| [version en cours de rédaction] | [version en cours de rédaction] |

| (Une révision intermédiaire par le même utilisateur non affichée) | |||

| Ligne 97 : | Ligne 97 : | ||

*Allows a more dynamic acceleration and deceleration on all x axis movements, therefore improving cycle time | *Allows a more dynamic acceleration and deceleration on all x axis movements, therefore improving cycle time | ||

| − | = “High Speed Ring” upgrade (R0010200C). = | + | =“High Speed Ring” upgrade (R0010200C).= |

| − | This improves the original Flowline design and brings it in line in terms of performance with a modern “ZX3” machine. | + | This improves the original Flowline design and brings it in line in terms of performance with a modern “ZX3” machine.{{#annotatedImageLight:Fichier:Stuga Flowline Overhaul Particulars R0010200C.jpg|0=300px|hash=|jsondata=|mediaClass=Image|type=frameless|align=left|src=https://stuga.dokit.app/images/3/37/Stuga_Flowline_Overhaul_Particulars_R0010200C.jpg|href=./Fichier:Stuga Flowline Overhaul Particulars R0010200C.jpg|resource=./Fichier:Stuga Flowline Overhaul Particulars R0010200C.jpg|caption=|size=300px}} |

| Ligne 111 : | Ligne 111 : | ||

*When the original flowline was designed in 1999, trickle vents were a small part of production (around 20%). In the years since, regulations have meant that a considerably higher percentage of frames need a trickle vent. This has put a much higher overhead on the machining side, slowing the entire machine down. With our upgrade, the balance between sawing and machining is redressed, allowing the machine side to keep up with the saw. | *When the original flowline was designed in 1999, trickle vents were a small part of production (around 20%). In the years since, regulations have meant that a considerably higher percentage of frames need a trickle vent. This has put a much higher overhead on the machining side, slowing the entire machine down. With our upgrade, the balance between sawing and machining is redressed, allowing the machine side to keep up with the saw. | ||

| + | |||

| + | |||

*The spindle speed is 50% faster allowing faster cutting. | *The spindle speed is 50% faster allowing faster cutting. | ||

*Stuga have also worked closely with tooling manufacturers, and coupled with the increased spindle speed, the tools can cut up to 4 times faster. The quality of cut and cutter life has also been improved. | *Stuga have also worked closely with tooling manufacturers, and coupled with the increased spindle speed, the tools can cut up to 4 times faster. The quality of cut and cutter life has also been improved. | ||

| Ligne 151 : | Ligne 153 : | ||

| − | = Optional Extra - Saw Y-Drive = | + | =Optional Extra - Saw Y-Drive= |

| − | Stuga have designed an addition to the sawing module of machine which gives the saw side the ability to create the Y notch pattern in one prep. This consists of a square then mitre cut using a variable offset central position to give the CNC depths of Y notch. The operation works much like an arrow-head cut. The advantages are | + | |

| + | |||

| + | Stuga have designed an addition to the sawing module of machine which gives the saw side the ability to create the Y notch pattern in one prep. This consists of a square then mitre cut using a variable offset central position to give the CNC depths of Y notch. | ||

| + | |||

| + | Video is available [https://vimeo.com/483934220 here] | ||

| + | |||

| + | The operation works much like an arrow-head cut. The advantages are | ||

| − | * Prep is done in one operation, not two as in machines without this upgrade. This means the prep is much more accurate | + | *Prep is done in one operation, not two as in machines without this upgrade. This means the prep is much more accurate |

| − | * The bar is centralised, meaning the machine mechanically alters the Y notch depth depending on the width of the profile (tolerant to profile variances) | + | *The bar is centralised, meaning the machine mechanically alters the Y notch depth depending on the width of the profile (tolerant to profile variances) |

| − | * The toothed gripper works in unison with this system, allowing a reverse move to pull the bar clear | + | *The toothed gripper works in unison with this system, allowing a reverse move to pull the bar clear |

| − | * The high accuracy of this cut makes the Y notching suitable for an H-welder (NOTE: '''''Finished Y notch accuracy is still completely dependent on consistency and accuracy of butt welding system''''') | + | *The high accuracy of this cut makes the Y notching suitable for an H-welder (NOTE: '''''Finished Y notch accuracy is still completely dependent on consistency and accuracy of butt welding system''''') |

