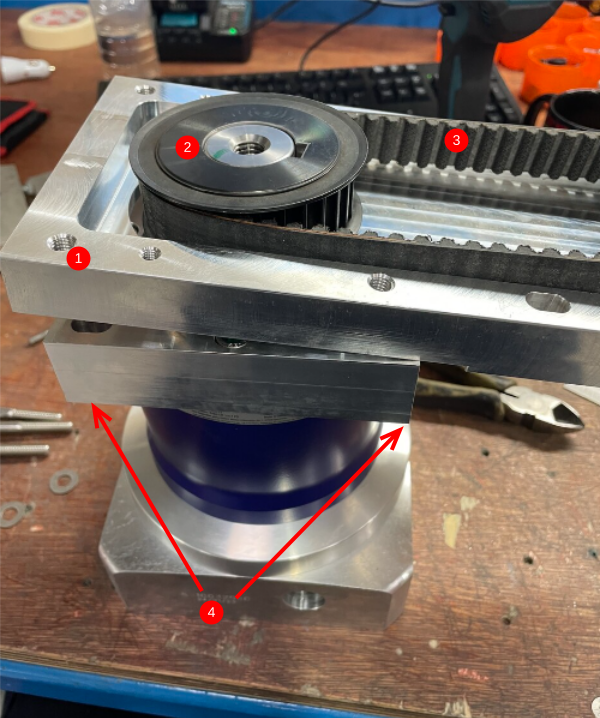

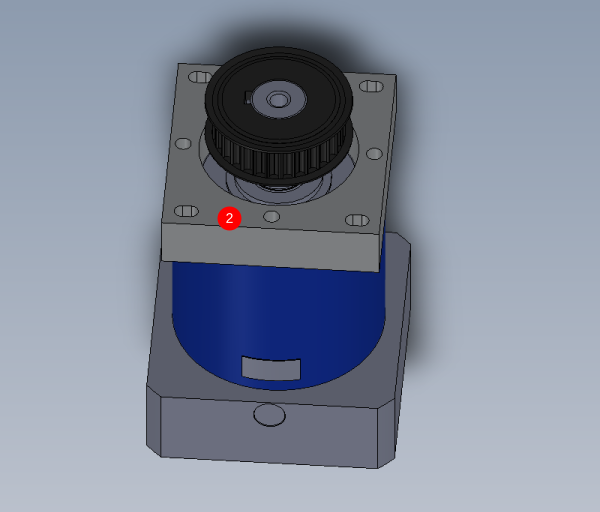

Étape 2 - Quality Check

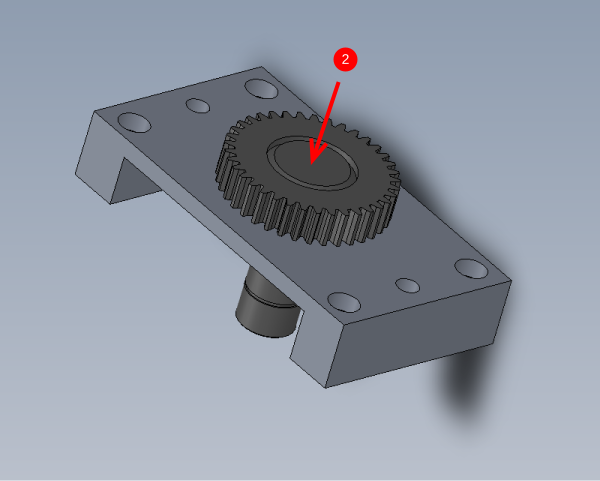

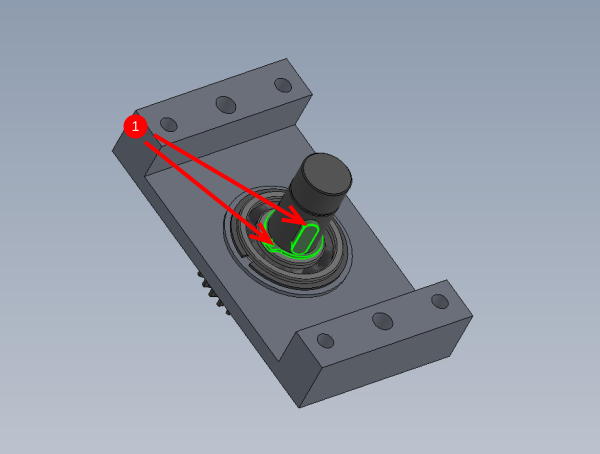

It is vital to check the correct pinion gear has been issued to build

D0001286B-2Mod should be issued

To check this is correct , perform a tooth count on the gear. If correct the gear will have 28 teeth it total

