| [version en cours de rédaction] | [version en cours de rédaction] |

| (2 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 15 : | Ligne 15 : | ||

| − | <u>'''Tools | + | <u>'''Tools Required'''</u> |

| Ligne 31 : | Ligne 31 : | ||

Degreasing bath | Degreasing bath | ||

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Ligne 78 : | Ligne 38 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Disassembly</translate> | |Step_Title=<translate>Disassembly</translate> | ||

Version actuelle datée du 4 juin 2024 à 11:15

Instructions for refurbishment of R0000728 and R0000729 stroke assemblies using Kit R0000299

Sommaire

- 1 Introduction

- 2 Étape 1 - Disassembly

- 3 Étape 2 - Remove blade Guard

- 4 Étape 3 - Remove Blade

- 5 Étape 4 - Remove damper bridge

- 6 Étape 5 - Disconnect front blade assembly

- 7 Étape 6 - Extract front blade assembly

- 8 Étape 7 - Extract 2 off shafts

- 9 Étape 8 - Remove hard stop

- 10 Étape 9 - Remove motor assembly

- 11 Étape 10 - Remove Pinion bolt and shaft bolt

- 12 Étape 11 - Remove drive pinion

- 13 Étape 12 - Remove drive shaft

- 14 Étape 13 - Extract shaft from bearing housing

- 15 Étape 14 - Remove keys from shaft

- 16 Étape 15 - Disconnect bevel gear

- 17 Étape 16 - Remove bevel gear

- 18 Étape 17 - Use press to remove blade flange

- 19 Étape 18 - Remove bearing from housing

- 20 Étape 19 - Remove bearing housing

- 21 Étape 20 - Remove motor pinion housing

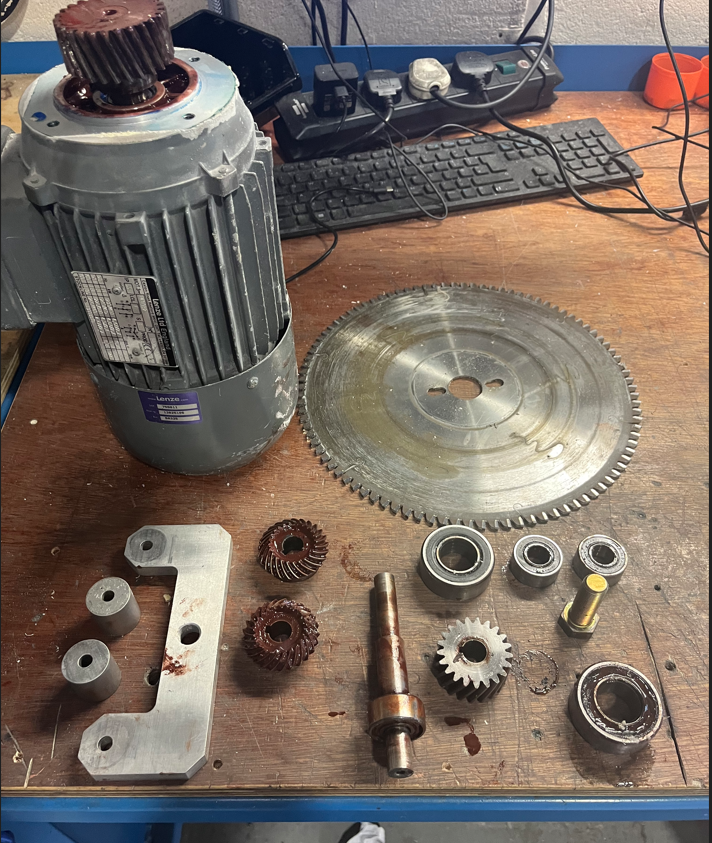

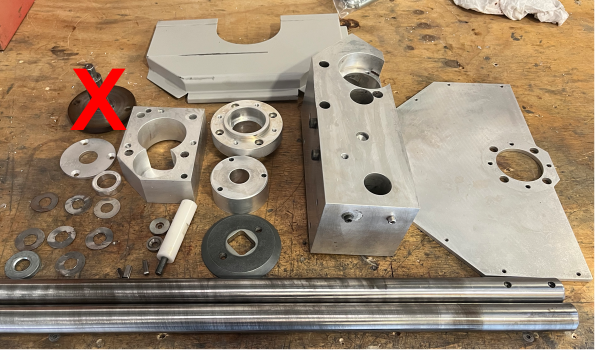

- 22 Étape 21 - Disposed parts not required

- 23 Étape 22 - Clean and degrease

- 24 Commentaires

Introduction

Assemblies fitted to MK1 ZX4 will require refurbishment at some point of life cycle.