Upgrade Includes: | Upgrade Includes: | ||

| − | * Additional CNC Saw Y axis drive on centraliser | + | *Additional CNC Saw Y axis drive on centraliser |

| − | * 6 Position auto turret heads for Z support | + | *6 Position auto turret heads for Z support |

| − | * Enlarged Saw hood to create the space for the upgrade | + | *Enlarged Saw hood to create the space for the upgrade |

Note: Due to the constraints of the original design, the Y notch facility has limitations on range. It is designed to cover over 95% of production, but cannot (for instance) Y notch a shallow notch in a wide transom, or wide notch in a narrow transom / outer) | Note: Due to the constraints of the original design, the Y notch facility has limitations on range. It is designed to cover over 95% of production, but cannot (for instance) Y notch a shallow notch in a wide transom, or wide notch in a narrow transom / outer) | ||

| − | * Depth +/-18mm from the centreline of the profile | + | *Depth +/-18mm from the centreline of the profile |

| − | * Rear “residual” >18mm | + | *Rear “residual” >18mm |

The machine will produce Y notches outside of this range but utilises the machining head to produce the square cut portion of the cut. | The machine will produce Y notches outside of this range but utilises the machining head to produce the square cut portion of the cut. | ||

Version actuelle datée du 26 février 2024 à 12:42

Details of the components replaced on a Flowline Overhaul

Overview

The Flowline was manufactured from 2000 to 2005, and all 76 machines are still in production today, outliving the expected design lifespan of 10 years and proving the machines’ long term reliability and suitability for the market place.

By 2019, 27 of the original machines have been fully overhauled and resold to new and existing customers, each with a full one year warranty from Stuga.

As with any cutting-edge technology, the drive systems and control components have been made obsolete by the original manufacturers, and so Stuga have kept up to date with an upgrade package to the latest control systems. The newer systems are more dynamic and reliable and allow these improvements to be passed on to the refurbished machines. A refurbished model is faster, more reliable and easier to use than the original model.

Overhaul Particulars

- Paint touch up to remove rust and bare metal surfaces

- Upgrade guarding all round to 2019 specification

- Replace all control system with latest Beckhoff control

- Control PC and PLC – Windows 10

- I/O interfaces

- Servo Drives

- Servo Motors

- Cables

- 2 off monitors

- Latest control software with graphical user interface and production timing reports

- Camera Diagnostic system

- Replace label printer

- Replace axis gearboxes

- Replace main rotary ring and journals

- Replace X axis and saw pusher linear rails and journals, including pinion gears

- Replace worn cylinders where necessary

- Replace worn bearings where necessary

- Replace Valve banks and broken regulators

- Replace contactors where necessary

- New dual bag extraction system

- Additional Upgrades to improve performance

- Side Roller guidefence on Saw

- Rear guidefence on Machining centre outfeed clamps

- Saw Eject conduit replacement

- Grease nipple addition on eject and saw cut shafts

- Outfeed Safety Gate

- Offcut Measuring system – measures offcuts as they are loaded and reoptimizes automatically

Control Components Replaced

| Component | Location | Quantity | Picture |

| Beckhoff Control PC | Machining Centre Cabinet | 1 | |

| Beckhoff IO Modules | Machining Centre Cabinet

Transfer Table Cabinet Saw Cabinet |

3 | |

| Beckhoff AX8000 series Dual Servo Drives | Machining Centre Cabinet | 3 | |

| Front End Interface PC and Touchscreen Monitors (Windows 10) | Machining Centre Cabinet | 1 | |

| Beckhoff Servo Motors and Cabling | X axis, Y axis, Z axis

R axis, Saw Pusher |

6 | |

| Gearboxes | X axis, Saw Pusher, R axis | 3 |

Tru-Loc Gripper Upgrade

All overhaul machines are supplied with the Tru-Loc gripper system, a dual-tooth fixed gripper design that accurately and reliably locates into the profile

