| [version en cours de rédaction] | [version en cours de rédaction] |

| (2 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Hard | |Difficulty=Hard | ||

| − | |Duration= | + | |Duration=4 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

| Ligne 147 : | Ligne 147 : | ||

|Step_Picture_04=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_082529.png | |Step_Picture_04=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_082529.png | ||

|Step_Picture_05=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_082535.png | |Step_Picture_05=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_082535.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Please ensure the following step is followed correctly</translate> | ||

| + | |Step_Content=<translate>Please ensure the gap is set correctly between the rollers and the cut tables. | ||

| + | |||

| + | |||

| + | Maximum gap is 2mm | ||

| + | |||

| + | |||

| + | Ensure gap is even over all rollers when setting</translate> | ||

| + | |Step_Picture_00=R0015338_Bench_Assemble_Serial_Plate_caution.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| Ligne 181 : | Ligne 192 : | ||

| − | Incorporate turret brackets at rear fixing point when mounting saddle brace | + | Incorporate turret brackets at rear fixing point when mounting saddle brace |

| + | |||

| + | Saddle brace has slots for sideways movement. Utilize this to ensure Z turret brackets sit square in position to fences | ||

| Ligne 190 : | Ligne 203 : | ||

|Step_Picture_02=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_084158.png | |Step_Picture_02=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_084158.png | ||

|Step_Picture_03=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_084512.png | |Step_Picture_03=R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_084512.png | ||

| + | |Step_Picture_03_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":499,"height":594,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.2,"scaleY":1.2,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/1/1d/R0015334_Fit_Centralise_Front_Table_Screenshot_2023-12-12_084512.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":368.76,"top":524.77,"width":221.01,"height":101.25,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.76,"scaleY":1.76,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"Use adjustment in saddle barce slots to ensure these faces are parallel","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} },{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":434,"top":286,"width":200,"height":200,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":100,"ry":100}],"height":714,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 2 avril 2024 à 08:00

Fitting and setting details for Sy assembly and centralise top table

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Add jacking points to frame

- 4 Étape 3 - Mount R0000562 Bench assemble centralise top table

- 5 Étape 4 - Add height adjustment points

- 6 Étape 5 - Add squareness adjustment points

- 7 Étape 6 - Adjust position

- 8 Étape 7 - Fit finger Guard

- 9 Étape 8 - Mount R0015037 Bench assemble SY Assembly

- 10 Étape 9 - Adjust square

- 11 Étape 10 - Please ensure the following step is followed correctly

- 12 Étape 11 - Adjust Height of Sy assembly

- 13 Étape 12 - Recheck squareness of rollers

- 14 Étape 13 - Attach saddle brace

- 15 Étape 14 - Set Parallel to backfences

- 16 Étape 15 - Quality check

- 17 Étape 16 - Recheck Settings

- 18 Étape 17 - Finalise Fasteners

- 19 Étape 18 - Recheck settings

- 20 Étape 19 - Check adjustment grubscrews

- 21 Étape 20 - Dowel Saddle brace

- 22 Étape 21 - Recheck settings

- 23 Étape 22 - Amend Turret brackets

- 24 Étape 23 - Fit turret stops to brackets

- 25 Étape 24 - Fit turret stops to saddle brace

- 26 Étape 25 - Dowel lower frame

- 27 Étape 26 - Dowel backfence

- 28 Étape 27 - Connect Damper and cylinder

- 29 Commentaires

Introduction

Tools Required

Standard hex keyset

1 meter straight edge

Large parallels

150mm engineers square

Engineers level 300mm

Parts Required

H0004543 Gap cover saw finger guard

R0000562 Bench assemble centralise top table

R0015037 Bench assemble SY AssemblyÉtape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Add jacking points to frame

Fit 2 off 1/2" x 1" dowels to frame as shown . Ensure dowels are fully seated . Ensure chamfered end of dowel is inserted first