8mm keyway should be present

Report any dicrepancy through he correct reporting method

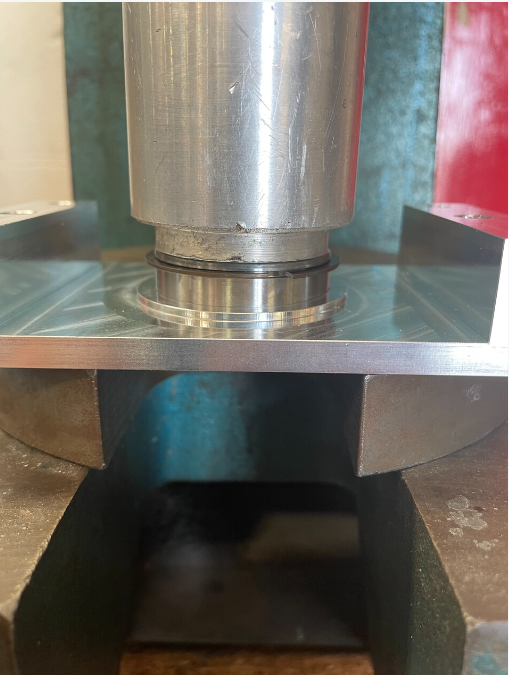

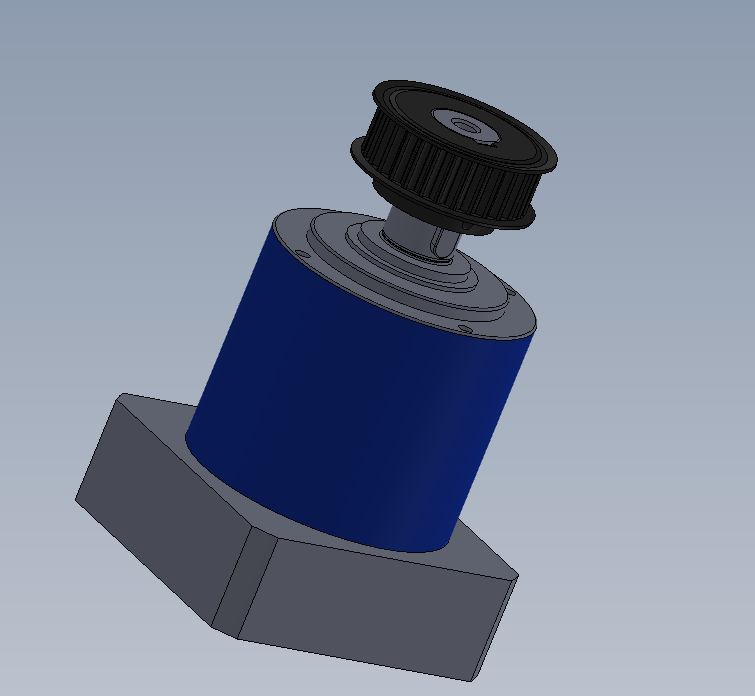

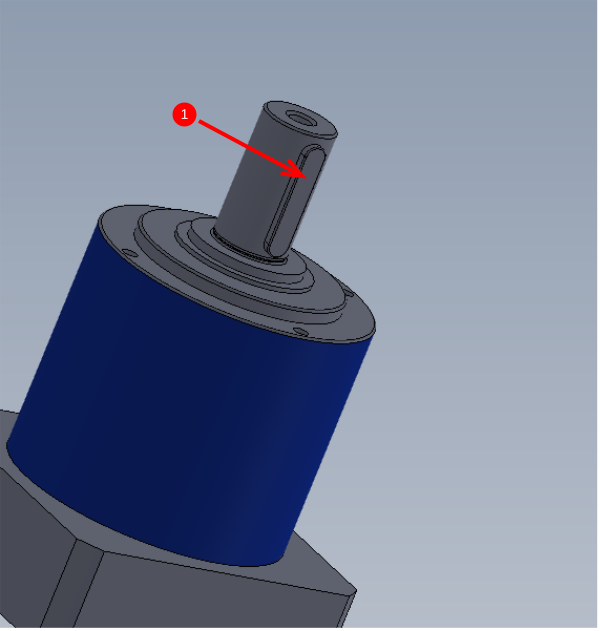

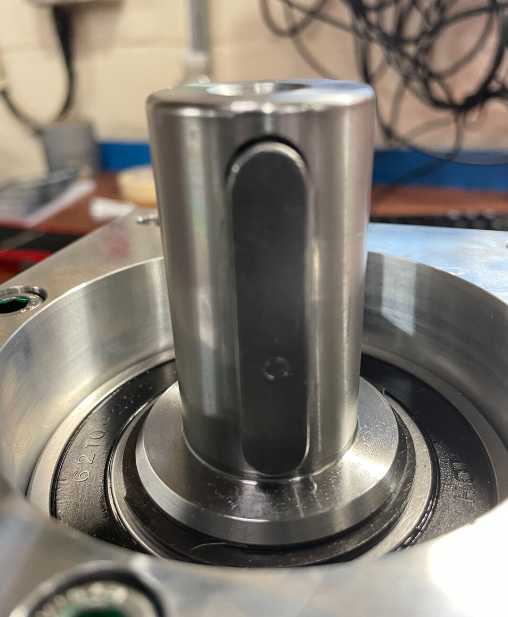

