| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 213 : | Ligne 213 : | ||

Use 2 off M8 60 socket caps with M8 motor plate washers to fix</translate> | Use 2 off M8 60 socket caps with M8 motor plate washers to fix</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_Part_2_2024-07-08_09-51-07.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit hard stop</translate> | ||

| + | |Step_Content=<translate>Refit D0007838 hardstop</translate> | ||

| + | |Step_Picture_00=R0000299_Stroke_assembly_rebuild_Part_2_2024-07-08_09-56-40.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit front flange</translate> | ||

| + | |Step_Content=<translate>Fit front flange</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 8 juillet 2024 à 10:00

Instructions for correct assembly and setting of stroke assembly gearboxes Original part numbers R0000728 and R0000729

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Check components and fit

- 4 Étape 3 - Mount spindle assembly

- 5 Étape 4 - Check backlash

- 6 Étape 5 - Adjusting backlash

- 7 Étape 6 - Adjust Backlash

- 8 Étape 7 - Finalise spindle assembly

- 9 Étape 8 - Degrease mating faces and prepare

- 10 Étape 9 - Final assemble

- 11 Étape 10 - Quality Check

- 12 Étape 11 - Fit Shafts

- 13 Étape 12 - Fit damper bridge

- 14 Étape 13 - Fit hard stop

- 15 Étape 14 - Fit front flange

- 16 Commentaires

Introduction

The following instructions should be followed to ensure that correct assembly and setting are performed

Tools / consumables Required

Standard hex key set

Standard spanner set

Large adjustable spanner

Drifts and punches

Ballpein hammer

Soft hammer

FE10 Solvent

Hylomar Gasket

Parts Required

Kit R0000299 containing

B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2

B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1

B0000335 3ph Brake motor 2 pole 3000rpm x 1

B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2

D0000059 Damper Bridge x 1

D0000062 Damper Bridge Boss x 2

D0007730 ZX4 V Notch Mk1 Spindle Shaft x1

D0007867 Bevel Gear (Left) x 1

D0007868 Bevel Gear (Right ) x 1

D0007873 Motor Gear x 1

D0007874 Pinion Gear x 1

D0007875 Pinion Shaft x 1Étape 1 - Unless otherwise stated

Always use Loctite 243 on all fasteners fitted unless stated different

All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required

All fasteners should be marked once finalised

Étape 2 - Check components and fit

Ensure that keyway B0000041 passes through bevel gear D0007867.

Fit key to shaft

Fit Pinion gear to shaft

Secure with M5x16 socket cap and D0007721 washer. Do not use adhesive at this point . Do not fit shims at this point

Étape 3 - Mount spindle assembly

Position spindle assembly to main gearbox body as shown.

Rotate spindle as shown to expose counterbored holes used for fixing

Fit 2 off M6x 30 socket caps and tension . Do not apply adhesive at this point

Étape 4 - Check backlash

Check backlash present by the following steps

1 Insert 4mm key into fastener shown and use to stop rotation of vertical shaft

2 Rock spindle clockwise and anti clockwise to gauge backlash present

Ideal backlash is 1mm movement in rotation of spindle (2)

Étape 5 - Adjusting backlash

Backlash can only be reduced, not increased. If no backlash is present when assembled with no shims, inform supervisor for correct route of action

To adjust backlash, shims can be used behind the bevel gear to move it closer to second bevel gear

As a general rule of thumb, the shims removed on stripdown of refurbished unit will be correct for rebuild. Work on this assumption but check when fitted that backlash setting is acceptable