Secure with 2 off M8 x 12 KCP grubscrews

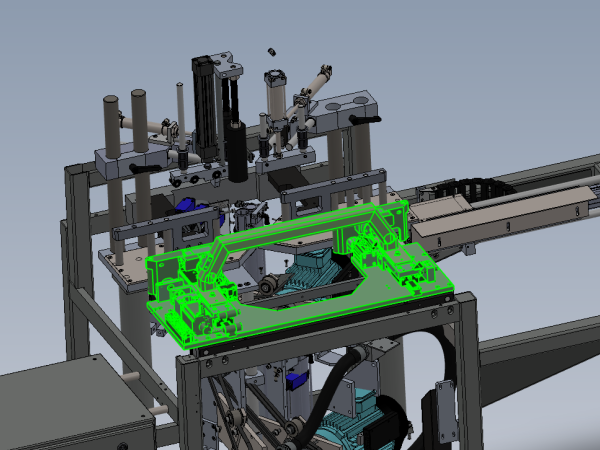

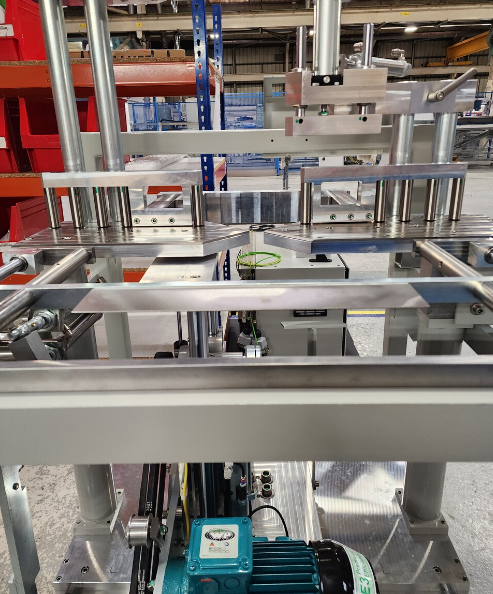

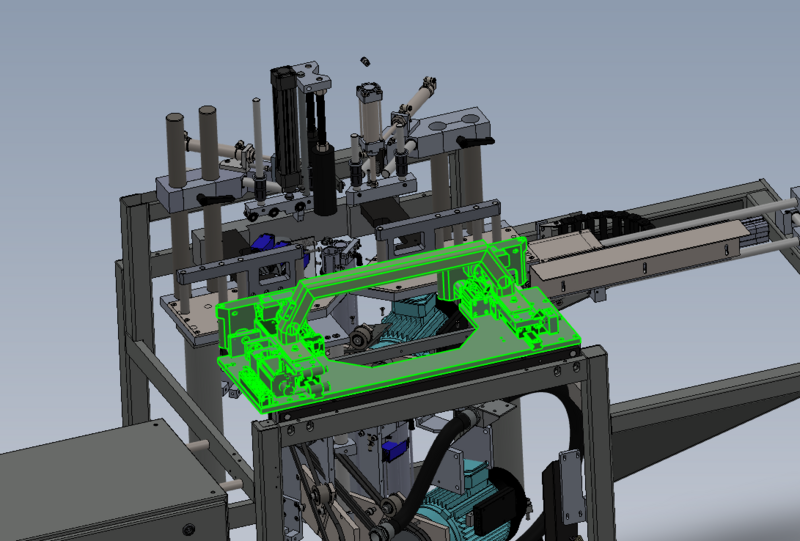

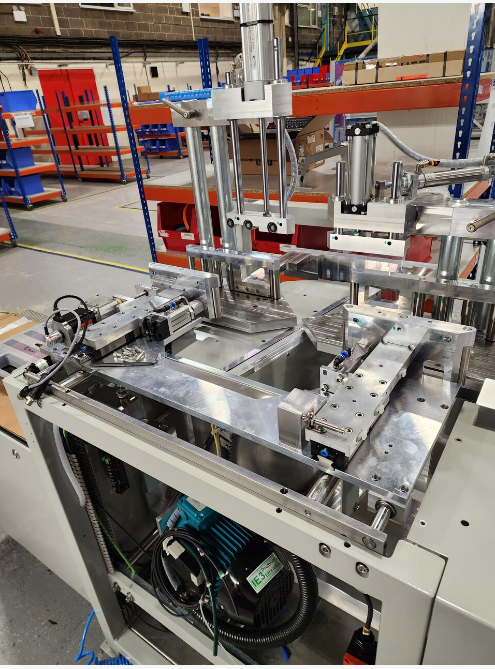

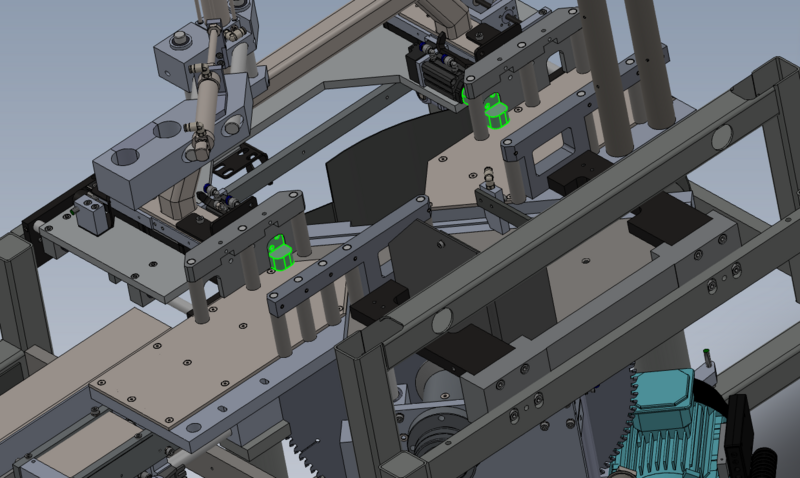

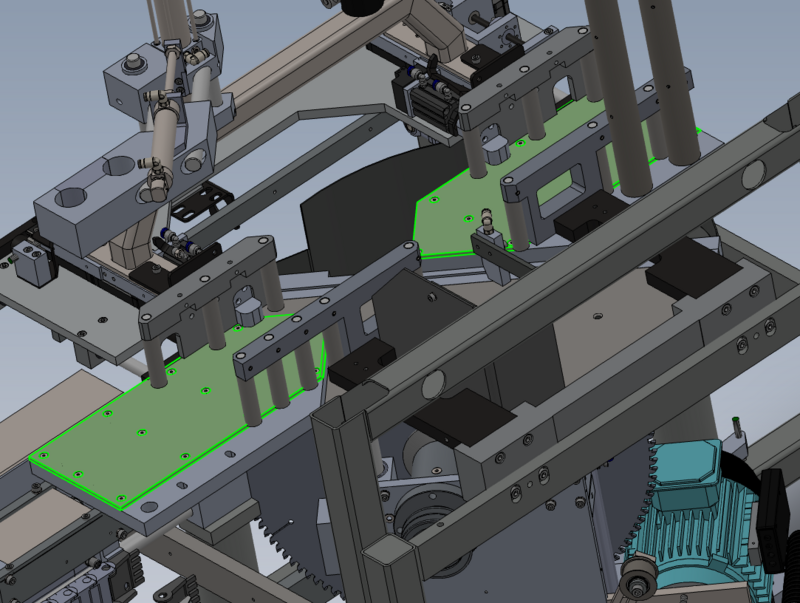

Étape 3 - Mount R0000562 Bench assemble centralise top table

Attach R0000562 Bench assemble centralise top table as shown

Use 4 off M8 x 20 socket caps

Fit assembly at highest position in slots

Dry fit fasteners, apply medium tension

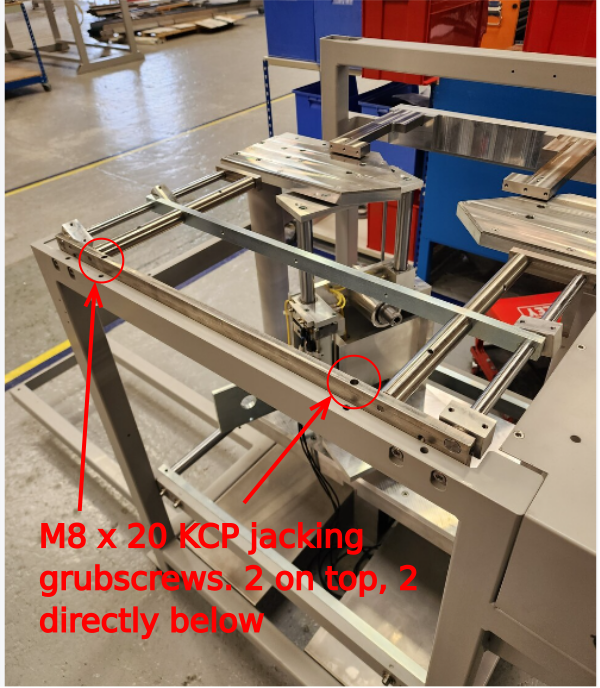

Étape 4 - Add height adjustment points

Add 4 off M8 x 20 KCP grubscrews to points shown .