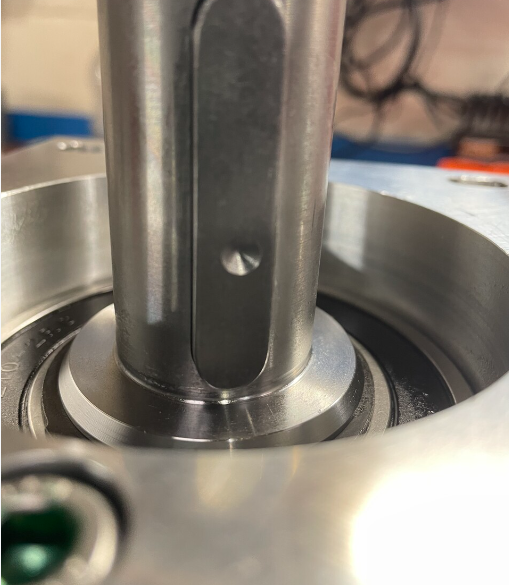

Étape 3 - Assemble drive spigot

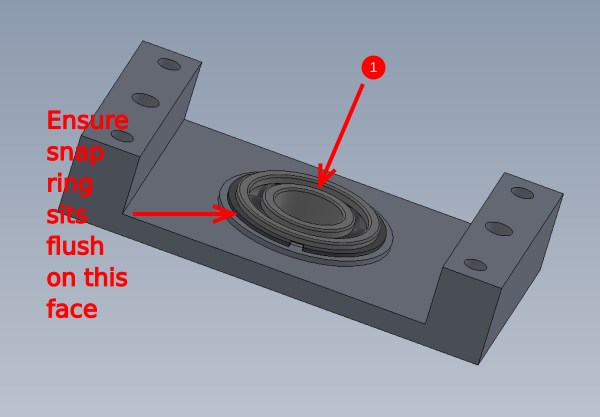

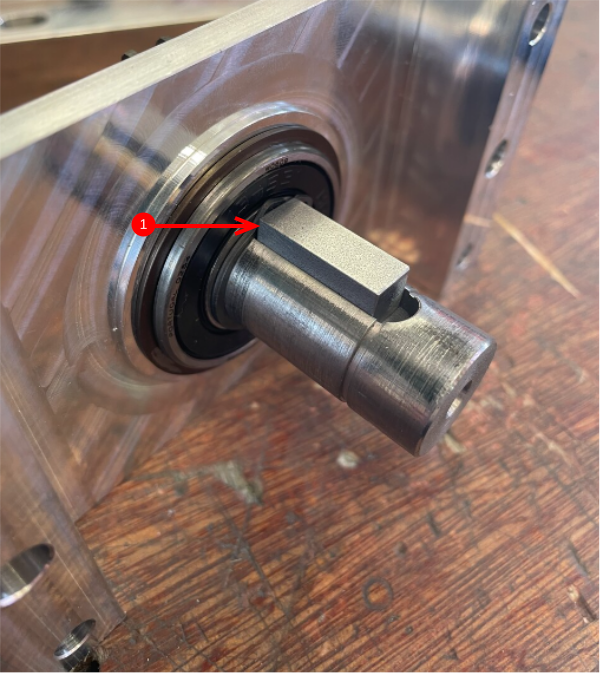

1 Press B0000095 Bearing into D0006060 Spigot Cap so snap ring sits flush