- Tapered pins on both sides of machine ensure an accurate and reliable datum

- 2 holes and pins are used to cover all profile types - this eliminates the need for a "G" axis sideways movement on the gripper

- Eliminates gripper slip

- Allows a more dynamic acceleration and deceleration on all x axis movements, therefore improving cycle time

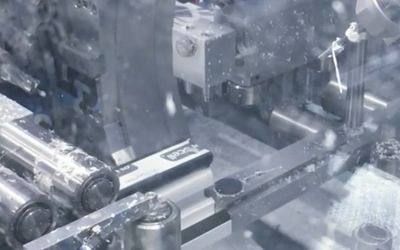

“High Speed Ring” upgrade (R0010200C).

This improves the original Flowline design and brings it in line in terms of performance with a modern “ZX3” machine.

What is involved?

The upgrade consists of a mechanical and electrical upgrade to the ring spindles. Four of the current spindle heads will be removed, and in their place are fitted 4 higher power, higher speed units, with two “Double Plunge” assemblies. This improves the machining cycle time of trickle vents, doors and letter boxes by over 300%. The improvements are gained by using higher specification spindle motors, higher quality tooling and (if applicable) by machining both sides of the profile at the same time. With these changes, it is possible to improve the current machine output by up to 50%, depending on your machine setup. A full assessment of the time saved can be undertaken on your machine on request.

How can it be so much faster?

Apart from the obvious fact of cutting both sides of the profile at the same time, there are other speed improvements:

- When the original flowline was designed in 1999, trickle vents were a small part of production (around 20%). In the years since, regulations have meant that a considerably higher percentage of frames need a trickle vent. This has put a much higher overhead on the machining side, slowing the entire machine down. With our upgrade, the balance between sawing and machining is redressed, allowing the machine side to keep up with the saw.

- The spindle speed is 50% faster allowing faster cutting.

- Stuga have also worked closely with tooling manufacturers, and coupled with the increased spindle speed, the tools can cut up to 4 times faster. The quality of cut and cutter life has also been improved.

| Standard Flowline | With Upgrade | |

| Spindle Speed | 11,000 rpm | 18,000 rpm |

| Spindle Power at Tool | 0.2kW | 0.75kW |

| Tooling | Standard | Carbide |

| Time Taken for 4000 Trickle Vent | 55 sec | 15 sec |

| Time Taken for Door Handle Prep | 90 sec |

Optional Extra - Saw Y-Drive

Stuga have designed an addition to the sawing module of machine which gives the saw side the ability to create the Y notch pattern in one prep. This consists of a square then mitre cut using a variable offset central position to give the CNC depths of Y notch.

Video is available here

The operation works much like an arrow-head cut. The advantages are

- Prep is done in one operation, not two as in machines without this upgrade. This means the prep is much more accurate

- The bar is centralised, meaning the machine mechanically alters the Y notch depth depending on the width of the profile (tolerant to profile variances)

- The toothed gripper works in unison with this system, allowing a reverse move to pull the bar clear

- The high accuracy of this cut makes the Y notching suitable for an H-welder (NOTE: Finished Y notch accuracy is still completely dependent on consistency and accuracy of butt welding system)

Upgrade Includes:

- Additional CNC Saw Y axis drive on centraliser

- 6 Position auto turret heads for Z support

- Enlarged Saw hood to create the space for the upgrade

Note: Due to the constraints of the original design, the Y notch facility has limitations on range. It is designed to cover over 95% of production, but cannot (for instance) Y notch a shallow notch in a wide transom, or wide notch in a narrow transom / outer)

- Depth +/-18mm from the centreline of the profile

- Rear “residual” >18mm

The machine will produce Y notches outside of this range but utilises the machining head to produce the square cut portion of the cut.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português