Adjust grubscrews to touch dowels

Étape 5 - Add squareness adjustment points

Fit 4 off M8 x 12 flat bottomed grubscrews to the points shown

Wind grubscrews to touch frame

Étape 6 - Adjust position

Set initial position of assembly using engineers level on the indicated axis

Use M8 squareness adjusting grubscrews to set position

Set both positions level

Étape 7 - Fit finger Guard

Fit H0004543 Gap cover saw finger guard to assembly

Use 3 off M5 x 12 socket caps and A form washers

finalise fasteners

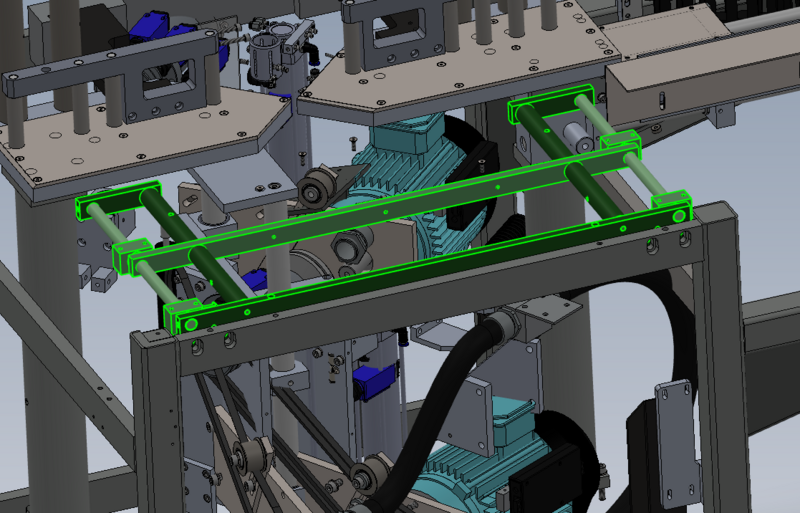

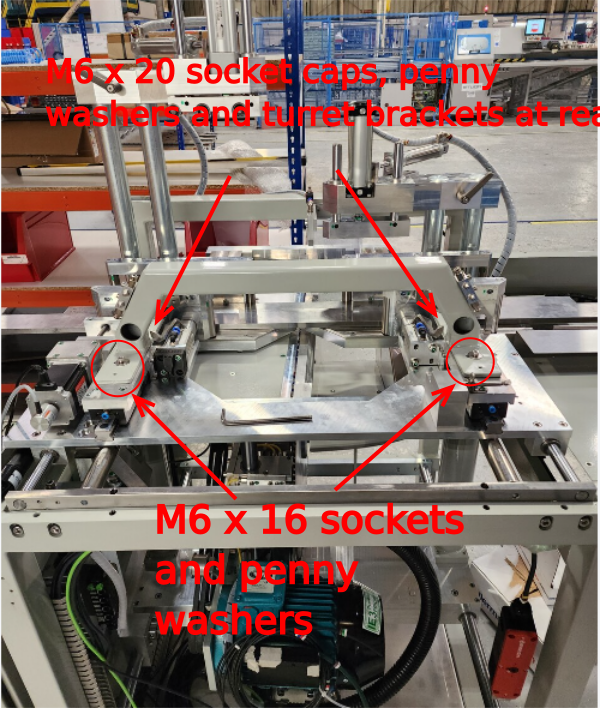

Étape 8 - Mount R0015037 Bench assemble SY Assembly

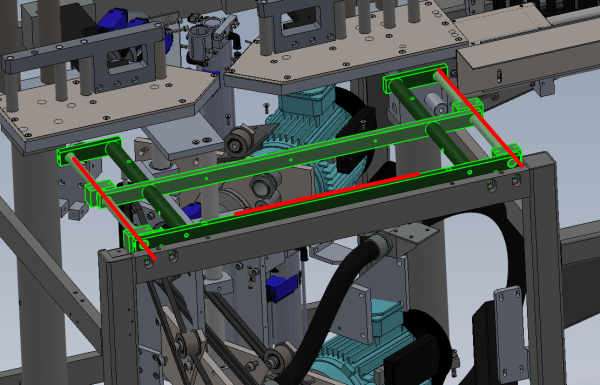

Mount R0015037 Bench assemble SY Assembly

Use 8 off M6 x 20 socket caps

Dry fit fasteners

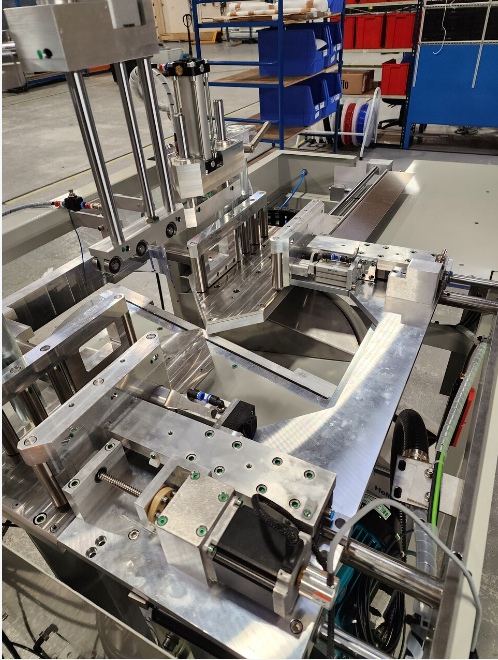