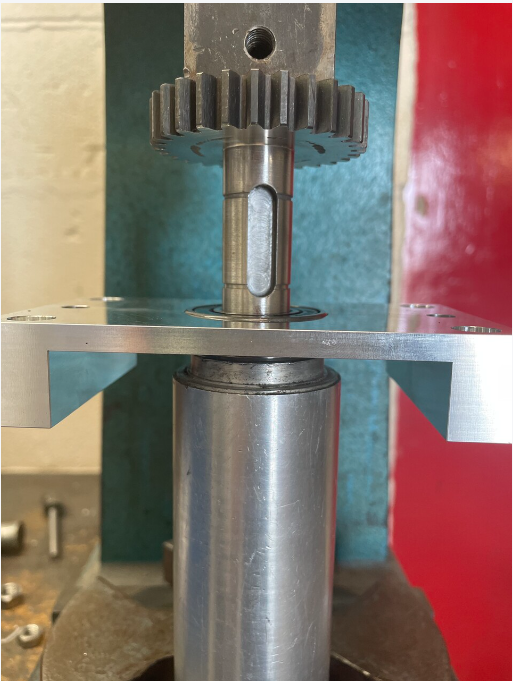

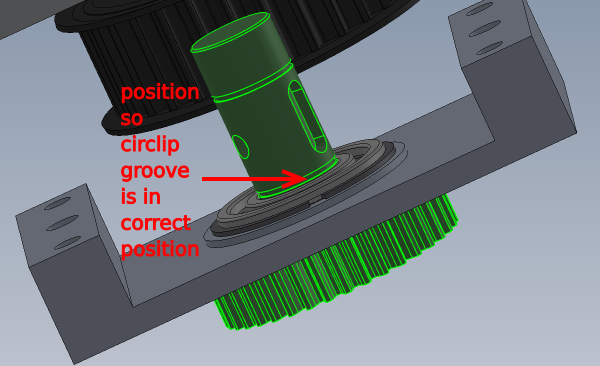

2 Fit D0001286B-2MOD Welded Ring Pinion Gear 2MOD as shown Use jig to ensure bearing is not moved from location. Push through until circlip groove is in correct place

