| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 146 : | Ligne 146 : | ||

| − | 3 Fit D0004338 Slide Support Bar and | + | 3 Fit D0004338 Slide Support Bar and orientated as shown. Ensure M8 grubscrew holes face downwards as shown . Use hide hammer to creep bar evenly into position |

Version du 3 novembre 2023 à 14:20

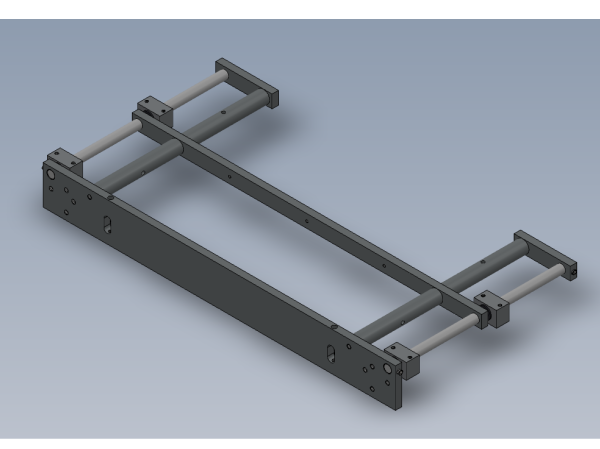

Bench assembly details for top table slide assembly

Introduction

Tools Required

Standard hex key set

Consumable M8 studding

Hacksaw and file

16mm hand reamer

1 meter straight edge

Parts Required

B0000034 Linear Bearing: Ø16 x 30 Compact (Metal Case Only) x 4

D0004138 Centralising Bearing Block x 4

D0004337 Slide Bar Holder x 1

D0004338 Slide Support Bar x 1

D0004545 Slide Support End x 2

D0005235 Support Post x 2

D0005236 Support Post x 2

H0004624 Shaft 16mm: 343 Centralise x 2

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Prepare parts

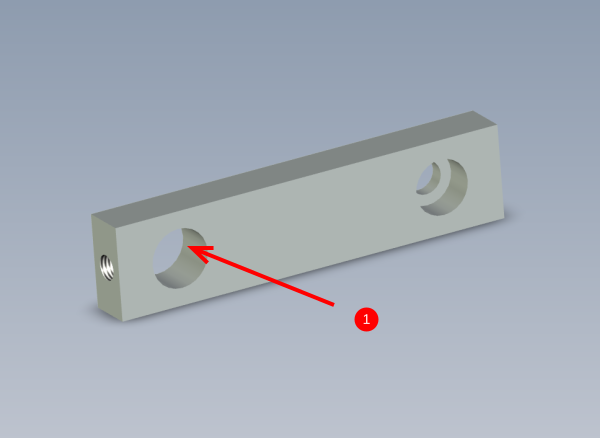

Use 16mm hand reamer to check sizing of bores in following parts

1 D0004545 Slide Support End x 2

2 D0004338 Slide Support Bar x 1