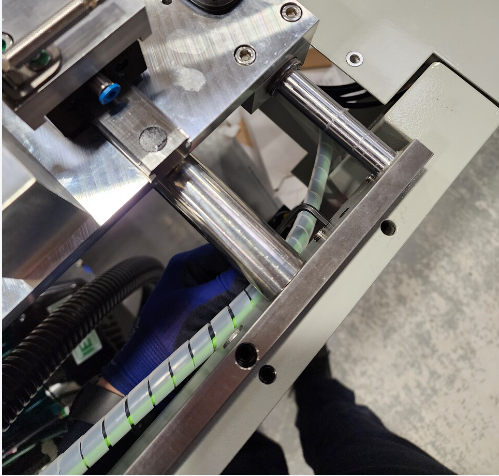

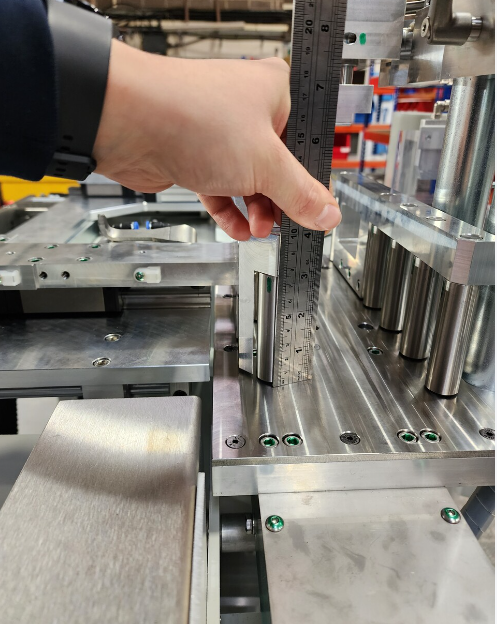

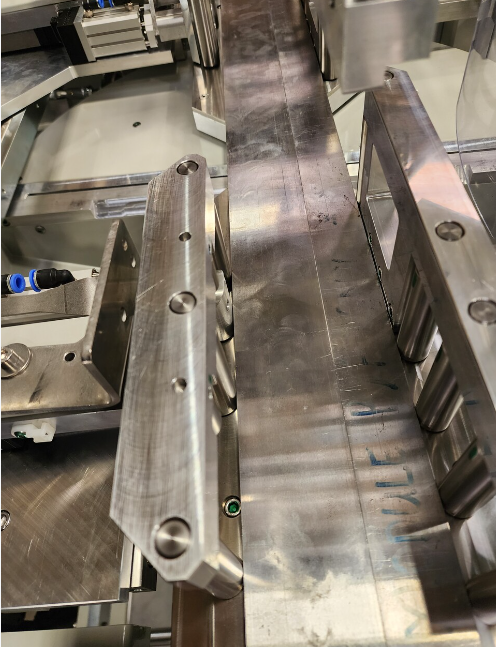

Étape 9 - Adjust square

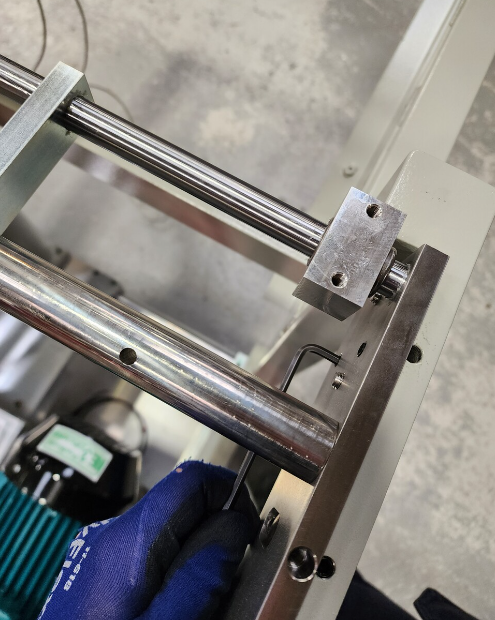

Use engineers square to check squareness of front rollers to infeed and outfeed cut tables

Use adjusting grubscrews to set square accurately

Adjusting grubscrews must be set under tension

Only adjust 1 off grubscrew in each pair. Do not jack top table frame away from main frame . 1 point of contact must always be present

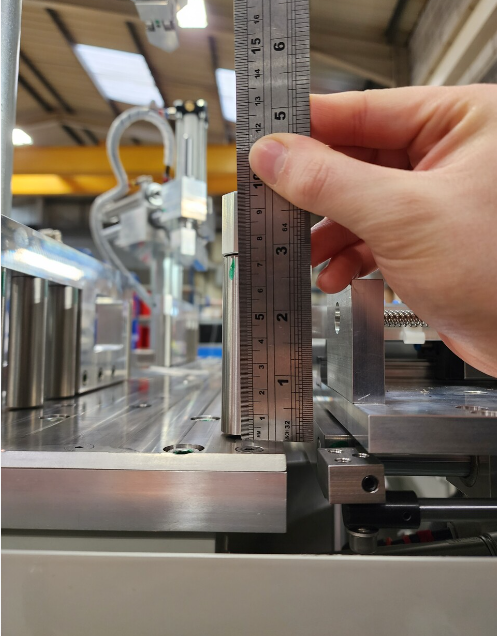

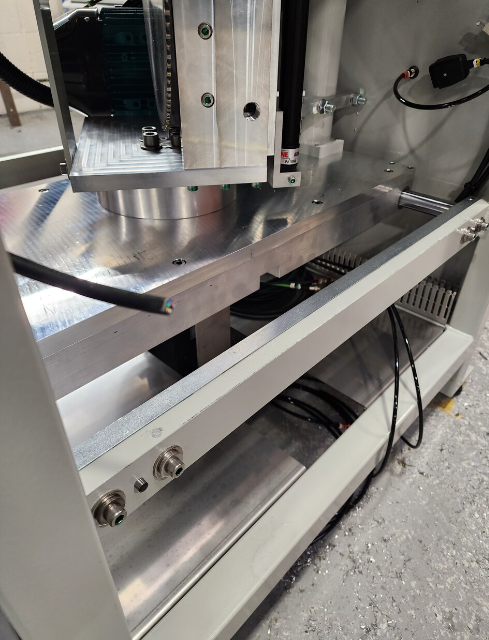

Étape 10 - Please ensure the following step is followed correctly

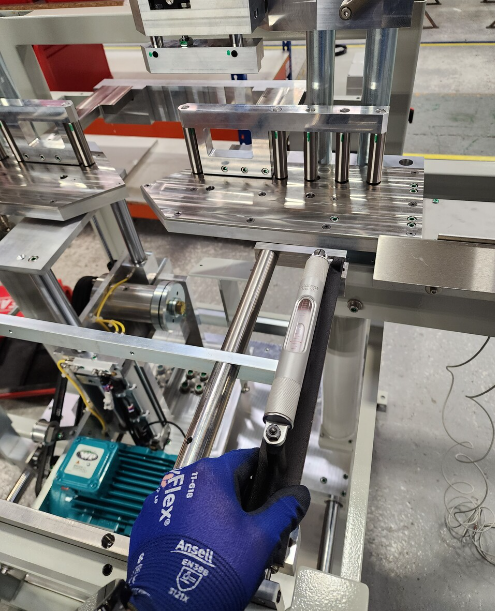

Please ensure the gap is set correctly between the rollers and the cut tables.