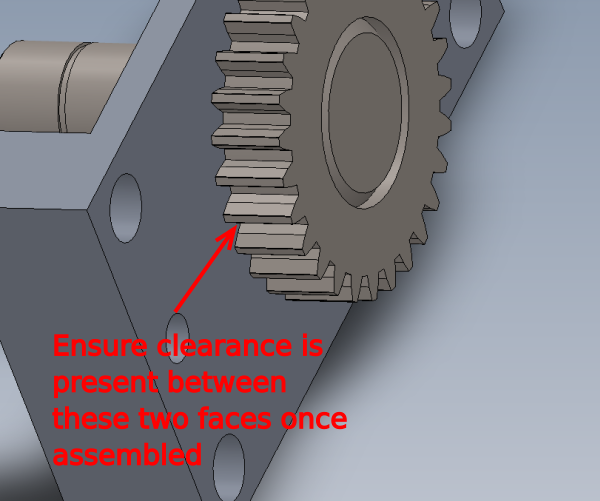

Check to ensure drive pinion does not contact bearing face as shown

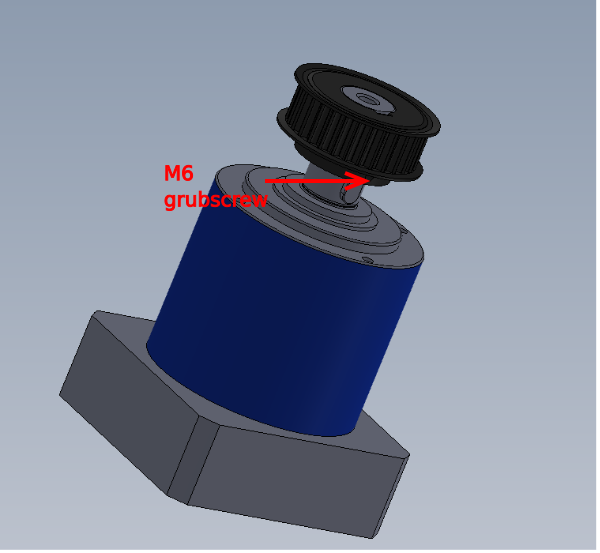

Étape 4 - fit key and pulley

1 Fit Circlip 20mm and D0015801 Feather Key 8mm x 8mm x 22mm as shown

2 Fit D0008585B Rotary Ring Drive Pulley as shown . Only press down until circlip groove is present

3 Fit 20mm external circlip

4 Tighten Grubscrew with pulley pulled against circlip

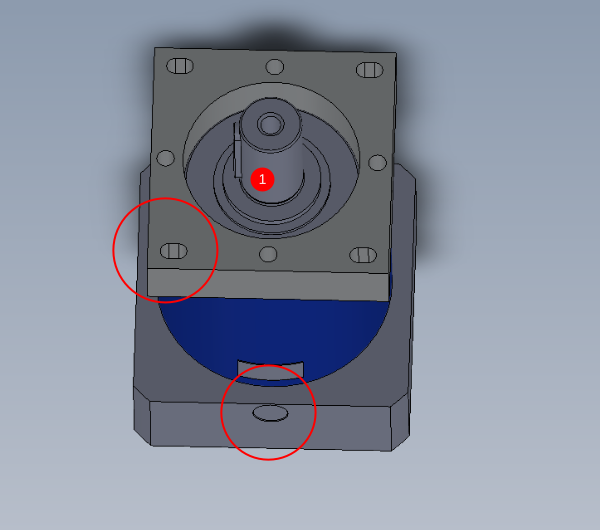

Étape 5 - Attach to gearbox plate

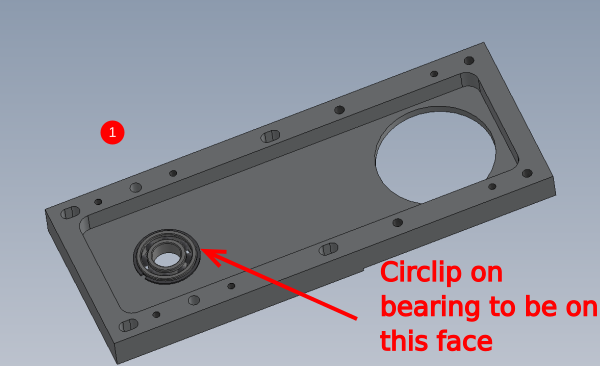

1 Fit B0000095 bearing to D0006058 plate as shown . Note circlip on bearing to be on indicated face

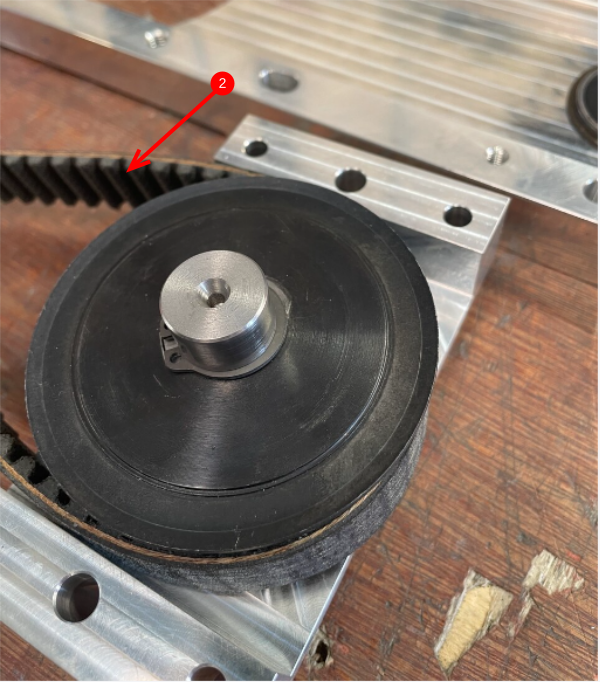

