| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration= | + | |Duration=2 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version du 21 septembre 2023 à 21:00

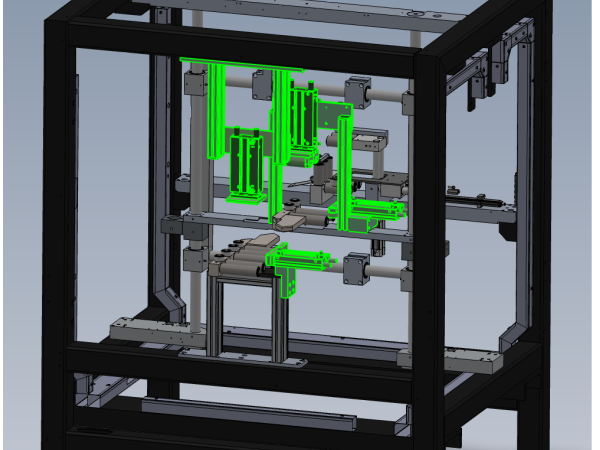

Alignment criteria for material clamps

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Attach Outfeed side clamp

- 4 Étape 3 - Attach outfeed clamp frame

- 5 Étape 4 - Fit top clamp cylinder

- 6 Étape 5 - Fit V notch side clamp

- 7 Étape 6 - Fit V Notch top clamp

- 8 Étape 7 - Align V notch clamp

- 9 Étape 8 - Fastener Quality check

- 10 Commentaires

Introduction

Tools Required