Maximum gap is 2mm

Ensure gap is even over all rollers when setting

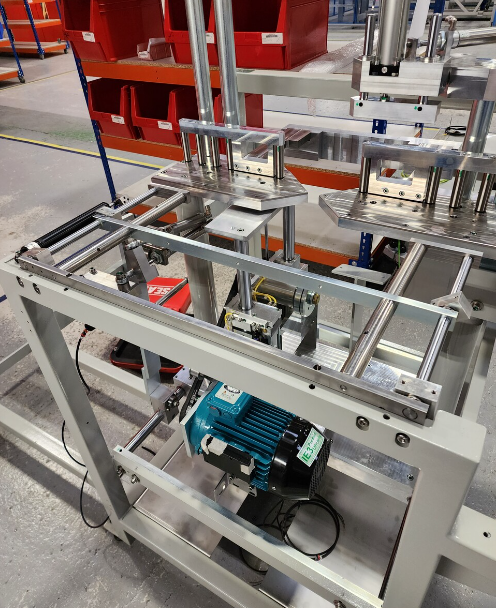

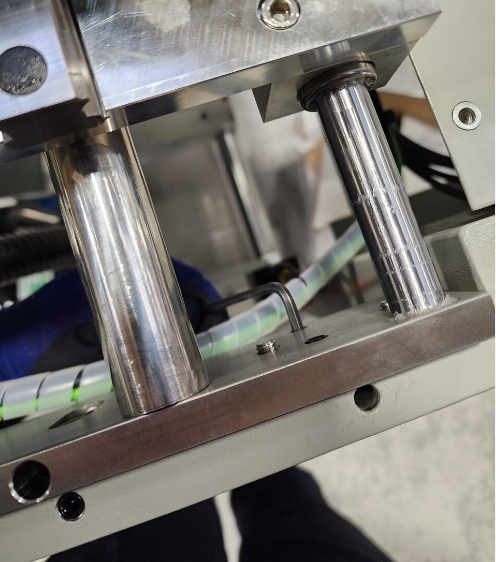

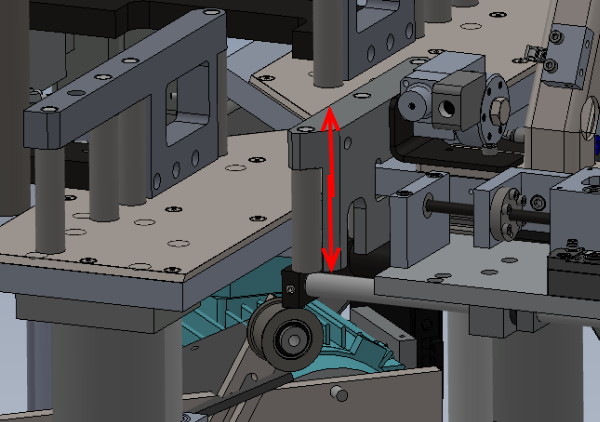

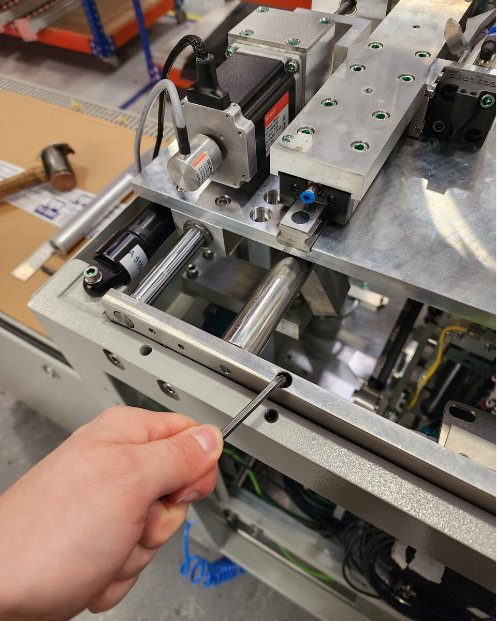

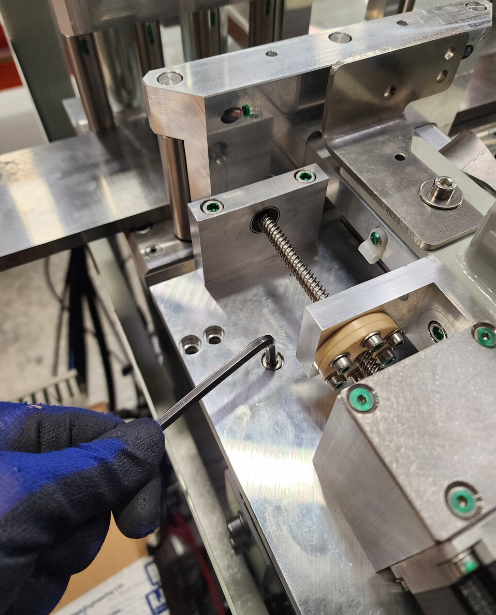

Étape 11 - Adjust Height of Sy assembly

Set height of Sy assembly to cut tables using jacking grubscrews

Release pressure on front 4 off M8 x 20 socket caps

Use M8 x 20 grubscrews to adjust height of assembly

Set to gap of 1.5mm -+ 0.5mm

Ensure assembly sits level/even across all rollers

Apply final tension with adhesive to front M8 x 20 socket caps

Étape 12 - Recheck squareness of rollers

Once height has been adjusted, roller squareness must be checked and reset if movement has occurred . Both height and squareness will have to be manipulated together to achieve all settings to requested specification