The following instructions should be followed to ensure that correct assembly and setting are performed

Tools Required

Standard hex key set

Standard spanner set

Double pin saw flange spanner

Drifts and punches

Ballpein hammer

Soft hammer

Degreasing bath

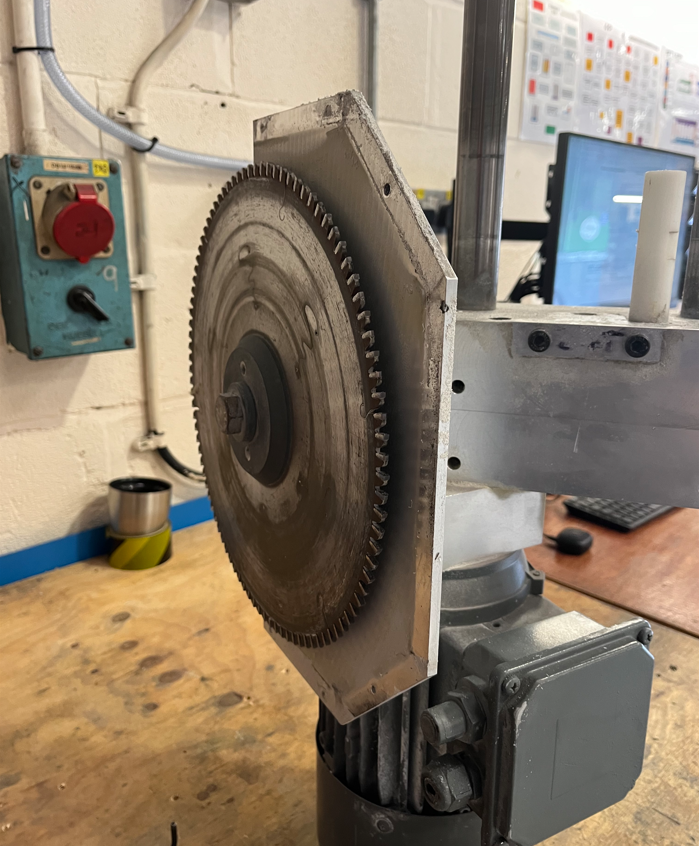

Étape 1 - Disassembly

The stroke assembly must be dismantled in the exact manner stated as many sections can only be removed once mating parts have been extracted