3 D0004337 Slide Bar Holder x 1

Étape 3 - Add tie base

ECR Raised 03/11/23

Add tie base as shown

This will require drilling M5

Fit black tie base with M5 x 10 button head

Étape 4 - Fit bearings

1 Degrease 4 off D0004138 Centralising Bearing Block

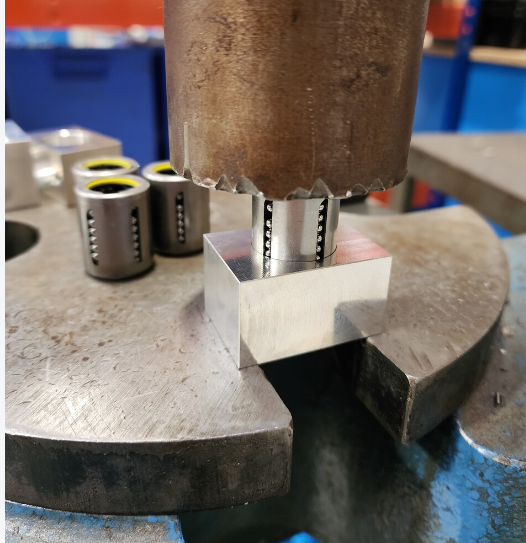

2 Use press to fit4 off B0000034 Linear Bearing. Fit bearing so yellow seal is almost flush with bearing block face

3 Apply grease to bearings

Étape 5 - Prepare support bar

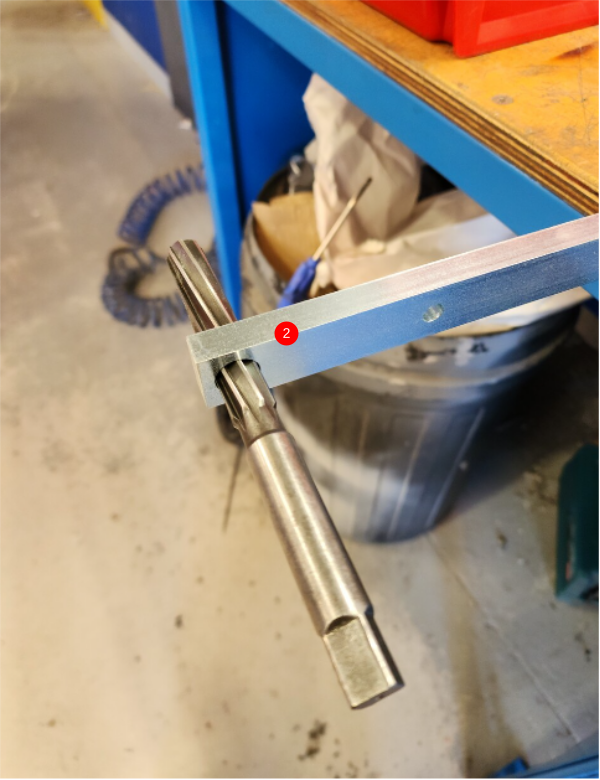

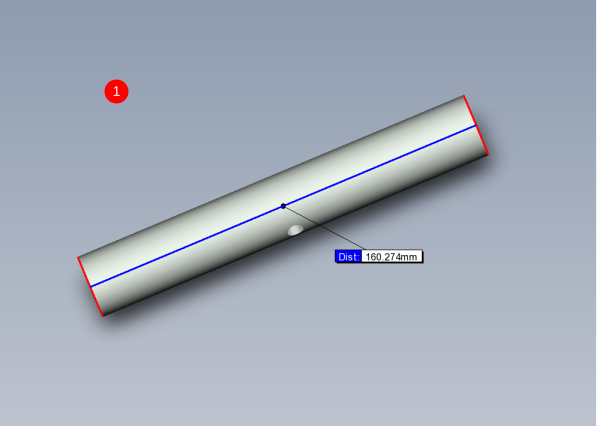

1 Identify 2 off D0005236 Support Post. Check length measures 160mm

2 Use loctite 270 and fasten a length of M8 studding into one end and tighten

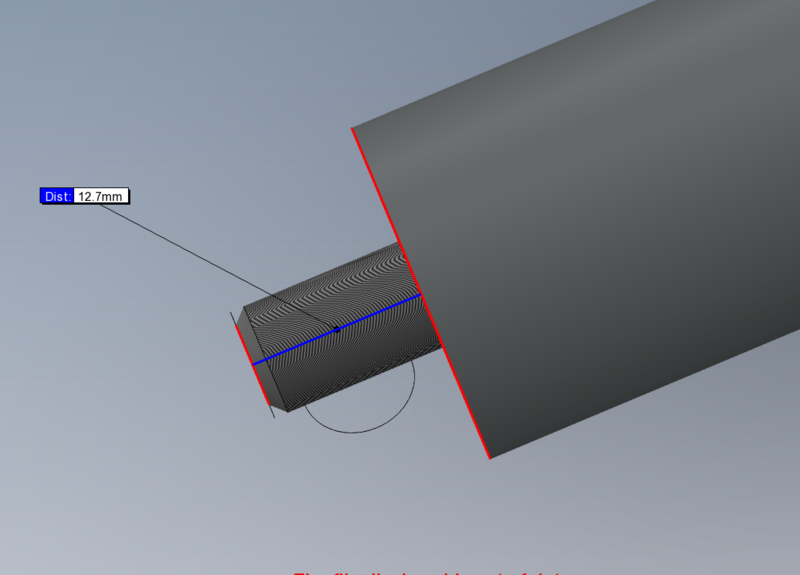

3 Cut M8 studding with hacksaw to leave 12.7mm protrusion as shown

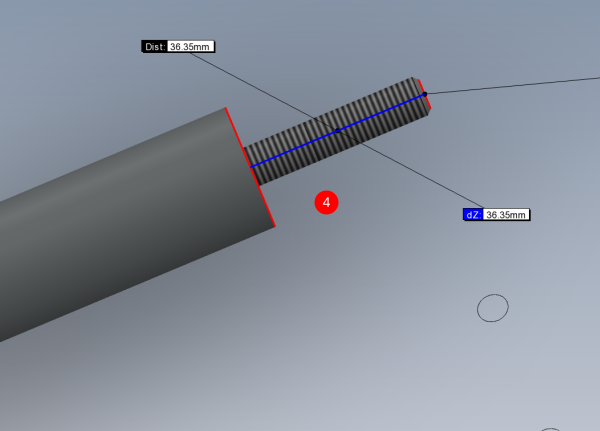

4 Fit studding to other end using steps above but cut to 36mm

5 Repeat for second support bar

6 quality check cut threads. Threads should be dressed clean with a file once cut . Use an M8 nut to check quality of thread before fitting to assembly