2 Attach B0000092 Belt: Toothed 640-8MGT 20 as shown

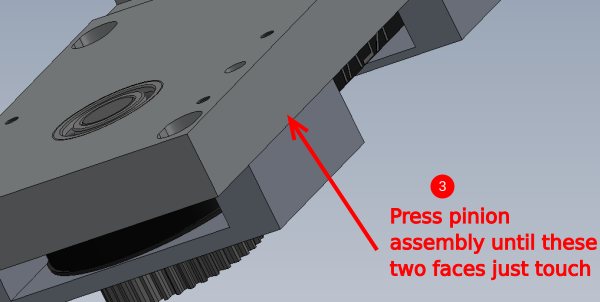

3 Press pinion assembly onto gearbox plate

4 Secure lightly with 4 off M6 x 35 socket caps

5 Add 2 off 8mm x 50mm dowels into indicated holes . Ream if holes are tight

6 Finalise 4 off M6 socket caps

Étape 6 - Gear box bung supplied with gearbox C0001211

Étape 7 - Check pulley fitment

Check D0000268 Rotary Drive Tooth Pulley fits onto C0001211 Gearbox

If pulley fits move to step 6, if it does not fit follow these steps

1 Remove key from gearbox shaft

2 Test pulley again for fitment.

- If the pulley still does not fit, polish inner face of pulley until fitment is achieved