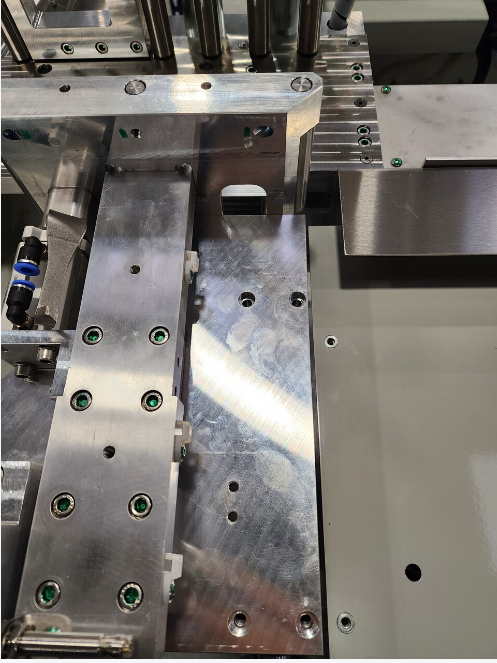

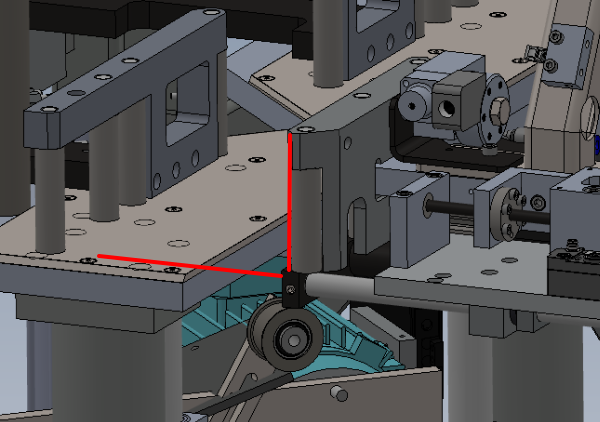

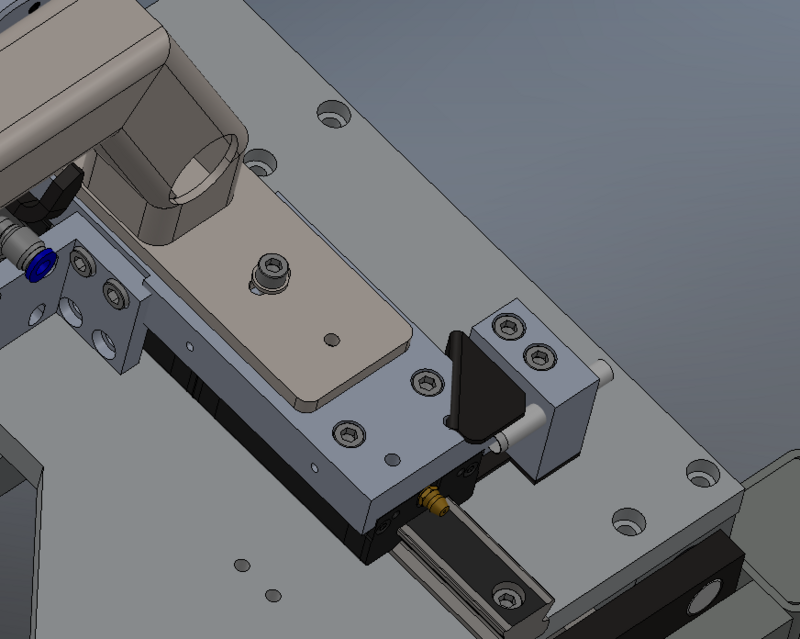

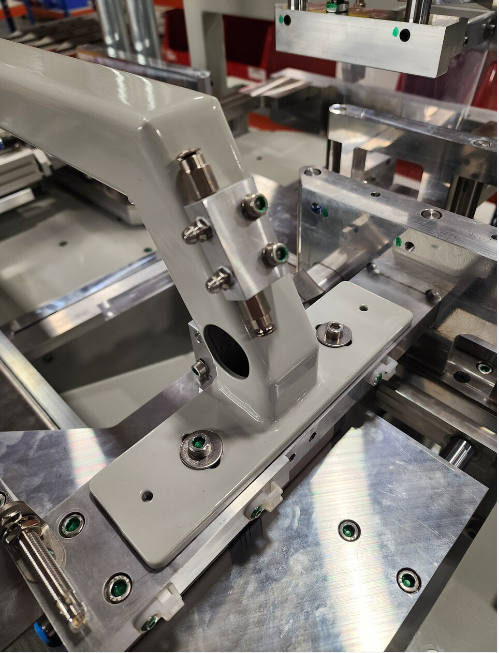

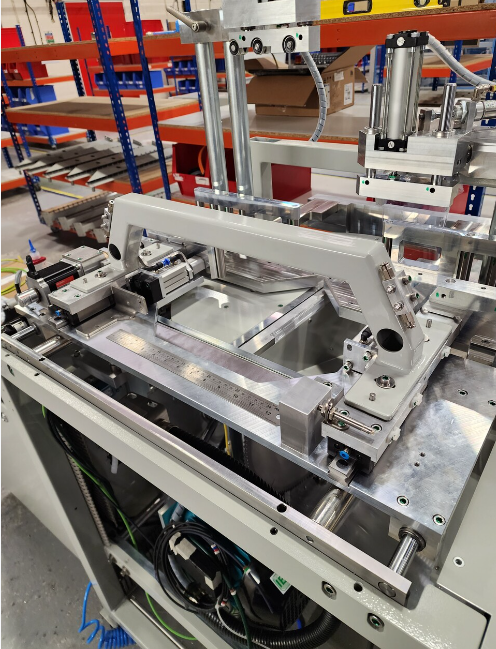

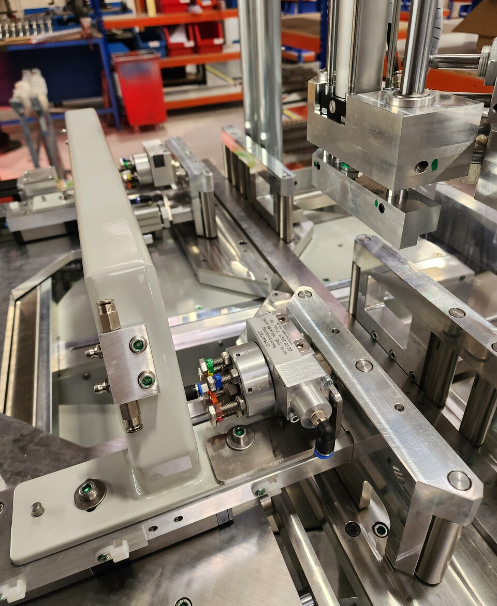

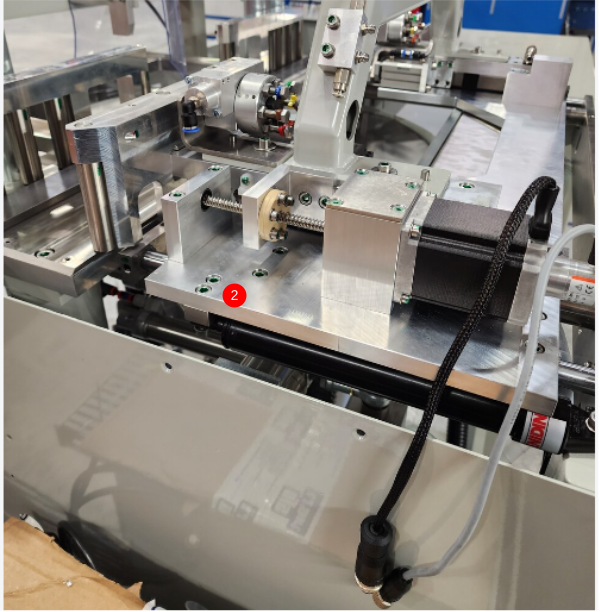

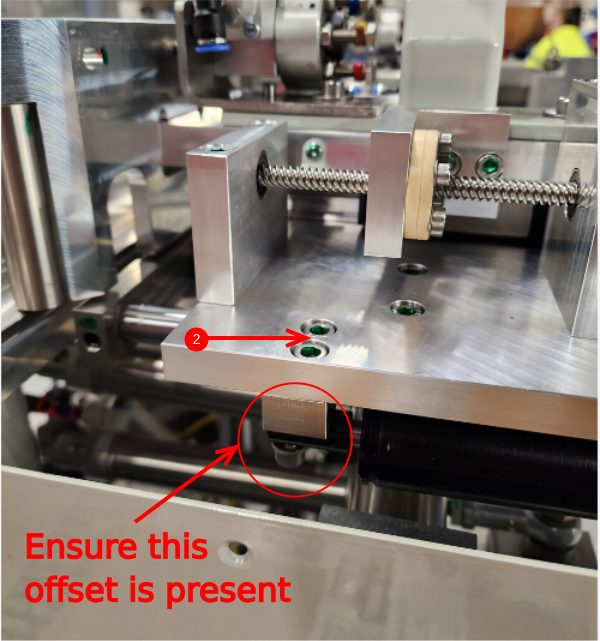

Étape 13 - Attach saddle brace

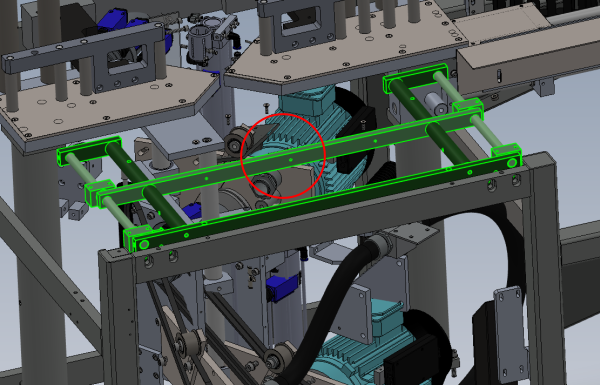

Attach saddle brace to assembly using 2 off M6 x 16 socket caps 2 off M6 x 20 socket caps all with penny washers

Incorporate turret brackets at rear fixing point when mounting saddle brace

Saddle brace has slots for sideways movement. Utilize this to ensure Z turret brackets sit square in position to fences

Do not apply tension or adhesive to bolts

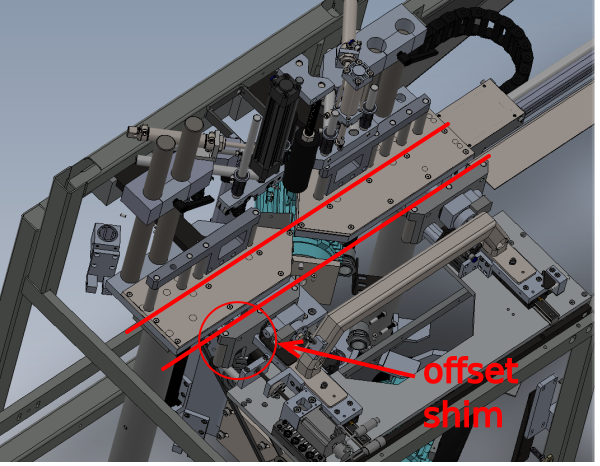

Étape 14 - Set Parallel to backfences

Use 2 off straight edges against back roller fence

Add offset shim of 0.002"/0.05mm to driven side

Set front rollers to touch, using M6 socket caps and counter bore clearance to adjust

Report if unable to achieve parallel from this movement

Étape 15 - Quality check

Check settings are adjusted, check that Z block operation does not foul cut tables

To do this move both z blocks by hand to active and home position and check contact is not made with the cut tables

Étape 16 - Recheck Settings

Recheck all settings once final adjustment has been made

Roller squareness to cut tables

Roller height to cut tables

Parallel to back fences

Étape 17 - Finalise Fasteners

Remove turret brackets ( required for later step of dowelling)

Individually remove and apply adhesive to all dry fasteners and apply final tension

Étape 18 - Recheck settings

Recheck all settings once final adjustment has been made

Roller squareness to cut tables

Roller height to cut tables

Parallel to back fences

Étape 19 - Check adjustment grubscrews

Check that no adjustment grubscrews are loose.

Any grubscrews that are not required should still have adhesive applied and lightly tensioned to set in position