Please use the following steps accurately

Étape 2 - Remove blade Guard

Remove M5 socket cap and washer and slide off blade guard

Blade guard to be reused

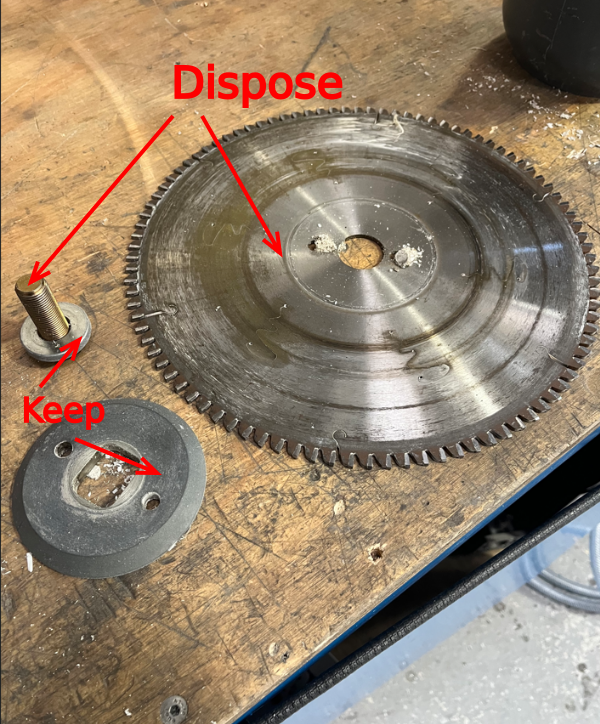

Étape 3 - Remove Blade

use 24mm ring spanner and saw blade pin spanner to remove blade from assembly

Dispose of saw blade and M16 bolt

Keep M16 Washer and blade flange for rebuid

Étape 4 - Remove damper bridge

Remove 2 off m8 fasteners to remove damper bridge and pillars

Dispose of all parts

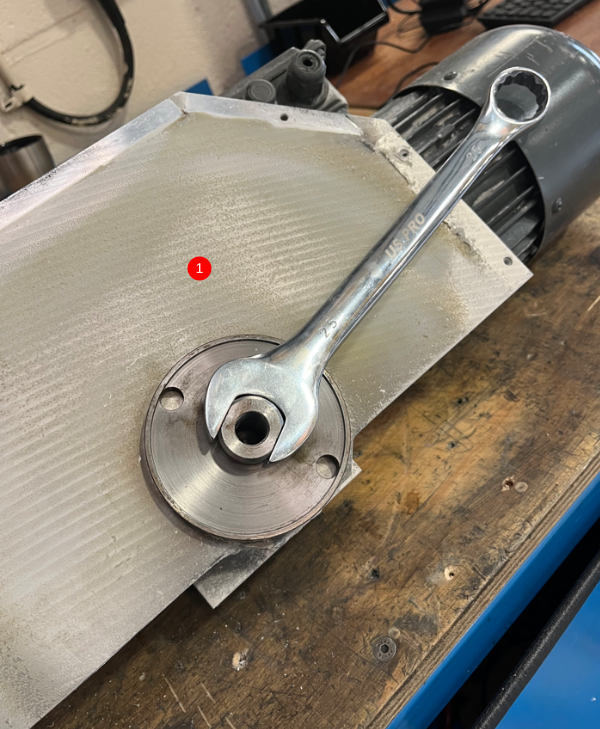