Étape 6 - Adjust Backlash

1 Remove Bevel gear and key from assembly

2 Identify original shims fitted to gearbox

3 Fit shims to shaft

4 Refit bevel gear and parts to spindle

5 Refit assemble to main gearbox body and recheck backlash (step 4 )

6 Repeat 1-5 and Add additional shims if backlash is still to much

Étape 7 - Finalise spindle assembly

Once backlash has been set, spindle assembly must be finalised

Ensure all threads are degreased with FE10 solvent

Usel Loctite 243 on M5x 16 socket cap

Tension adequately , holding spindle as shown

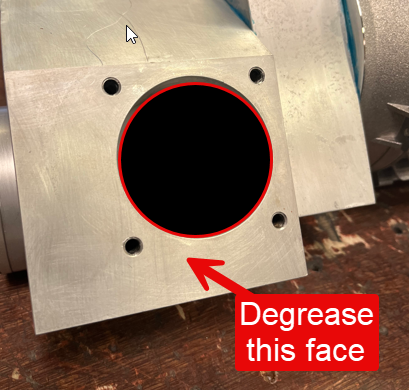

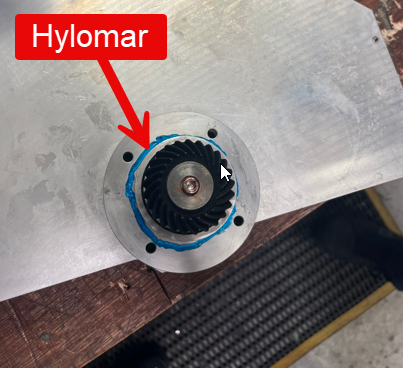

Étape 8 - Degrease mating faces and prepare

Indicated faces should be degreased with FE10 solvent

Apply Hylomar as shown

Add remainder of M0000603 grease as shown

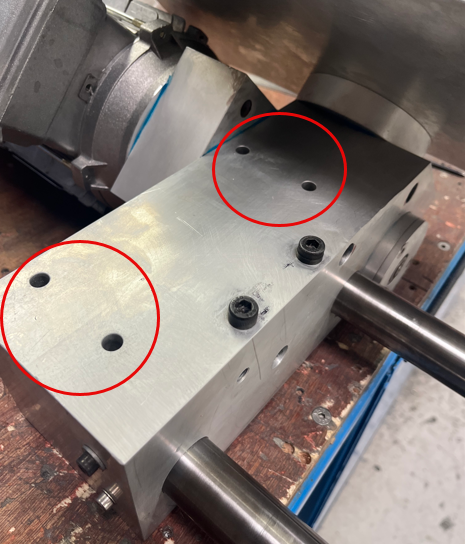

Étape 9 - Final assemble

Final fit spindle housing to main gearbox body

Use 4 off M6 x 30 socket caps with Loctite 243

Rotate spindle as shown to allow access to all fixing points

Smooth any excess hylomar with a clean rag

Étape 10 - Quality Check

Double check rotation is smooth and backlash is still correct after final fixings

Motor fitted is a braked variant, so rotation will have resistance, But should be smooth and consistent when rotated as shown

Report any discrepancies to supervisor

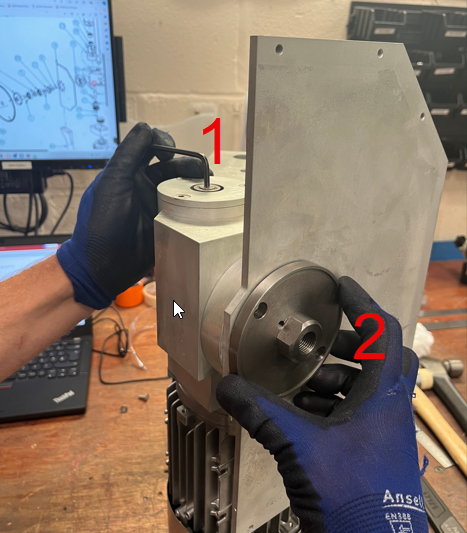

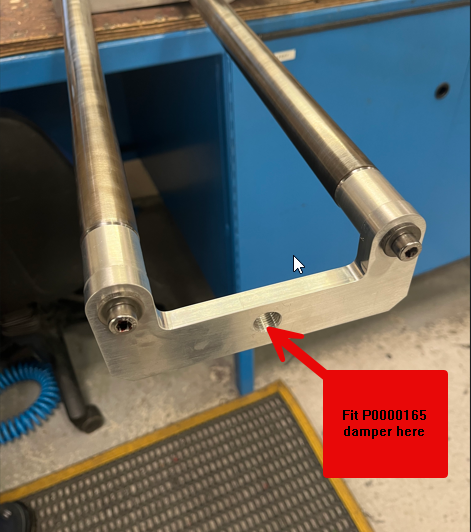

Étape 12 - Fit damper bridge

Fit damper bridge D000000059, Spacers D0000062 and damper P0000165 as shown

Use 2 off M8 60 socket caps with M8 motor plate washers to fix

Étape 14 - Fit front flange

Fit front flange

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português