- if the pulley does fit when the key is removed , move to next step

3 Refit key

4 Test pulley , if the pulley still doesn't fit correctly dress keyway slot gently until fit is achieved

Étape 8 - Fit Servo gearbox cap

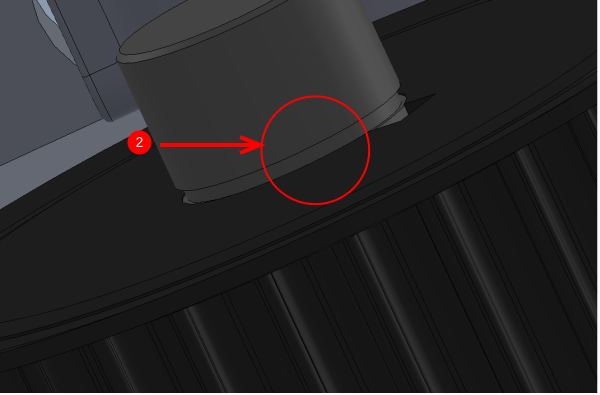

1 Fit D0007849 Servo gearbox cap as shown. No adhesive on the 4 off M8 x 35 socket caps

Orientate as shown

2 Fit D0000268 pulley

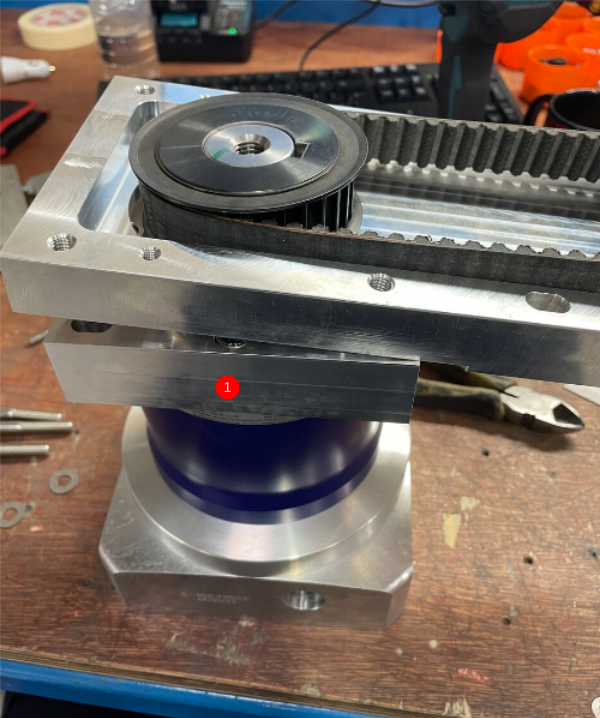

Étape 9 - Couple and align gearbox and pinion assembly

Insert part1 through part 2

Hook over belt (3)

insert 4 off m8 x 50 with a form washers a pull to face lightly

Étape 11 - Remove pulley assembly

Reverse steps to remove assembly 1

Remove part 2

Tighten grubscrew to leave witness mark , Remove pulley and drill 5mm dimple at indicated point