Étape 5 - Disconnect front blade assembly

1 Rotate blade flange with a 25mm spanner to align 2 off M6 cap heads through access holes

2 Remove 2 off m6 socket cap bolts

3 Rotate blade flange to align second set of M6 socket caps and remove

4 off in total M6 socket caps to be removed

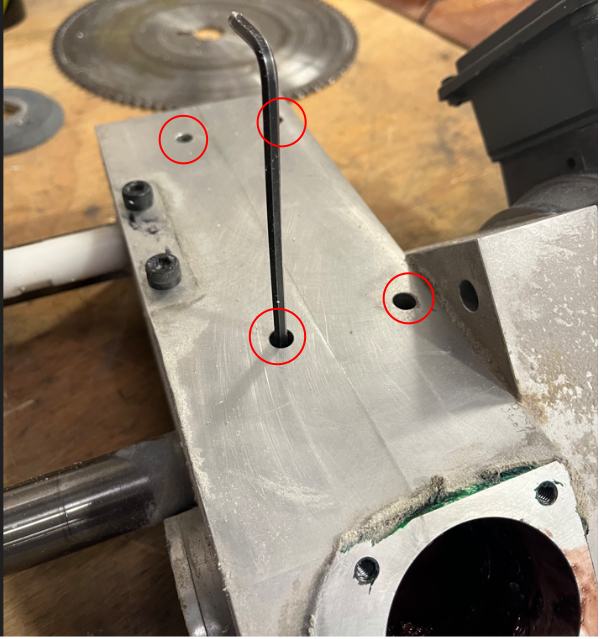

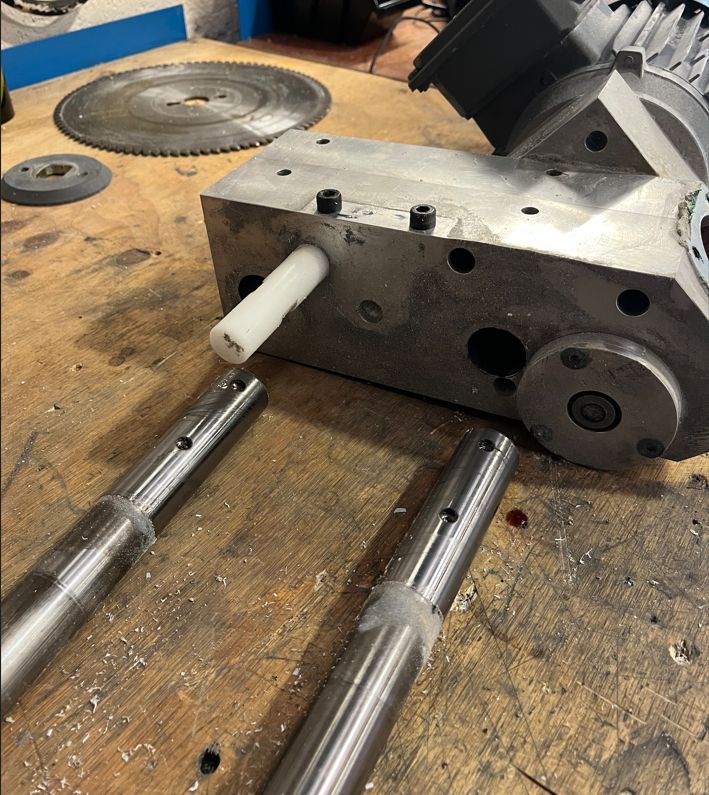

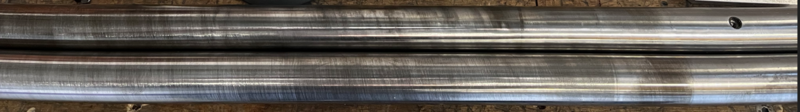

Étape 7 - Extract 2 off shafts

Remove 4 off M8 grubscrews indicated and extract 2 off hardened shafts from main body

