| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Description=<translate>Instructions to prepare parts for fitting to main frame</translate> |Categories=Production |Difficulty=Medium |Duration=3 |Duration-... ») |

|||

| (3 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| + | |Main_Picture=R0015287_Bench_Assemble_Shafts__Bearings_and_Pinions_Screenshot_2023-07-14_124844.png | ||

| + | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":2,"top":3,"width":997,"height":748,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.6,"scaleY":0.6,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/9/96/R0015287_Bench_Assemble_Shafts_Bearings_and_Pinions_Screenshot_2023-07-14_124844.png","filters":[]}],"height":450.314465408805,"width":600} | ||

|Description=<translate>Instructions to prepare parts for fitting to main frame</translate> | |Description=<translate>Instructions to prepare parts for fitting to main frame</translate> | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration= | + | |Duration=1 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

{{Introduction | {{Introduction | ||

| − | |Introduction=<translate></translate> | + | |Introduction=<translate>'''<u>Tools Required</u>''' |

| + | |||

| + | |||

| + | Compressed air line | ||

| + | |||

| + | 180 grit emery tape | ||

| + | |||

| + | Fe10 solvent | ||

| + | |||

| + | Cleaning cloth | ||

| + | |||

| + | Standard Hex key set | ||

| + | |||

| + | Standard spanner set | ||

| + | |||

| + | Grease gun | ||

| + | |||

| + | |||

| + | '''<u>Parts Required</u>''' | ||

| + | |||

| + | |||

| + | D0015556 x 1 | ||

| + | |||

| + | D0015555 x 1 | ||

| + | |||

| + | B0001094 x 9 | ||

| + | |||

| + | B0000228 x 9</translate> | ||

}} | }} | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Quality check</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>That that indicated 2 of M6 tapped holes are taped through |

| + | |||

| + | |||

| + | To check wind M6 grubscrew through hole and make sure it exits the other side | ||

| + | |||

| + | |||

| + | 9 off to check</translate> | ||

| + | |Step_Picture_00=R0015287_Bench_Assemble_Shafts__Bearings_and_Pinions_Screenshot_2023-12-11_075546.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":1014,"height":789,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.59,"scaleY":0.59,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/2/26/R0015287_Bench_Assemble_Shafts_Bearings_and_Pinions_Screenshot_2023-12-11_075546.png","filters":[]},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":175.3,"top":147.7,"width":80.38,"height":80.38,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":40.190745797712054,"ry":40.190745797712054},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":201.72,"top":294.28,"width":73.39,"height":73.39,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":36.69682287823881,"ry":36.69682287823881}],"height":467,"width":600} | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Clean shafts</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Ensure shafts D0015556 and D0015555 are clean before trial fitting . |

| + | |||

| + | 1 check for any burrs or damage to shafts . Remove with File/emery tape 180 grit if present | ||

| + | |||

| + | 2 Use compressed air to clean debris from all keyways on shafts . | ||

| + | |||

| + | 3 Use Fe10 solvent to remove contaminants on | ||

| + | |||

| + | shafts</translate> | ||

| + | |Step_Picture_00=R0015287_Bench_Assemble_Shafts__Bearings_and_Pinions_Screenshot_2023-11-16_152247.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Clean and prepare bearings</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Ensure bearings B0000228 9 off are clean before trial fitting |

| + | |||

| + | 1 Check for any internal burrs especially around grubscrew point . | ||

| + | |||

| + | If present remove with emery tape 180 grit | ||

| + | |||

| + | 2 Use compressed air to remove and debris | ||

| + | |||

| + | 3 Use Fe10 solvent to remove any contamination</translate> | ||

| + | |Step_Picture_00=R0015287_Bench_Assemble_Shafts__Bearings_and_Pinions_Screenshot_2023-11-16_152348.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Clean and prepare Pinions</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Ensure B0001094 Pinions 9 off are clean before trial fitting |

| + | |||

| + | 1 Check for any internal burrs especially around grubscrew point . | ||

| + | |||

| + | If present remove with emery tape 180 grit | ||

| + | |||

| + | 2 Use compressed air to remove and debris | ||

| + | |||

| + | 3 Use Fe10 solvent to remove any contamination</translate> | ||

| + | |Step_Picture_00=R0015287_Bench_Assemble_Shafts__Bearings_and_Pinions_Screenshot_2023-11-16_152407.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Check fitment of prepared parts.</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Check the following |

| + | |||

| + | 1 Every B0000228 bearing passes freely over each shaft | ||

| + | |||

| + | 2 Every B0001094 pinion passes freely over each shaft | ||

| + | |||

| + | If tight spots are found, these steps should be followed | ||

| + | |||

| + | * If all pinions/bearings pass freely on a shaft but one is tight, polish out individual pinion to achieve correct fitment | ||

