| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 12 : | Ligne 12 : | ||

| − | '''<u>Parts Required</u>'''</translate> | + | '''<u>Parts Required</u>''' |

| + | |||

| + | D0015513 Arm brace x 2 | ||

| + | |||

| + | D0015514 Arm brace x 1 </translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

| Ligne 61 : | Ligne 65 : | ||

|Step_Title=<translate>Disconnect air supply</translate> | |Step_Title=<translate>Disconnect air supply</translate> | ||

|Step_Content=<translate></translate> | |Step_Content=<translate></translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit brace 1</translate> | ||

| + | |Step_Content=<translate>Fit D0015513 at load motor end of frame . | ||

| + | |||

| + | Use M8 x 35 socket caps, M8 motor plate washers and M8 nyloc nuts .</translate> | ||

| + | |Step_Picture_00=R0015268_Pneumatic_module_Test_Screenshot_2023-12-11_111307.png | ||

| + | |Step_Picture_01=R0015266B_mount_completed_assemblies_photorequired.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit brace 2</translate> | ||

| + | |Step_Content=<translate>fit second brace D00155122</translate> | ||

| + | |Step_Picture_00=R0015268_Pneumatic_module_Test_Screenshot_2023-12-11_111413.png | ||

| + | |Step_Picture_01=R0015266B_mount_completed_assemblies_photorequired.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit brace 3</translate> | ||

| + | |Step_Content=<translate>Fit D0015514 at final position . Add M8 motor plate washer as spacer as shown</translate> | ||

| + | |Step_Picture_00=R0015268_Pneumatic_module_Test_Screenshot_2023-12-11_111845.png | ||

| + | |Step_Picture_01=R0015268_Pneumatic_module_Test_Screenshot_2023-12-11_111852.png | ||

| + | |Step_Picture_02=R0015266B_mount_completed_assemblies_photorequired.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 11 décembre 2023 à 12:19

Instructions for performing pneumatic test on completed module

Sommaire

- 1 Introduction

- 2 Étape 1 - Prepare area for testing

- 3 Étape 2 - Connect mains air supply

- 4 Étape 3 - check home positions

- 5 Étape 4 - Test Y154 output

- 6 Étape 5 - Test Y157 Output

- 7 Étape 6 - Test Y375 Output

- 8 Étape 7 - Disconnect air supply

- 9 Étape 8 - Fit brace 1

- 10 Étape 9 - Fit brace 2

- 11 Étape 10 - Fit brace 3

- 12 Commentaires

Introduction

Tools Required

Parts Required

D0015513 Arm brace x 2

D0015514 Arm brace x 1Étape 1 - Prepare area for testing

Ensure area is clear and free from personnel

Étape 2 - Connect mains air supply

Connect mains air supply and check for any leaks present is components natural state

Étape 3 - check home positions

Check home positions are correct in natural state

Loader wheel Y154 should be up away from roller beds in home position

Roller beds Y157 should be in the up position in home position

Blowers Y375 should be switched off in the home position

Étape 4 - Test Y154 output

On valve bank, manually fire Y154 output.

Check for air leaks when output is fired

Check regulator shows pressure when fired by increasing pressure with adjusted .Once confirmed correct operation, a djust regulator to 1 bar or 0.1 mpa

Étape 5 - Test Y157 Output

On valve bank, manually fire valve Y157 roller lift output

All rollers should drop down into position. When fired, check there are no air leaks present in the active position

Étape 6 - Test Y375 Output

Manually fire Y357 output Check each blowers flow regulator can adjust flow rate when turned . Once confirmed , fully close flow regulator and wind out 2 turns

Étape 7 - Disconnect air supply

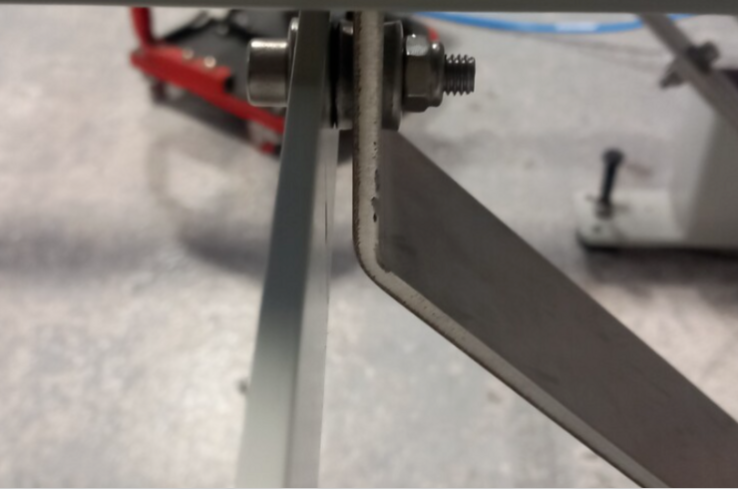

Étape 8 - Fit brace 1

Fit D0015513 at load motor end of frame .

Use M8 x 35 socket caps, M8 motor plate washers and M8 nyloc nuts .

Étape 10 - Fit brace 3

Fit D0015514 at final position . Add M8 motor plate washer as spacer as shown

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português