Shafts to be refurbished

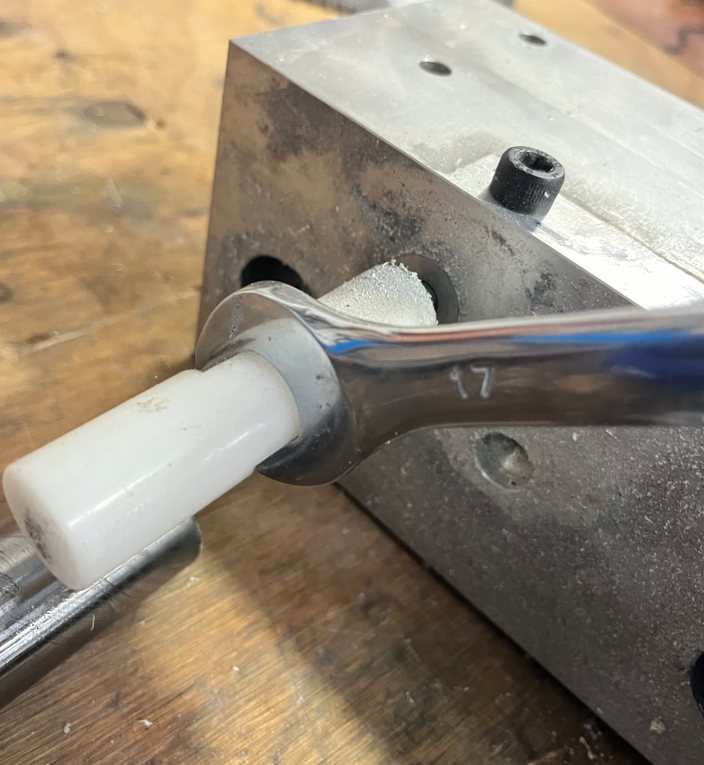

Étape 8 - Remove hard stop

Use 17mm spanner to remove hard stop as shown

Hard stop to be refurbished

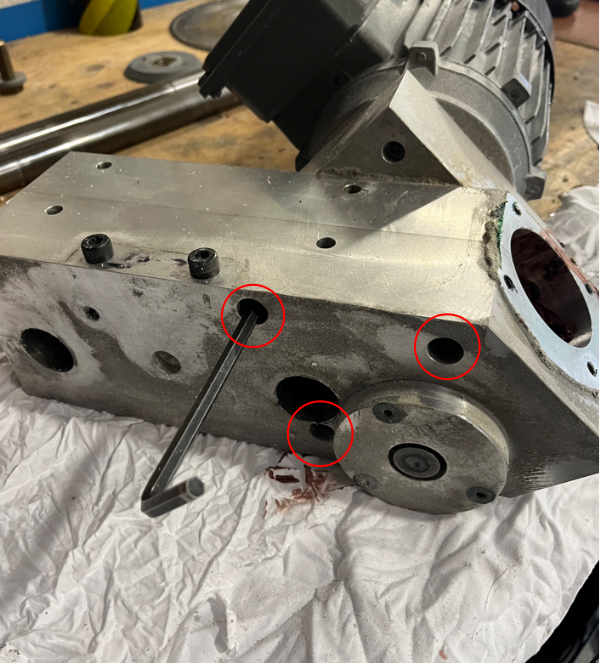

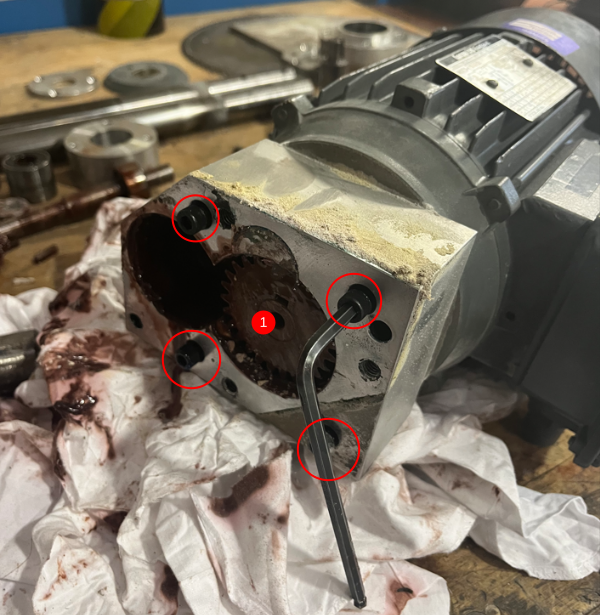

Étape 9 - Remove motor assembly

1 Remove 3 off M8 socket caps indicated

2 Separate as shown . Two components are doweled together, use caution to not damage any faces when separating two parts

Étape 11 - Remove drive pinion

Raise pinion shown to allow blocks to be added beneath

Use drift to separate pinion from shaft