Standard hex key set

12 " square

300mm parallels

Parts Required

Étape 1 - Unless otherwise stated

Use locktite 243 on all fasteners

Use loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

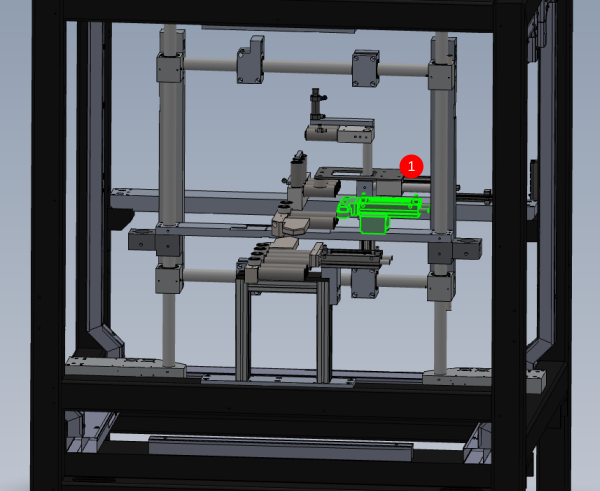

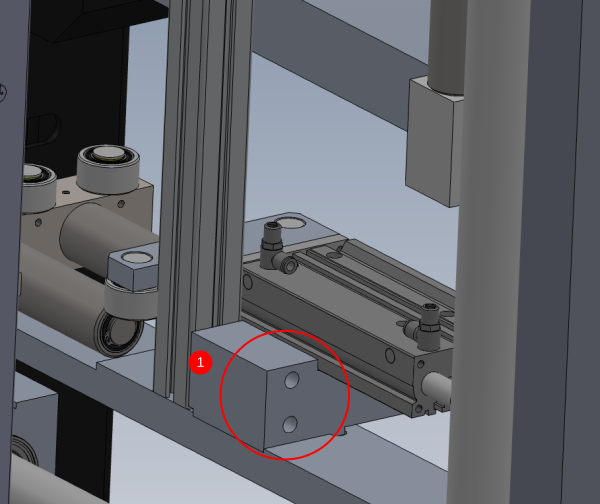

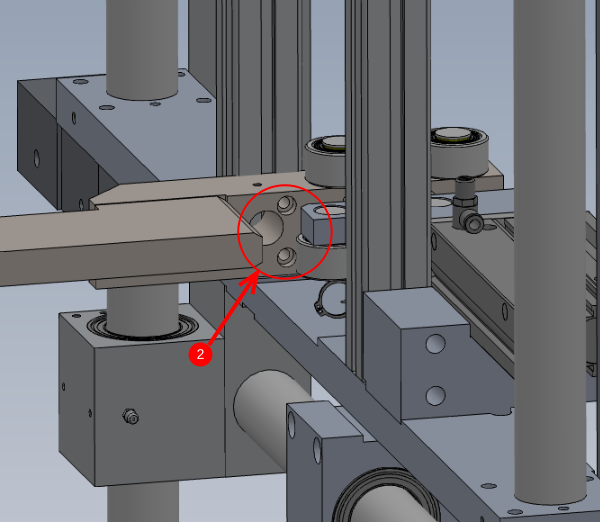

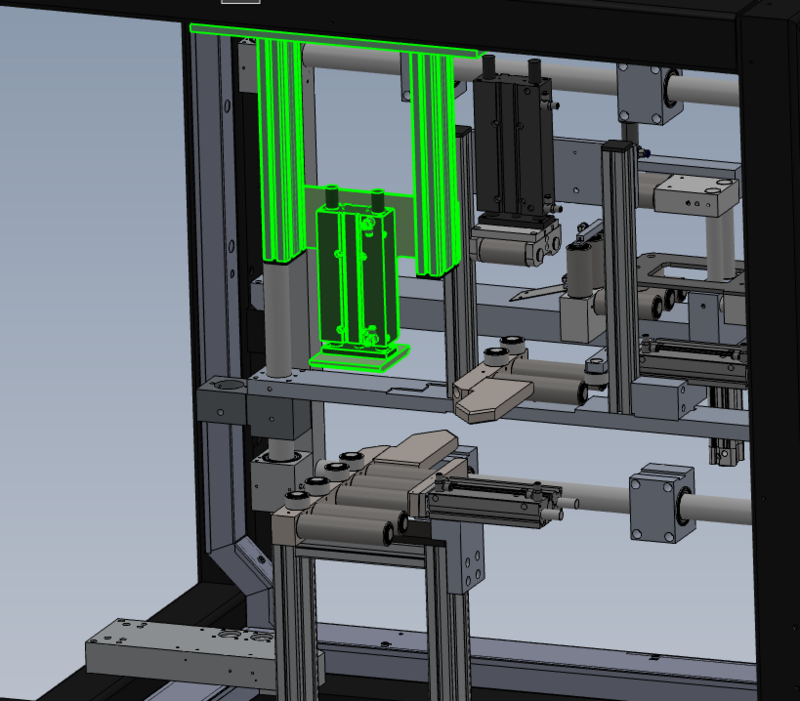

Étape 2 - Attach Outfeed side clamp

1 Attach outfeed side clamp assembly as shown

2 Fix with 4 off M6 x 25 socket caps

3 Ensure block sits correctly in pocket as shown

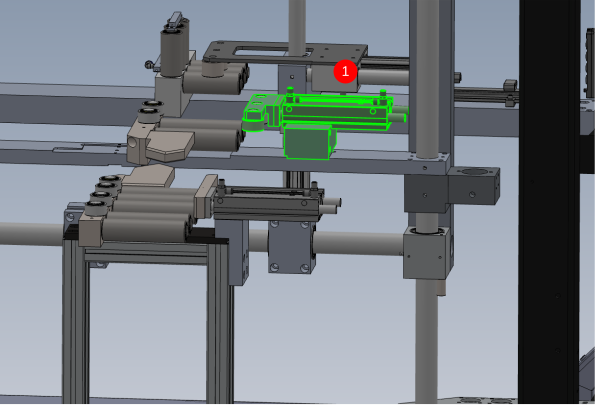

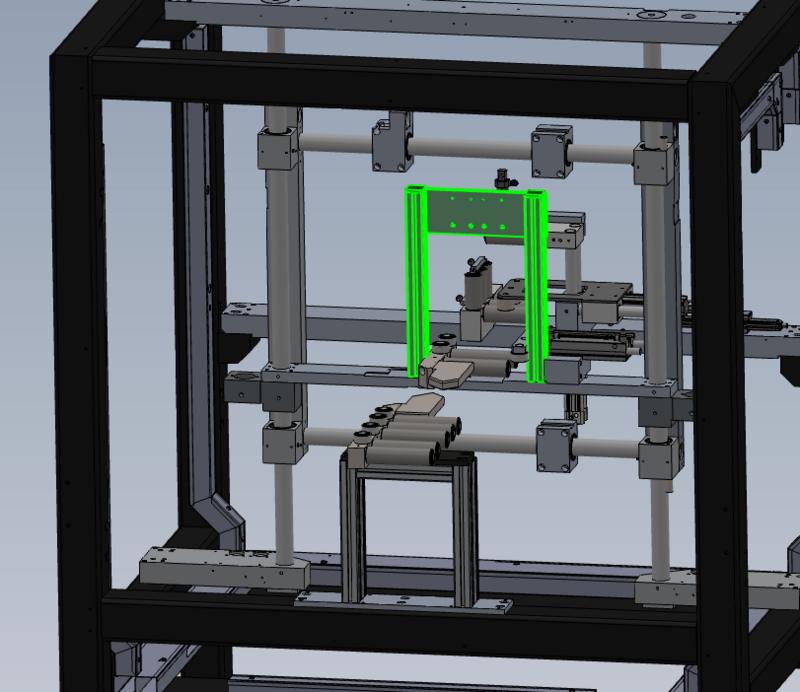