Use M6 x 10 kcp grubscrew to lock pulley in final position

Rebuild parts to get to 3

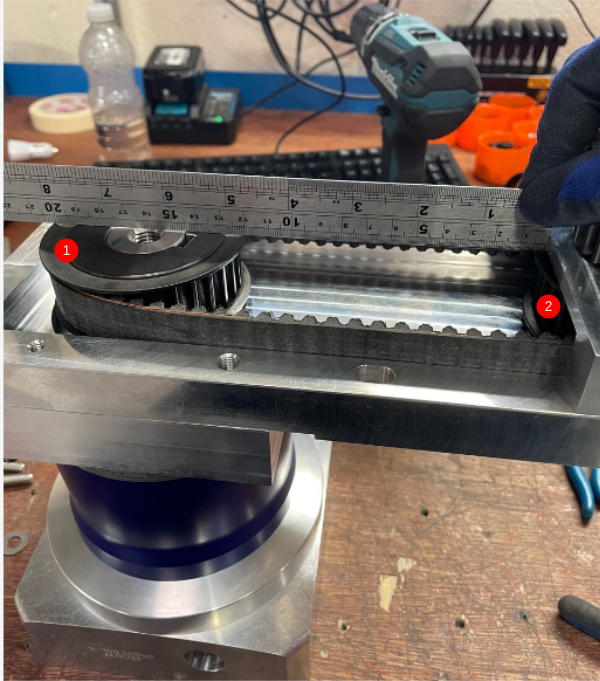

Étape 12 - Tension belt

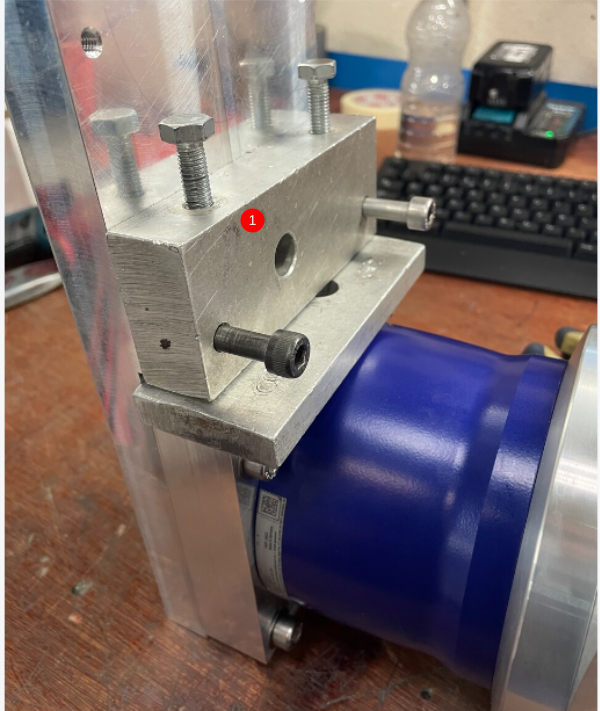

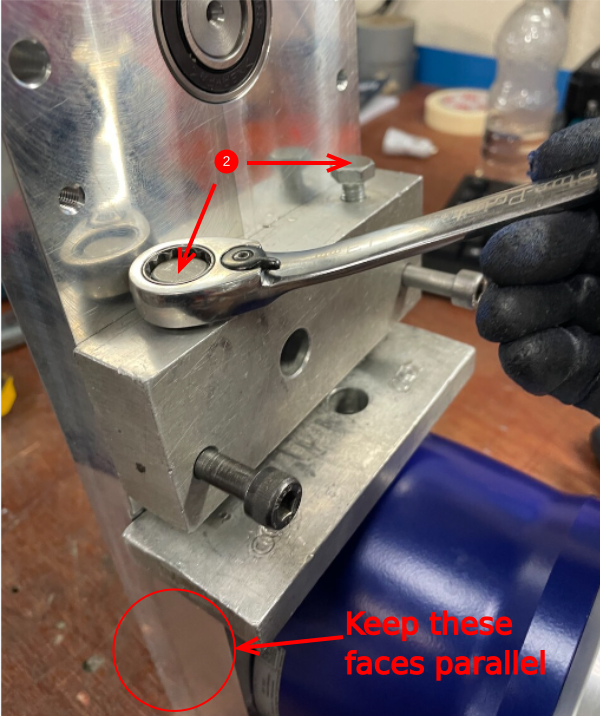

1 Attach tensioning jig as shown

2 Apply tension to belt , spreading tension over two bolts indicated . Maintain parallel on these faces as adjusting

Set belt tension to 5mm deflection (Drum Tight )

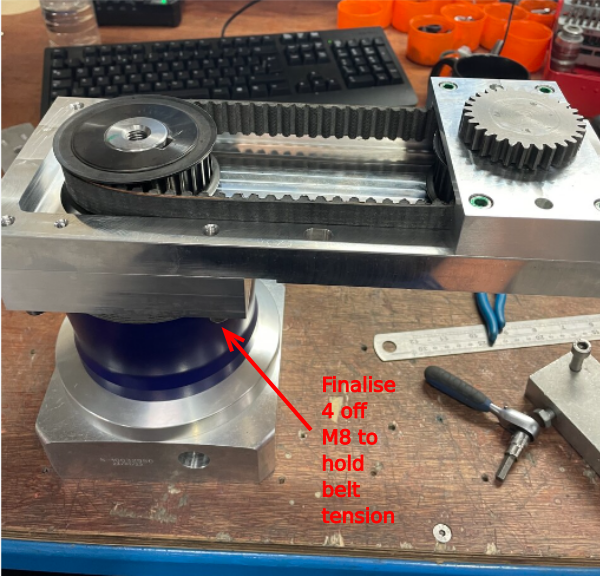

Étape 13 - finalise position

finalise 4 off m8 socket caps to hold tension

Remove setting jig plates

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português