Dispose of pinion gear

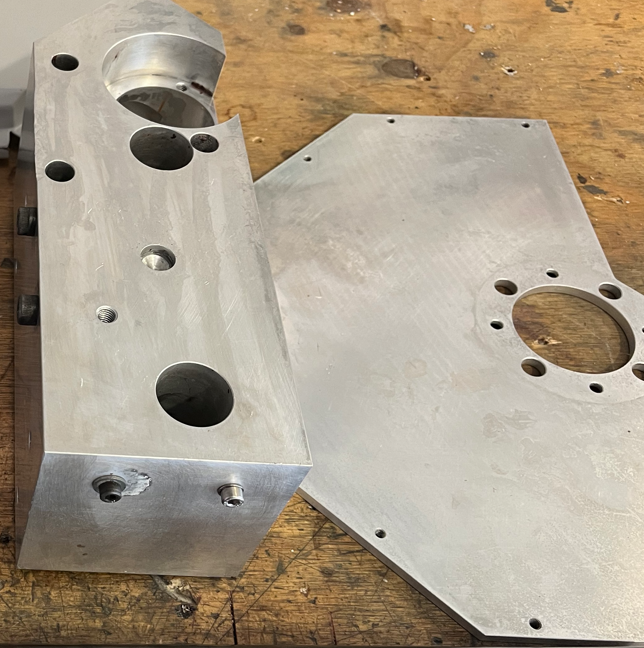

Étape 12 - Remove drive shaft

1 Remove 3 off M6 countersunk bolts shown

2 Remove top cap and keep for refurbishment

3 drive shaft from base to extract assembly from housing

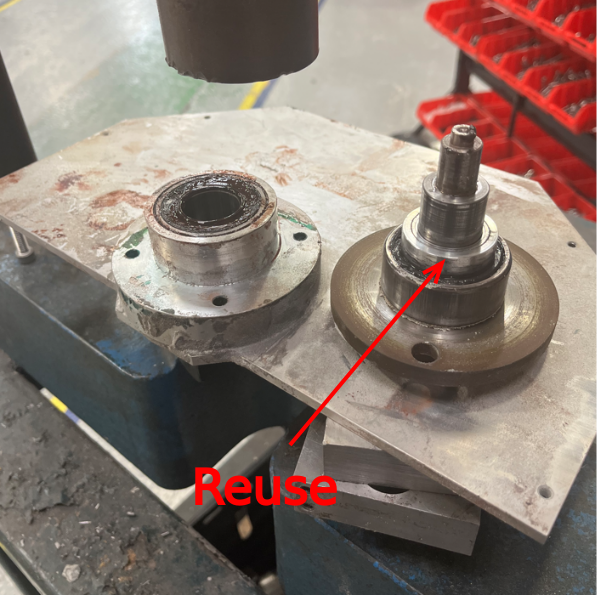

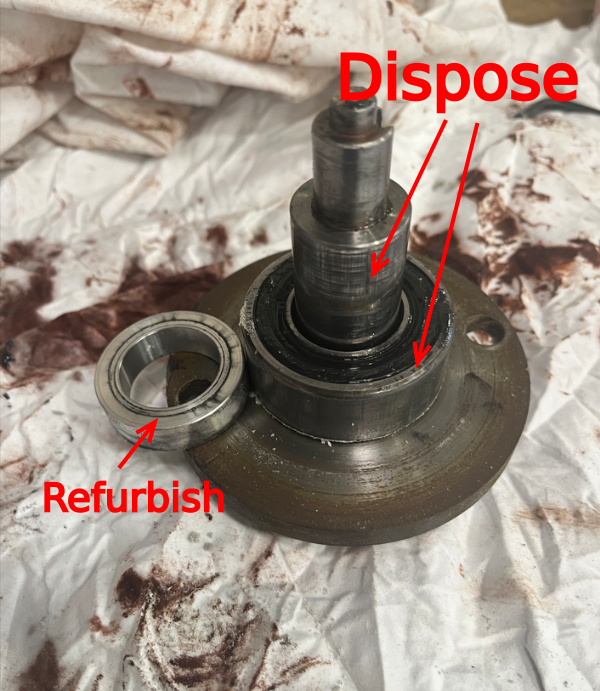

Étape 13 - Extract shaft from bearing housing

Extract shaft as shown, and remove bearings from housing

Dispose of bearings

Étape 14 - Remove keys from shaft

Remove two off keys from shaft to reuse and dispose f rest of components