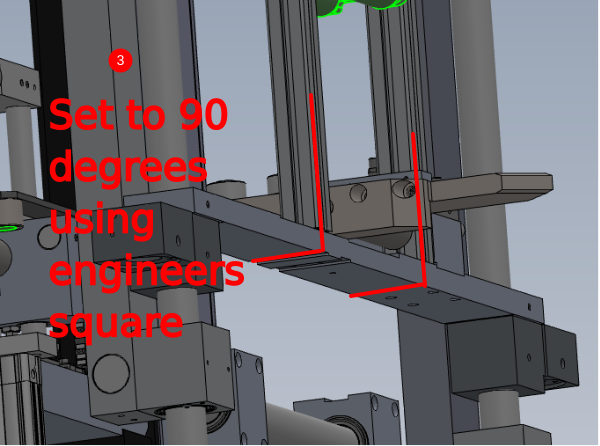

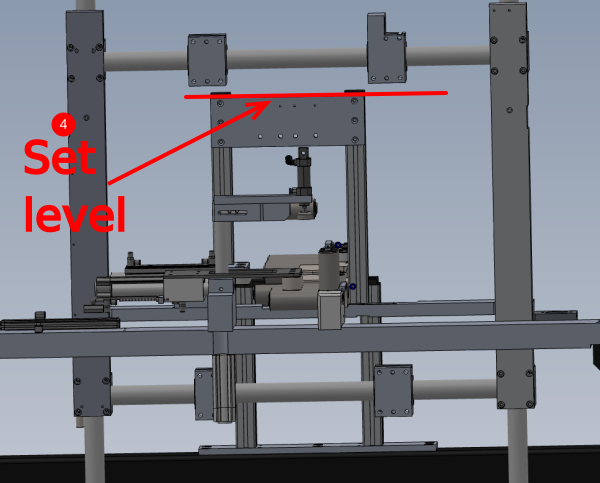

Étape 3 - Attach outfeed clamp frame

Attach outfeed clamp frame as shown

1 Use 2 of M6 x 35 socket caps and 2 off M6 fat d nuts to fasten

2 Use 2 off M6 x 40 socket caps and 2 off M6 D nuts to secure

indicated roller will require removing to fix upright, then refit

3 Ensure uprights are fitted vertical . Use engineers square at indicated point to set vertical position

4 use engineers level to ensure indicated face is level . Ensure one edge of plate remains flush with the top of the maytec section