| + | * If all pinions ( Or most off) are tight , polish main shaft down with emery tape 180 to remove high spot | ||

| + | {{Warning|...When performing any adjustments using emery tape., parts must be thoroughly cleaned before trial fitting again as grit residue can caused components to bind together on assembly}}<br /></translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Fit grease points</translate> |

| − | |Step_Content=<translate> | + | |Step_Content=<translate>1 Attach supplied grease points and covers to B0000228 bearings (18 off) |

| − | + | ||

| − | + | 2 Use grease gun to grease bearings to aid assembly</translate> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version actuelle datée du 11 décembre 2023 à 10:00

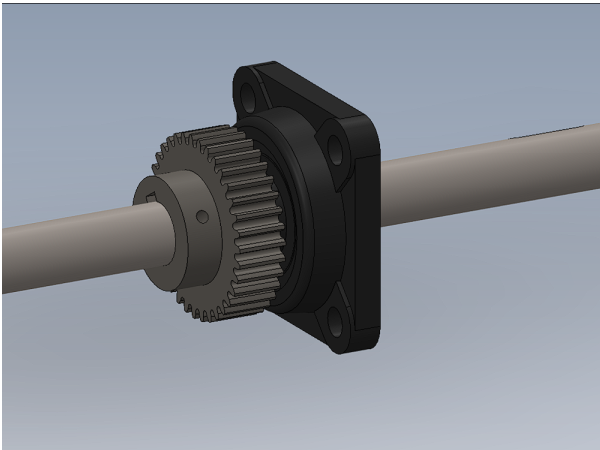

Instructions to prepare parts for fitting to main frame

Introduction

Tools Required

Compressed air line

180 grit emery tape

Fe10 solvent

Cleaning cloth

Standard Hex key set

Standard spanner set

Grease gun

Parts Required

D0015556 x 1

D0015555 x 1

B0001094 x 9

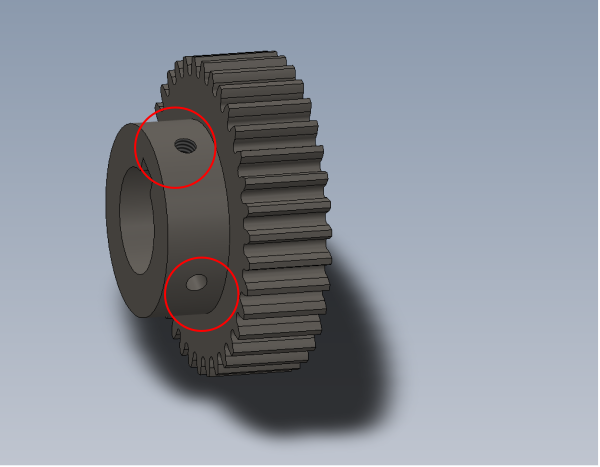

B0000228 x 9Étape 1 - Quality check

That that indicated 2 of M6 tapped holes are taped through

To check wind M6 grubscrew through hole and make sure it exits the other side

9 off to check

Étape 2 - Clean shafts

Ensure shafts D0015556 and D0015555 are clean before trial fitting .

1 check for any burrs or damage to shafts . Remove with File/emery tape 180 grit if present

2 Use compressed air to clean debris from all keyways on shafts .

3 Use Fe10 solvent to remove contaminants on

shafts

Étape 3 - Clean and prepare bearings

Ensure bearings B0000228 9 off are clean before trial fitting

1 Check for any internal burrs especially around grubscrew point .

If present remove with emery tape 180 grit

2 Use compressed air to remove and debris

3 Use Fe10 solvent to remove any contamination

Étape 4 - Clean and prepare Pinions

Ensure B0001094 Pinions 9 off are clean before trial fitting

1 Check for any internal burrs especially around grubscrew point .

If present remove with emery tape 180 grit

2 Use compressed air to remove and debris

3 Use Fe10 solvent to remove any contamination

Étape 5 - Check fitment of prepared parts.

Check the following

1 Every B0000228 bearing passes freely over each shaft

2 Every B0001094 pinion passes freely over each shaft

If tight spots are found, these steps should be followed

- If all pinions/bearings pass freely on a shaft but one is tight, polish out individual pinion to achieve correct fitment

- If all pinions ( Or most off) are tight , polish main shaft down with emery tape 180 to remove high spot

Étape 6 - Fit grease points

1 Attach supplied grease points and covers to B0000228 bearings (18 off)

2 Use grease gun to grease bearings to aid assembly

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português