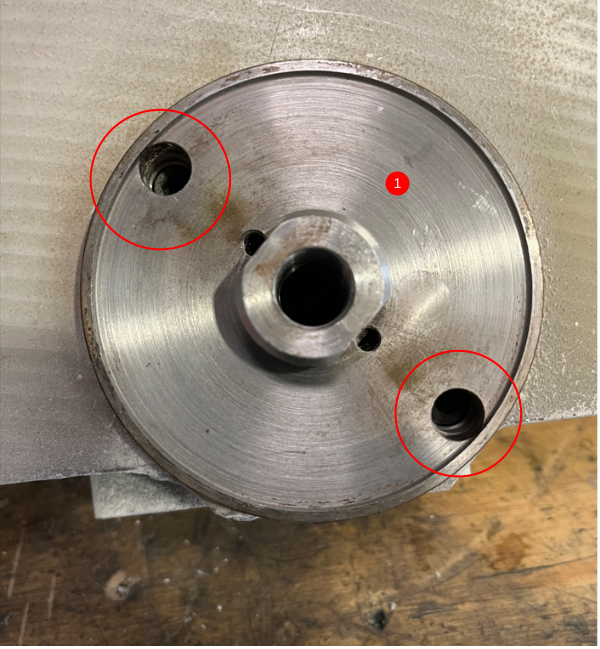

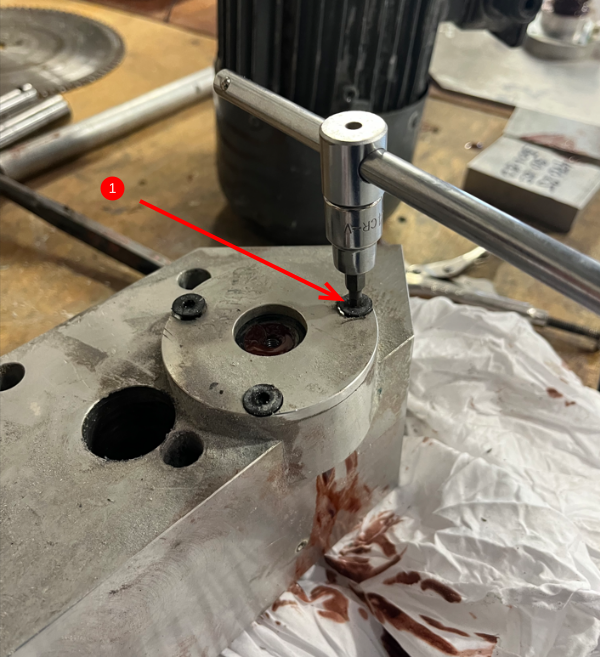

Étape 15 - Disconnect bevel gear

Lock drive flange as shown and remove M5 fastener on end of bevel gear

Machined washer to be reused

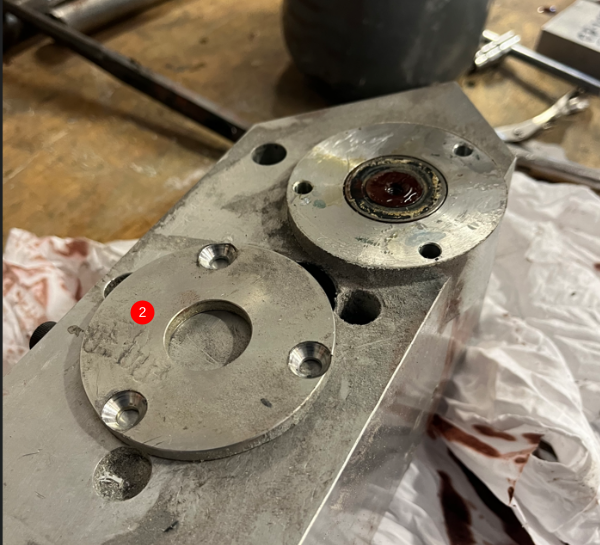

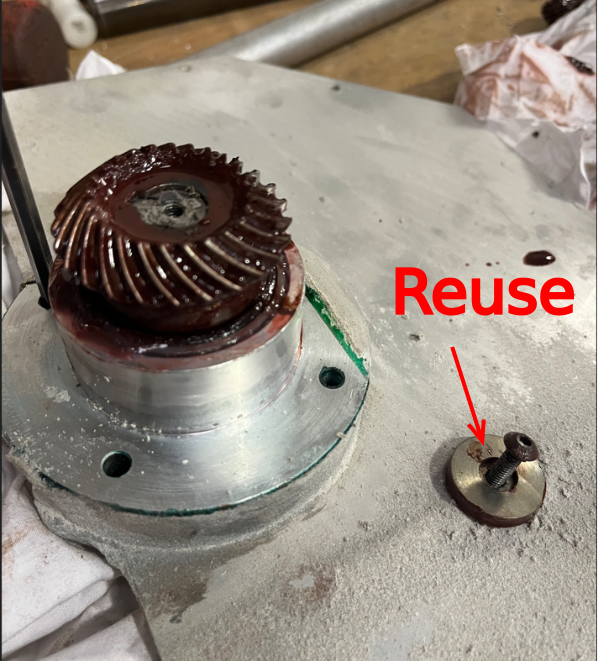

Étape 16 - Remove bevel gear

1 Use drift to move bevel gear enough to allow pry bars to be used underneath

2 Use pry bars to remove gear

3 Key and shim washers to be reused

Bevel gear to be disposed

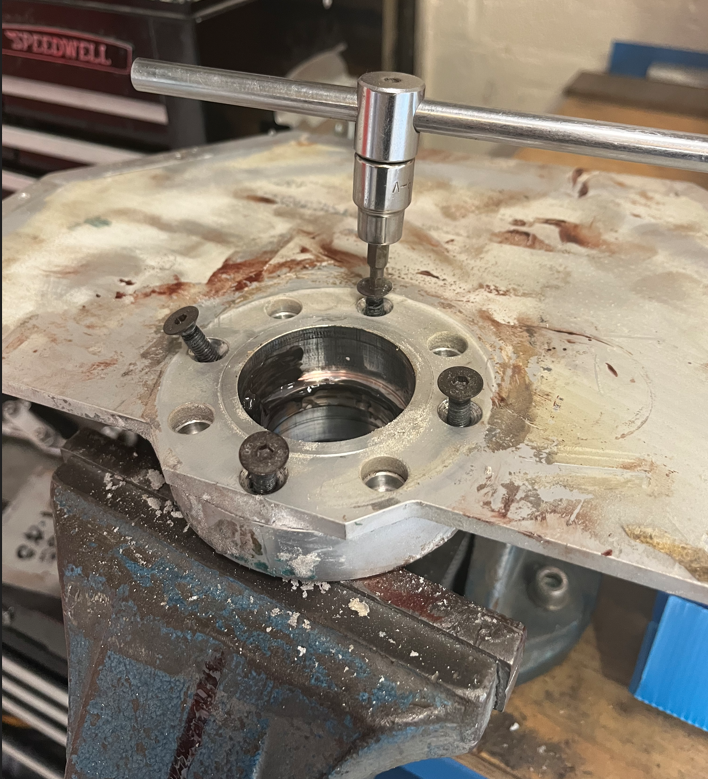