Étape 6 - Assemble Frame

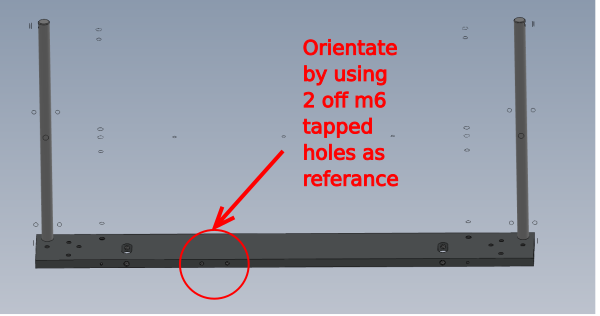

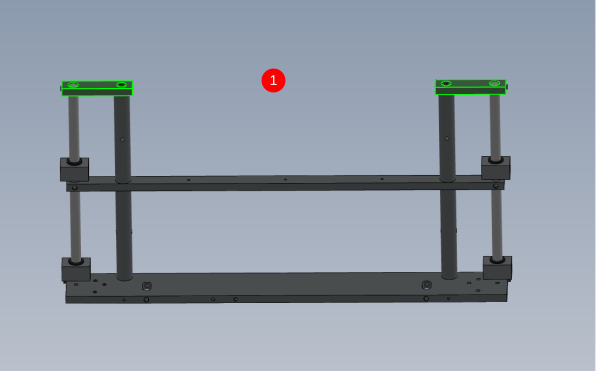

1 Orientate D0004337 Slide Bar Holder as shown and fit 2 off H0004624 Shaft 16mm: 343 and secure with 2 off M x 12 kcp grubscrews , ensuring dimple on shaft is correctly aligned with grubscrew

2 Fit 2 off bearing blocks as indicated . Fit 2 off pre assembled support bars as shown, using Loctite 243

3 Fit D0004338 Slide Support Bar and orientated as shown. Ensure M8 grubscrew holes face downwards as shown . Use hide hammer to creep bar evenly into position

4 Fit 2 off D0005235 Support Post as shown and finalise

5 Fit 2 bearing blocks orientated same as previous two fitted

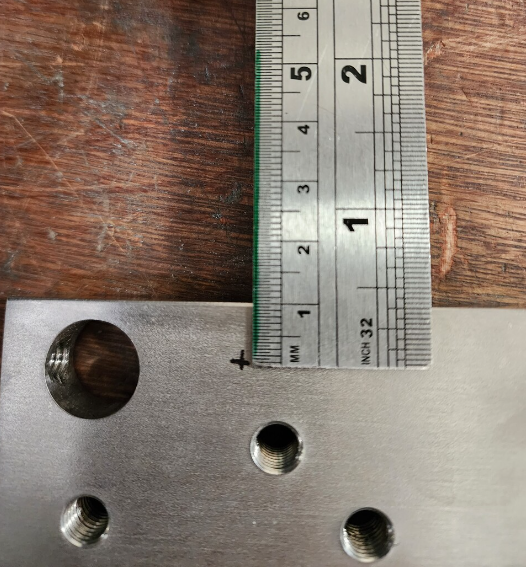

Étape 7 - End plate alignment

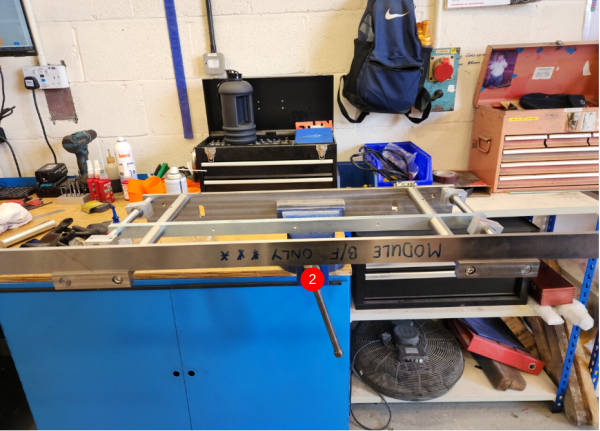

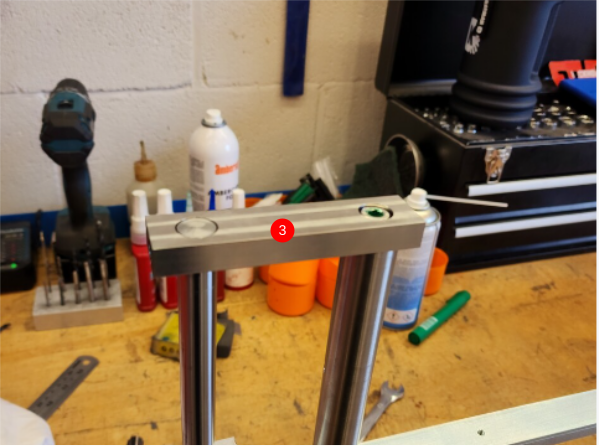

1 Fit 2 off D0004545 Slide Support End and fix with M8 x 20 socket cap and M8 x 12 kcp grubscrew per side . Do not finalise fasteners

2 Align end plates as shown using straight edge , to set end plates flat to each other

3 Finalise fixings and recheck end plate position has been held with straight edge

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português