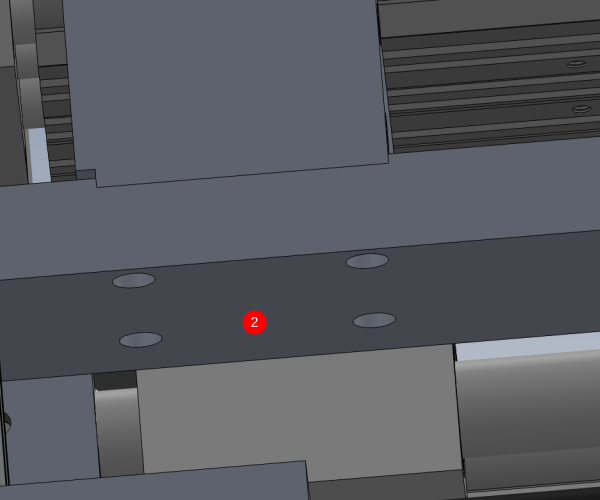

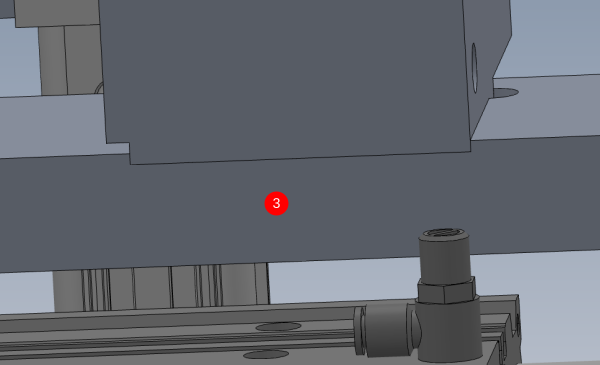

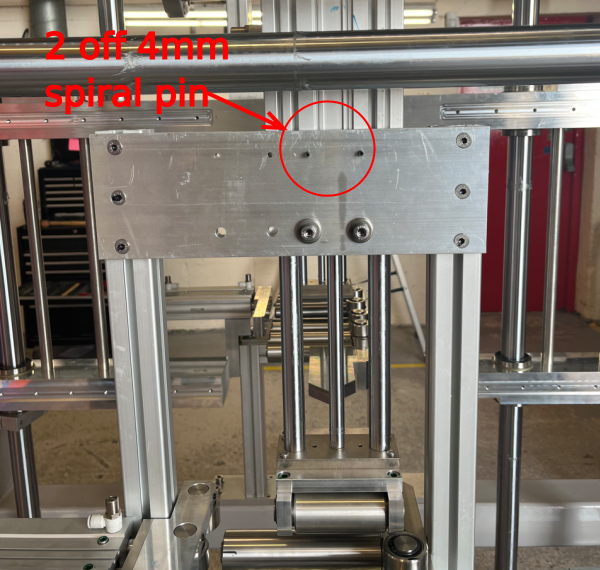

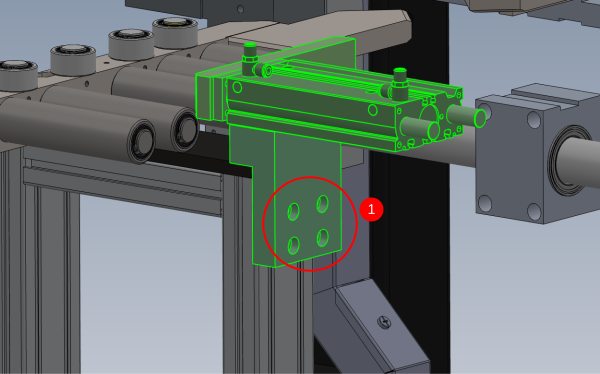

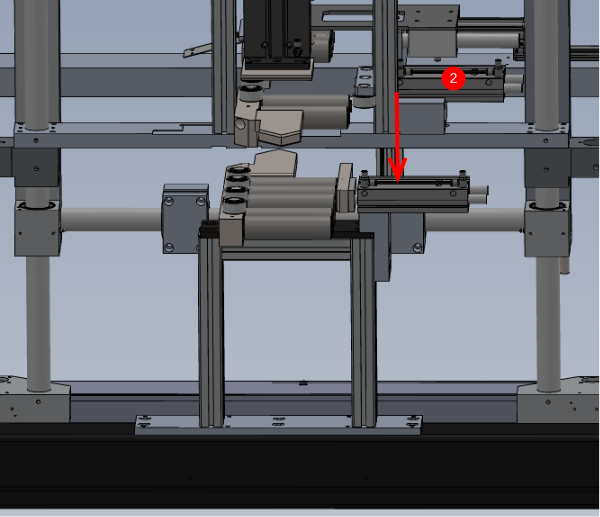

Étape 4 - Fit top clamp cylinder

Fit top clamp cylinder using 2 off M8 x 30 socket caps with

heavy washers and 2 off 4mm x 18mm spiral pins

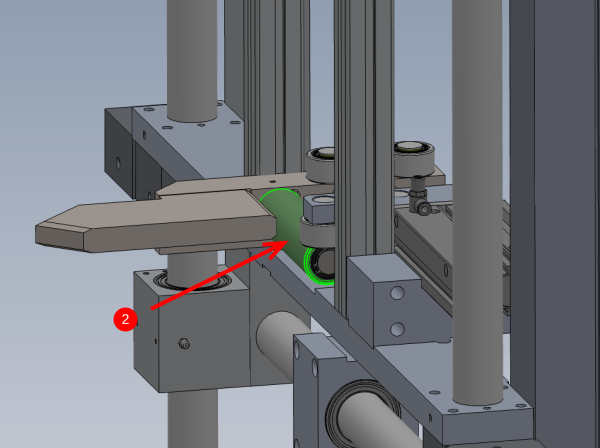

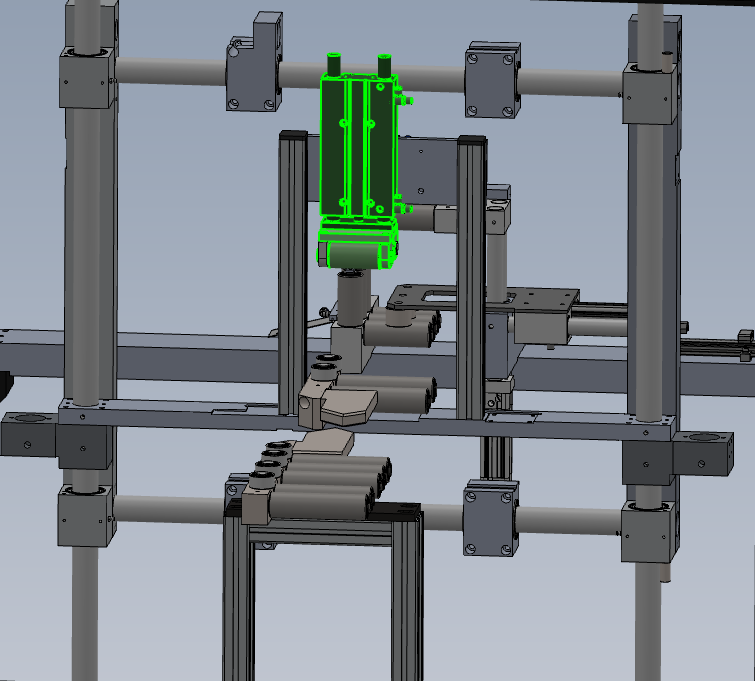

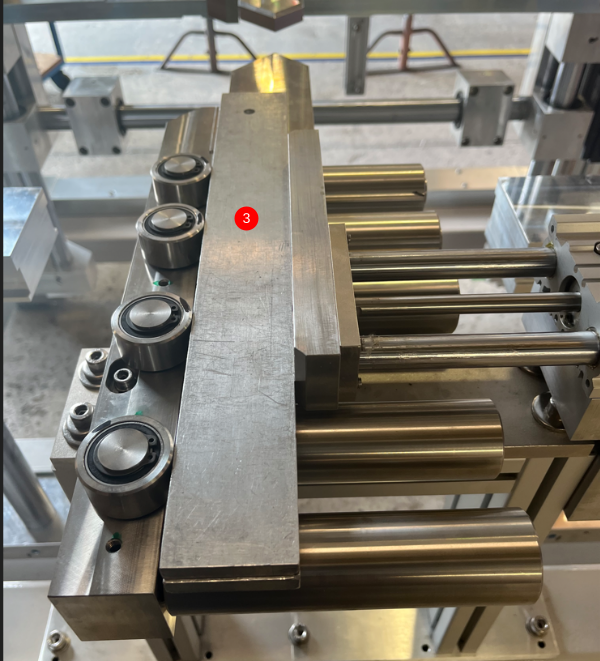

Étape 5 - Fit V notch side clamp

1 Use 4 off M8 x 30 socket caps and 4 off M8 fat D nuts to fix

2 Ensure clamp is as low as possible in the direction shown

3 Align to datum rollers by using 300mm parallel as shown. Side clamp rollers must all touch the parallel edge. To adjust , release M5 bolts , adjust and reglue and tighten

Étape 6 - Fit V Notch top clamp

Fit top frame to main frame as shown

Use 6 off M10 x 30 socket caps and a form washers to fix

Étape 7 - Align V notch clamp

Using M8 grubscrews, adjust top clamp so pad is parallel to datum rollers in both plains

Use parallels as shown, no movement should be possible in any direction when the top clamp pad is sat on top of [parallel blocks

Étape 8 - Fastener Quality check

All fasteners used in the alignment and build up of the clamp assembly should now be quality checked

Ensure EVERY bolt is glued and tight and marked

Ensure every adjustment grubscrew has loctite 290 applied in situ , to lock in place

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português