Étape 17 - Use press to remove blade flange

Press blade flange out of bearing assembly

Spacer between 2 bearings should be reused

Étape 19 - Remove bearing housing

Disconnect 4 off M6 countersunk bolts and separate bearing housing from face plate

Both parts to be reused

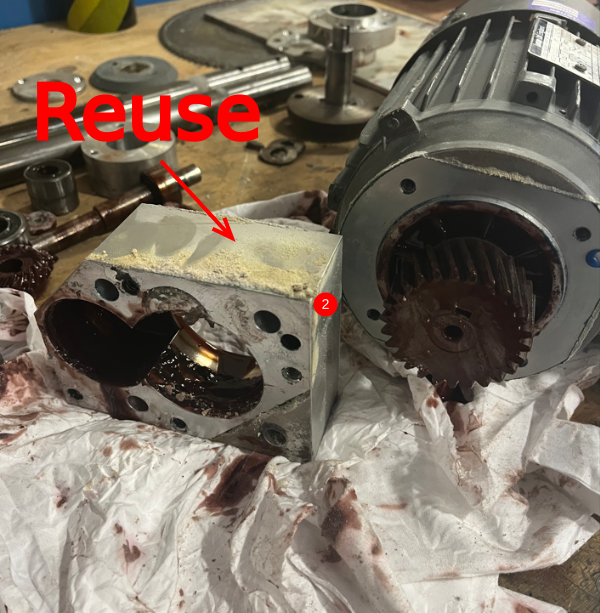

Étape 20 - Remove motor pinion housing

1 Remove 4 off M6 socket caps as shown

2 Separate block from motor

Motor pinion housing to be refurbished . Motor and pinion to be disposed

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português