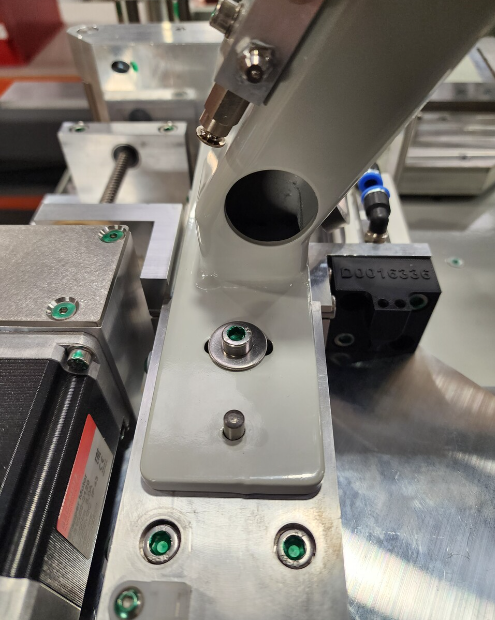

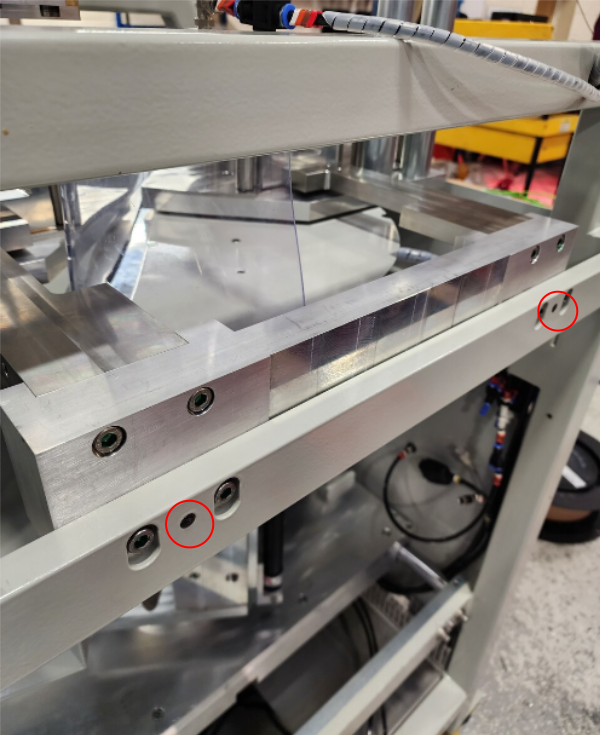

Étape 20 - Dowel Saddle brace

Drill4 off dowel points in saddle brace 5.8mm to a depth of 20mm

Ream to 6mm H7 tolerance

Use 4 off 6mm x 20 dowels to secure

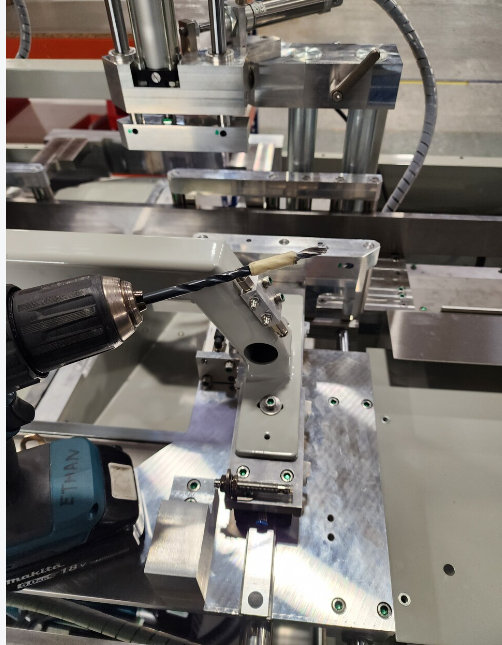

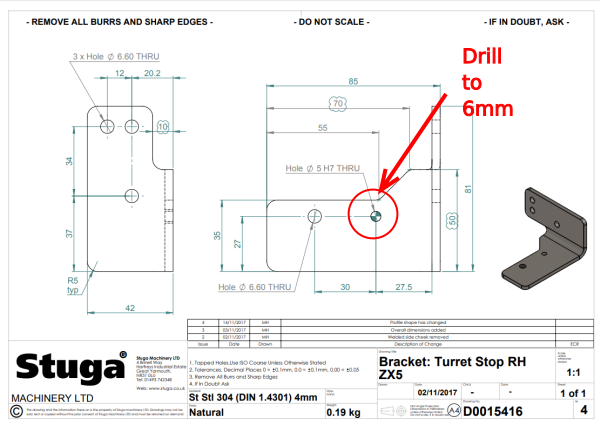

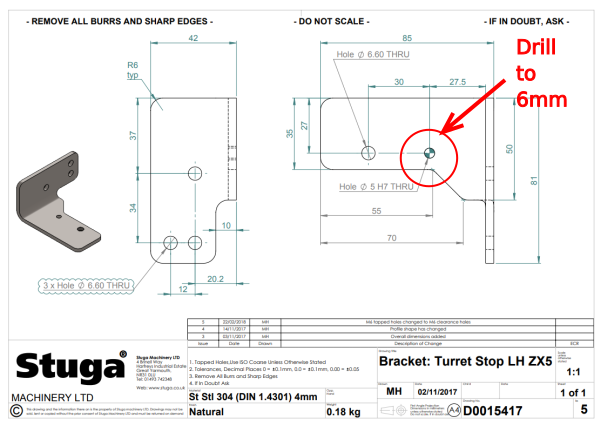

Étape 22 - Amend Turret brackets

Ecr raised 12/12/23 to amend turret bracket D0015416 and D0015417 hole size to 6mm

Amend hole size by hand to 6mm until

Étape 23 - Fit turret stops to brackets

Fit turret assemblies to brackets using 6 off M6 x 16 socket caps and A form washers

Étape 24 - Fit turret stops to saddle brace

Fit turret stops to saddle braces as shown. Use existing m6 x 20 socket caps and washers to fix. Align over dowels on rear of saddle brace

Étape 25 - Dowel lower frame

Drill 4 off holes indicated to 7.8mm through and Ream to 8mm H7

Clean with FE 10

fit 4 off 8mm x 50mm dowels to fix

Add Loctite 270 to dowels

Étape 26 - Dowel backfence

Drill 2 off back fence dowel points to 7.8mm . Drill to 65mm deep to allow flush fitment of dowel

Ream to 8mm H7

Wash out with solvent

Fit 2 off 8mm x 50mm dowels with Loctite 270

Étape 27 - Connect Damper and cylinder

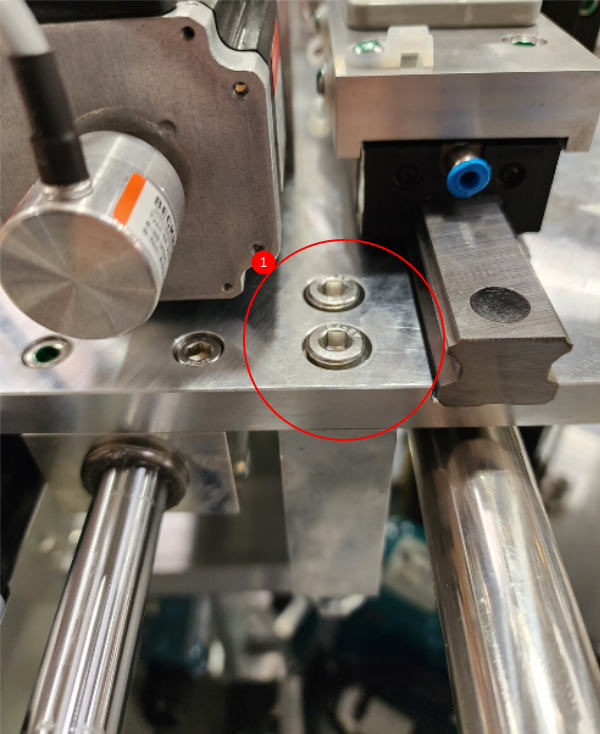

1 Connect Cylinder mount block with 2 off M8 x 25 socket caps

2 Connect Damper using 2 of M6 x 16 socket caps

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português